UTBILDNINGSMATERIAL CONDRY - IdéTrading

UTBILDNINGSMATERIAL CONDRY - IdéTrading

UTBILDNINGSMATERIAL CONDRY - IdéTrading

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chandra Byggref ab page 2 of 3<br />

Testing and consultants for building and refractory materials<br />

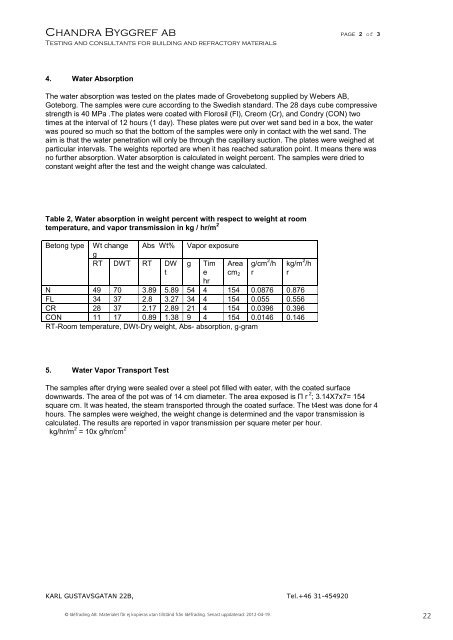

4. Water Absorption<br />

The water absorption was tested on the plates made of Grovebetong supplied by Webers AB,<br />

Goteborg. The samples were cure according to the Swedish standard. The 28 days cube compressive<br />

strength is 40 MPa .The plates were coated with Florosil (Fl), Creom (Cr), and Condry (CON) two<br />

times at the interval of 12 hours (1 day). These plates were put over wet sand bed in a box, the water<br />

was poured so much so that the bottom of the samples were only in contact with the wet sand. The<br />

aim is that the water penetration will only be through the capillary suction. The plates were weighed at<br />

particular intervals. The weights reported are when it has reached saturation point. It means there was<br />

no further absorption. Water absorption is calculated in weight percent. The samples were dried to<br />

constant weight after the test and the weight change was calculated.<br />

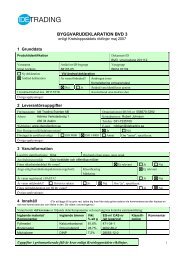

Table 2, Water absorption in weight percent with respect to weight at room<br />

temperature, and vapor transmission in kg / hr/m 2<br />

Betong type<br />

Wt change Abs Wt%<br />

g<br />

RT DWT RT DW<br />

t<br />

Vapor exposure<br />

g<br />

Tim<br />

e<br />

hr<br />

Area<br />

cm 2<br />

g/cm 2 /h<br />

r<br />

kg/m 2 /h<br />

r<br />

N 49 70 3.89 5.89 54 4 154 0.0876 0.876<br />

FL 34 37 2.8 3.27 34 4 154 0.055 0.556<br />

CR 28 37 2.17 2.89 21 4 154 0.0396 0.396<br />

CON 11 17 0.89 1.38 9 4 154 0.0146 0.146<br />

RT-Room temperature, DWt-Dry weight, Abs- absorption, g-gram<br />

5. Water Vapor Transport Test<br />

The samples after drying were sealed over a steel pot filled with eater, with the coated surface<br />

downwards. The area of the pot was of 14 cm diameter. The area exposed is Π r 2 ; 3.14X7x7= 154<br />

square cm. It was heated, the steam transported through the coated surface. The t4est was done for 4<br />

hours. The samples were weighed, the weight change is determined and the vapor transmission is<br />

calculated. The results are reported in vapor transmission per square meter per hour.<br />

kg/hr/m 2 = 10x g/hr/cm 2<br />

KARL GUSTAVSGATAN 22B, Tel.+46 31-454920<br />

S-411 25 GOTHENBURG, SWEDEN Org. nr: 5562375435<br />

© IdéTrading AB. Materialet får ej kopieras utan tillstånd från IdéTrading. Senast uppdaterad: 2012-04-19.<br />

22