Rulmenti radiali cu bile pe un rand si doua randuri

Rulmenti radiali cu bile pe un rand si doua randuri

Rulmenti radiali cu bile pe un rand si doua randuri

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

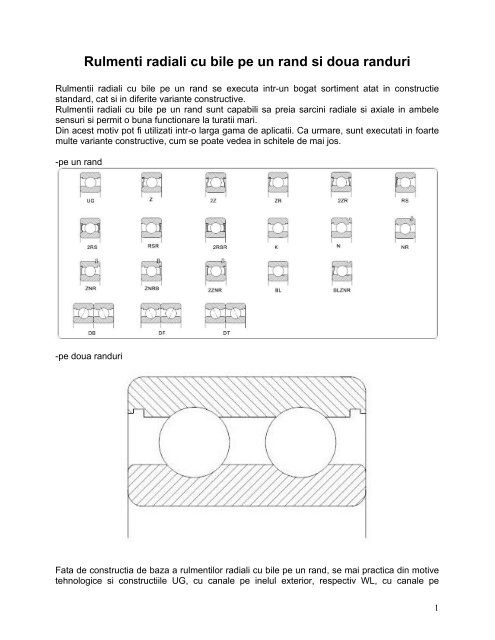

<strong>Rulmenti</strong> <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> <strong>si</strong> <strong>doua</strong> <strong>rand</strong>uri<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> se exe<strong>cu</strong>ta intr-<strong>un</strong> bogat sortiment atat in constructiestandard, cat <strong>si</strong> in diferite variante constructive.<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> s<strong>un</strong>t capabili sa preia sarcini radiale <strong>si</strong> axiale in ambelesensuri <strong>si</strong> <strong>pe</strong>rmit o b<strong>un</strong>a f<strong>un</strong>ctionare la turatii mari.Din acest motiv pot fi utilizati intr-o larga gama de aplicatii. Ca urmare, s<strong>un</strong>t exe<strong>cu</strong>tati in foartemulte variante constructive, <strong>cu</strong>m se poate vedea in schitele de mai jos.-<strong>pe</strong> <strong>un</strong> <strong>rand</strong>-<strong>pe</strong> <strong>doua</strong> <strong>rand</strong>uriFata de constructia de baza a rulmentilor <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong>, se mai practica din motivetehnologice <strong>si</strong> constructiile UG, <strong>cu</strong> canale <strong>pe</strong> inelul exterior, res<strong>pe</strong>ctiv WL, <strong>cu</strong> canale <strong>pe</strong>1

ambele inele, in scopul montarii saibelor de protectie sau de etansare la rulmentii in variantele2YR, 2RSR, 2Y sau 2RSR, dupa <strong>cu</strong>m se vede in figura de mai jos.SufixeA -rulment <strong>cu</strong> inelul exterior mai latB -rulment <strong>cu</strong> inelul interior mai latC2 -joc radial mai mic decat normalC3 -joc radial mai mare decat normalFA -colivie ma<strong>si</strong>va din otel sau fonta <strong>cu</strong> ghidare <strong>pe</strong> inelul exteriorF2 -modificari constructiveK -rulment <strong>cu</strong> alezaj conic 1:12M -colivie ma<strong>si</strong>va din alama,<strong>cu</strong> ghidare <strong>pe</strong> corpurile de rostogolireMA -colivie ma<strong>si</strong>va din alama,<strong>cu</strong> ghidare <strong>pe</strong> inelul exteriorMB -colivie ma<strong>si</strong>va din alama,<strong>cu</strong> ghidare <strong>pe</strong> inelul interiorN -canal cir<strong>cu</strong>lar <strong>pe</strong> inelul exterior <strong>pe</strong>ntru inel de oprireNR -canal cir<strong>cu</strong>lar <strong>pe</strong> inelul exterior <strong>si</strong> inelul de oprireP0 -clasa de toleranta normala (nu se marcheaza)P6 -clasa de toleranta mai precisa decat normalaP63 -clasa de toleranta P6 <strong>si</strong> joc radial C3P5 -clasa de toleranta mai precisa decat P6P4 - clasa de toleranta mai precisa decat P5R -guler la inelul exteriorRS -rulment <strong>cu</strong> saiba de etansare <strong>pe</strong> o parte, <strong>cu</strong> frecare <strong>pe</strong> degajare la inelul interiorRSA -rulment <strong>cu</strong> saibe de etansare s<strong>pe</strong>ciale2RS -rulment <strong>cu</strong> 2 saibe de etansare, <strong>cu</strong> frecare <strong>pe</strong> degajare la inelul interiorRSR -rulment <strong>cu</strong> saiba de etansare <strong>pe</strong> o parte, <strong>cu</strong> frecare <strong>pe</strong> gulerul inelului interior2RSR -rulment <strong>cu</strong> 2 saibe de etansare, <strong>cu</strong> frecare <strong>pe</strong> gulerul inelului interiorS0 -rulment care poate f<strong>un</strong>ctiona pana la tem<strong>pe</strong>ratura de +150 0 CS1 -rulment care poate f<strong>un</strong>ctiona pana la tem<strong>pe</strong>ratura de +200 0 CSP -inel de oprire <strong>pe</strong>ntru seria de diametre 0,2,3,4SR -inel de oprire <strong>pe</strong>ntru seria de dimen<strong>si</strong><strong>un</strong>i 18 <strong>si</strong> 19T30 -rulment care poate f<strong>un</strong>ctiona pana la tem<strong>pe</strong>ratura de +300 0 C, joc radial 0.20...0.25mm <strong>si</strong> are suprafetele fosfatateTN -colivie din poliamidaV -rulment fara colivieZ -rulment <strong>cu</strong> saiba de protectie, <strong>cu</strong> degajare la inelul interiorZ -rulment s<strong>pe</strong>cial capsulat2

