FahrwerkFedern SuSpenSion SpringS

FahrwerkFedern SuSpenSion SpringS

FahrwerkFedern SuSpenSion SpringS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A TRADITION OF QUALITY.<br />

RUVILLE has been offering products for the aftermarket<br />

to OE quality standards for 90 years. Our customers, therefore,<br />

have been benefiting from our experience, expertise,<br />

and confidence in our competence for many decades.<br />

Today, we are a member of the Schaeffler Group, and we<br />

have established ourselves as a reliable and flexible trading<br />

partner, as well as a well-known specialist for engines,<br />

chassis and service in the worldwide aftermarket for<br />

private and commercial vehicles. Our replacement parts<br />

and kits, just like our service and ability to supply, must<br />

correspond with our quality requirements.<br />

As a service provider who always thinks ahead, we orientate<br />

ourselves to the latest needs of our customers. But<br />

we also like to be ahead of the times and continually set<br />

new standards with our intelligent and practice orientated<br />

repair solutions. We cooperate with selected partners,<br />

who are listed as international original equipment manufacturers<br />

and quality suppliers, in order to achieve these<br />

successes. In order to continually fulfill our quality claims,<br />

our products undergo additional thorough checks by<br />

independent test institutions.<br />

RUVILLE would like to thank you for your confidence, and<br />

to wish you every success with our OE quality products.<br />

RUVILLE suspension springs –<br />

your advantages at a glance<br />

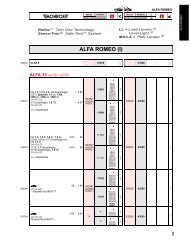

Our range: pressure springs of the coil-spring type<br />

The most frequent spring types cover practically all<br />

market demands:<br />

– cylindrical springs<br />

– conical springs<br />

– Mini-block springs<br />

– KMP (force-centre) or side-load springs<br />

All suspension springs in OE quality<br />

Proven procedures ensure safety and reliability:<br />

– automated CNC cold-forming<br />

– stress relief annealing at 400°C,<br />

hardening at 880°C, tempering at 400°C<br />

– bottoming out prevents relaxation so that the vehicle<br />

won’t sag<br />

– shot blasting to optimise surface hardness<br />

– zinc phosphate or epoxy powder for excellent<br />

corrosion protection<br />

Testing the spring characteristics<br />

2-year guarantee with unlimited mileage<br />

On top: Sound practival advice, made-to-measure<br />

services and RUVILLE program trainings<br />

5