GITAL GILDEMEISTER AS16 AS20 GS20 GM20

GITAL GILDEMEISTER AS16 AS20 GS20 GM20

GITAL GILDEMEISTER AS16 AS20 GS20 GM20

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

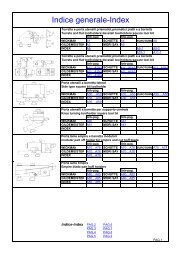

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>CAMME STANDARD PER SLITTE RADIALISTANDARD CAMS FOR CROSS SLIDESPOS. 1 POS. 2-3-4-5-608.29.105 08.29.10108.29.106 08.29.10208.29.107 08.29.10308.29.117 08.29.11816.29.301 08.29.10408.29.111CAMME STANDARD PER SLITTE ASSIALISTANDARD CAMS FOR AXIAL SLIDESPOS. 1 POS. 2-3-4-5-616.29.207 08.29.60716.29.206 08.29.60616.29.202 08.29.60216.29.205 08.29.60516.29.201 08.29.60116.29.204 08.29.60416.29.203 08.29.603CAMME STANDARD PER MANDRINI FRONTALISTANDARD CAMS FOR TOOL-SPINDLESPOS. 1 POS. 2-3-4-5-616.29.401 08.29.20516.29.402 08.29.20116.29.405 08.29.20216.29.406 08.29.20316.29.407 08.29.20416.29.403 16.29.40816.29.404

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>Apparecchio fresa poligoni e filettiPolygon Generating and Thread Milling AttachmentMehrkantdreh Und GewindefraseinrichtungADBEGCG1D/1La Scatola Presamoto (A) va posizionata sul castello dei mandrini frontali. Il moto sincronizzato le viene trasmesso dall’ingranaggio (G1D/1), che può essere già presente in macchina. La Scatola Presamoto è stata progettata per essere ingrado di servire contemporaneamente due Scatole anteriori Portafresa (B e C), attraverso due Alberi Telescopici (D e E).Le Scatole Portafresa vanno posizionate sui carri trasversali, nelle stazioni 4 e 5.Ogni Scatola Portafresa è intercambiabile tra la stazione 4 e 5. Le Scatole Portafresa possono essere di due tipi:con rapporto 1:1 per fresatura di filetti oppure con rapporto 1:2 per poligonatura.Vi è anche la possibilità di ottenere due operazioni di poligunatura in fase, grazie al nostro giunto registrabile.Forniamo inoltre platorelli portalame e inserti di varia larghezza per le operazioni di poligonatura.Se si necessita usare il comando di spinta assiale dei carri nelle stazioni 4 e 5 viene fornita la modifica dell’asta di spintache la rende compatibile con la presenza della nostra Scatola Presamoto (vedi foto in basso a destra).The “A” Driving Gear-box must be placed on the tool-spindle casting as you can see in the bottom right picture.The “A” Driving Gear-box is driven by the “G1D/1” gear that is usually already fitted in the casting.The “A” Driving Gear-box has been designed to drive two Tool Gear-boxes at the same time, on the cross slides in 4thand 5th position. Tool Gear-boxes can be fitted in 4th or 5th position as you like.To make flats and polygons you need to order the “C” Tool Gear-box with 1:2 ratio inside. Meanwhile to mill threads youneed to order the “B” Tool Gear-box with 1:1 ratio inside.If you need two phased polygon generating operations, you can do that by using our adjustable joint in one of the two outputsin the “A” Gear-box. We also supply “G” Tool-holder for polygon generating operations and hard metal cutters.When needed we can supply a modified rod to keep pushing axially the cross slides in 4th and 5th if our Driving Gear-boxis present.