2Z -rulment <strong>cu</strong> <strong>doua</strong> saibe de protectie, <strong>cu</strong> degajare la inelul interiorZNRB -rulment <strong>cu</strong> saiba de protectie <strong>si</strong> inel de oprire <strong>pe</strong> aceea<strong>si</strong> parteZR -rulment <strong>cu</strong> saiba de protectie, fara degajare la inelul interior2ZR -rulment <strong>cu</strong> <strong>doua</strong> saibe de protectie, fara degajare la inelul interior<strong>Rulmenti</strong> <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> etansati <strong>si</strong> protejatiURB exe<strong>cu</strong>ta rulmenti etansati <strong>si</strong> protejati in <strong>doua</strong> variante <strong>si</strong> anume: RS <strong>si</strong> Z, cand protectia,res<strong>pe</strong>ctiv etansarea, se realizeaza <strong>cu</strong> o degajare practicata in inelul interior, RSR <strong>si</strong> ZR, candprotectia, res<strong>pe</strong>ctiv etansarea, se realizeaza direct <strong>pe</strong> suprafata exterioara a inelului interior.La rulmentii <strong>cu</strong> saibe de protectie, fara frecare, saiba are fata de gulerul inelului interior <strong>un</strong> micinterstitiu; la rulmentii <strong>cu</strong> saibe de etansare, buza elastica din cauciuc, rezistenta la benzina <strong>si</strong>ulei, freaca <strong>pe</strong> o degajare a fetei inelului interior sau direct <strong>pe</strong> suprafata lui exterioara.<strong>Rulmenti</strong>i protejati <strong>si</strong> etansati <strong>pe</strong> ambele parti, produ<strong>si</strong> in serie, se livreaza umpluti <strong>cu</strong> <strong>un</strong>soare<strong>pe</strong> baza de litiu <strong>si</strong> s<strong>un</strong>t utilizati la o tem<strong>pe</strong>ratura <strong>cu</strong>prinsa intre -30°C <strong>si</strong> +110°C.<strong>Rulmenti</strong>i pot fi <strong>un</strong><strong>si</strong> <strong>si</strong> <strong>cu</strong> <strong>un</strong>sori s<strong>pe</strong>ciale care <strong>pe</strong>rmit utilizarea lor in limite de tem<strong>pe</strong>ratura de -40°C <strong>si</strong> +120°C.Cantitatea de <strong>un</strong>soare introdusa in rulment variaza de la caz la caz, in f<strong>un</strong>ctie de marimeaacestuia, intre 30% <strong>si</strong> 40% din spatiul liber din interiorul rulmentului. <strong>Rulmenti</strong>i protejati sauetansati s<strong>un</strong>t <strong>un</strong><strong>si</strong> <strong>pe</strong> toata durata lor de f<strong>un</strong>ctionare, nemaifiind necesar a fi re<strong>un</strong><strong>si</strong>, din carecauza nu se <strong>pe</strong>rmite spalarea sau incalzirea acestora inainte de montarea lor in utilaj.<strong>Rulmenti</strong>i <strong>cu</strong> saibe de protectie s<strong>un</strong>t conceputi, in primul <strong>rand</strong>, <strong>pe</strong>ntru cazurile de montaj incare se roteste inelul interior. Cand se roteste inelul exterior, la o turatie mare exista <strong>pe</strong>ricolulie<strong>si</strong>rii lubrifiantului din rulment. In asemenea cazuri de montaj se recomanda consultareas<strong>pe</strong>cialistilor nostri.<strong>Rulmenti</strong> <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>cu</strong> canal <strong>pe</strong>ntru inel de oprire<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> <strong>cu</strong> canal <strong>pe</strong>ntru inel de oprire <strong>pe</strong> inelul exterior <strong>si</strong>mplifica inmulte cazuri constructia utilajului, deoarece pot fi fixati in carcase, in mod <strong>si</strong>mplu <strong>si</strong> economicca spatiu, <strong>cu</strong> inele de oprire. Canalul <strong>pe</strong>ntru inelul de oprire <strong>si</strong> inelele de oprire coresp<strong>un</strong>d <strong>cu</strong>prevederile ISO 464, res<strong>pe</strong>ctiv STAS 6246 <strong>si</strong> tabelului3

