Jaarboek no. 89. 2010/2011 - Koninklijke Maatschappij voor ...

Jaarboek no. 89. 2010/2011 - Koninklijke Maatschappij voor ... Jaarboek no. 89. 2010/2011 - Koninklijke Maatschappij voor ...

Natuurkundige voordrachten I Nieuwe reeks 89 Schakelbare spiegels: een samenspel van licht en waterstof 32 Figure 4 Comparison of the volume and weight of various energy storage systems needed to drive 400 km. The car considered here needs 15.9 kWh mechanical energy per 100 km. Present research is aiming at metal-hydride storage systems even more compact and lighter that the hybrid system ΄MH+350 bar΄ developed by Toyota. 10 Figure 5 Left panel: Seven gun sputtering system. For the preparation of a gradient sample suitable for the investigation of hydrogen permeability in Pd-Cu alloys, four guns Pd, Cu, Y and Pd are needed. Right panel: Hydrogenographic picture of the hydrogen permeation (in black) in the gradient sample. The Pd-concentration increases from left to right. The white arrows indicate the direction of hydrogen permeation. Within a few hours the maximum of the front has moved by 1 cm. This corresponds to the fastest hydrogen diffusion ever observed in a metal. Details on the visualisation of hydrogen diffusion are given by Den Broeder et al. 11

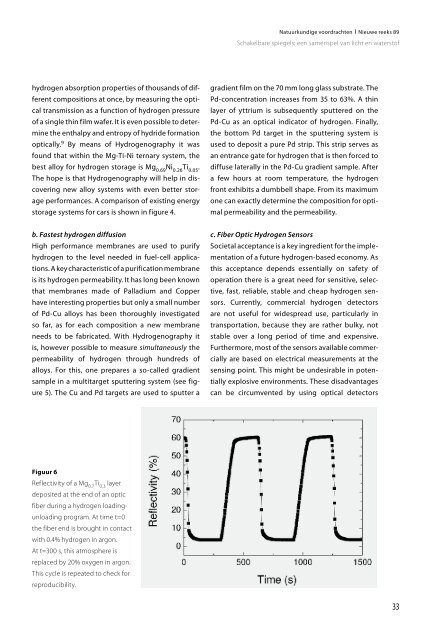

hydrogen absorption properties of thousands of dif- ferent compositions at once, by measuring the opti- cal transmission as a function of hydrogen pressure of a single thin film wafer. It is even possible to determine the enthalpy and entropy of hydride formation optically. 9 By means of Hydrogenography it was found that within the Mg-Ti-Ni ternary system, the best alloy for hydrogen storage is Mg0.69Ni 0.26Ti 0.05 . The hope is that Hydrogenography will help in discovering new alloy systems with even better storage performances. A comparison of existing energy storage systems for cars is shown in figure 4. b. Fastest hydrogen diffusion High performance membranes are used to purify hydrogen to the level needed in fuel-cell applications. A key characteristic of a purification membrane is its hydrogen permeability. It has long been known that membranes made of Palladium and Copper have interesting properties but only a small number of Pd-Cu alloys has been thoroughly investigated so far, as for each composition a new membrane needs to be fabricated. With Hydrogenography it is, however possible to measure simultaneously the permeability of hydrogen through hundreds of alloys. For this, one prepares a so-called gradient sample in a multitarget sputtering system (see figure 5). The Cu and Pd targets are used to sputter a Figuur 6 Reflectivity of a Mg0.7Ti 0.3 layer deposited at the end of an optic fiber during a hydrogen loadingunloading program. At time t=0 the fiber end is brought in contact with 0.4% hydrogen in argon. At t=300 s, this atmosphere is replaced by 20% oxygen in argon. This cycle is repeated to check for reproducibility. Natuurkundige voordrachten I Nieuwe reeks 89 Schakelbare spiegels: een samenspel van licht en waterstof gradient film on the 70 mm long glass substrate. The Pd-concentration increases from 35 to 63%. A thin layer of yttrium is subsequently sputtered on the Pd-Cu as an optical indicator of hydrogen. Finally, the bottom Pd target in the sputtering system is used to deposit a pure Pd strip. This strip serves as an entrance gate for hydrogen that is then forced to diffuse laterally in the Pd-Cu gradient sample. After a few hours at room temperature, the hydrogen front exhibits a dumbbell shape. From its maximum one can exactly determine the composition for optimal permeability and the permeability. c. Fiber Optic Hydrogen Sensors Societal acceptance is a key ingredient for the implementation of a future hydrogen-based economy. As this acceptance depends essentially on safety of operation there is a great need for sensitive, selective, fast, reliable, stable and cheap hydrogen sensors. Currently, commercial hydrogen detectors are not useful for widespread use, particularly in transportation, because they are rather bulky, not stable over a long period of time and expensive. Furthermore, most of the sensors available commercially are based on electrical measurements at the sensing point. This might be undesirable in potentially explosive environments. These disadvantages can be circumvented by using optical detectors 33

- Page 1: NATUURKUNDIGE VOORDR ACHTEN 2010 -

- Page 4 and 5: ISBN 978 90-72644-23-7 Drukkerij Vi

- Page 7 and 8: INHOUD Diligentiaprijs voor Scholie

- Page 9 and 10: VERSLAG VAN DE KONINKLIJKE MAATSCHA

- Page 11 and 12: Oprichting in 1793 Het Gezelschap t

- Page 13 and 14: N.Th. Michaelis 1898-1904 Dr. E.H.

