WORLD OF INDUSTRIES 5/2019

WORLD OF INDUSTRIES 5/2019

WORLD OF INDUSTRIES 5/2019

- TAGS

- industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

05/<strong>2019</strong><br />

www.world-of-industries.com<br />

16<br />

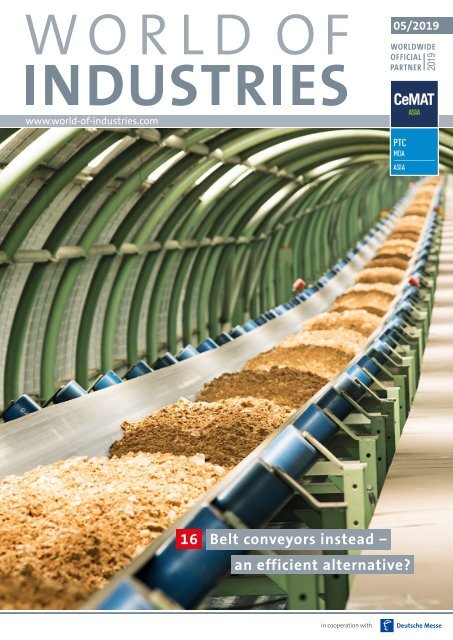

Belt conveyors instead −<br />

an efficient alternative?<br />

in cooperation with

SORTATION<br />

CHALLENGES<br />

SOLVED.<br />

Whether25items perminuteor25,000 itemsper hour,increase your productivity with the<br />

broadestrange of sortation solutionsinthe industry. VisitusatCeMat, Hall W2,Stand A2.<br />

©<strong>2019</strong>Honeywell Intelligrated. All rights reserved.<br />

2 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 3/<strong>2019</strong>

EDITORIAL<br />

Shifting of<br />

balance of<br />

power<br />

Global Excellence<br />

for Intralogistics<br />

Dear readers,<br />

Since we are living in the era of industry 4.0, it is important to<br />

understand it’s global market dynamics on basis of technology<br />

verticals, end user industry sectors, growth and maturity<br />

geography-wise. On the basis of end user industry sectors,<br />

automotive, industrial equipment, electrical equipment,<br />

healthcare, food & beverage, chemical, and energy & power<br />

are the leading sectors where the penetration of technology,<br />

availability of educated professionals and suppliers is higher<br />

as compared to other sectors. Industry 4.0 technologies assist<br />

in multiple areas of an industry’s working, for example, on<br />

the factory floor, data analytics contributes in analyzing the<br />

condition of machines and avoids unplanned breakdowns,<br />

the same data analytics technology also helps in smart<br />

routing of trucks and improve logistics performance.<br />

Today, Industry 4.0 offers many technologies under its<br />

umbrella, like industrial robotics, cyber security, Internet of<br />

Things, 3D printing, advanced human–machine interface,<br />

data analytics, augmented reality & virtual reality, and<br />

artificial intelligence. Geographically speaking, Asia Pacific<br />

holds the largest market share and is expected to grow at the<br />

highest rate from 2017 – 2022. One of the reasons, Asia Pacific<br />

has overtaken rest of world is because of favorable government<br />

policies and initiatives mainly from China, Japan, India,<br />

Vietnam and South Korea etc.<br />

As these waves of change reshape the competitive landscape,<br />

organizations need to think strategically when determining<br />

where to build their capabilities. Depending on their long<br />

term strategic objective, manufacturers can decide which<br />

Industry 4.0 technology they wish to adopt across multiple<br />

objectives. However, it is often very difficult, to build up new<br />

advanced capabilities right from scratch. Therefore, collaborating<br />

with third party solutions providers and working with<br />

industry 4.0 competent vendors and suppliers of various<br />

industrial products becomes all the more important.<br />

With this in mind, you can visit the international trade fair<br />

Power transmission and Control Asia along with CeMAT Asia<br />

being held at the Shanghai New International Expo Center,<br />

Shanghai from the 23rd to 26th of October.<br />

<br />

Yours Sincerely<br />

Sushen Doshi<br />

TRANSNORM’S range of conveyor modules and<br />

solutions guarantee the logistical competitiveness of<br />

global players such as parcel services, mail order companies<br />

and distribution service providers.<br />

Use this experience to speed up your logistics processes!<br />

Whether individual modules, Solutions or Sub-Systems -<br />

the choice is yours!<br />

ASIA<br />

Shanghai | China<br />

23.-26. October <strong>2019</strong><br />

German Pavilion<br />

www.transnorm.com

TABLE <strong>OF</strong> CONTENT<br />

14<br />

10<br />

24 20<br />

NEWS AND MARKETS<br />

03 EDITORIAL<br />

06 <strong>WORLD</strong>WIDE NEWS<br />

08 CHINA: A STRONG PARTNER AND<br />

ALSO A FIERCE COMPETITOR FOR<br />

GERMAN <strong>INDUSTRIES</strong><br />

10 DIGITALIZATION TAKES CENTER STAGE<br />

AT CHINA’S LEADING INDUSTRIAL<br />

TRADE FAIRS<br />

LOGISTICS<br />

12 THE NEW INTERROLL DC<br />

PLATFORM<br />

14 THERE IS ROOM IN THE SMALLEST<br />

SHOP<br />

16 BELT CONVEYORS INSTEAD <strong>OF</strong> TRUCKS<br />

− AN EFFICIENT ALTERNATIVE?<br />

MOTION AND DRIVES<br />

05 PRODUCT NEWS<br />

18 IN TIME WITH THE SUN<br />

20 CHANGI AIRPORT SINGAPORE:<br />

SAFETY FOR FLOATING PETALS<br />

AUTOMATION<br />

22 PICK AND PLACE WITH<br />

THERMAL IMAGING CAMERAS<br />

24 COLORFUL CHALLENGE FOR<br />

MEASUREMENT TECHNOLOGIES<br />

10 TH ANNIVERSARY<br />

27 PERFECTLY PREPARED FOR<br />

INTERNATIONALIZATION<br />

4 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong>

Gearboxes with integrated sensor module<br />

Smart gearboxes with “cynapse” by Wittenstein alpha are identical<br />

to the existing models in terms of design, size and contour, so that<br />

a drive solutions which has already been designed needs no further<br />

modification. It is the sensor module integrated in the smart gearbox<br />

that makes the difference. Thanks to the integrated sensor module,<br />

influencing quantities in the process and the environment which<br />

impact on gearbox operation can be identified, measured and<br />

output via an IO link. In other words, these smart gearboxes allow<br />

parameters such as temperature, vibration, operating hours and<br />

mounting position to be recorded<br />

and communicated to the cloud<br />

level using the standardized connectivity<br />

of the IO link interface and an<br />

IO link master. Both there and in the<br />

machine’s immediate environment<br />

this information can be used, for<br />

instance, to improve the availability<br />

and productivity of processes and<br />

equipment in condition monitoring<br />

or predictive maintenance applications. Gearboxes with “cynapse”<br />

thus provide universal connectivity: data flows to their own machine<br />

infrastructures as well as to all standard IIoT platforms.<br />

Kostal introduces decentralized<br />

drive controller<br />

Kostal Industrie<br />

Elektrik presents<br />

the new Inveor MP<br />

series for decentralized<br />

drive technology.<br />

That technology<br />

delivers maximum energy efficiency to all<br />

synchronous reluctance, synchronous and<br />

asynchronous motors. The sensorless motor<br />

control and extended speed setting range gets the<br />

very best out of every application and does so<br />

while consuming minimal energy. Thanks to the<br />

universal motor adaptation concept, the INVEOR<br />

MP (Motor-mounted Performance class) is suited<br />

to any motor and because of its robust IP 65<br />

protective class design can also be used in<br />

heavy-duty environments. Smart features, such as<br />

the pluggable connections and commissioning via<br />

Bluetooth app or PC software, make the INVEOR<br />

universal yet individual.<br />

background: fotolia<br />

www.wittenstein.de/en-en/<br />

www.kostal-industrie-elektrik.com<br />

Change your bearing now<br />

... and reduce costs by up to 40%withdrylin ® linear bearings<br />

Ready for<br />

delivery in<br />

24<br />

hrs<br />

Corroding<br />

Corrosion-free<br />

Plastic instead of metal: replace recirculating ball bearing guides and immediately<br />

profit from the advantages ofcorrosion-free drylin ®<br />

linear technology. Thanks to<br />

the use of stainless steel and tribo-polymers, igus ®<br />

linear systems are resistant to<br />

corrosion, even in underwater applications.<br />

www.igus.eu/plasticvsmetal<br />

motion plastics ® ...for longer life<br />

Tel. +49 2203 9649-145info@igus.eu<br />

Please visit us: PTC/MDA Asia – Booth C2-1<br />

Igus_EN.indd 1 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 23.09.<strong>2019</strong> 5/<strong>2019</strong> 19:47:55 5