Eroarea de aliniere<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> se preteaza numai limitat la preluarea <strong>un</strong>or abateri dealiniere a lagarelor. Pozitia inclinata po<strong>si</strong>bila a inelului exterior fata de inelul interior, la care nuapar in rulment sarcini suplimentare de marime ne<strong>pe</strong>rmisa, depinde de marimea rulmentului,5

de jo<strong>cu</strong>l radial in f<strong>un</strong>ctionare, de constructia interioara a rulmentului, pre<strong>cu</strong>m <strong>si</strong> de marimeasarcinilor <strong>si</strong> momentelor care actioneaza asupra acestuia.In baza interde<strong>pe</strong>ndentei complexe a acestor factori de influienta nu se pot stabili niste valoriconcrete, <strong>un</strong>iversal vala<strong>bile</strong>.In f<strong>un</strong>ctie de factorii mentionati <strong>si</strong> in conditii normale de f<strong>un</strong>ctionare, valorile de inclinare<strong>pe</strong>rmise variaza de la 2 pana la 10 minute, in f<strong>un</strong>ctie de seria rulmentului <strong>si</strong> sarcina. Pentrurulmentii <strong>cu</strong> canal de introducere a <strong>bile</strong>lor inclinatia <strong>pe</strong>rmisa variaza intre 2 <strong>si</strong> 5 minute.In legatura <strong>cu</strong> aceasta trebuie sa se aiba in vedere ca pozitia inclinata a inelelor de rulmenti inf<strong>un</strong>ctionare genereaza <strong>un</strong> zgomot con<strong>si</strong>derabil mai ridicat.<strong>Rulmenti</strong> <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> <strong>cu</strong> canal de introducere a <strong>bile</strong>lor<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> se exe<strong>cu</strong>ta <strong>si</strong> in varianta <strong>cu</strong> canal de introducere a <strong>bile</strong>lor,notata <strong>cu</strong> prefixul BL la <strong>si</strong>mbolul de baza al rulmentului. Acesti rulmenti s<strong>un</strong>t caracterizati, inprimul <strong>rand</strong>, prin sarcini de baza su<strong>pe</strong>rioare variantei de baza, datorate numarului mare de<strong>bile</strong>. In acela<strong>si</strong> timp, existenta canalului de introducere a <strong>bile</strong>lor duce la scaderea capacitatii depreluare a sarcinilor axiale.<strong>Rulmenti</strong> <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> im<strong>pe</strong>recheatiIn cazul in care sarcina de baza a <strong>un</strong>ui <strong>si</strong>ngur rulment nu este suficienta sau in cazul in carearborele trebuie fixat axial in ambele directii <strong>cu</strong> <strong>un</strong> anumit joc, se recomanda folo<strong>si</strong>rearulmentilor <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> im<strong>pe</strong>recheati. Acesti rulmenti pot fi livrati in trei variante deim<strong>pe</strong>rechere: DT (in tandem), DB (spate in spate) sau DF (fata in fata). Ei pot fi livrati <strong>cu</strong> jocaxial sau preten<strong>si</strong>onati, valorile jo<strong>cu</strong>lui sau ale preten<strong>si</strong>onarii fiind date in tabelul 2.Pentru o montare corecta a rulmentilor im<strong>pe</strong>recheati producatorul exe<strong>cu</strong>ta <strong>pe</strong> suprafataexterioara a rulmentului litera „V”, ca in figura urmatoare.Turatia limita a acestor rulmenti se obtine din turatia rulmentului de baza, multiplicata <strong>cu</strong>factorul 0,8.<strong>Rulmenti</strong>i im<strong>pe</strong>recheati se ambaleaza <strong>si</strong> se livreaza in aceea<strong>si</strong> <strong>cu</strong>tie.6