- Page 15 and 16: ALFABETISCH REGISTER VAN DE VOORDRA

- Page 17 and 18: Natuurkundige voordrachten I Nieuwe

- Page 19 and 20: Natuurkundige voordrachten I Nieuwe

- Page 21 and 22: Natuurkundige voordrachten I Nieuwe

- Page 23 and 24: Elektriciteitopslag in batterijen m

- Page 25 and 26: De vermogensdichtheid van een batte

- Page 27 and 28: Figuur 3 Het effect dat vacatures (

- Page 29 and 30: Schakelbare spiegels: een samenspel

- Page 31: Applications Beside their purely fu

- Page 35 and 36: Gammaflitsen: extreem nieuws uit de

- Page 37 and 38: ster ontstaat. Het directe bewijs v

- Page 39 and 40: Figuur 2 Als we voor alle 2704 gamm

- Page 41 and 42: gammaflits kan miljarden jaren na h

- Page 43 and 44: Genetica en genoomonderzoek naar ve

- Page 45 and 46: zingen in de code aanwezig die aang

- Page 47 and 48: omdat we beschikken over de gezondh

- Page 49 and 50: Microreactortechnologie; de chemisc

- Page 51 and 52: matografie, maar is zeer succesvol

- Page 53 and 54: Figuur 5 De economische haalbaarhei

- Page 55 and 56: Natuurkundige voordrachten I Nieuwe

- Page 57 and 58: qubit can now be described as follo

- Page 59 and 60: games not only nicely demonstrates

- Page 61: Natuurkundige voordrachten I Nieuwe

- Page 64 and 65: Natuurkundige voordrachten I Nieuwe

- Page 66 and 67: Natuurkundige voordrachten I Nieuwe

- Page 68 and 69: Natuurkundige voordrachten I Nieuwe

- Page 70 and 71: Natuurkundige voordrachten I Nieuwe

- Page 72 and 73: Natuurkundige voordrachten I Nieuwe

- Page 74 and 75: Natuurkundige voordrachten I Nieuwe

- Page 76 and 77: Natuurkundige voordrachten I Nieuwe

- Page 78 and 79: Natuurkundige voordrachten I Nieuwe

- Page 80 and 81: Natuurkundige voordrachten I Nieuwe

hydrogen absorption properties of thousands of dif-<br />

ferent compositions at once, by measuring the opti-<br />

cal transmission as a function of hydrogen pressure<br />

of a single thin film wafer. It is even possible to determine<br />

the enthalpy and entropy of hydride formation<br />

optically. 9 By means of Hydroge<strong>no</strong>graphy it was<br />

found that within the Mg-Ti-Ni ternary system, the<br />

best alloy for hydrogen storage is Mg0.69Ni 0.26Ti 0.05 .<br />

The hope is that Hydroge<strong>no</strong>graphy will help in discovering<br />

new alloy systems with even better storage<br />

performances. A comparison of existing energy<br />

storage systems for cars is shown in figure 4.<br />

b. Fastest hydrogen diffusion<br />

High performance membranes are used to purify<br />

hydrogen to the level needed in fuel-cell applications.<br />

A key characteristic of a purification membrane<br />

is its hydrogen permeability. It has long been k<strong>no</strong>wn<br />

that membranes made of Palladium and Copper<br />

have interesting properties but only a small number<br />

of Pd-Cu alloys has been thoroughly investigated<br />

so far, as for each composition a new membrane<br />

needs to be fabricated. With Hydroge<strong>no</strong>graphy it<br />

is, however possible to measure simultaneously the<br />

permeability of hydrogen through hundreds of<br />

alloys. For this, one prepares a so-called gradient<br />

sample in a multitarget sputtering system (see figure<br />

5). The Cu and Pd targets are used to sputter a<br />

Figuur 6<br />

Reflectivity of a Mg0.7Ti 0.3 layer<br />

deposited at the end of an optic<br />

fiber during a hydrogen loadingunloading<br />

program. At time t=0<br />

the fiber end is brought in contact<br />

with 0.4% hydrogen in argon.<br />

At t=300 s, this atmosphere is<br />

replaced by 20% oxygen in argon.<br />

This cycle is repeated to check for<br />

reproducibility.<br />

Natuurkundige <strong>voor</strong>drachten I Nieuwe reeks 89<br />

Schakelbare spiegels: een samenspel van licht en waterstof<br />

gradient film on the 70 mm long glass substrate. The<br />

Pd-concentration increases from 35 to 63%. A thin<br />

layer of yttrium is subsequently sputtered on the<br />

Pd-Cu as an optical indicator of hydrogen. Finally,<br />

the bottom Pd target in the sputtering system is<br />

used to deposit a pure Pd strip. This strip serves as<br />

an entrance gate for hydrogen that is then forced to<br />

diffuse laterally in the Pd-Cu gradient sample. After<br />

a few hours at room temperature, the hydrogen<br />

front exhibits a dumbbell shape. From its maximum<br />

one can exactly determine the composition for optimal<br />

permeability and the permeability.<br />

c. Fiber Optic Hydrogen Sensors<br />

Societal acceptance is a key ingredient for the implementation<br />

of a future hydrogen-based eco<strong>no</strong>my. As<br />

this acceptance depends essentially on safety of<br />

operation there is a great need for sensitive, selective,<br />

fast, reliable, stable and cheap hydrogen sensors.<br />

Currently, commercial hydrogen detectors<br />

are <strong>no</strong>t useful for widespread use, particularly in<br />

transportation, because they are rather bulky, <strong>no</strong>t<br />

stable over a long period of time and expensive.<br />

Furthermore, most of the sensors available commercially<br />

are based on electrical measurements at the<br />

sensing point. This might be undesirable in potentially<br />

explosive environments. These disadvantages<br />

can be circumvented by using optical detectors<br />

33