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>Scatola presa-moto per pettinatore Saco-Autor “GR.1”Driving Gear-box for Saco-Autor “GR.1” thread chasing attachmentLa scatola a ingranaggi G1D/6 è utilizzata per poter impiegarein pos. 4-5 il pettinatore Saco “GR.1” e contemporaneamentenon smontare la nostra scatola Presamoto, che può continuaread azionare una scatola a poligonare nella posizione nonoccupata dal pettinatore.Oltre alla scatola siamo in grado di fornire le 2 coppie diingranaggi da montare all’interno per ottenere i vari tipi difiletto.G1D/6If you are using our polygon/threadmilling attachment you can’t fitthe driving gear-box for Saco-Autor “GR.1” thread chasingattachment. In this case we can supply the G1D/6 gear box.So you can leave our 2-outputs driving unit on the machine and fixthe G1D/6 on the output of the position where you want to place theSaco thread chasing attachment. Inside the G1D/6 you fit the sametwo pairs of gear that you have in your Saco driving unit.If you don’t have a thread chasing attacchment but you plan to buyone please note that you just need the cross slide unit from Sacoand you can drive it with the G1D/6, that you can buy from uscomplete with the 2 pairs of gear.Tabella rapporti ingranaggi pettinatoreThread-chasing attach. Gears ratioz1 z2 Rapportoratio21 42 1:224 40 3:520 44 5:1126 39 2:327 36 3:432 32 1:130 35 6:724 52 6:1315 28 15:2818 45 2:515 32 15:3230 34 15:1730 33 10:11

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>15.22.009PAG. 405.09.00105.08.01405.10.00115.04.10515.04.10601.27.02501.14.756d=8.010 / d=7.98505.04.012dd15.21.30405.09.01301.27.024 05.09.00806.07.00915.21.10708.07.01205.09.01206.07.01005.07.00301.07.24715.21.10801.11.02613.05.12710.46.10305.07.00405.07.00602.07.01605.07.00205.02.00305.19.01409.18.00408.46.03701.06.61505.02.00114.03.003

<strong>AS16</strong> <strong>AS20</strong>SERRAGGIO BARRA - BAR CLAMPINGPAG. 6<strong>AS16</strong> - <strong>AS20</strong> OPTIONAL :MANDATA RINFORZATA PER BARRE FINO A 25mmSPECIAL CLAMPING MECHANISM FOR BARS UP TO 25mm200963012009630320093605200963042009360220093606

<strong>GS20</strong> <strong>GM20</strong>SERRAGGIO BARRA - BAR CLAMPINGPAG. 731.01.10631.60.20231.01.10801.01.40508.01.35101.33.55331.01.110← 31.01.107 →01.25.20205.02.00905.02.012

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 801.01.50514.01.25101.01.51014.01.20208.01.01708.01.01215.01.00315.01.35115.01.35208.01.40202.01.20308.01.40102.01.20208.01.016 08.01.015

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>MACCHINA STOP-MANDRINO - SPINDLE STOPPING MACHINEPAG. 9B08.53.15108.53.152

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 10MANDRINI FISSINON-ROTATING TOOL-SPINDLES15.26.10101.30.00115.26.101-ER3215.26.00715.26.101-ISO3015.26.005MANDRINI ROTANTIROTATING TOOL-SPINDLES15.26.001-ISO30ISO30→ER2015.26.001-ER32ISO30→ER3215.26.00145.24.183cuscinetti specialispecial bearings

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>LEVE PER MANDRINI FRONTALI - TOOL SPINDLES LEVERSPAG. 11APos. 1-608.07.002 <strong>AS20</strong>-<strong>GS20</strong>31.22.112 <strong>GM20</strong>15.22.00815.22.00705.25.65408.40.01915.22.00915.22.001 <strong>AS20</strong>-<strong>GS20</strong>31.22.116 <strong>GM20</strong>06.07.00906.07.010Pos. 2-308.07.004 <strong>AS20</strong>-<strong>GS20</strong>31.22.113 <strong>GM20</strong>01.11.02501.11.026

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 11B08.14.00508.07.01205.14.00905.14.00705.14.01201.11.02605.14.00808.07.01108.14.00605.13.03805.13.03611.03.00214.18.00216.40.651 08.40.202

<strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 12PICK-UP15.58.10915.58.15115.58.14615.58.10515.58.10708.14.00615.58.11815.25.01815.58.154A = 144.5 31.58.071A = 156 31.58.072A = 176 31.58.073A = 196 31.58.074A = 216 31.58.075A = 236 31.58.076A = 256 31.58.077A15.58.14615.58.14415.58.11315.58.11415.58.12815.58.14910.49.01515.58.11115.58.112

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>OPTIONAL : 31.42.101 - 45.42.001PAG. 13BBRACCIO CON COMANDO INDIPENDENTE POS.6SWINGING TOOL-HOLDER FOR BACK OPERATIONS WITH PICK-UP ATTACHMENT08.47.10315.42.26015.42.30208.44.10105.21.10231.42.10231.42.00131.42.101

<strong>AS16</strong>PAG. 13MANDRINO FRONTALETOOL SPINDLE08.14.01308.58.35508.47.028(08.47.006)(08.47.021)PICK-UP <strong>AS16</strong>08.47.027(08.47.005)(08.47.020)

08.10.010<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>08.10.018PAG. 1408.10.01308.10.049Ortlinghaus14.17.00508.10.03508.10.00915.17.00108.10.01208.10.01915.17.01531.17.10931.17.11015.17.016150FAL/I15.16.202 - 15.16.204 - 14.16.20131.17.10815.15.201

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 1514.06.00405.17.01314.06.00308.29.30305.05.00105.07.00605.07.00205.07.00305.07.00414.20.101 08.05.10215.10.00314.06.10231.20.101 - 15.20.00115.06.00115.04.00314.06.10105.05.00515.06.00715.06.00614.06.001

15.17.017<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>GRUPPO FILETTATORE - THREADING UNITPAG. 1608.10.20108.10.202GRUPPO INTERNO FILETTATOREFULL THREADING SET20mm08.10.203 Ortlinghaus08.10.03914.17.20112mm14.17.00108.10.02008.10.00608.10.00108.10.00505.13.021

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>LEVE SLITTE RADIALI - CROSS SLIDES LEVERSPAG. 1705.09.00105.09.009Pos.101.27.02505.09.00805.09.01205.09.01305.09.205Pos.205.08.01405.08.02501.27.02505.09.40208.20.003Pos. 3-601.27.02405.08.02601.29.00605.08.008 M10x1.508.22.005 M10x108.22.003 M10x1.501.27.30601.29.03305.08.01105.09.011

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>LEVE SLITTE RADIALI - CROSS SLIDES LEVERSPAG. 17B05.10.201Pos.505.09.01305.09.01205.10.00101.27.02501.27.02405.10.002Pos.4OPTIONAL :LEVE ROBUSTE PER CARRI POS.4 E POS.5 CON APPARECCHI RULLATORIHEAVY DUTY LEVERS FOR POS.4 AND POS.5 CROSS SLIDES WITHROLL-THREADING ATTACHMENTS ON08.61.201Pos.501.07.24710.46.10305.09.01305.10.00105.09.01208.61.101Pos.4

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>FERMO BARRA - BAR STOPPAG. 17C31.19.10431.19.10301.07.24715.19.01413.05.12715.19.01215.19.02415.19.017

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 1845.21.003 POS.445.21.004 POS.5OPTIONAL :COMANDO SPINTA ASSIALE COMPLETAPUSHING SET FOR COMPOUND SLIDES45.21.002 POS.245.21.001 POS.1

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 1915.21.101 AS/<strong>GS20</strong>31.21.105 <strong>GM20</strong>15.21.201 AS/<strong>GS20</strong>31.21.106 <strong>GM20</strong>15.22.00815.22.00915.22.00717.01.51315.21.10815.21.10915.22.00115.21.10608.40.01915.21.107Ø2005.25.65406.07.00915.21.30515.21.30315.21.10431.22.116Ø24

