strunguri industriale - SC Pentagon SRL

strunguri industriale - SC Pentagon SRL

strunguri industriale - SC Pentagon SRL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

86<br />

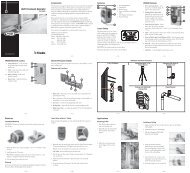

GHID ALEGERE<br />

DENTIȚIE PÂNZĂ ȘI VITEZĂ DE TĂIERE<br />

Dacă aveți nevoie să tăiați două sau mai multe țevi așezate alăturat, utilizați acest tabel luând în considerație dublul grosimii de perete<br />

Grosimea peretelui<br />

DEBITAREA PROFILELOR (ŢEVI, PROFILE RECTANGULARE,U, I, T, ETC.)<br />

Diametrul exterior al ţevii<br />

20 40 60 80 100 120 150 200 300 400 500 600 700 800 900 1000<br />

2 10/14 10/14 10/14 10/14 10/14 10/14 10/14 10/14 8/12 8/12 6/10 6/10 5/8 5/8 5/8 5/8<br />

3 10/14 10/14 10/14 10/14 10/14 8/12 8/12 8/12 6/10 6/10 5/8 5/8 5/8 4/6 4/6 4/6<br />

4 10/14 10/14 10/14 10/14 8/12 8/12 8/12 8/12 6/10 6/10 5/8 5/8 4/6 4/6 4/6 4/6<br />

5 10/14 10/14 10/14 10/14 8/12 8/12 8/12 6/10 5/8 5/8 4/6 4/6 4/6 4/6 3/4 3/4<br />

6 10/14 10/14 10/14 8/12 8/12 8/12 5/8 5/8 4/6 4/6 4/6 3/4 3/4 3/4 3/4 3/4<br />

8 10/14 10/14 6/10 8/12 6/10 6/10 5/8 4/6 4/6 4/6 4/6 3/4 3/4 3/4 3/4 2/3<br />

10 8/12 6/10 6/10 6/10 5/8 5/8 4/6 4/6 4/6 3/4 3/4 3/4 3/4 2/3 2/3<br />

12 8/12 6/10 6/10 5/8 5/8 4/6 4/6 4/6 3/4 3/4 3/4 3/4 2/3 2/3 2/3<br />

15 8/12 6/10 5/8 5/8 4/6 4/6 4/6 3/4 3/4 3/4 2/3 2/3 2/3 2/3 2/3<br />

20 6/10 5/8 4/6 4/6 4/6 3/4 3/4 3/4 2/3 2/3 2/3 2/3 2/3 2/3<br />

30 4/6 4/6 4/6 3/4 3/4 3/4 2/3 2/3 2/3 2/3 2/3 2/3 1,4/2<br />

50 3/4 3/4 3/4 2/3 2/3 2/3 2/3 2/3 2/3 1,4/2 1,4/2<br />

75 2/3 2/3 2/3 2/3 2/3 1,4/2 1,4/2 1,4/2 1,4/2<br />

plin 10/14 8/12 6/10 4/6 4/6 3/4 3/4 2/3 2/3 2/3 1,4/2 1,4/2 1,4/2 1,4/2 1,4/2 1,4/2<br />

RECOMANDARI PENTRU VITEZELE BENZII<br />

RECOMANDARI PENTRU VITEZELE BENZII<br />

Observaţie: viteza de taiere in tabel este aproximativa.<br />

Observaţie: viteza de taiere in tabel este aproximativa.<br />

Material<br />

Tipul<br />

Viteza de taiere Lichid de racire<br />

Tipul materialului Viteza de taiere Lichid de racire<br />

materialului<br />

Concentratie Material<br />

Concentratie<br />

DIN<br />

Panza Bi-Metal<br />

DIN<br />

Panza Bi-Metal<br />

emulsie<br />

emulsie<br />

Oţel de St 35 – St 42 60 - 80 1:10<br />

X 10 CrAl 7 20 - 35 1:10<br />

construcţii<br />

Oţel<br />

St 350 – St 70 50 - 70 1:20 x 15 CrNiSi 25 / 20 20 - 35 1:10<br />

refractar<br />

C 10 - C 16 60 - 90 1:10 X 10 CrSi 6 20 - 35 1:10<br />

Oţel<br />

14 NICr 14 40 – 50 1:10 Oţel X 5 CrNi 189 25 - 35 1:10<br />

îmbunătăţit 21 NICr Mo 2 45 - 55 1:10 inoxidabil x 10 CrNiMpT 1810 25 - 35 1:10<br />

16 MrCr 5 50 - 65 1:10 X 10 Cr 13 25 - 35 1:10<br />

C 35 C 45 55 - 75 1:20 x 5 CrNiMo 1810 25 - 35 1:10<br />

41 Cr 4 40 - 60 1:20 Oţel<br />

GS – 38 50 - 60 1:50<br />

Oţel tratabil 40 Mn 4 50 - 65 1:20 turnat<br />

GS – 60 50 - 60 1:50<br />

termic<br />

42 Crmo 4 35 - 50 1:20 Fontă GG – 16 40 - 50 ------<br />

36 NI Cr 6 50 - 60 1:20 GG – 30 40 - 50 ------<br />

24 NI Cr 14 40 - 60 1:20 GTW – 40 40 - 50 ------<br />

Oţel de<br />

rulmenţi<br />

Oţel arc<br />

Oţel de scule<br />

nealiat<br />

Oţel de scule<br />

aliat<br />

100 - Cr 6 50 - 65 1:30 GTS – 65 40 - 50 ------<br />

105 – Cr 4 50 - 65 1:30<br />

NiMoNic 15 - 25 1:10<br />

Oţel aliat<br />

100 – CrMo 6 40 - 50 1:30 Hastelloy 15 - 25 1:10<br />

cu Nichel<br />

65 SI 7 40 - 60 1:30 Inconel 15 - 25 1:10<br />

50 CrV 4 40 - 60 1:30 Aliaje de Al 99,5 100 - 700 1:10<br />

C 80 W 1 50 - 60 1:30 aluminiu AlMg 3 100 - 700 1:10<br />

C 125 W 1 20 - 35 1:30<br />

CuSn 6 70 - 100 1:50<br />

Bronz<br />

C 105 W 2 40 - 50 1:30 G – CuSn 10 70 - 100 1:50<br />

105 Cr 5 50 - 60 1:30 Aluminiu CuAl 8 50 - 70 1:30<br />

X 210 Cr 12 20 - 35 ------ - Bronz CuAl 8 Fe 38 40 - 50 1:20<br />

x 40 Cr Mo V 51 30 - 40 1:30<br />

G – CuSn 10 Zn 70 - 100 1:50<br />

Alamă<br />

x 210 Cr W 12 20 - 30 ------ G – CuSn 5 Zn Pb 70 - 100 1:50<br />

x 165 Cr Mp V 12 20 - 35 1:30<br />

S 5-6-2 25 - 40 1:30<br />

56 NICrMoV 7 20 - 40 1:30 S 5-6-2-5 25 - 40 1:30<br />

Oţel rapid<br />

100 CrMo 5 35 - 45 1:30 S 18-0-1 25 - 40 1:30<br />

x 32 CrMoV 33 30 - 45 1:20 S 18-1-2-10 25 - 40 1:30<br />

www.proma.ro<br />

Pentru oferta completă de accesorii speciale<br />

accesaţi site-ul nostru