Air compressor - Lomax

Air compressor - Lomax

Air compressor - Lomax

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

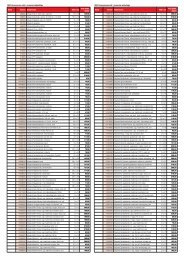

Warning!The condensation water from the pressure vesselwill contain residual oil. Dispose of the condensationwater in an environmentally compatible manner atthe appropriate collection point.6.3 Safety valve (ref. 10)The safety valve has been set for the highest permittedpressure of the pressure vessel. It is prohibited to adjustthe safety valve or remove its seal. Actuate the safetyvalve from time to time to ensure that it works whenrequired. Pull the ring with sufficient force until you canhear the compressed air being released. Then releasethe ring again.6.4 StorageWarning!Pull the mains plug out of the socket and ventilatethe appliance and all connected pneumatic tools.Switch off the <strong>compressor</strong> and make sure that it issecured in such a way that it cannot be started upagain by any unauthorized person.Warning!Store the <strong>compressor</strong> only in a dry location whichis not accessible to unauthorized persons.Always store upright, never tilted!7. Disposal and recyclingThe unit and its accessories are made of various typesof material, such as metal and plastic.Defective components must be disposed of as specialwaste. Ask your dealer or your local council.GB8. Possible faults and related permitted remediesFault Cause RemedyLeakage of air from the valveof the pressure switch with the<strong>compressor</strong> off.Reduction of performance.Frequent start-up. Low pressurevalues.The <strong>compressor</strong> stops and restartsautomatically after a few minutes.After a few attempts to restart, the<strong>compressor</strong> stops.The <strong>compressor</strong> does not stop andthe safety valve is tripped.Check valve that, due to wear ordirt on the seal, does not performits function correctly.Excessive performance request,check for any leaks from thecouplings and/or pipes. Intake filtermay be clogged.Tripping of the thermal cutout dueto overheating of the motor.Tripping of the thermal cutoutdue to overheating of the motor(removal of the plug with the<strong>compressor</strong> running, low powervoltage).Irregular functioning of the<strong>compressor</strong> or breakage of thepressure switch.Unscrew the hexagonal head ofthe check valve, clean the valveseat and the special rubber disk(replace if worn). Reassemble andtighten carefully.Replace the seals of the fitting,clean or replace the filter.Clean the air ducts in theconveyor. Ventilate the work area.Activate the on/off switch. Ventilatethe work area. Wait a few minutes.The <strong>compressor</strong> will restartindependently.Remove the plug and contact theService Center.Any other type of operation must be carried out by authorized Service Centers, requesting original parts.Tampering with the machine may impair its safety and in any case make the warranty null and void.19