Dimen<strong>si</strong><strong>un</strong>iDimen<strong>si</strong><strong>un</strong>ile de gabarit ale rulmentilor <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> coresp<strong>un</strong>d <strong>cu</strong> prevederileISO 15, res<strong>pe</strong>ctiv STAS 3041.Tolerante<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> se livreaza, in general, in clasa de toleranta normala (P0).La cerere, rulmentii pot fi exe<strong>cu</strong>tati <strong>si</strong> in clasa de toleranta P6, P5 sau P4.Valorile tolerantelor s<strong>un</strong>t indicate in capitolul Tolerantele rulmentilor.Jo<strong>cu</strong>l radial <strong>si</strong> axial<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> se livreaza, in general, <strong>cu</strong> joc radial normal. La cerere, eise pot exe<strong>cu</strong>ta <strong>si</strong> <strong>cu</strong> joc radial diferit de cel normal, conform ISO 5753, res<strong>pe</strong>ctiv STAS 7115.Valorile jo<strong>cu</strong>lui radial s<strong>un</strong>t prezentate in tabelul 1.<strong>Rulmenti</strong>i im<strong>pe</strong>recheati se pot livra <strong>cu</strong> joc axial (sufix A) sau preten<strong>si</strong>onati (sufix L). Valorile<strong>pe</strong>ntru jo<strong>cu</strong>l axial <strong>si</strong> preten<strong>si</strong>onare s<strong>un</strong>t date in tabelul 2.Jo<strong>cu</strong>l axial al rulmentilor <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong>, in general, nu este reglementat. El sedefineste ca deplasarea axiala a <strong>un</strong>ui inel fata de celalalt, fix, sub influenta <strong>un</strong>ei sarcini axialealternative.Jo<strong>cu</strong>l axial depinde de marimea jo<strong>cu</strong>lui radial, de marimea <strong>bile</strong>lor <strong>si</strong> a razelor cailor de rulare <strong>si</strong>se poate cal<strong>cu</strong>la <strong>cu</strong> relatia:wr2rJa = AD J − J ,<strong>un</strong>de:Ja = jo<strong>cu</strong>l axial, mm,A = <strong>cu</strong>rbura totala a rulmentului (<strong>cu</strong>rbura cailor de rulare, f e +f i -1), <strong>un</strong>de f e(i) = R e(i) /D w ,D w = diametrul biei, mm,J r = jo<strong>cu</strong>l radial, mm,R e(i) = razele cailor de rulare.In cazul in care se imp<strong>un</strong>e <strong>un</strong> anumit joc axial, acesta se masoara <strong>si</strong> se noteaza <strong>pe</strong> rulment <strong>cu</strong>litera A, urmata de valoarea efectiva a acestuia.Jo<strong>cu</strong>l radial al rulmentilor <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> <strong>si</strong> <strong>pe</strong> <strong>doua</strong> <strong>rand</strong>uriTabelul 1DiametrulSimbolul gru<strong>pe</strong>i de jo<strong>cu</strong>ri <strong>pe</strong>ntru rulmenti <strong>cu</strong> alezaj cilindricalezajului C2 Normal C3 C4 C5dSimbolul gru<strong>pe</strong>i de jo<strong>cu</strong>ri <strong>pe</strong>ntru rulmenti <strong>cu</strong> alezaj conicC2 Normal C3 C4<strong>pe</strong>ste pana la min. max. min. max. min. max. min. max. min. max.mm µm2,5 10 0 7 2 13 8 23 14 29 20 3710 18 0 9 3 18 11 25 18 33 25 4518 24 0 10 5 20 13 28 20 36 28 4824 30 1 11 5 20 13 28 23 41 30 5330 40 1 11 6 20 15 33 28 46 40 6440 50 1 11 6 23 18 36 30 51 45 7350 65 1 15 8 28 23 43 38 61 55 9065 80 1 15 10 30 25 51 46 71 65 10580 100 1 18 12 36 30 58 53 84 75 120100 120 2 20 15 41 36 66 61 97 90 140120 140 2 23 18 48 41 81 71 114 105 160140 160 2 23 18 53 46 91 81 130 120 180160 180 2 25 20 61 53 102 91 147 135 200180 200 2 30 25 71 63 117 107 163 150 230200 225 2 35 25 85 75 140 125 195 175 2657