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 2005.09.109 pos. 4-508.06.308 pos. 1-215.21.30414.21.40301.34.90715.21.102 pos. 4-515.21.301 pos. 1-215.21.11015.21.10515.21.651<strong>GS20</strong>-<strong>GM20</strong>pos. 1-205.09.45115.21.652<strong>GS20</strong>-<strong>GM20</strong>pos. 1-215.21.302<strong>AS16</strong>-<strong>AS20</strong>pos. 1-215.21.11111.09.207<strong>AS16</strong>-<strong>AS20</strong>pos. 1-215.21.103pos. 4-5 11.09.101

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 2115.04.10215.04.11415.04.10515.04.10615.04.10415.04.10315.04.11701.14.75605.04.01205.06.00108.04.20114.04.00131.04.11408.04.00415.04.101

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 2205.02.00705.03.01001.06.60601.06.61505.02.00108.02.00305.02.00314.03.00315.04.11131.02.103ecc. 2mm45.29.10208.29.30515.04.11608.04.30245.29.101

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>6x 08.01.00805.13.017PAG. 2308.01.00505.13.01205.13.01005.13.00811.12.10308.01.003 <strong>AS16</strong>05.13.00608.14.01515.18.006

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 24OPTIONAL: 31.27.001COMANDO SUPPORTO CENTRALECENTRE BLOCK MOVING SET

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>PAG. 2508.10.501FEED GEARSINGRANAGGI TEMPI DI PRODUZIONEZAHNRÄDER GESCHWINDIGKEIT SPINDEL UNDPIGNONS DE PRODUCTIONENGRANAJES TIEMPO PRODUCCIONZ1 Z219 7120 7023 6726 6429 6132 5841 4908.10.401SPEED AND THREAD RATIO GEARSINGRANAGGI VELOCITA’ E RAPPORTI FILETTATURAZAHNRÄDER PRODUKTIONSZEITPIGNONS DE VITESSE ET RAPPORTS TARAUDAGEENGRANAJES VELOCIDAD Y ROSCADURAZ1 Z227 6329 6130 6032 5838 5240 5041 4942 4843 4744 46VOGEL 34-24VOGEL 34-34VOGEL MFE5

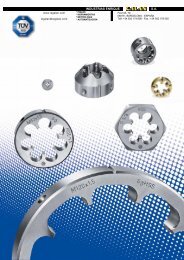

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>LAMELLE PER FRIZIONI ELETTROMAGNETICHE ORTLINGHAUSDISKS FOR ORTLINGHAUS ELECTROMAGNETIC CLUTCHESPAG. 26Ø83 Ø94.825 denti25 teethØ54.3GR.11Ø100Ø11419 denti19 teethØ64.4GR.15Ø119Ø13422 denti22 teethØ74.2GR.23

<strong>AS16</strong> <strong>AS20</strong> <strong>GS20</strong> <strong>GM20</strong>Apparecchio timbratoreRoll marking attachmentQuesto dispositivo è concepito per ottenere in modo pratico e veloce delle incisioni sul pezzo in rotazione.Le sigle da marcare sul pezzo devono essere incise da ditte professioniste sui dischi grezzi che forniamo eche trovano alloggiamento sul perno del timbratore.Il funzionamento è il seguente: il carro trasversale, su cui viene montato il timbratore, si sposta in avanti sinoa che il disco entra in contatto con il pezzo rotante.Per effetto dell’attrito il disco viene portato in trascinamento ed incide la sigla, fermandosi poi in una zonascaricata per evitare altri contatti col pezzo.Durante il ritorno del carrello, un puntalino opportunamente predisposto, provoca la ricarica dell’apparecchio.This attachment is used for marking the components in a very simple and quick way, because it is based ona completely mechanical logic.With our attachment on, the cross slide of the machine moves forward till the engraved disk touches thecomponent.Because of the friction between them, the disk starts to turn and mark the component.When the engraving is over, the disk stops in a fixed position to avoid further contact whit the component.During the return stroke a proper pin resets the marking roll in position.