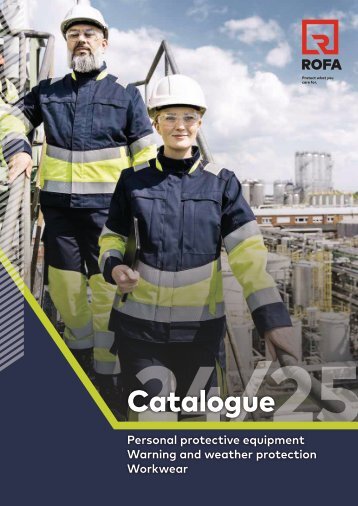

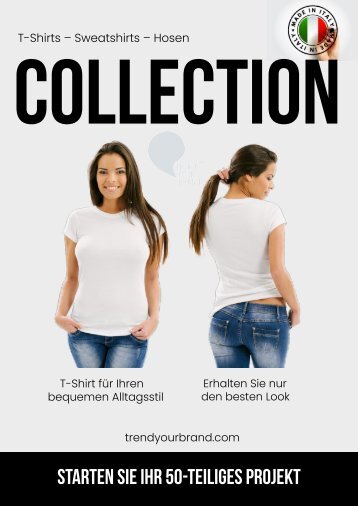

TrendyourBrand by ROFA WORKWEAR (EN) "Products on demand"

- Text

- Wwwtrendyourbrandcom

- Welding

- Layer

- Velcro

- Reflective

- Fluorescent

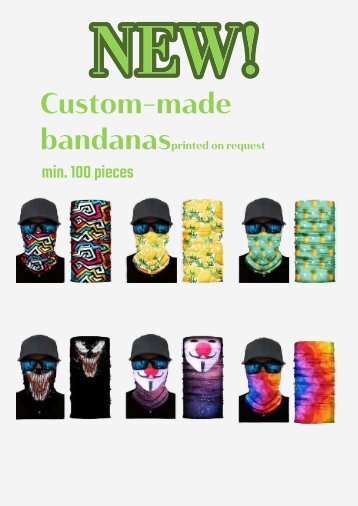

- Accessories

- Studs

- Fabric

- Flap

- Pockets

PROTECTIVE CLOTHING

PROTECTIVE CLOTHING STANDARDS Service PROTECTIVE CLOTHING SCHUTZSTANDARDSSTANDARDS Class 2 – related to the process Manual welding techniques with considerable formation of welding spatter and metal droplets: » MMA welding » MIG welding with high voltage current » self-protective Flux-cored arc welding » Plasma welding » Gouging » Oxygen cutting » thermal spray welding Class 2 – related to the ambient conditions » narrow spaces » Overhead welding or cutting or work in comparable constrained positions. The clothing is not suitable for permanent grinding procedures.

- Page 1 and 2:

Protect what you care for. 24/25 Ca

- Page 4:

TABLE OF CONTENTS

- Page 8:

CERTIFICATIONS About ROFA

- Page 12:

PERSONAL PROTECTIVE EQUIPME

- Page 16:

TISSUE INFORMATION About RO

- Page 20:

MULTI-LIGHT Multi-standard protecti

- Page 24:

MULTI-LIGHT HI-VIS I + II Multi-sta

- Page 28:

MULTI-LIGHT HI-VIS II Multi-standar

- Page 32:

TREND Multi-standa

- Page 36:

PRO-LINE Multi-standard protection

- Page 40:

VIS-LINE I + II Multi-standard prot

- Page 44:

VIS-LINE II Multi-standard protecti

- Page 48:

MULTISIX Multi-standard protection

- Page 52:

MULTISEVEN Multi-s

- Page 56:

WARNING PROTECTION COMBINATIONS Mul

- Page 60:

MULTININE Multi-standard protection

- Page 64:

WELDER PROTECTION Flame-retardant c

- Page 68:

SPLASH LIGHT welding protection SPL

- Page 72:

JEANS FR welding protection PRODUCT

- Page 76:

PRO-LINE II welding protection PRO-

- Page 80:

SPLASH HEAVY welding protection SPL

- Page 84:

LAYERING PRINCIPLE Protection again

- Page 88:

BASIC Protection against electric a

- Page 92:

X-LINE Protection against electric

- Page 96:

SPARC Protection against electric a

- Page 100:

ACCESSORIES Protection against elec

- Page 104:

PRO-LINE Protection against electri

- Page 108:

PRO-LINE Protection against electri

- Page 112:

VIS-LINE II Protection against elec

- Page 116:

MULTI-LIGHT HI-VIS I Protection aga

- Page 120:

MULTISIX Protection against electri

- Page 124:

MULTISEVEN Protect

- Page 128:

FR WARNING PROTECTION IN FLUORESC

- Page 132:

VIS-LINE II Warning protection FR f

- Page 136:

MULTISEVEN Warning

- Page 140:

MULTININE PLUS Warning protection F

- Page 144:

ALU SPLASH Protection against liqui

- Page 148:

MULTI-STANDARD-ACCESSORIES Multi-St

- Page 152:

MULTI-STANDARD-ACCESSORIES Multi-St

- Page 156:

TEAMWORK HI-VIS Warning protection

- Page 160:

WARNING PROTECTION COMBINATIONS TEA

- Page 164:

DUO COLOR Warning Protection DUO CO

- Page 168:

WARNING PROTECTION COMBINATIONS CLA

- Page 172: SHIRTS Warning Protection TO THE WE

- Page 176: DRY-LIGHT HI-VIS Winter-weather-pro

- Page 180: DRY-LIGHT Winter-weather-protection

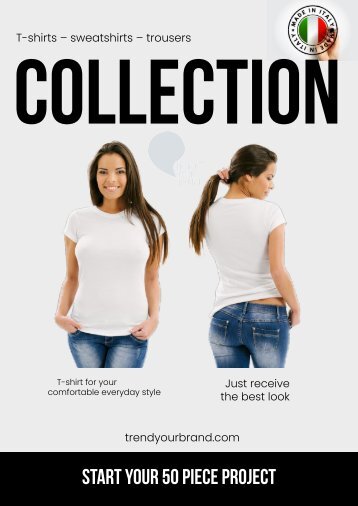

- Page 184: WORKWEAR For doers

- Page 188: PRIME-LIGHT Workwear PRODUCT INFORM

- Page 192: NEW ACTIVE Workwear PRODUCT INFORMA

- Page 196: TEAMWORK Workwear NEW TEAMWORK RECY

- Page 200: TEAMWORK Workwear WAISTCOAT Band co

- Page 204: CLASSICS Workwear CLASSIC COTTON CL

- Page 208: SPECIAL Workwear SPECIAL COTTON TO

- Page 212: OK Workwear OK COTTON-RICH TO THE W

- Page 216: SCAFFOLDING Workwear SCAFFOLDING BL

- Page 220: PROTECTIVE CLOTHING STANDARDS PROTE

- Page 226: PROTECTIVE CLOTHING STANDARDS Servi

- Page 230: CARE INSTRUCTIONS Service CARE INST

- Page 234: SIZE CHARTS Service SIZE CHARTS BOD

- Page 238: ARTICLE OVERVIEW Service ARTICLE OV

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...

Italiano

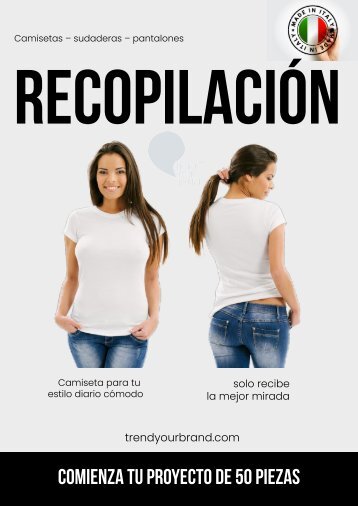

- 1. Abbigliamento per il tempo libero

- 2. Abbigliamento da lavoro

- 3. Abbigliamento sportivo

- 4.Borse

- 5. Valigie

- 6. Ombrelli

- 7. Cappellini e berretti

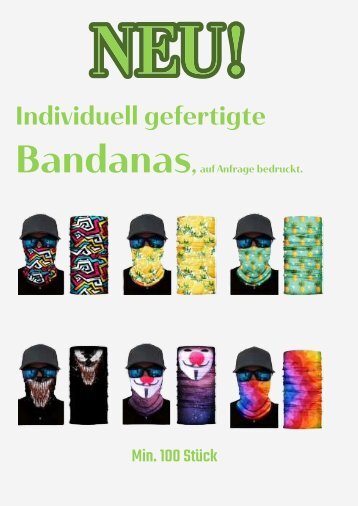

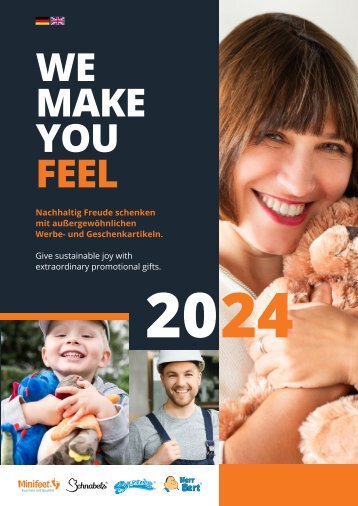

- 8. Articoli promozionali e peluche

- 9. Presse transfer e accessori

- 10. Cataloghi di produttori su richiesta

- 11. Produzione speciale

- 12. Video & Flyer

- 13. Certificati

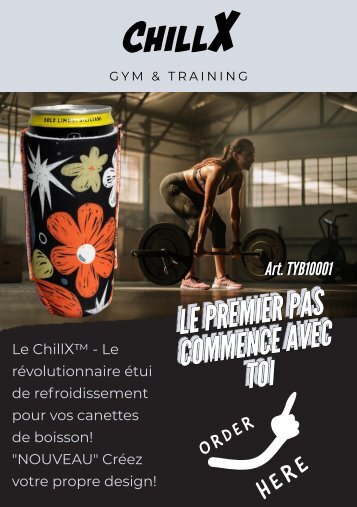

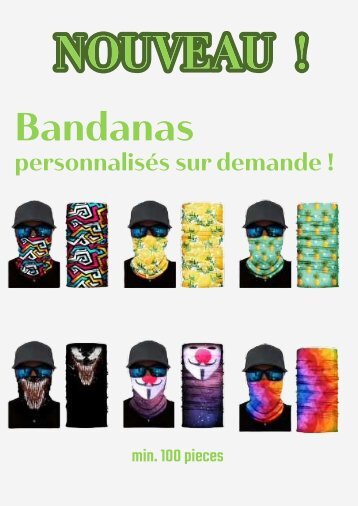

Français

- 1. Vêtements de loisirs

- 2. Vêtements Vêtements de travail

- 3. Vêtements de sport

- 4. Sacs

- 5. Valises

- 6. Parapluies

- 7. Casquettes et bonnets

- 8. Articles promotionnels et peluches

- 9. Presses à transfert et accessoires

- 10. Catalogues de fabricants sur demande

- 11. Fabrications spéciales

- 12. Vidéo & Flyer

- 13. Certificats

KONTAKT

WT Group SAS di Karl Ladurner & Co.

Via Giuseppe Verdi 21

39031 Brunico

Italia

Phone: +39 0474 476 243

Fax: +39 0474 470 977

E-Mail: info@wtgroup.it