225 250 2 40 30 95 85 160 145 225 205 300250 280 2 45 35 105 90 170 155 245 225 340280 315 2 55 40 115 100 190 175 270 245 370315 355 3 60 45 125 110 210 195 300 275 410355 400 3 70 55 145 130 240 225 340 315 460400 450 3 80 60 170 150 270 250 380 350 510450 500 3 90 70 190 170 300 280 420 390 570500 560 10 100 80 210 190 333 310 470 440 630560 630 10 110 90 230 210 360 340 520 490 690630 710 20 130 110 260 240 400 380 570 540 780710 800 20 140 120 290 270 450 430 630 600 840800 900 20 160 140 320 300 500 480 700 670 940900 1 000 20 170 150 350 330 550 530 770 740 1 0401 000 1 120 20 180 160 380 360 600 580 850 820 1 1501 120 1 250 20 190 170 410 390 650 630 920 890 1 2601 250 1 400 30 220 200 450 430 710 680 1 100 980 1 380Jo<strong>cu</strong>l axial <strong>si</strong> preten<strong>si</strong>onarea de montaj la rulmentii im<strong>pe</strong>recheati din seriile 60,62,63Tabelul 2Diam. alezaj Joc axial Preten<strong>si</strong>onared (sufix A) (sufix L)<strong>pe</strong>ste pana la min. max. seria rulmentului60 62 63mm µm N- 10 15 35 30 30 -10 18 20 40 50 50 10018 30 25 45 100 100 10030 50 35 55 100 100 20050 80 40 70 200 200 35080 120 50 80 300 400 600120 180 60 100 500 700 900180 250 70 110 800 1 000 1 200Unghiul de contact<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> s<strong>un</strong>t capabili de a prelua, <strong>pe</strong> langa sarcini pur radiale <strong>si</strong>sarcini combinate, in care caz, rostogolirea <strong>bile</strong>lor <strong>pe</strong> caile de rulare se face sub <strong>un</strong> <strong>un</strong>ghi decontact α , care depinde de jo<strong>cu</strong>l radial al rulmentului, razele cailor de rulare <strong>si</strong> diametrul <strong>bile</strong>i.Aceasta se cal<strong>cu</strong>leaza <strong>cu</strong> relatia:α =arccos⎛⎜ 1 −⎝2JrADw⎟ ⎞,⎠<strong>un</strong>de:J r = jo<strong>cu</strong>l radial, mm,A = <strong>cu</strong>rbura totala a cailor de rulare f e +f i -1,f e(i) = R e(i) /D w ,D w = diametrul biei, mm,R e(i) = razele cailor de rulare.Determinarea <strong>un</strong>ghiului α al rulmentilor finiti, <strong>cu</strong> suficienta precizie, se poate face, daca tinemcont de numarul de rotatii ale coliviei n c <strong>si</strong> de numarul de rotatii ale inelului interior n i , sub osarcina usoara axiala, <strong>cu</strong> ajutorul relatiei:8

nc0 ⎛ D. 5 1 cos ⎟ ⎞w= n⎜i−α ,⎝ Dm ⎠α =arccos⎡ D⎢⎣ Dmw⎛ nc⎜ 1 −⎝ 0 . 5 ni⎞ ⎤⎟ ⎥ ,⎠ ⎦<strong>un</strong>de :D m = diametrul mediu al rulmentului, mm,D w = diametrul <strong>bile</strong>i, mm.Colivii<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> se exe<strong>cu</strong>ta, in general, <strong>cu</strong> colivii ambutisate din tabla deotel. Rezultate b<strong>un</strong>e dau <strong>si</strong> coliviile din poliamida 6.6 armata <strong>cu</strong> fibre de sticla, fara a depa<strong>si</strong>,insa, tem<strong>pe</strong>ratura de f<strong>un</strong>ctionare de +120°C.Acestea din urma au o greutate redusa, o f<strong>un</strong>ctionare <strong>si</strong>lentioasa <strong>si</strong> <strong>un</strong> coeficient de frecareredus. <strong>Rulmenti</strong>i de dimen<strong>si</strong><strong>un</strong>i mai mari se exe<strong>cu</strong>ta <strong>cu</strong> colivii ma<strong>si</strong>ve din alama.Forma <strong>si</strong> <strong>un</strong>ele date tehnice s<strong>un</strong>t date in tabelul 3.9

