Practical_Antenna_Handbook_0071639586

C h a p t e r 2 8 : S u p p o r t s f o r W i r e s a n d V e r t i c a l s 633 that connection is made, wrap high-Âquality black vinyl electrical tape around the joint, starting on the vinyl cable jacket below the plug and continuing completely over and past the PL-Â259 until reaching the molded case that supports the SO-Â239 receptacle. Half-Âlapping the tape like siding or roof shingles should ensure minimal water ingress at the end of the coaxial cable. To minimize water vapor ingress caused by changes in humidity, the vinyl tape should also be sprayed with acrylic lacquer or painted with nail polish. Alternatively, use heat-Âshrink tubing and a heat gun to totally encase the connection from the threads of the SO-Â239 above the PL-Â259 to the outer jacket of the cable a half-Âinch or so below the bottom edge of the PL-Â259. In most installations, the weight of the feedline will keep the entire center assembly oriented as shown in Fig. 28.5, thus eliminating the need for a drip loop on the coaxial cable. If, however, a specific installation results in the SO-Â239 connector being anywhere other than beneath the body of the device, the coaxial line near the connector should be routed with a half-Âloop that is arranged so as to send any precipitation running along the cable away from the connector. At the top of the center insulator a small eyebolt is provided for strain-Ârelief of the system or for suspension from a center support (such as when the antenna is an inverted-Â vee). One disadvantage of coaxial cable and commercial center insulator assemblies (as compared to open-Âwire line directly connected to the two sides of the dipole) is that both add quite a bit of deadweight to the center of the antenna. Unless some kind of auxiliary support (nylon twine, polypropylene rope, or small-Âdiameter aircraft cable pulling up to a high point on a tower, mast, or tree) is available, the sag in a dipole for 80 or 40 m fed with RG-Â8 or RG-Â213 cable may be unacceptable to the user. If the VSWR on the line is kept close to 1.0:1 or power to the line is kept substantially below 1000 W, some weight can be removed by using the smaller-Âdiameter RG-Â58 or RG-Â59 cables instead of RG-Â8— especially at 10 MHz and below, where line loss is lowest. The longer, lower barrel of the center insulator shown in Fig. 28.4B indicates the presence of either a 4:1 or 1:1 impedance ratio balun transformer. The 1:1 size is recommended for ordinary dipoles, whereas a 4:1 unit is a good match for folded dipoles and certain other wire antennas with feedpoint impedances substantially larger than the Z 0 of the feedline. Some users form the coaxial cable into a 6-Â to 12-Âin multiturn loop just below the coaxial connector, as shown in Fig. 28.6. This forms a common-Âmode RF choke intended 1:1 BALUN OR CENTER INSULATOR WIRE SPLICES END INSULATOR HEAVY DUTY DOOR SPRING ROPE TO SUPPORT STOUT STRING COAX LOOP (15-25 CM DIAM.) COAX CABLE TO RECEIVER OR TRANSMITTER Figure 28.6 Dipole and wire antenna installation.