W RLDWIDE NEWS<br />

Aucotec continues to grow<br />

Aucotec AG, the engineering software developer based in Hannover, Germany,<br />

can look back on the most successful financial year in its 34-year history.<br />

Sales in 2018/19 reached € 21.8 million, exceeding not only the previous year’s<br />

result by 13 %, but also the original expectations. This development also<br />

continued in some subsidiaries. Thus, Aucotec Shanghai Ltd. almost doubled<br />

its turnover. The French branch Aucotec SARL in Dijon is reporting an<br />

increase in turnover of 44 %. “The decisive reason for these<br />

very pleasing figures is our cooperative platform<br />

Engineering Base Plant (EB). Its unique ability to<br />

accelerate highly complex processes, especially for<br />

the oil, gas, chemical and pharmaceutical industries,<br />

has already secured im portant major orders in<br />

the current financial year,” explained Aucotec board<br />

member Uwe Vogt (picture).<br />

www.aucotec.com<br />

New Managing Director at E&K Automation Ltd.<br />

On August 23, <strong>2019</strong>, Nicola Magrone (picture) was appointed as the new<br />

Managing Director of E&K Automation Ltd. in England. The 43-year-old takes<br />

over the baton from Mike Burke, who will take on the role of Head of Operations<br />

for the UK’s Project and Service Management operations. Magrone has<br />

been working for the E&K Group since March 2018 as Managing<br />

Director of E&K Automation S.r.l. in Italy.<br />

In that time he has successfully expanded the Italian business and<br />

he will now turn his attention to expanding the market share of<br />

the E&K Automation Limited in the UK. Mike Burke, who has<br />

been with the company since 1986, has for the past eight years<br />

been working successfully in England as Managing Director. The<br />

experienced industry expert now takes over the management of the<br />

Project and Operations business in the English market.<br />

Siemens receives upgrade<br />

contract for Munich Airport<br />

Siemens Logistics<br />

has received an<br />

order to<br />

upgrade the<br />

baggage<br />

handling<br />

system in<br />

Terminal 2<br />

and its satellite<br />

building at the<br />

Franz Josef<br />

Strauss Airport in<br />

Munich. By integrating<br />

innovative screening units, Siemens<br />

supports the customer to ensure that<br />

international specifications for baggage<br />

checking are met to the highest degree,<br />

and to continue to successfully manage the<br />

ever-increasing number of passengers. The<br />

customer is the “Terminal 2 Gesellschaft”, a<br />

joint subsidiary of Munich Airport and<br />

Lufthansa. This upgrade to the current safety<br />

and security regulations for baggage<br />

handling, which require explosives detection<br />

systems based on Standard 3 of the European<br />

Civil Aviation Conference (ECAC), calls<br />

for replacement of the X-ray equipment in<br />

the baggage handling system. Siemens is also<br />

implementing screening units of the latest<br />

generation that provide high-resolution<br />

3D-imaging and enhanced scanning quality.<br />

www.siemens-logistics.com<br />

www.ek-automation.com<br />

NEWS AND MARKETS<br />

Editorial board:<br />

Winfried Bauer (Editor-in-chief), E-mail: w.bauer@vfmz.de<br />

Peter Becker (Editor-in-chief), E-mail: p.becker@vfmz.de<br />

Nicole Steinicke (Editor-in-chief), E-mail: s.steinicke@vfmz.de<br />

Manfred Weber, E-mail: m.weber@vfmz.de<br />

Svenja Stenner, E-mail: s.stenner@vfmz.de<br />

Managing editor:<br />

Winfried Bauer<br />

Assistant editors:<br />

Petra Weidt, Melanie Lerch, Angelina Haas, Ulla Winter<br />

Design/Layout:<br />

Anna Schätzlein, Sonja Daniel, Anette Fröder, Mario Wüst<br />

E-paper designer:<br />

Katja Rüdell<br />

Publishing house:<br />

Vereinigte Fachverlage GmbH<br />

Lise-Meitner-Str. 2, 55129 Mainz, Germany<br />

Commercial register No.:<br />

HRB 2270, District Court of Mainz<br />

VAT-ID:<br />

DE149063659<br />

Privacy statement:<br />

ds-vfv.vfmz.de<br />

Managing director:<br />

Dr. Olaf Theisen<br />

Publishing director:<br />

Dr. Michael Werner, E-mail: m.werner@vfmz.de<br />

Correspondent India:<br />

Sushen Haresh Doshi M.Sc.<br />

Advertising sales director:<br />

Beatrice Thomas-Meyer, E-mail: b.thomas-meyer@vfmz.de<br />

Advertising sales manager:<br />

Oliver Jennen, E-mail: o.jennen@vfmz.de<br />

Andreas Zepig, E-mail: a.zepig@vfmz.de<br />

Sales representatives<br />

Austria:<br />

Heinz-Joachim Greiner,<br />

E-mail: verlagsbuero-greiner@vfmz.de<br />

France:<br />

Marc Jouanny, E-mail: marc-jouanny@wanadoo.fr<br />

Great Britain, Ireland:<br />

Rob Brewer, E-mail: rob.brewer1@btinternet.com<br />

Switzerland, Italy:<br />

Hermann Jordi, E-mail: info@jordipublipress.de<br />

Denmark, Sweden, Finland, Norway:<br />

Malte Mezger,<br />

E-mail: verlagsbuero-mezger@vfmz.de<br />

USA, Canada, Mexico:<br />

Patrick Venezia Jr,<br />

E-mail: verlagsbuero-venezia@vfmz.de<br />

Advertising disposition:<br />

Annemarie Benthin, E-mail: a.benthin@vfmz.de<br />

Heike Rauschkolb, E-mail: h.rauschkolb@vfmz.de<br />

Nevenka Islamovic, E-mail: n.islamovic@vfmz.de<br />

In cooperation with:<br />

Hannover Fairs International GmbH,<br />

Messegelände, 30521 Hannover, Germany<br />

Internet:<br />

www.world-of-industries.com<br />

6 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong>

MICROMO is now FAULHABER MICROMO LLC<br />

As of July <strong>2019</strong>, MicroMo Electronics Inc. (MICROMO) has been officially reorganized as FAULHABER MICROMO LLC and now becomes<br />

a fully integrated part of the FAULHABER Drive Systems division of the FAULHABER GROUP. The restructuring represents the realization<br />

of the long-term vision of the late owner of the company, Dr. Fritz Faulhaber Jr., and serves to solidify<br />

FAULHABER MICROMO’s position in the North American market as a leading provider in the area<br />

of high precision miniature motion systems. Dr. Faulhaber’s vision of a family-owned single<br />

corporate entity was carried through by his widow, Ping Faulhaber. FAULHABER MICROMO<br />

remains under family ownership, including Ping Faulhaber, as a 100% subsidiary of<br />

