Problematik vid höga flöden - Gästrike Vatten AB

Problematik vid höga flöden - Gästrike Vatten AB

Problematik vid höga flöden - Gästrike Vatten AB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

O 2 (mg/l)<br />

5<br />

4<br />

3<br />

2<br />

1<br />

(a) Aerobic reactor 1<br />

0<br />

2009-04-10 06 2009-04-12 18<br />

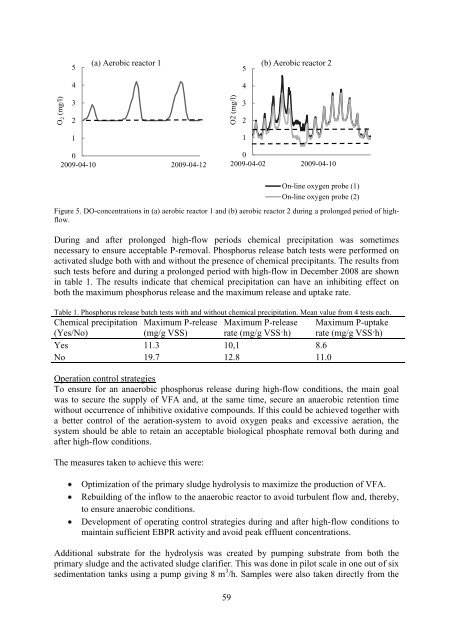

Figure 5. DO-concentrations in (a) aerobic reactor 1 and (b) aerobic reactor 2 during a prolonged period of highflow.<br />

During and after prolonged high-flow periods chemical precipitation was sometimes<br />

necessary to ensure acceptable P-removal. Phosphorus release batch tests were performed on<br />

activated sludge both with and without the presence of chemical precipitants. The results from<br />

such tests before and during a prolonged period with high-flow in December 2008 are shown<br />

in table 1. The results indicate that chemical precipitation can have an inhibiting effect on<br />

both the maximum phosphorus release and the maximum release and uptake rate.<br />

Table 1. Phosphorus release batch tests with and without chemical precipitation. Mean value from 4 tests each.<br />

Chemical precipitation Maximum P-release Maximum P-release Maximum P-uptake<br />

(Yes/No)<br />

(mg/g VSS) rate (mg/g VSS·h) rate (mg/g VSS·h)<br />

Yes 11.3 10,1 8.6<br />

No 19.7 12.8 11.0<br />

Operation control strategies<br />

To ensure for an anaerobic phosphorus release during high-flow conditions, the main goal<br />

was to secure the supply of VFA and, at the same time, secure an anaerobic retention time<br />

without occurrence of inhibitive oxidative compounds. If this could be achieved together with<br />

a better control of the aeration-system to avoid oxygen peaks and excessive aeration, the<br />

system should be able to retain an acceptable biological phosphate removal both during and<br />

after high-flow conditions.<br />

The measures taken to achieve this were:<br />

O2 (mg/l)<br />

Optimization of the primary sludge hydrolysis to maximize the production of VFA.<br />

Rebuilding of the inflow to the anaerobic reactor to avoid turbulent flow and, thereby,<br />

to ensure anaerobic conditions.<br />

Development of operating control strategies during and after high-flow conditions to<br />

maintain sufficient EBPR activity and avoid peak effluent concentrations.<br />

Additional substrate for the hydrolysis was created by pumping substrate from both the<br />

primary sludge and the activated sludge clarifier. This was done in pilot scale in one out of six<br />

sedimentation tanks using a pump giving 8 m 3 /h. Samples were also taken directly from the<br />

59<br />

5<br />

4<br />

3<br />

2<br />

1<br />

(b) Aerobic reactor 2<br />

0<br />

2009-04-02 00 2009-04-10 08<br />

On-line oxygen probe (1)<br />

On-line oxygen probe (2)