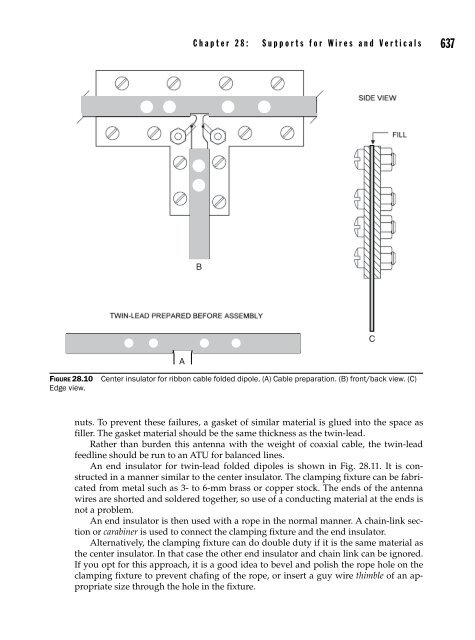

634 p a r t V I I I : M e c h a n i c a l C o n s t r u c t i o n a n d I n s t a l l a t i o n T e c h n i q u e s to keep currents from flowing on the outside of the cable shield, thus helping to keep the feedline from becoming an unintended part of the radiating antenna. The number of turns is inversely proportional to the lowest operating frequency. For an 80-Âm dipole, 16 turns of 8-Â to 12-Âin diameter is probably not too few . . . but will be very heavy! Bind the turns together with black electrician’s tape or some similar adhesive medium and then fasten the entire loop to the top eyelet with stout string or fishing line for strain relief. End Insulators Over the years, end insulators have been made from wood, glass, ceramics, plastics, and composites. In fact, at low power levels (say, 100 W or less), garden-Âvariety polypropylene rope often used for stringing the dipole up is perfectly adequate as its own insulator! Nonetheless, since the wire ends of a dipole are usually high-Âvoltage points, take care to keep the conductors away from flammable surfaces. More than one licensed amateur has set a tree on fire by transmitting into a wire draped across tree limbs! End insulators come in a large variety of shapes and sizes. Examples of two basic shapes are found in Fig. 28.7. Figure 28.7A depicts the standard strain insulator, and Fig. 28.7B is representative of an egg insulator. The egg insulator has two sets of wire grooves and through-Âholes that are orthogonal to each other (only one set is shown). Wire passes through one hole and its grooves, while the supporting rope passes through the other hole/groove set. The purpose of the orthogonal holes is to prevent the antenna from totally separating from the support line if the insulator should fracture. For higher power levels, the standard strain insulator of Fig. 28.7A is preferable. This style often has a number of grooves or ridges along the body that serve to lengthen A Figure 28.7 End insulators. B

