Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

eng<br />

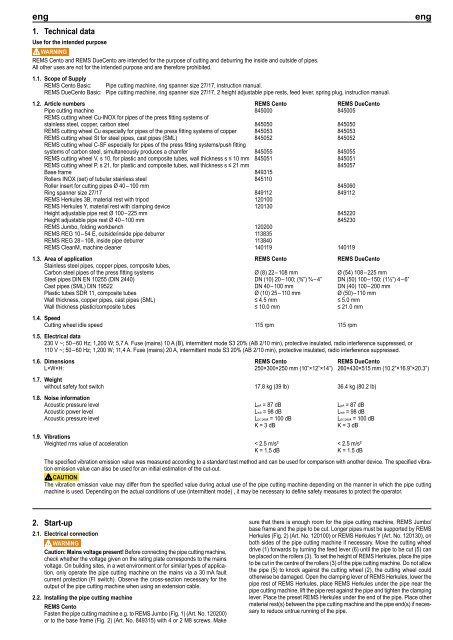

1. Technical data<br />

Use for the intended purpose<br />

WARNING<br />

<strong>REMS</strong> <strong>Cento</strong> and <strong>REMS</strong> Due<strong>Cento</strong> are intended for the purpose of cutting and deburring the inside and outside of pipes.<br />

All other uses are not for the intended purpose and are therefore prohibited.<br />

1.1. Scope of Supply<br />

<strong>REMS</strong> <strong>Cento</strong> Basic: Pipe cutting machine, ring spanner size 27/17, instruction manual.<br />

<strong>REMS</strong> Due<strong>Cento</strong> Basic: Pipe cutting machine, ring spanner size 27/17, 2 height adjustable pipe rests, feed lever, spring plug, instruction manual.<br />

1.2. Article numbers <strong>REMS</strong> <strong>Cento</strong> <strong>REMS</strong> Due<strong>Cento</strong><br />

Pipe cutting machine 845000 845005<br />

<strong>REMS</strong> cutting wheel Cu-INOX for pipes of the press fitting systems of<br />

stainless steel, copper, carbon steel 845050 845050<br />

<strong>REMS</strong> cutting wheel Cu especially for pipes of the press fitting systems of copper 845053 845053<br />

<strong>REMS</strong> cutting wheel St for steel pipes, cast pipes (SML) 845052 845052<br />

<strong>REMS</strong> cutting wheel C-SF especially for pipes of the press fitting systems/push fitting<br />

systems of carbon steel, simultaneously produces a chamfer 845055 845055<br />

<strong>REMS</strong> cutting wheel V, s 10, for plastic and composite tubes, wall thickness s ≤ 10 mm 845051 845051<br />

<strong>REMS</strong> cutting wheel P, s 21, for plastic and composite tubes, wall thickness s ≤ 21 mm 845057<br />

Base frame 849315<br />

Rollers INOX (set) of tubular stainless steel 845110<br />

Roller insert for cutting pipes Ø 40 – 100 mm 845060<br />

Ring spanner size 27/17 849112 849112<br />

<strong>REMS</strong> Herkules 3B, material rest with tripod 120100<br />

<strong>REMS</strong> Herkules Y, material rest with clamping device 120130<br />

Height adjustable pipe rest Ø 100 – 225 mm 845220<br />

Height adjustable pipe rest Ø 40 – 100 mm 845230<br />

<strong>REMS</strong> Jumbo, folding workbench 120200<br />

<strong>REMS</strong> REG 10 – 54 E, outside/inside pipe deburrer 113835<br />

<strong>REMS</strong> REG 28 – 108, inside pipe deburrer 113840<br />

<strong>REMS</strong> CleanM, machine cleaner 140119 140119<br />

1.3. Area of application <strong>REMS</strong> <strong>Cento</strong> <strong>REMS</strong> Due<strong>Cento</strong><br />

Stainless steel pipes, copper pipes, composite tubes,<br />

Carbon steel pipes of the press fitting systems Ø (8) 22 – 108 mm Ø (54) 108 – 225 mm<br />

Steel pipes DIN EN 10255 (DIN 2440) DN (10) 20 – 100; (⅜”) ¾ – 4” DN (50) 100 – 150; (1½”) 4 – 6”<br />

