Neomat A 89.028 NS rev1 - Rollo Rieper

Neomat A 89.028 NS rev1 - Rollo Rieper

Neomat A 89.028 NS rev1 - Rollo Rieper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

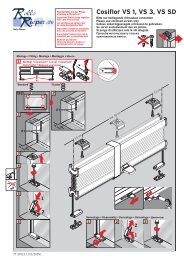

2.1.1) “Step-by-Step” Input:<br />

To control the automation in manual mode it is possible to connect<br />

a simple button (between the Common wire and the Step-by-Step<br />

input). The operating mode follows this sequence: up-stop-downstop.<br />

If the button is held down for more than 3 seconds (but less than 10),<br />

an UP movement is always activated (the one corresponding to key<br />

▲ on the radio controls). If the button is held down for more than 10<br />

seconds, a DOWN movement is always activated (corresponding to<br />

key ▼). This feature can be useful in order to “synchronise” multiple<br />

motors to the same operation regardless of their current status.<br />

GB<br />

2.1.2) “TTBUS” input:<br />

The “TTBUS” has been designed to control the control units of<br />

motors for shutters and rolling shutters. This Bus enables separate<br />

control of up to 100 control units by connecting them in parallel<br />

using only 2 conductors (Common and “TTBUS” wires). For further<br />

information see the operating instructions for the remote controls via<br />

“TTBUS”.<br />

2.1.3) Weather sensors:<br />

In the “Weather Sensor” input between the Common wire (black<br />

wire) and the Weather sensor input (orange wire) you can connect a<br />

simple wind sensor (anemometer) or a special wind-sun-rain sensor.<br />

Up to 5 control units can be connected in parallel to a single sensor.<br />

Be careful to observe the polarity of the signals (on all the motors,<br />

the black wire must be connected with the black, the orange with<br />

the orange).<br />

2.2) Connector and power supply cable (this section refers only to the NEOMAT A version and concerns customer service personnel<br />

only)<br />

! WARNING: if the power cord is damaged it must be replaced with an identical type supplied by the manufacturer or<br />

an authorised customer service centre.<br />

!If it is necessary to disconnect the motor from the power supply cable proceed as shown in the figures below:<br />

Rotate the ring nut until the notch<br />

matches one of the latch-on<br />

teeth, then release.<br />

Repeat the operation for the<br />

other tooth<br />

Bend the cable towards the inside<br />

and remove the protection by rotating<br />

it gently towards the outside<br />

Pull out the connector<br />

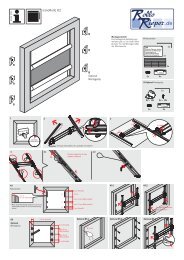

3) Adjustments<br />

The NEOMAT series tubular motors are equipped with an electronic<br />

limit switch system. The electronic control unit interrupts the movement<br />

when the shutter reaches the programmed open or closed<br />

positions. These positions must be programmed into the memory<br />

after the motor has been installed and the shutter has been fully<br />

mounted.<br />

The motor can still be controlled even if these two positions, “0”<br />

(shutter open) and “1” (shutter close), have not yet been memorised;<br />

however, the movement in this case must be controlled manually. It<br />

is also possible to program an intermediate position (Pos. “I”) for partial<br />

opening of the shutter.<br />

Shutter open (Pos. “0”) Shutter close (Pos.”1”) Intermediate position (“I”)<br />

3