FAULHABER Drive Systems, headquartered in Schönaich near Stuttgart, Germany. This<br />

organizational change will be underscored by a transition from the existing MICROMO<br />

company brand to the FAULHABER brand which bears the name of the founding family<br />

and has become known around the world as a symbol of high quality and innovation in<br />

the precision drives industry.<br />

www.faulhaber.com<br />

Designing intelligent<br />

buildings together<br />

The BACnet International<br />

industry association supports the<br />

successful, global application of<br />

the BACnet protocol. Phoenix<br />

Contact is now an official<br />

member of this Who’s Who of<br />

Building Automation. In building<br />

automation networks, the open,<br />

the neutral BACnet (Building<br />

Automation and Control Networks)<br />

communication protocol<br />

creates the option for exchange<br />

among the sensors, actuators, and<br />

management systems of different<br />

manufacturers. With the Emalytics<br />

building management system<br />

Conductor Rails<br />

forShuttle Systems<br />

Head<br />

xxx<br />

xxx<br />

Foto: KNAPP AG<br />

We move your business!<br />

Conductix-Wampfler has onecritical mission:<br />

To provideyou with energyand data transmission<br />

systemsthatwill keep youroperations up<br />

and running 24/7/365. Our systemstransmit<br />

energyand data to electrified monorails,<br />

shuttle systems, storage and retrieval systems,<br />

packaging machines, sorting systems, AGVs<br />

and much more.<br />

and matching IoT controllers,<br />

the company from Blomberg,<br />

Germany facilitates building<br />

automation using protocols that<br />

are widespread in the building<br />

sector: BACnet, for example. At<br />

the same time, Phoenix Contact<br />

solutions successfully build a<br />

bridge to smart IoT technologies,<br />

taking the increasingly complex<br />

security requirements of the IT<br />

world into account.<br />

www.phoenixcontact.com<br />

Charging Solutions forAGVs<br />

and Shuttle Systems<br />

Conductor Rails for<br />

Electrified Monorail Systems<br />

Our rugged, low maintenance products are time<br />

tested in the most demanding environments<br />

and theyare backed by aworldwide sales and<br />

service network unmatched in our industry.<br />

www.conductix.com<br />

Conductix-Wampfler.indd 1 26.09.<strong>2019</strong> 16:28:55<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong> 7

Author: Sushen Doshi,<br />

International Correspondent<br />

for World of Industries<br />

China: a strong partner and also a fierce<br />

competitor for German industries<br />

NEWS AND MARKETS<br />

For so long, Germany and the E.U. have been handling<br />

China with caution, as it was too important a market<br />

for exports. But now, various industry sectors have<br />

been complaining openly about restrictions and unfair<br />

treatment to foreign companies. Even the Federation<br />

of German Industries (BDI) now defines China as<br />

a systemic competitor. China as a market is<br />

indispensable, but there is a major shift in approach<br />

from Germany and the E.U.<br />

For the third consecutive year, China has managed to maintain its<br />

position as Germany’s most important trading partner with a total<br />

trade volume nearing € 200 billion in 2018, according to preliminary<br />

figures published by the German Federal Statistical Office.<br />

China accounted for the largest share of imports into Germany with<br />

goods worth € 106 billion, followed by the Netherlands with € 98<br />

billion and France with € 65 billion. Germany’s trade surplus was<br />

highest with the United States, totaling € 49 billion, followed by the<br />

UK € 45 billion and France € 40 billion. Germany’s trade deficit with<br />

China amounted to € 13 billion in 2018. It is worth noting that Germany’s<br />

trade with China is almost balanced, and mutually beneficial<br />

for both the countries. For Germany’s mechanical and plant<br />

engineering sector, China has been the most important export market<br />

and second most important foreign investment destination. The<br />

interest in this market is uninterrupted and a further expansion of<br />

business activities in China is expected. A positive factor for German<br />

engineering companies is that the Chinese demand for automation<br />

and digitization will increase in the coming years. The modernization<br />

efforts of China’s industry in particular offer good business<br />

opportunities in the short term. But what about the medium and<br />

long term?<br />

The China’s economy started to blossom after the strategic reforms<br />

of 1978 that led to opening of the Chinese economy. Since<br />

then there was a belief that China would gradually move towards<br />

being an open market and integrate into the global economy. It<br />

looks like this convergence is no longer possible as China is in the<br />

process of consolidating its trade and economic model. At the same<br />

time, China’s economic and industrial strength remains one of the<br />

key driving forces of the global economy and is shaping international<br />

markets. From Germany’s perspective, it is also one of the<br />

important sales and procurement market for German industry. As<br />

such, German industry wants to engage and create more opportunities<br />

in China, but the Chinese state controlled economic model<br />

creates systemic unfair competition with open market economies,<br />

which poses challenges that the EU simply cannot ignore.<br />

Foul, but play on!<br />

China has a hybrid economic system that has a mix of state and<br />

market elements. Despite considerable liberalization of the economy,<br />

the state still continues to play a strong role in the allocation of<br />

resources. Its influence on prices of land, energy, capital, labor and<br />

indirect or direct subsidies for companies or entire industry sector<br />

have led to production overcapacities and global market distortions,<br />

like in the steel sector. In future, overcapacities can be expected<br />

in areas of robotics and electric vehicle batteries. Also, while<br />

Chinese companies have enjoyed relatively free access to the EUs<br />

internal market, this does not apply equally to foreign companies in<br />

China. Even today, many industry sectors attract investment bans,<br />

caps or obligation to set up joint ventures. Along with this, China<br />

also has high levels of industrial tariffs and also multiple non-tariff<br />

barriers for foreign companies.<br />

8 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong>

In order to protect its own market and acquire strategic technology, Beijing introduced<br />

new restrictions on foreign firms like investment restrictions, forced technology transfer,<br />

lack of implementation of intellectual property rights, customs clearance issues, unequal<br />

access to licenses, financing, subsidies etc. Frequent and non-transparent regulatory<br />

changes make it difficult for foreign firms to do business, especially in industries that<br />

have to rely on long-term investments. Despite multiple announcements on a global<br />

level to support free and fair trade, China falls short in implementation, and thus restricting<br />

the long-term prospects for foreign companies in China.<br />

With the help of state investments in high value technologies and strategic takeovers of<br />

foreign high-tech companies, China is rapidly climbing the technological ladder. Thus<br />

diminishing Europe’s technological lead over its Chinese counterparts. Chinese mechanical<br />

engineering companies are increasingly active on international markets and<br />

are thus intensifying global competition. China is already the most important foreign<br />

machine supplier in North America and Asia and is further expanding this position. The<br />

Federation of German Industries (BDI), has been urging the German government and<br />

the European Commission to strengthen the European Union (EU) in the face of growing<br />

competition from China. For quite some time now, the BDI has been concerned with<br />

China’s state-controlled economy and its impact on German engineering companies.<br />

Steps EU and Germany needs to take<br />

Choosing what actions to take in dealing with China is a very crafty thing. The EU needs<br />

to posture itself strong and decisive but not too strong to create a trade war like situation.<br />

There is a fine line between maintaining the liberal, social and open market economy on<br />

one hand and a protectionist stance that isolates one’s own markets on the other hand.<br />

Measures taken by the Trump administration indicate that protection against Chinese<br />

distortions can quickly slide into protectionism. Germany and the EU must strike the<br />

right balance in their reactions to China.<br />

Germany and the EU cannot rest on its laurels that their model of a liberal and social<br />

market economy will bring long-term macroeconomic advantages over the Chinese system.<br />

In order to compete with China, Germany and other EU states need to focus on increasing<br />

innovation and R&D, improving technical education system, making EU as an<br />

attractive business destination, and encouraging strong entrepreneurship. On a policy<br />

level, EU needs to reform its industrial policy and set itself an ambitious industrial target<br />

for 2030, thereby prioritizing the strengthening of industry a policy objective on equal<br />

terms with other objectives such as environmental, climate and consumer protection. It<br />

needs to introduce tax incentives on research and reducing existing tax obstacles to<br />

private R&D activities. At the same time more work needs to be done on ensuring that<br />

