saturs - Latvijas LauksaimniecÄ«bas universitÄte

saturs - Latvijas LauksaimniecÄ«bas universitÄte

saturs - Latvijas LauksaimniecÄ«bas universitÄte

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

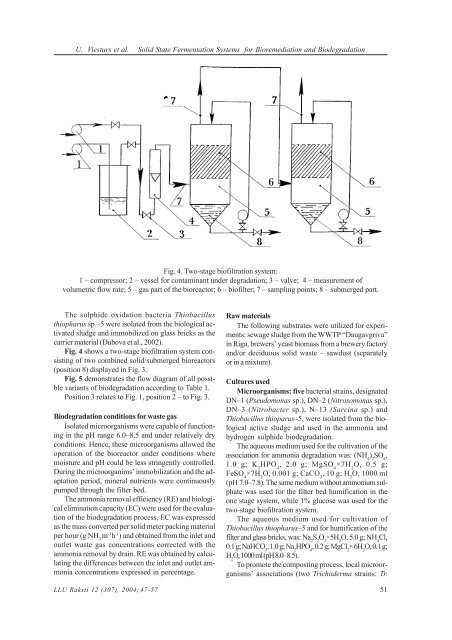

U. Viesturs et al. Solid State Fermentation Systems for Bioremediation and BiodegradationFig. 4. Two-stage biofiltration system:1 – compressor; 2 – vessel for contaminant under degradation; 3 – valve; 4 – measurement ofvolumetric flow rate; 5 – gas part of the bioreactor; 6 – biofilter; 7 – sampling points; 8 – submerged part.The sulphide oxidation bacteria Thiobacillusthiopharus sp.–5 were isolated from the biological activatedsludge and immobilized on glass bricks as thecarrier material (Dubova et al., 2002).Fig. 4 shows a two-stage biofiltration system consistingof two combined solid/submerged bioreactors(position 8) displayed in Fig. 3.Fig. 5 demonstrates the flow diagram of all possiblevariants of biodegradation according to Table 1.Position 3 relates to Fig. 1, position 2 – to Fig. 3.Biodegradation conditions for waste gasIsolated microorganisms were capable of functioningin the pH range 6.0–8.5 and under relatively dryconditions. Hence, these microorganisms allowed theoperation of the bioreactor under conditions wheremoisture and pH could be less stringently controlled.During the microorganims’ immobilization and the adaptationperiod, mineral nutrients were continuouslypumped through the filter bed.The ammonia removal efficiency (RE) and biologicalelimination capacity (EC) were used for the evaluationof the biodegradation process. EC was expressedas the mass converted per solid meter packing materialper hour (g NH 3m -3 h -1 ) and obtained from the inlet andoutlet waste gas concentrations corrected with theammonia removal by drain. RE was obtained by calculatingthe differences between the inlet and outlet ammoniaconcentrations expressed in percentage.LLU Raksti 12 (307), 2004; 47-57 1-18Raw materialsThe following substrates were utilized for experiments:sewage sludge from the WWTP “Daugavgriva”in Riga, brewers’ yeast biomass from a brewery factoryand/or deciduous solid waste – sawdust (separatelyor in a mixture).Cultures usedMicroorganisms: five bacterial strains, designatedDN–1 (Pseudomonas sp.), DN–2 (Nitrosomonas sp.),DN–3 (Nitrobacter sp.), N–13 (Sarcina sp.) andThiobacillus thioparus–5, were isolated from the biologicalactive sludge and used in the ammonia andhydrogen sulphide biodegradation.The aqueous medium used for the cultivation of theassociation for ammonia degradation was: (NH 4) 2SO 4,1.0 g; K 2HPO 4, 2.0 g; MgSO 4×7H 2O, 0.5 g;FeSO 4×7H 2O, 0.001 g; CaCO 3, 10 g; H 2O, 1000 ml(pH 7.0–7.8). The same medium without ammonium sulphatewas used for the filter bed humification in theone stage system, while 1% glucose was used for thetwo-stage biofiltration system.The aqueous medium used for cultivation ofThiobacillus thiopharus–5 and for humification of thefilter and glass bricks, was: Na 2S 2O 3×5H 2O, 5.0 g; NH 4Cl,0.1 g; NaHCO 3, 1.0 g; Na 2HPO 4, 0.2 g; MgCl 2× 6H 2O, 0.1 g;H 2O, 1000 ml (pH 8.0–8.5).To promote the composting process, local microorganisms’associations (two Trichoderma strains: Tr.51