Cast pipes (SML) DIN 19522 DN 40 – 100 mm DN (40) 100 – 200 mm<br />

Plastic tubes SDR 11, composite tubes Ø (10) 25 – 110 mm Ø (50) – 110 mm<br />

Wall thickness, copper pipes, cast pipes (SML) ≤ 4.5 mm ≤ 5.0 mm<br />

Wall thickness plastic/composite tubes ≤ 10.0 mm ≤ 21.0 mm<br />

1.4. Speed<br />

Cutting wheel idle speed 115 rpm 115 rpm<br />

1.5. Electrical data<br />

230 V ~; 50 – 60 Hz; 1,200 W; 5,7 A. Fuse (mains) 10 A (B), intermittent mode S3 20% (AB 2/10 min), protective insulated, radio interference suppressed, or<br />

110 V ~; 50 – 60 Hz; 1,200 W; 11,4 A. Fuse (mains) 20 A, intermittent mode S3 20% (AB 2/10 min), protective insulated, radio interference suppressed.<br />

1.6. Dimensions <strong>REMS</strong> <strong>Cento</strong> <strong>REMS</strong> Due<strong>Cento</strong><br />

L×W×H: 250×300×250 mm (10”×12”×14”) 260×430×515 mm (10.2”×16.9”×20.3”)<br />

1.7. Weight<br />

without safety foot switch 17.8 kg (39 lb) 36.4 kg (80.2 lb)<br />

1.8. Noise information<br />

Acoustic pressure level LpA = 87 dB LpA = 87 dB<br />

Acoustic power level Lwa = 98 dB Lwa = 98 dB<br />

Acoustic pressure level Lpc peak = 100 dB Lpc peak = 100 dB<br />

K = 3 dB<br />

K = 3 dB<br />

1.9. Vibrations<br />

Weighted rms value of acceleration < 2.5 m/s² < 2.5 m/s²<br />

K = 1.5 dB<br />

K = 1.5 dB<br />

The specified vibration emission value was measured according to a standard test method and can be used for comparison with another device. The specified vibration<br />

emission value can also be used for an initial estimation of the cut-out.<br />

CAUTION<br />

The vibration emission value may differ from the specified value during actual use of the pipe cutting machine depending on the manner in which the pipe cutting<br />

machine is used. Depending on the actual conditions of use (intermittent mode) , it may be necessary to define safety measures to protect the operator.<br />

eng<br />

2. Start-up<br />

2.1. Electrical connection<br />

WARNING<br />

Caution: Mains voltage present! Before connecting the pipe cutting machine,<br />

check whether the voltage given on the rating plate corresponds to the mains<br />

voltage. On building sites, in a wet environment or for similar types of application,<br />

only operate the pipe cutting machine on the mains via a 30 mA fault<br />

current protection (FI switch). Observe the cross-section necessary for the<br />

output of the pipe cutting machine when using an extension cable.<br />

2.2. Installing the pipe cutting machine<br />

<strong>REMS</strong> <strong>Cento</strong><br />

Fasten the pipe cutting machine e.g. to <strong>REMS</strong> Jumbo (Fig. 1) (Art. No. 120200)<br />

or to the base frame (Fig. 2) (Art. No. 849315) with 4 or 2 M8 screws. Make<br />

sure that there is enough room for the pipe cutting machine, <strong>REMS</strong> Jumbo/<br />

base frame and the pipe to be cut. Longer pipes must be supported by <strong>REMS</strong><br />

Herkules (Fig. 2) (Art. No. 120100) or <strong>REMS</strong> Herkules Y (Art. No. 120130), on<br />

both sides of the pipe cutting machine if necessary. Move the cutting wheel<br />

drive (1) forwards by turning the feed lever (6) until the pipe to be cut (5) can<br />

be placed on the rollers (3). To set the height of <strong>REMS</strong> Herkules, place the pipe<br />

to be cut in the centre of the rollers (3) of the pipe cutting machine. Do not allow<br />

the pipe (5) to knock against the cutting wheel (2), the cutting wheel could<br />

otherwise be damaged. Open the clamping lever of <strong>REMS</strong> Herkules, lower the<br />

pipe rest of <strong>REMS</strong> Herkules, place <strong>REMS</strong> Herkules under the pipe near the<br />

pipe cutting machine, lift the pipe rest against the pipe and tighten the clamping<br />

lever. Place the preset <strong>REMS</strong> Herkules under the end of the pipe. Place other<br />

material rest(s) between the pipe cutting machine and the pipe end(s) if necessary<br />

to reduce untrue running of the pipe.