Chinese government further improves the protection of intellectual property, technology,<br />

patents and trademarks in China. To ensure a level playing field against China’s<br />

production overcapacities and dumping of products in market, EU needs to create an<br />

effective and balanced trade defense instruments, strengthen anti-subsidy instrument,<br />

and prevent dumping of products and services in the European market. Europe also<br />

needs to address the issue of shortage of skilled workers, not just university graduates but<br />

also master craftsmen, finding the right labor market oriented immigration policy and<br />

securing the workforce base for the long term.<br />

On the digitalization front, Europe risks falling behind USA and China in the competition<br />

for a leading role in the digital transformation of industry and economy. In order to<br />

keep up with large and dynamic digital markets in China and the US, EU needs to further<br />

develop the European digital market, adapt and synchronize the legal and regulatory<br />

framework into a single market. The size of the collective market is a decisive factor for<br />

the international competitiveness of digital business models.<br />

The German industry body has called for a strong economic policy framework which<br />

ensures that companies from ‘non-open market, state-led economies’ are bound to the<br />

liberal market economy regulations of the EU if they want to be active in Europe. Internationally,<br />

the German industry is not alone in its demands regarding China’s interventionism.<br />

Instead of seeking individual answers, the German government and the EU<br />

Commission should go for a coordinated approach with like-minded liberal market<br />

economies. The EU must strengthen its foreign policy profile in the world.<br />

Photographs: Lead Photo Fotolia<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong> 9<br />

Turkish Machinery.indd 1 12.09.<strong>2019</strong> 10:50:29

Digitalization takes center stage<br />

at China’s leading industrial trade fairs<br />

NEWS AND MARKETS<br />

As industry 4.0 gains more and more traction, all<br />

sectors of industry are currently undergoing<br />

transformation; and like all changes, this too brings<br />

along both risk and opportunity. At PTC and CeMAT<br />

Asia, explore new technologies, new market players,<br />

new business models and understand the evolving<br />

customer expectations.<br />

China has always been a fan of international trade fairs and exhibitions.<br />

With more than 3000 trade fairs being hosted all over<br />

the country, they have become an influential part of the Chinese<br />

economy. Over the last two decades, these industrial trade fairs<br />

have been largely contributing to China’s rise as an industrial and<br />

manufacturing power. Multinational gatherings and events like<br />

Power, Transmission and Control Asia (PTC Asia) and CeMAT Asia<br />

are best examples of how impactful they are as a medium of marketing<br />

and reaching out to potential customers. One of the major<br />

reasons of success is the possibility to communicate to people faceto-face.<br />

For exhibitors, a well represented company booth and a<br />

personalized approach to every visitor, keeping in mind that majority<br />

of expo attendees are decision makers from all types of companies,<br />

leaves a lasting impression on the visitors.<br />

PTC and CeMAT Asia <strong>2019</strong><br />

PTC Asia, the leading industrial trade fair for hydraulics, pneumatics,<br />

mechanical and electrical power transmission and CeMAT Asia,<br />

the globally renowned trade fair brand for logistics and supply chain<br />

Author: Sushen Doshi, International Correspondent for World of Industries<br />

management have proven to be an important platform for domestics<br />

as well as foreign companies. For years, PTC and CeMAT Asia,<br />

have managed to bring together thousands of domestic and international<br />

buyers and sellers under one roof, and offer opportunities<br />

that day-to-day business correspondence usually cannot. Organized<br />

at the Shanghai New International Expo Centre, by Germany’s leading<br />

trade fair specialist, Deutsche Messe AG and Hannover Milano<br />

Fairs Shanghai Ltd, the event has a large number of visitors coming<br />

in from Asia’s top economies like South Korea, Japan, India, Indonesia,<br />

Thailand and Vietnam. With a total display area of around<br />

70,000 square meters, the show attracted more than 100,000 visitors<br />

and 1300 leading companies as exhibitors. Just like last year, PTC<br />

Asia and CeMAT Asia <strong>2019</strong> will be co-located along with other important<br />

trade fairs like ComVac Asia, Cold Chain Asia, Industrial<br />

Supply Asia. These sector specific fairs have earned quite a good<br />

reputation for themselves in a short span of time. This year, the<br />

event will commence on October 23rd and run until October 26th.<br />

Product categories at PTC Asia <strong>2019</strong><br />

PTC’s display area features a large number of products and technologies<br />

from domestic as well as international exhibitors who are<br />

looking to expand their business in the Chinese market. The booth<br />

planning and management has been carried out with minute details<br />

in mind that will help visitors to evaluate and compare products<br />

of interest, to attend conferences and to carry out in-depth discussions<br />

and negotiations.<br />

Exhibit area E1 to E5 are dedicated for fluid power sector, which<br />

has companies exhibiting products and technologies in hydraulics<br />

and pneumatics segment like pumps, motors, gears pumps, gear<br />

motors, power packs, cylinders, variable speed drive units, actuators,<br />

control valves, pressure switches, pipes hoses and connectors,<br />

sealing devices, filters and oil lubrication systems. Complementing<br />

the hydraulic and pneumatic segment is the sealing technology<br />

equipments like squeeze seals, rotating seals, reciprocating seals,<br />

10 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong>

Cemat Asia <strong>2019</strong><br />

Asian leg of the globally renowned brand CeMAT, has become the<br />

biggest annual meeting platform of the logistics industry in the<br />

Asia-Pacific region. The show’s focus on smart and integrated logistics<br />

attracts a lots of visitors. In this four-day event more than 600<br />

exhibitors from various countries showcase their innovative products<br />

and technologies. In recent years, the fast development of the<br />

e-commerce industry has become one of the main drivers of innovation<br />

in the logistics equipment industry. In 2018, CeMAT joined<br />

hands with China’s e-commerce giant JD as exhibitor and companies<br />

like Cainiao, Suning, Kaola and SF-Express organized visitor<br />

delegations to the show. JD’s logistics and innovation hub JDX<br />

showcased unmanned warehousing solutions on their booth.<br />

As a result of industrial modernization, logistics sector has become<br />

one of the biggest buyers for robotics and AGV technologies.<br />

Leading robotics manufacturers like ABB, Fanuc, and Siasun and<br />

emerging robotics providers like Geek+, Quicktron, HIK, Zhuineng<br />

Robotics and Ares Robotics also participate at the show to increase<br />

their international reach. Well established AGV manufacturers, e.g.<br />

Comwin, JingYuan, SiWei, I-Cow, BoZhong and AGV Robot also<br />

demonstrate their innovations such as forklift truck AGVs.<br />

Product Categories at CeMAT <strong>2019</strong><br />

mechanical seals, and sealing materials. In exhibit area E3 and E4<br />

visitors can witness various international pavilions, like German,<br />

Italian and Korean pavilion. Mechanical transmission parts and<br />

equipments (MTPE) sector is represented in the E6, E7, E8 and N5<br />

exhibit area. The display consists of vital engineering parts and<br />

components in the mechanical power transmission sector. Products<br />

like gears for automotive, aircraft, marine, railways, construction<br />

machinery, agricultural machinery, high speed and heavy duty<br />

gear boxes, planetary gear boxes, worm gears, and machine tools<br />

for gears. The exhibition also has chain and belt transmission products<br />

like conveyor short pitch precision roller chains, duplex pitch<br />

roller chains, heavy transmission chains, sprocket wheels, v-belts,<br />

flat belts and variable speed belt drives. Manufacturers of couplings<br />

and brakes also showcase their product portfolio which includes<br />

rigid, flexible couplings, universal joints, universal shafts, cam<br />

mechanisms, fluid couplings, clutch systems, locking assemblies,<br />

brakes and complete braking systems. Of the entire mechanical<br />

parts and equipment portfolio, the most in-demand component is<br />

the bearing. Keeping in mind the high participation from bearing<br />

manufacturers, PTC highlights the bearings section. Visitors can<br />

find deep groove ball bearings, cylindrical, spherical roller bearings,<br />

self aligning ball bearings, needle roller bearings, angular contact<br />

ball bearings, tapered roller bearings, thrust ball bearings,<br />

thrust roller bearing, bearing components like rings, steel ball, antidust<br />

shield seals, cage, sleeve, wheel and axle etc. Apart from this,<br />

visitors can also find equipment for bearing production and machining,<br />

all kinds of materials and accessories required in bearing<br />

production such as lubricant, anti-rust materials, grinding wheels,<br />

coolant, packing material, electric spindle frequency converter etc.<br />

In the electrical power transmission sector, of which China has<br />

been the top manufacturer and exporter, products like motors, servomotors,<br />

frequency converters, electrical drive control systems,<br />

electro-magnetic equipments, relays, contactors and other accessories<br />

that complete the industrial electrical circuitry, will all be on<br />

display at PTC Asia.<br />

Exhibit area W1, W2 focus on warehousing systems and related logistics<br />

technologies. Halls W3 and W4 focus on robotics in logistics,<br />

packaging equipment, pallets and consumables, this area also plays<br />

a host to various international pavilions. Halls W5 and N1 have exhibitors<br />

exhibiting products like forklift trucks, automated guided<br />

vehicles and their accessories. CeMAT’s product portfolio is divided<br />

in 7 main categories namely, mechanical handling equipment, warehousing<br />

technology and workshop equipment, packaging and order<br />

picking equipment, logistics services and outsourcing, traffic engineering,<br />

