KD MCT-EC - Dusar

KD MCT-EC - Dusar

KD MCT-EC - Dusar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GB<br />

ASSEMBLY WITH WATER HEATER<br />

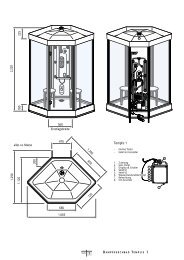

• Connection to the domestic water supply system: (FIG. 4)<br />

You require: æ " connection with shut-off device (with non-return valve) for cold water. Follow instructions given by the local Water Company.<br />

• Connection to the domestic drainage system: (FIG. 4)<br />

Provided by the built-in suction pump and the discharge hose to be connected. The discharge hose may be hung in a sink or connected to an existing drain.<br />

The discharge hose must not be suspended or connected at a level higher than 1.5 m.<br />

1. ASSEMBLING THE FITTING: (Fig. 1-3)<br />

Slip O-ring (11.2) over copper pipes as far as the fitting. Put copper pipes through drill hole in the rear wall and fasten with washer (11.3) and nut (11.4). Fasten connecting<br />

angle Nr.14.1 to bottom part. Secure connection piping against distortion with open-end wrench size 17 mm.<br />

Attention: Pay attention to the "Cold” and "Hot” markings !<br />

2. WATER SUPPLY: (FIG. 4)<br />

The step regulator Nr.15 supplied serves as protection against excessive pressure load. Adjust step regulator to water pressure at place of installation, as per the pressure table,<br />

and push into cold water feed pipe (11.1) down to the collar.<br />

WATER STOPPER (hose safety connection Nr.17): stops the water flow if hoses split or slip. Screw the water stopper onto the tap tightly, by hand. Screw the feed hose Nr.16<br />

onto the water stopper. Turn the tap on very slowly, until it is completely open. Switch the machine on to bleed the hose. After turning off the tap, open the closed water stopper<br />

safety connection by ! a turn (bleeding) and then tighten again.<br />

MAINTENANCE: Please check the water stopper Nr.17 once a year for your own safety. To do this, unscrew the water stopper from the tap and apply pressure on the inner piece<br />

with one finger and push as far as the stop (FIG. 4a). Should the inner piece be stuck due to lime scale, then lay the complete piece of equipment in commercial lime scale<br />

remover. Rinse well before assembly and carry out function test on the shower hose as described above.<br />

Now move cubicle into desired installation place. Connect shower hose to connection [ C ] of fitting. (FIG 1)<br />

Attention ! The water supply must be fitted with a non-return valve, which has been installed by a recognised plumber. The æ” water supply hose Nr.16 and the water<br />

stopper Nr.17 must be used, otherwise the guarantee is not valid! Follow instructions given by the local Water Company !<br />

Expansion water will drip from the outlet whilst the water heater is heating up. As this is due to a physical process, even turning the feed control even tighter cannot<br />

stop the dripping. The functional safety of the system is not guaranteed at a water pressure of less than 1 bar (even for short periods) this is therefore not<br />

acceptable as a complaint.<br />

3. WATER DISCHARGE: (FIG. 5)<br />

Put hose clip Nr.18 on water discharge hose Nr.19 and connect with the support of suction pump. Tighten hose clip Nr.18.The bent part (20) of the water discharge hose is<br />

for hanging in a sink. Where assembly is carried out horizontally, the hose can be extended up to 10 m. The water discharge hose Nr.19 must be hung up at a level not higher<br />

than 1.5 m, otherwise the pump cannot pump out all the wastewater. Avoid bending the hose during assembly!<br />

4. EL<strong>EC</strong>TRICAL CONN<strong>EC</strong>TION: (FIG. 6)<br />

Connecting the bottom part: An approved electrician must under all circumstances carry out electrical connection of the shower cubicle. Installation is to be carried out to VDE<br />

0100 as a fixed connection. (30 mA fault current circuit breaker is imperative).<br />

The shower cubicle is to be connected by means of a movable cable, which is to be in at least medium rubber jacket cord, via a stationary appliance coupler socket.<br />

Potential equalization: The potential equalization line for all shower cubicles must be included in the potential equalization as prescribed (to VDE 0100) (see Fig. 8).<br />

Please also follow the technical data and the circuit diagram, as well as the protective area in the interior.<br />

5. INITIAL OPERATION: (FIG. 1)<br />

Filling the water heater with water: It is useful for the same person to carry out the initial operation. The water heater should be filled with water prior to initial operation. To do this,<br />

turn the mixing tap temperature control toggle switch [ a ] for temperature control to hot water. Open toggle switch [ b ] to fill the water heater. (For the <strong>KD</strong>/RD model, turn revolving<br />

switch to "Hot" and open). Open water tap Nr.WH. The water heater is full, as soon as water runs out of the showerhead. Turn rotary switch without marking to the right until the<br />

valve is shut (or for the <strong>KD</strong>/RD model, close lever). The water heater needs only to be filled once as water taken from the boiler will continually be replaced.<br />

6. OPERATING THE SWITCHBOARD: (FIG 7)<br />

The green rocker switch [ B ] is set to "Operation". The individual functions are now ready for operation. Rotary switch [ T ] is for the stepless adjustment of water temperature. The<br />

green indicator lamp [ H ] lights up when the water has been heated to the desired temperature. Once the selected temperature has been reached, the thermostat will switch off<br />

and the green indicator lamp goes out. As the temperature falls the heating is restarted automatically. Water coming out of the showerhead during heating up is the result of a<br />

physical process (water expansion during heating), which cannot be prevented, not even by excessive tightening of the temperature tap. Please take care that the showerhead is<br />

not held closed or submerged under water. The water should always be given free flow. For showers with low-pressure water heater only the shower gear included in the supply<br />

must be connected. Failure to do this may cause damage to the water heater. The rocker switch [ P ] is for switching on the pump to pump off the wastewater. Every shower<br />

cubicle with a water heater is fitted with a safety thermostat, which switches off at a heating-up temperature of approx. 100° C = 4°, if there is a defect at the control thermostat.<br />

Contrary to the control thermostat, the safety thermostat is not switched on automatically. This blocks heating-up of the water heater !<br />

Attention: Should the safety thermostat be triggered, this thermostat can be unlocked by simply pushing in the pin. [ E ]<br />

Unlocking pin [ E ] is located above the temperatureregulator.<br />

Entsperrknopf<br />

E.<br />

(FIG.7)<br />

7. THE FOLLOWING STEPS MUST BE TAKEN AFTER OPERATING THE SHOWER: (FIG 7)<br />

To switch off, close the shower cubicle and domestic water supply system water taps. The pump is switched<br />

off at rocker switch [ P ] , when the shower tray is empty. Then set rocker switch [ T ] to "OFF". Now the<br />

switchboard is out of operation. Special instructions! Please note! Before emptying the water heater and before<br />

doing any other work to the bottom part of the shower cubicle, an approved electrician must disconnect the<br />

cubicle from the power system.<br />

T.<br />

B. H. P.<br />

Temperatur Betrieb Heizung Pumpe<br />

8. EMPTYING THE WATER HEATER: (FIG2 / TYPE B)<br />

Unscrew the two corner angles Nr.14.1 from the connection pipes (15.5) coming from the bottom part. Attention: Countercheck to avoid a distortion of connection pipes.<br />

Now connect a suction pump to the connection marked in blue, and pump out the water.<br />

Seite<br />

16