Incarcarea radiala minima a rulmentilorPentru garantarea <strong>un</strong>ei f<strong>un</strong>ctionari corecte a rulmentilor <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> trebuie a<strong>si</strong>gurata oincarcare minima a acestora, mai ales in cazul utilizarii lor la turatii ridicate. Fortele de inertiecare apar in rulment, pre<strong>cu</strong>m <strong>si</strong> frecarea din lubrifiant au o influienta negativa asupra conditiilorde f<strong>un</strong>ctionare <strong>si</strong> pot provoca miscari da<strong>un</strong>atoare de al<strong>un</strong>ecare intre <strong>bile</strong> <strong>si</strong> caile de rulare.Incarcarea radiala minima depinde de marimea rulmentului, de turatia <strong>si</strong> de viscozitatealubrifiantului la tem<strong>pe</strong>ratura de f<strong>un</strong>ctionare. Aceasta poate fi aproximata <strong>cu</strong> relatia:F rmin =0,01C r , (C r = sarcina radiala dinamica de baza)Sarcina radiala dinamica echivalenta<strong>Rulmenti</strong>i <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> pot prelua <strong>si</strong> sarcini combinate radiale <strong>si</strong> axiale.Sarcina radiala dinamica echivalenta <strong>pe</strong>ntru rulmentii <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong>, individuali sauim<strong>pe</strong>recheati in tandem (DT), se cal<strong>cu</strong>leaza <strong>cu</strong> relatiile:P r = F r , kN,cand F a /F r ≤e,P r =XF r +Y F a , kN, cand F a /F r >e.Pentru rulmentii <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong>, <strong>cu</strong> canal de introducere a <strong>bile</strong>lor, aceasta secal<strong>cu</strong>leaza <strong>cu</strong> relatia:P r =F r +F a , kN, <strong>cu</strong> conditia ca F a /F r

<strong>Rulmenti</strong>i <strong>cu</strong> canal de introducere a <strong>bile</strong>lor nu se recomanda <strong>pe</strong>ntru sarcini axiale F a mai maridecat 0,6F r . In acest caz se recomanda rulmentii <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong>, fara canal de introducere a<strong>bile</strong>lor. Unghiul de contact al acestor rulmenti creste odata <strong>cu</strong> sarcina axiala.Factorii e, X <strong>si</strong> Z depind de expre<strong>si</strong>a f 0 F a /C 0r . Factorul f 0 se sta<strong>bile</strong>ste <strong>cu</strong> ajutorul diagramei dinfigura de mai jos, in f<strong>un</strong>ctie de seria de dimen<strong>si</strong><strong>un</strong>i <strong>si</strong> de diametrul mediu (d+D)/2. F a estesarcina axiala, iar C 0r este sarcina radiala statica de baza a rulmentului.In tabelul 4, coresp<strong>un</strong>zator valorii <strong>pe</strong> care o primeste expre<strong>si</strong>a f 0 F a /C 0r , se determina valorilefactorilor e, X, Y, care depind de jo<strong>cu</strong>l rulmentului. Valorile din tabel se aplica rulmentilormontati <strong>cu</strong> ajustaje normale, res<strong>pe</strong>ctiv, arbori prelucrati in j5 sau k5 <strong>si</strong> carcase in j6.Factorii de cal<strong>cu</strong>l e, X <strong>si</strong> Z <strong>pe</strong>ntru rulmenti <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong>, montati individual sauim<strong>pe</strong>recheati in tandemJoc radial normal Joc radial C3 Joc radial C4Tabelul 411