intralogistics systems and software, loading technology.<br />

The mechanical handling portfolio consists of equipment like<br />

cranes, lifting platforms, hoist-able man platforms, monorail conveyors,<br />

industrial trucks, forklifts, trolleys, driverless transport systems,<br />

lift, elevators, escalators, moving pavements, cable cars, components<br />

of drive technology, entire conveying systems, robotics<br />

handling systems, driverless transport systems, storage, and retrieval<br />

equipment for shelves and rack, manual trolleys etc. Warehousing<br />

technology and workshop equipment consists of shelving<br />

systems, factory and warehousing equipment, pallets, bins and<br />

containers, industrial doors and gates, cleaning systems for warehouses<br />

and storage facilities. Packaging and order picking systems<br />

for warehouses and shop floors, weighers and metering devices.<br />

Apart from products, exhibitors at CeMAT also offer logistics services<br />

like consulting, planning, financing, project management and<br />

maintenance services in the transport, e-logistics sector, etc.<br />

Logistics companies are facing an era of unprecedented change<br />

as digitalization takes center stage and customer expectations<br />

evolve. To cater this demand, CeMAT has special attention given to<br />

intralogistics IT and software systems like computer and control<br />

systems for material planning, warehouse management, transportation<br />

management, identification technology, Auto ID systems,<br />

sensors for intralogistics etc, that will be on display at the event.<br />

Apart from the serious and business part of the event, make time<br />

for small breaks and non-business conversations, in order to truly<br />

connect to people from various walks of industry. After all the true<br />

purpose of the trade fair is to bond and create long lasting relationships<br />

with fellow attendees, that translates into successful business<br />

partnership.<br />

Photographs: lead Fotolia, Deutsche Messe AG<br />

www.cemat-asia.com | www.ptc-asia.com<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong> 11

The new Interroll DC Platform<br />

With the launch of its new DC platform, Interroll is once again<br />

setting standards in material-handling technology. The range<br />

of perfectly matched RollerDrive, controls and power supply<br />

units enables system integrators and machine builders to<br />

provide an even better fit for their customers’ needs – from<br />

standard applications to equipment with Industry 4.0 or smart<br />

digital manufacturing functionality. The new DC platform has<br />

a solution to match every challenge.<br />

01 The new DC platform − made up of coordinated components<br />

such as the RollerDrive, controls systems, power supplies<br />

and accessories<br />

LOGISTICS<br />

Technology at a glance<br />

The RollerDrive EC5000 is the main component of the new DC platform.<br />

Combined with the control systems, the motor rollers in this<br />

product family are the key component of zero-pressure accumulation<br />

conveyors with individually driven conveyor zones, such as<br />

those used in the MCP. The RollerDrive EC5000 offers the following<br />

technical innovations over the popular and still available Roller-<br />

Drive EC310:<br />

n 48V/24V: Alongside a 24V version, the new RollerDrive is now<br />

also available with 48V technology.<br />

n 20/35/50 watt: Users can choose between three power levels: 20,<br />

35 and 50 watt. The 35-watt version is compatible with existing<br />

RollerDrive Installations.<br />

n Analog or bus interface: The new RollerDrive EC5000 is available<br />

with an analog or a bus interface.<br />

n Tube diameter: Alongside the versions with 50-mm tubes, the<br />

RollerDrive EC5000 is also available with 60-mm tubes for heavy<br />

transport materials.<br />

n Other features: Depending on the conditions in which the system<br />

will be used, you can choose versions of the RollerDrive EC5000<br />

product family with IP54 and IP66 protection and suitable for<br />

freezer applications.<br />

n Controls solution for every application: Alongside DriveControl<br />

2048 for standard applications with few RollerDrive, MultiControl<br />

– a four-zone control compatible with multiple protocols –<br />

offers the right solution for both simple and demanding applications,<br />

from autonomous conveyors with integrated logic to<br />

conveyors with customized PLC programming via fieldbus communication.<br />

n New power supplies − Unpack, plug in and use: The new power<br />

supply units do not need to be installed in the control cabinet.<br />

Instead, the robust devices with protection rating IP54 are mounted<br />

directly where the extra-low voltage is needed, enabling much<br />

shorter cable lengths. All functions of the 24V and 48V power<br />

units can be used straight out of the box. Automatic power limitation<br />

and configurable line protection are integrated, as is status<br />

evaluation via LED or a signal line to the PLC. Individual conveyor<br />

zones can be serviced while others remain in operation<br />

thanks to a switch secured against inadvertent start-up. With a<br />

higher peak output up to 50 percent and built-in brake chopper,<br />

the power supplies are perfect for use with RollerDrive.<br />

12 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong>

The “acid test”<br />

Interroll’s Global Center of Excellence for conveyor<br />

rollers, RollerDrive and controls in Wermelskirchen<br />

is responsible for the development,<br />

production and market launch of the DC<br />

platform. At the heart of the company is a test<br />

center covering an area of around 1,600 square<br />

meters.<br />

Interroll’s engineers at the center submit<br />

existing products and new innovations to comprehensive<br />

fatigue and load tests. Special<br />

chambers are used to test products’ resistance<br />

to heat and cold, ensuring that customers can<br />

rely on the quality of the Interroll range at anytime<br />

and anywhere. “Our test facilities work<br />

around the clock; we leave nothing to chance,”<br />

says managing director Armin Lindholm. “We<br />

have subjected the new DC platform to the acid<br />

test, involving all conceivable application scenarios<br />

and millions of test hours for the products<br />

and their components.”<br />

Built-to-order on an industrial scale<br />

Production of the new DC platform in Wermelskirchen<br />

works on the built-to-order principle.<br />

Intelligent processes based on the Interroll<br />

Production System (IPS) enable<br />

build-to-order with numerous options and<br />

short delivery times, even for small batches.<br />

Interroll has a long history of manufacturing<br />

expertise in this area, which applies to other<br />

product groups as well.<br />

“For the DC platform, we not only expanded<br />

and reorganized our motor roller production,<br />

but also systematically protected it against static<br />

discharges so that we could work with sensitive<br />

components,” says Lindholm. “We also<br />

store the data on all products and their components<br />

in the corporate cloud, allowing us to<br />

identify them years later through their serial<br />

numbers.” To ensure the same high product<br />

quality in the manufacturing facilities all<br />

around the globe, Interroll is steadily implementing<br />

the relevant manufacturing processes<br />

and equipment in America and Asia.<br />

Photographs: Interroll<br />

www.interroll.com<br />

02 The RollerDrive EC5000<br />

is the main component of<br />

the new DC platform<br />

Intelligent conveyor<br />

solution<br />

What’s behind the new Interroll DC<br />

Platform? In this interview, Armin<br />

Lindholm, Managing Director, Global<br />

Center of Excellence Rollers & RollerDrive<br />

in Wermelskirchen, discusses its benefits,<br />

development and production.<br />

What was the reason for bringing the new DC<br />

platform − made up of coordinated components<br />

such as the RollerDrive, controls systems, power<br />

supplies and accessories − to the market?<br />

Armin Lindholm emphasizes that<br />

the new DC platform was a holistic<br />

project that included both hardware<br />

and software development<br />

Lindholm: Because we wanted to use this innovation<br />

to offer our customers, by which I mean system<br />

integrators and manufacturers, real added value for their businesses. With our<br />

new DC Platform, this added value comes in the form of the unique variety of new<br />

options for providing users with an even more efficient material flow − precisely<br />

tailored to their individual needs.<br />

What new technical features are hidden “behind the scenes”<br />

of this range of applications?<br />

Lindholm: First, customers can now choose between three power levels − 20 W,<br />

