PONTIFÍCIA UNIVERSIDADE CATÓLICA DO PARANÁ - PUCPR

PONTIFÍCIA UNIVERSIDADE CATÓLICA DO PARANÁ - PUCPR

PONTIFÍCIA UNIVERSIDADE CATÓLICA DO PARANÁ - PUCPR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

dinâmicas dos clientes. Porém, Yusuf et al. (2002) destacam que os princípios do<br />

Lean Production por si só não são suficientes para atender a demanda dinâmica dos<br />

clientes. Vinodh et al. (2008) afirmam que existe uma proximidade entre os<br />

princípios Lean Production e os princípios Agile Manufacturing (NAYLOR et al.,<br />

1999; MASON-JONES et al., 2000; AITKEN et al., 2005; GOLDSBY et al., 2006).<br />

Além disso, alguns pesquisadores (BROWN e BESSANT, 2003; RAO et al., 2006)<br />

afirmam que as empresas que implementam Agile Manufacturing tornam-se<br />

vencedoras nos mercados que atuam. As pesquisas em Lean Production sobre o<br />

ponto de vista da CM direcionam-se para verificar como os princípios do Lean<br />

Production suportam a implementação de uma estratégia financeiramente viável de<br />

CM, combinado com outros habilitadores. Como sugestões de leitura, recomenda-se<br />

a lista da Tabela 2.9.<br />

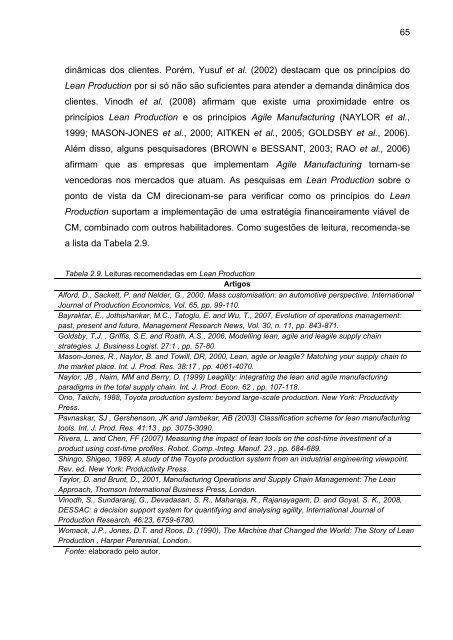

Tabela 2.9. Leituras recomendadas em Lean Production<br />

Artigos<br />

Alford, D., Sackett, P. and Nelder, G., 2000, Mass customisation: an automotive perspective. International<br />

Journal of Production Economics, Vol. 65, pp. 99-110.<br />

Bayraktar, E., Jothishankar, M.C., Tatoglu, E. and Wu, T., 2007, Evolution of operations management:<br />

past, present and future, Management Research News, Vol. 30, n. 11, pp. 843-871.<br />

Goldsby, T.J. , Griffis, S.E. and Roath, A.S., 2006, Modelling lean, agile and leagile supply chain<br />

strategies. J. Business Logist. 27:1 , pp. 57-80.<br />

Mason-Jones, R., Naylor, B. and Towill, DR, 2000, Lean, agile or leagile? Matching your supply chain to<br />

the market place. Int. J. Prod. Res. 38:17 , pp. 4061-4070.<br />

Naylor, JB , Naim, MM and Berry, D. (1999) Leagility: integrating the lean and agile manufacturing<br />

paradigms in the total supply chain. Int. J. Prod. Econ. 62 , pp. 107-118.<br />

Ono, Taiichi, 1988, Toyota production system: beyond large-scale production. New York: Productivity<br />

Press.<br />

Pavnaskar, SJ , Gershenson, JK and Jambekar, AB (2003) Classification scheme for lean manufacturing<br />

tools. Int. J. Prod. Res. 41:13 , pp. 3075-3090.<br />

Rivera, L. and Chen, FF (2007) Measuring the impact of lean tools on the cost-time investment of a<br />

product using cost-time profiles. Robot. Comp.-Integ. Manuf. 23 , pp. 684-689.<br />

Shingo, Shigeo, 1989, A study of the Toyota production system from an industrial engineering viewpoint.<br />

Rev. ed. New York: Productivity Press.<br />

Taylor, D. and Brunt, D., 2001, Manufacturing Operations and Supply Chain Management: The Lean<br />

Approach, Thomson International Business Press, London.<br />

Vinodh, S., Sundararaj, G., Devadasan, S. R., Maharaja, R., Rajanayagam, D. and Goyal, S. K., 2008,<br />

DESSAC: a decision support system for quantifying and analysing agility, International Journal of<br />

Production Research, 46:23, 6759-6780.<br />

Womack, J.P., Jones, D.T. and Roos, D. (1990), The Machine that Changed the World: The Story of Lean<br />

Production , Harper Perennial, London..<br />

Fonte: elaborado pelo autor.<br />

65