- Page 604 and 605: C h a p t e r 2 6 : T h e S m i t h

- Page 606 and 607: C h a p t e r 2 6 : T h e S m i t h

- Page 608 and 609: CHAPTER 27 Testing and Troubleshoot

- Page 610 and 611: C h a p t e r 2 7 : T e s t i n g a

- Page 612 and 613: C h a p t e r 2 7 : T e s t i n g a

- Page 614 and 615: C h a p t e r 2 7 : T e s t i n g a

- Page 616 and 617: C h a p t e r 2 7 : T e s t i n g a

- Page 618 and 619: C h a p t e r 2 7 : T e s t i n g a

- Page 620 and 621: C h a p t e r 2 7 : T e s t i n g a

- Page 622 and 623: C h a p t e r 2 7 : T e s t i n g a

- Page 624 and 625: C h a p t e r 2 7 : T e s t i n g a

- Page 626 and 627: C h a p t e r 2 7 : T e s t i n g a

- Page 628 and 629: C h a p t e r 2 7 : T e s t i n g a

- Page 630 and 631: C h a p t e r 2 7 : T e s t i n g a

- Page 632 and 633: C h a p t e r 2 7 : T e s t i n g a

- Page 634 and 635: C h a p t e r 2 7 : T e s t i n g a

- Page 636 and 637: C h a p t e r 2 7 : T e s t i n g a

- Page 638 and 639: C h a p t e r 2 7 : T e s t i n g a

- Page 640 and 641: C h a p t e r 2 7 : T e s t i n g a

- Page 642 and 643: C h a p t e r 2 7 : T e s t i n g a

- Page 644 and 645: Mechanical Construction and Install

- Page 646 and 647: CHAPTER 28 Supports for Wires and V

- Page 648 and 649: C h a p t e r 2 8 : S u p p o r t s

- Page 650 and 651: C h a p t e r 2 8 : S u p p o r t s

- Page 652 and 653: C h a p t e r 2 8 : S u p p o r t s

- Page 656 and 657: C h a p t e r 2 8 : S u p p o r t s

- Page 658 and 659: C h a p t e r 2 8 : S u p p o r t s

- Page 660 and 661: C h a p t e r 2 8 : S u p p o r t s

- Page 662 and 663: C h a p t e r 2 8 : S u p p o r t s

- Page 664 and 665: C h a p t e r 2 8 : S u p p o r t s

- Page 666 and 667: C h a p t e r 2 8 : S u p p o r t s

- Page 668 and 669: C h a p t e r 2 8 : S u p p o r t s

- Page 670 and 671: C h a p t e r 2 8 : S u p p o r t s

- Page 672 and 673: C h a p t e r 2 8 : S u p p o r t s

- Page 674 and 675: CHAPTER 29 Towers At some point, th

- Page 676 and 677: C h a p t e r 2 9 : T o w e r s 655

- Page 678 and 679: C h a p t e r 2 9 : T o w e r s 657

- Page 680 and 681: C h a p t e r 2 9 : T o w e r s 659

- Page 682 and 683: C h a p t e r 2 9 : T o w e r s 661

- Page 684 and 685: C h a p t e r 2 9 : T o w e r s 663

- Page 686 and 687: C h a p t e r 2 9 : T o w e r s 665

- Page 688 and 689: C h a p t e r 2 9 : T o w e r s 667

- Page 690 and 691: C h a p t e r 2 9 : T o w e r s 669

- Page 692 and 693: C h a p t e r 2 9 : T o w e r s 671

- Page 694 and 695: C h a p t e r 2 9 : T o w e r s 673

- Page 696 and 697: C h a p t e r 2 9 : T o w e r s 675

- Page 698 and 699: C h a p t e r 2 9 : T o w e r s 677

- Page 700 and 701: C h a p t e r 2 9 : T o w e r s 679

- Page 702 and 703: C h a p t e r 2 9 : T o w e r s 681

C h a p t e r 2 8 : S u p p o r t s f o r W i r e s a n d V e r t i c a l s 633<br />

that connection is made, wrap high-Âquality black vinyl electrical tape around the joint,<br />

starting on the vinyl cable jacket below the plug and continuing completely over and<br />

past the PL-Â259 until reaching the molded case that supports the SO-Â239 receptacle.<br />

Half-Âlapping the tape like siding or roof shingles should ensure minimal water ingress at<br />

the end of the coaxial cable. To minimize water vapor ingress caused by changes in humidity,<br />

the vinyl tape should also be sprayed with acrylic lacquer or painted with nail<br />

polish. Alternatively, use heat-Âshrink tubing and a heat gun to totally encase the connection<br />

from the threads of the SO-Â239 above the PL-Â259 to the outer jacket of the cable<br />

a half-Âinch or so below the bottom edge of the PL-Â259.<br />

In most installations, the weight of the feedline will keep the entire center assembly<br />

oriented as shown in Fig. 28.5, thus eliminating the need for a drip loop on the coaxial<br />

cable. If, however, a specific installation results in the SO-Â239 connector being anywhere<br />

other than beneath the body of the device, the coaxial line near the connector should be<br />

routed with a half-Âloop that is arranged so as to send any precipitation running along<br />

the cable away from the connector.<br />

At the top of the center insulator a small eyebolt is provided for strain-Ârelief of the<br />

system or for suspension from a center support (such as when the antenna is an inverted-Â<br />

vee). One disadvantage of coaxial cable and commercial center insulator assemblies (as<br />

compared to open-Âwire line directly connected to the two sides of the dipole) is that both<br />

add quite a bit of deadweight to the center of the antenna. Unless some kind of auxiliary<br />

support (nylon twine, polypropylene rope, or small-Âdiameter aircraft cable pulling up to<br />

a high point on a tower, mast, or tree) is available, the sag in a dipole for 80 or 40 m fed<br />

with RG-Â8 or RG-Â213 cable may be unacceptable to the user. If the VSWR on the line is<br />

kept close to 1.0:1 or power to the line is kept substantially below 1000 W, some weight<br />

can be removed by using the smaller-Âdiameter RG-Â58 or RG-Â59 cables instead of RG-Â8—<br />

especially at 10 MHz and below, where line loss is lowest.<br />

The longer, lower barrel of the center insulator shown in Fig. 28.4B indicates the<br />

presence of either a 4:1 or 1:1 impedance ratio balun transformer. The 1:1 size is recommended<br />

for ordinary dipoles, whereas a 4:1 unit is a good match for folded dipoles and<br />

certain other wire antennas with feedpoint impedances substantially larger than the Z 0<br />

of the feedline.<br />

Some users form the coaxial cable into a 6-Â to 12-Âin multiturn loop just below the<br />

coaxial connector, as shown in Fig. 28.6. This forms a common-Âmode RF choke intended<br />

1:1 BALUN OR<br />

CENTER INSULATOR<br />

WIRE SPLICES<br />

END INSULATOR<br />

HEAVY DUTY<br />

DOOR SPRING<br />

ROPE TO SUPPORT<br />

STOUT STRING<br />

COAX LOOP<br />

(15-25 CM DIAM.)<br />

COAX CABLE TO RECEIVER<br />

OR TRANSMITTER<br />

Figure 28.6 Dipole and wire antenna installation.