35 W and 50 W − for the motor rollers, our RollerDrive. This enables customers to<br />

find individual solutions for light and heavy material to be transported. Next, the<br />

new optional bus interface, which is based on the CANOpen standard, makes the<br />

systems data-transparent. This means that the customer can read out, process and<br />

visualize a range of operating data whenever they want. Additionally, the corresponding<br />

control system means that users can not only control the acceleration,<br />

speed and deceleration of the conveyed goods in the system more precisely; they<br />

can also position the relevant goods on the conveyor to the nearest millimeter −<br />

for seamless conveying interplay with robots or automated gripper arms.<br />

And why did Interroll decide to offer two versions of this solution<br />

with 24 V and 48 V technology?<br />

Lindholm: Because this technology offers so many advantages. For instance, 48 V<br />

systems facilitate the use of up to 50 percent fewer power supply units than 24 V<br />

systems. They allow for smaller wire cross-sections in cabling and for longer cable<br />

lengths, and they reduce the number of error sources, for instance as a result of<br />

voltage drops on the wires. This significantly reduces the investment required in<br />

the entire system and substantially decreases the risk of errors during commissioning.<br />

What was it like developing the new solution?<br />

Lindholm: It was a holistic project that encompassed both hardware and software<br />

development. Alongside our own skills as a technology leader, we also relied on<br />

the expertise of five partner companies over the course of this project. With<br />

around 150 engineers and technicians working on it, this was the most extensive<br />

innovation project that Interroll had ever taken on. And of course, we also redesigned<br />