f 0* F a /C 0re X Y e X Y e X Y0,2 0,19 0,56 2,25 0,32 0,46 1,77 0,38 0,44 1,440,4 0,22 0,56 1,95 0,34 0,46 1,63 0,42 0,44 1,360,8 0,26 0,56 1,68 0,38 0,46 1,44 0,45 0,44 1,251,6 0,31 0,56 1,40 0,43 0,46 1,27 0,48 0,44 1,163 0,37 0,56 1,20 0,48 0,46 1,14 0,52 0,44 1,086 0,44 0,56 1,02 0,54 0,46 1 0,56 0,44 1Pentru rulmentii impachetati in aranjament DB sau DT sarcina radiala dinamica echivalenta secal<strong>cu</strong>leaza <strong>cu</strong> relatia:P r = F r +Y 1 F a , kN,cand F a /F r ≤e,P r =0,75F r +Y 2 F a , kN,cand F a /F r >e.Valorile factorilor e, Y 1 , Y 2, in f<strong>un</strong>ctie de raportul F a /C 0r , s<strong>un</strong>t date in tabelul 5.Valorile factorilor e, Y 1 , Y 2 <strong>pe</strong>ntru aranjamente DB <strong>si</strong> DFF a /C 0re Y 1 Y 20,03 0,32 2 2,80,10 0,4 1,55 2,20,25 0,47 3 1,65Tabelul5Sarcina radiala statica echivalentaPentru rulmentii <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong>, individuali sau im<strong>pe</strong>recheati in tandem (DT), sarcinaradiala statica echivalenta se cal<strong>cu</strong>leaza <strong>cu</strong> relatiile:P 0 = F r , kN,cand F a /F r ≤0,8,P 0 =0,6F r +0,5F a , kN, cand F a /F r >0,8.Pentru rulmentii <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong>, <strong>cu</strong> canal de introducere a <strong>bile</strong>lor, aceasta secal<strong>cu</strong>leaza <strong>cu</strong> relatia:P 0 =F r +0,5F a , kN, <strong>cu</strong> conditia ca F a /F r ≤0,6.Pentru rulmentii im<strong>pe</strong>recheati in aranjament DB sau DF se cal<strong>cu</strong>leaza <strong>cu</strong> relatia:P 0 =F r +1,7F a , KnSarcina de incarcare axialaDaca rulmentii <strong>radiali</strong> <strong>cu</strong> <strong>bile</strong> <strong>pe</strong> <strong>un</strong> <strong>rand</strong> se incarca <strong>cu</strong> o sarcina pur axiala, aceasta nu trebuiesa depaseasca, de regula, 0,5C 0r . La rulmentii mici, pre<strong>cu</strong>m <strong>si</strong> la rulmentii din seriile usoare(seriile de diametre 8,9,0 <strong>si</strong> 1), sarcina axiala nu trebuie sa depaseasca 0,25C 0r .Incarcarile axiale mari duc la reducerea con<strong>si</strong>derabila a durabilitatii rulmentilor. In acestecazuri se recomanda consultarea s<strong>pe</strong>cialistilor nostri.Dimen<strong>si</strong><strong>un</strong>i de montajPentru sprijinirea coresp<strong>un</strong>zatoare a inelelor rulmentului <strong>pe</strong> umarul arborelui <strong>si</strong> res<strong>pe</strong>ctiv, alcarcasei, este necesar ca raza maxima de racordare r umax. a arborelui (carcasei), sa fie maimica decat te<strong>si</strong>tura minima de montaj r smin. a rulmentului.Inaltimea umarului trebuie sa fie, de asemenea, suficient dimen<strong>si</strong>onata <strong>pe</strong>ntru cazul te<strong>si</strong>turii demontaj maxime a rulmentului.Valorile razei de racordare (r u ) <strong>si</strong> inaltimii umarului de sprijin (h u ), in f<strong>un</strong>ctie de te<strong>si</strong>turile demontaj, s<strong>un</strong>t precizate in tabelul 6 <strong>si</strong> coresp<strong>un</strong>d <strong>cu</strong> prevederile STAS 6603.12

Dimen<strong>si</strong><strong>un</strong>i de montajTabelul6r s r u h umin max minSeria rulmentului618, 619, 161, 60, 64160 62, 63mm0,15 0,15 0,4 0,7 -0,20 0,20 0,7 0,9 -0,30 0,30 1 1,2 -0,60 0,60 1,6 2,1 -1 1 2,3 2,8 -1,1 1 3 3,5 4,51,5 1,5 3,5 4,5 5,52 2 4,4 5,5 6,52,1 2,1 5,1 6 73 2,5 6,2 7 84 3 7,3 8,5 105 4 9 10 126 5 11,5 13 157,5 6 14 - -13