production. z<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong> 13

There is room<br />

in the smallest shop<br />

LOGISTICS<br />

E-commerce business, including the handling of<br />

returns, has not only led to an extreme increase in<br />

parcel volume in recent years - the variety of<br />

shipments and the requirements for the handling of<br />

goods have also increased drastically. Smaller and<br />

medium-sized courier, express or parcel locations<br />

(CEP locations) are thus confronted with a delicate<br />

challenge. Despite the necessity to unload large<br />

volumes of parcels and above all to sort them,<br />

there is often no space for a sorter. Flexible telescopic<br />

conveyors as well as scalable sorting solutions can help<br />

to use the space even in the smallest shop.<br />

At the interface between extra logistics and intralogistics, rigid<br />

loading concepts and a high proportion of manual work are<br />

used in many places. This takes a lot of time and makes an increase<br />

in parcel throughput almost impossible. Modern, flexible telescopic<br />

conveyors can be a first step here. Even with standard models,<br />

productivity can be increased by up to 30 percent compared to<br />

manual handling and a large variety of applications can be implemented.<br />

For example, the telescopes can be moved to the side so<br />

that several loading docks can be operated simultaneously. If further<br />

space is required from time to time in front of the ramp, compact<br />

models are available which can be pulled back into a parking<br />

position by personnel. This makes a mixed transport of general<br />

cargo, roll containers or pallets possible.<br />

Operating different vehicle types<br />

with a single solution<br />

Thanks to a lowerable front telescopic segment, it is also possible to<br />

load and unload different vehicle profiles from containers and<br />

trucks to delivery vans with one and the same telescopic conveyor.<br />

For example, the Sovex Bendy Boom telescopic conveyor, which<br />

was developed in close cooperation with market leaders in the parcel<br />

industry, can be used to serve transporters, trucks or containers<br />

with a length of up to 14 m on the same swap body. This is made<br />

possible by the 1.8 m long, movable front telescope segment, which<br />

can be angled by max. 25°. In addition to flexibility, this also allows<br />

the boom to be positioned in the optimal ergonomic position at all<br />

times. This prevents muscle-skeletal problems for operators or<br />

work-related accidents. The model, which can be extended up to a<br />

length of 15 m, provides the necessary conditions for a loading and<br />

unloading capacity of 1,200 parcels per hour.<br />

01 With lowerable front telescopic segments,<br />

even smaller transporters can be operated<br />

14 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong>

Flexible, scalable sorting solutions eliminate<br />

the need for sorters<br />

Sorting solutions such as the Transnorm Sorting Modules (TSM),<br />

which are easy to install, adapt, expand and duplicate, are available<br />

so that smaller CEP locations can also achieve a high degree of<br />

automation in shipment processing and distribution. Instead of a<br />

sorter, a Smartsort Linesplitter forms the heart of every TSM layout.<br />

With this reliable and robust solution, even the smallest mailing<br />

bags or packages can be sorted quickly and safely, thanks to short<br />

switching times and small spaces between the parcels.<br />

If required, the terminals can be equipped with various functionalities,<br />

such as slides or gravity roller conveyors up to the<br />

functionality for loading and unloading. In combination with the<br />

Linesplitter, they form a functional unit that requires just one simple<br />

controller. These solutions enable gentle product handling<br />

and can also be used efficiently as a simple discharging solution in<br />

a conveyor line. Finally, several line splitters can be combined in a<br />

layout to form a smart, modular subsystem with high sorting performance<br />

and functionality, in which the modules and controllers<br />

are simply interconnected.<br />

The TSM modules were each optimized for specific functionalities<br />

and cover all processes required at smaller CEP locations. TMS<br />

thus covers the functions unloading, splitting and merging lines,<br />

aligning, cycling, separating, sorting and finally loading. Due to the<br />

flexibility of this modular solution, the layout can be adopted or<br />

supplemented in peak season or when sudden order peaks occur in<br />

line with the increasing volume of parcels.<br />

02 At the heart of every TSM layout is a Smartsort line splitter<br />

The result<br />

While telescopic conveyors increase flexibility and productivity at<br />

the loading ramp, the use of a single TSM line splitter module can<br />

already provide a simple sorting solution. This makes it possible to<br />

automate a delivery center without the space requirement and<br />

investment costs of a sorter installation.<br />

www.transnorm.com<br />

DER ANTRIEB<br />

Reliable. Versatile. Global.<br />

NORD<br />

4.0<br />

READY!<br />

THE GEAR UNIT<br />

Strong bearings<br />

Quiet running<br />

THE MOTOR<br />

High efficiency<br />

Global standards<br />

THE DRIVE ELECTRONIC<br />

Field distribution system<br />

Easy implementation<br />

Getriebebau NORD GmbH &Co. KG |Fon +49 4532 289-0 |info@nord.com<br />

nord.com

Belt conveyors instead of trucks −<br />

an efficient alternative?<br />

LOGISTICS<br />

Recovered raw materials have to be transported from<br />

the quarry to the factory or port, often over uneven<br />

ground and across populated areas. Companies often<br />

choose trucks for transportation. As an alternative,<br />

system suppliers including Beumer Group offer open<br />

troughed belt conveyors or closed Pipe Conveyors.<br />

These solutions are more environmentally friendly and<br />

can be considerably more economical. Deciding if the<br />

investment is worthwhile depends on several factors.<br />

A feasibility study and a cost comparison can help with<br />

the decision.<br />

Companies often choose trucks to transport limestone, coal ores<br />

and other raw materials as efficiently as possible to the factory<br />

and from there to the port, sometimes over distances spanning several<br />

kilometers. Most of the time, the vehicles drive on public roads,<br />

which are not always well-paved. And as the route can go through<br />

hilly areas and nature reserves, across rivers and instable grounds,<br />

the trip often includes detours which costs time and money. If it<br />

goes through populated areas, it can be particularly taxing for local<br />

residents. The more raw materials are transported, the more trips<br />

are necessary. These factors motivate companies to take a closer<br />

look at the alternatives. Beumer Group offers open troughed belt<br />

conveyors and closed Pipe Conveyors for these scenarios. But will<br />

the investment pay off? “That depends on the particular application,”<br />

says Richard Munson. He has been with Beumer Group in<br />

Kansas City, Missouri, since 2010 where he manages the development<br />

and sales of conveying systems for the energy, cement and<br />

mining industries and port terminals. “Companies should carry out<br />

a profitability evaluation beforehand,” he advises.<br />

An economic evaluation pays off<br />

There are different methods to run an economic evaluation, including<br />

the net present value method, which is a type of profitability<br />

calculation. “Simply put, it means that all future income is discounted<br />

to time zero and compared, including the initial investment,”<br />

explains Munson. This method uses a calculation interest<br />

rate that reflects the best available alternative investment. The user<br />

receives a capital value, also called net present value or NPV. If this<br />

value is positive, it means that the company will make a profit with<br />

the investment.<br />

“Another option is cashflow analysis. It estimates the surplus that<br />

remains when deducting expenses from earnings,” Munson explains.<br />

Based on the annual difference of the total operational costs between<br />

conveying and trucking, the user calculates if investing in a<br />

conveying system will pay off. Different variables are required to exactly<br />

evaluate both transport options, for example the transport costs<br />

per ton, the material volume that needs to be moved within a set<br />

period of time, and also the specific investment cost and tax depreciation<br />

plan. “A comparison of conveying and trucking in a time<br />

diagram results in the break-even point,” explains the Beumer expert.<br />

Cost comparison<br />

Depending on the topography, length and power consumption,<br />

costs for conventional conveying systems average between EUR<br />

1,000 and 3,000 per meter. More costs are added for the construction,<br />

supply and the mechanical and electrical installation. Complex<br />

construction work is also often necessary. This makes the initial<br />

investment in a conveying system fairly high. “The operational<br />

costs however are considerably lower than with the use of trucks,”<br />

reports Munson. “The costs for the vehicles also include the labour<br />

input, vehicle depreciation, maintenance, repair, fuel and street<br />

maintenance for example. And oftentimes there are additional,<br />

more difficult to identify charges.”<br />

To operate a conventional conveying system, the typical costs for<br />

transporting one ton of material amounts to 20 Cents, with trucks<br />

the costs are roughly three Euro. “The biggest variable for the vehicles<br />

is the number of trips per hour,” says Munson. In case of short<br />

and direct routes, this ranks better than for long routes, where<br />

detours are necessary to get to the destination.” Troughed belt conveyors<br />

and closed Pipe Conveyors lead directly to the destination.<br />

They can also be adapted to the specific surroundings. An essential<br />

feature of the technology is that it enables horizontal and vertical<br />

curves. Angles of inclination of up to 15 degrees are possible, de<br />

16 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong>

01<br />

02 Sichuan project: The troughed belt<br />

conveyor runs through rough terrain and over<br />

instable ground<br />

02<br />

01 Sichuan project: whenever technically possible, the routing of the<br />

conveyor has been adapted to the topography<br />

pending on the characteristics of the material to be transported and<br />

the topography, with lengths greater than twelve kilometers. Due to<br />

their ability to navigate curves, considerably fewer and in some<br />

cases no transfer towers are required. This results in substantial cost<br />

savings for the customer and the system continuously transports<br />

the material even over challenging ascending and descending<br />

sections, rivers or street crossings. Using Beumer calculation programs,<br />

the experts precisely calculate the static and dynamic<br />

tractive forces of the belt during the system development phase.<br />

This is the prerequisite for the safe dimensioning of the curves.<br />

For trucks, more cost factors must be taken into account that are<br />

not as easy to estimate as the number of routes: control measures<br />

against dust and rain drainage, for example. These variables are<br />

eliminated completely in case of closed Pipe Conveyors. “If circa<br />

1,000,000 tons of bulk material are moved per year, then the gross<br />

differential value between trucks and a conveyor, using the above<br />

mentioned costs of the material that needs to be conveyed, is at<br />

2.8 million euro,” calculates Munson. That’s quite a number, in his<br />

opinion. The conveying system pays for itself after only a few years.<br />

Ecological and economical<br />

The electric drives and low-energy belts have a positive effect on the<br />

operational costs of the belt conveying systems. They are also better<br />

for the environment compared to the truck drives. Therefore, especially<br />

in these times of climate change and increasing greenhouse<br />

gas emissions they are considered a more sustainable option. The<br />

motors used for these systems are usually adjustable which permits<br />

04 The civil engineering work for conveying systems is usually very<br />

complex<br />

the loads to be optimally distributed on the drive units under various<br />

operating conditions. If the belt conveying system conveys<br />

downhill, the system works in regenerative operation. The generated<br />

electric energy is fed to the mains by a regenerative feedback<br />

unit. This way the owners can further reduce the operational costs<br />

of the entire system.<br />

“Depending on the project, belt conveying systems require up to<br />

90 percent less primary energy than comparable truck transports,”<br />

says the sales manager, referring to a concrete project implemented<br />

for the Chinese cement manufacturer Sichuan Yadong Cement.<br />

Trucks operated with diesel fuel required a specific primary energy<br />

of 11.4 kwh for each ton of transported material at their site. The belt<br />

conveying system which was built later on required on the contrary<br />

only 1.44 kwh. If, as in this case, 7.5 million tons of raw material are<br />

transported annually, the user can save a total of 74 million kwh per<br />

year with the belt conveyor. This corresponds to an energy consumption<br />

of more than 20,000 single-family houses. Solely by saving<br />

diesel fuel, the operational costs of the company are reduced<br />

by more than 5.5 million Euro per year.<br />

So does the investment in a belt conveying system pay off? “More<br />

often than people realize,” explains Munson. “In the end, the operator<br />

needs to consider the total costs per ton over time when evaluating<br />

both transport options.” The fact is: The operational costs for a<br />

belt conveyor are considerably lower than for a truck. The decisive<br />

factor is how much material is transported during the project term,<br />

then it can pay for itself quickly. Not to mention the Beumer conveying<br />

systems are more environmentally friendly from the beginning.<br />

Photographs: Beumer Group<br />

03 View of the enclosed conveyor flight in the area of the bridge<br />

www.beumergroup.com<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong> 17

In time with the sun<br />

Since July 2018, the sewage treatment plant at<br />

Chur (Switzerland) features a very special roof: The<br />

HORIZON foldable solar roof by dhp technology is a<br />

one of its kind worldwide and allows for an intelligent<br />

dual use of industrial sites. Decentralised drives from<br />

NORD DRIVESYSTEMS are used for autonomously<br />

expanding and collapsing the folding roof panels.<br />

Power producer, sun shade, sun worshipper, weather expert and<br />

master in space saving – the HORIZON foldable solar roof by<br />

dhp technology, a Swiss start-up, is a one of its kind worldwide. It is<br />

erected over already used areas and thus allows for intelligent dual<br />

use without needing to cover a single additional square metre with<br />

buildings or restricting the primary use of the area below. This saves<br />

resources such as space and ground in populated areas, makes<br />

large decentralised solar power plants possible where electrical<br />

power is needed, and provides shade for persons, goods and infrastructures.<br />

In this way, car parks turn into charging stations, logistics<br />

spaces into freshness zones, and sewage treatment plants into<br />

power plants.<br />

Solar technology redefined<br />

“The foldable solar roof is a unique solution for generating solar electricity<br />

on infrastructure areas because supporting columns can be<br />

set wide apart”, explains Andreas Hügli, co-founder and co- manager<br />

of dhp technology. “This is possible because we have chosen to opt<br />

for cableway technology, and the flexible and lightweight foldable<br />

roofs can be retracted to a protective position. Thanks to this protective<br />

position, the entire photovoltaic system need not be designed to<br />

withstand extreme weather; instead, we can make the modules lighter<br />

and then protect them against wind, snow, and hail in the garage.”<br />

dhp technology, founded in 2015, made energy history in the<br />

Swiss city of Chur where the world’s first foldable solar roof covering<br />

a sewage treatment plant was commissioned – covering the<br />

Chur sewage treatment plant. On board: intelligent, decentralised<br />

drive technology by NORD DRIVESYSTEMS.<br />

Intelligent drive technology from NORD<br />

With an area of 5,800 m 2 , the foldable solar roof of the Chur sewage<br />

treatment plant covers the pretreatment, secondary (biological)<br />

treatment, and tertiary treatment basins. The 2,120 modules produce<br />

550,000 kWh of electrical power per year – equalling about<br />

20 % of the auxiliary power required by the plant. The foldable solar<br />

roof operates completely autonomously and adapts to ambient<br />

MOTION AND DRIVES<br />

www.mayr.com<br />

Safety 4.0<br />

ROBA ® -topstop ® —the certified<br />

braking system for vertical axes<br />

with brake monitoring<br />

your reliable partner<br />

MAYR-eng.indd 1 19.08.<strong>2019</strong> 14:34:12<br />

18 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 5/<strong>2019</strong>

conditions automatically using weather data provided by a local<br />

weather station and external sources. The sun controls the intelligent<br />

drive units with integrated PLC automatically: Using robust<br />

cableway technology, the solar panels unfold automatically as soon<br />

as the first sun rays penetrate the clouds in the morning. They return<br />

to their protective garage position when the sun goes down in the<br />

evening. The foldable solar roof also returns to this position automatically<br />

in case of snow, hail or wind, and extreme situations –<br />

such as power or communication failures.<br />

Intelligent NORD DRIVESYSTEMS drives are used for retracting<br />

and extending the folding roof panels. The company, headquartered<br />

in North Germany, is one of the leading global full-service providers<br />

in the industry and supplies optimally matched drive systems consisting<br />

of gear unit, motor, and frequency inverter – an important<br />

asset for dhp technology. “We chose a solution provided by NORD<br />

because we wanted a provider that supplied drive technology from<br />

a single source” says Andreas Hügli. “And what’s more: NORD products<br />

perfectly meet our requirements. The fact that frequency inverters<br />

are directly mounted on the motors makes installation much<br />

easier. The PLC integrated in the drive unit also convinced us. With<br />

this intelligent control system, we can retract the foldable roof<br />

groups to the garage using an autonomous homerun function at any<br />

time if communication should fail. This maximizes the operational<br />

safety of the system and for us is a key factor of the drive solution.”<br />

The NORD drives – consisting of a UNIVERSAL worm geared motor<br />

with brake, magnetic encoder and motor-mounted NORDAC<br />

FLEX SK 205E frequency inverter – are mounted in a protected position<br />

on the supporting structure and can be addressed separately.<br />

This allows the maintenance personnel to retract individual folding<br />

roof groups into the garage and perform maintenance to specific<br />

basins. Each of the 53 folding roof groups has a drive of its own and<br />

can be extended and retracted, depending on the weather. Four<br />

drives each are electrically linked via the internal CAN bus, with<br />

one of the drives controlling the movement sequences as master.<br />

01 The drives are worm<br />

geared motors with<br />

motor-mounted frequency<br />

inverters. The revision<br />

switch is easily accessible<br />

for maintenance<br />

personnel.<br />

02 The drives are safely<br />

mounted on the supporting<br />

structure. Each of the<br />

53 folding roof groups has<br />

a drive of its own.<br />

NORD.” No wonder that additional optimisations and joint projects<br />

have already been wrapped up. Detection of a communication failure,<br />

for example, is to be implemented in the PLC integrated in NORD<br />

frequency inverters. Another objective is to simplify installation by<br />

providing preassembled connectors. And the successful partnership<br />

between dhp technology and NORD DRIVESYSTEMS will also be<br />

continued for installations of foldable solar roofs to come.<br />

www.nord.com<br />

Automated extension and retraction<br />

But how do the drives know when to extend and when to retract?<br />

This is where the powerful PLC integrated in the NORD frequency<br />

inverters comes into play. “The PLC reads local and external weather<br />

data and processes this data using a generic meteo algorithm to<br />

issue the “Extend” and “Retract” commands,” explains Philip Racine,<br />

dhp technology system engineer. Rotary encoders ensure that<br />

the position of the panels is known at any time. “The ramp function<br />

is also very important for us as it ensures we can retract the panels<br />

in an adequate period of time,” Racine continues. The ramps start<br />

up slowly, accelerate in the middle, and slow down when the garage<br />

is reached. The drive unit PLC controls this as well. The ramps for<br />

extending and retracting the foldable roofs are always identical and<br />

for this reason always require the same amount of energy. Thanks to<br />

their high overload capacity, the compact and robust NORD worm<br />

geared motors are capable of handling any malfunction that requires<br />

more energy to return the panels into the garage.<br />

Talking about malfunctions: The control unit has been programmed<br />

to retract the solar panels into the secure garage position<br />

automatically in case of a power or communication failure. This<br />

means: Manual intervention via remote maintenance is possible<br />

but unnecessary for secure operation.<br />

Sunny outlook<br />

“Cooperation with NORD was very agreeable. Everything just fitted<br />

perfectly – the product range and also the personal contact,” reports<br />

Andreas Hügli enthusiastically. “They offer top quality, quick delivery<br />

times, and perfect consulting and servicing. The good support in case<br />

of problems, further development and program extensions must also<br />

be pointed out. To sum up: we felt we were in very good hands with<br />

www.rheintacho.com

Changi Airport Singapore:<br />

Safety for floating petals<br />

Singapore’s Changi Airport opened its Terminal 4 in October 2017. A large kinetic<br />

sculpture is one of the artistic highlights of the building: Aluminium elements in the<br />

form of petals move to specially composed music. Safety brakes from the Allgäu-based<br />

specialist mayr power transmission, who runs a Chinese subsidiary in Zhangjiagang,<br />

protect the elements from falling and thus protect the passengers.<br />

MOTION AND DRIVES<br />

Soft music sounds. Slowly, 96 aluminium elements set themselves<br />

in motion high above the viewers - the rings are based on the<br />

shape of orchid leaves. In the rhythm of the music they move softly<br />

and precisely coordinated with each other, constantly forming new<br />

constellations. The installation “Petalclouds” can be admired in Terminal<br />

4 of Changi Airport in Singapore. The airport opened the new<br />

building in October 2017, and since 2018 the movable work of art<br />

has also been in operation as the heart of the artistic concept.<br />

Artistic heavyweight<br />

What looks light and airy in the Central Galleria of the new terminal<br />

is technically a heavyweight: with a length of 200 m and a weight of<br />

40 kg per element, a total of approximately 4 t of steel and aluminium<br />

move over the passengers. Each element is suspended from four<br />

thin steel cables. Two servo motors with winches per petal ensure<br />

the flowing movements according to a given choreography. In regular<br />

operation, the control system is also a matter for the motors - yet<br />

each one is individually equipped with an emergency stop brake,<br />

just in case. This is where the ROBA-stop-M series from mayr power<br />

transmission is used, two brakes are applied per winch. For smooth<br />

control, each winch is supplied by a ROBA-SBCplus control module.<br />

The SBCplus modules are particularly suitable here because they are<br />

designed for security applications. So there is no cultural break<br />

when they are combined with special safety PLCs. Thanks to its fully<br />

electric functionality, the SBCplus dispenses with mechanical components<br />

- a big plus for reliability. In addition, the modules make a<br />

compact design possible. Each SBCplus controls two brakes at the<br />

Petalclouds, so that both of its channels are fully utilised. The result:<br />

less volume requirement in the control cabinet and a space-saving<br />

design of the control electrics. Another advantage of the modules:<br />

They can evaluate the release monitoring of the brakes and thus provide<br />

information at any time as to whether the brakes are open or<br />

closed. The motors only run when the brakes are open, thus avoiding<br />

expensive damage to the drive from the outset.<br />

The design for the installation comes from the Berlin-based<br />