Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

eng<br />

Translation of the Original Instruction Manual<br />

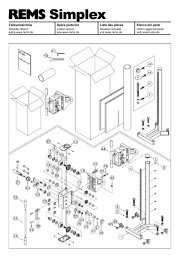

Fig. 1– 8<br />

1 Cutting wheel drive<br />

2 Cutting wheel<br />

3 Rollers<br />

4 Holes for stand<br />

(only <strong>REMS</strong> <strong>Cento</strong>)<br />

5 Pipe<br />

6 Feed lever<br />

7 Safety foot switch<br />

8 Spindle<br />

General Power Tool Safety Warnings<br />

9 Spring plug<br />

10 Height adjustable pipe rest<br />

Ø 100 – 225 mm<br />

11 Clamping lever<br />

12 <strong>REMS</strong> REG 28-108<br />

13 <strong>REMS</strong> REG 10-54 E<br />

14 Roller insert for cutting pipes<br />

Ø 40 – 100 mm (accessory,<br />

only <strong>REMS</strong> Due<strong>Cento</strong>)<br />

WARNING<br />

Read all safety warnings and all instructions. Failure to follow the warnings and<br />

instructions may result in electric shock, fire and/or serious injury.<br />

Save all warnings and instructions for future reference.<br />

The term "power tool" in the warnings refers to your mains-operated (corded) power<br />

tool or battery-operated (cordless) power tool.<br />

1) Work area safety<br />

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.<br />

b) Do not operate power tools in explosive atmospheres, such as in the presence<br />

of flammable liquids, gases or dust. Power tools create sparks which<br />

may ignite the dust or fumes.<br />

c) Keep children and bystanders away while operating a power tool. Distractions<br />

can cause you to lose control.<br />

2) Electrical safety<br />

a) Power tool plugs must match the outlet. Never modify the plug in any way.<br />

Do not use any adapter plugs with earthed (grounded) power tools. Unmodified<br />

plugs and matching outlets will reduce risk of electric shock.<br />

b) Avoid body contact with earthed or grounded surfaces, such as pipes,<br />

radiators, ranges and refrigerators. There is an increased risk of electric shock<br />

if your body is earthed or grounded.<br />

c) Do not expose power tools to rain or wet conditions. Water entering a power<br />

tool will increase the risk of electric shock.<br />

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging<br />

the power tool. Keep cord away from heat, oil, sharp edges or moving<br />

parts. Damaged or entangled cords increase the risk of electric shock.<br />

e) When operating a power tool outdoors, use an extension cord suitable for<br />

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric<br />

shock.<br />

f) If operating a power tool in a damp location is unavoidable or there is the<br />

likelihood of cutting into the cord, use a residual current device (RCD)<br />

protected supply. Use of an RCD reduces the risk of electric shock.<br />

3) Personal safety<br />

a) Stay alert, watch what you are doing and use common sense when operating<br />

a power tool. Do not use a power tool while you are tired or under the influence<br />

of drugs, alcohol or medication. A moment of inattention while operating<br />

power tools may result in serious personal injury.<br />

b) Use personal protective equipment. Always wear eye protection. Protective<br />

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection<br />

used for appropriate conditions will reduce personal injuries.<br />

c) Prevent unintentional starting. Ensure the switch is in the off-position before<br />

connecting to power source and/or battery pack, picking up or carrying the<br />

tool. Carrying power tools with your finger on the switch or energising power<br />

tools that have the switch on invites accidents.<br />

d) Remove any adjusting key or wrench before turning the power tool on. A<br />

wrench or a key left attached to a rotating part of the power tool may result in<br />

personal injury.<br />

e) Do not overreach. Keep proper footing and balance at all times. This enables<br />

better control of the power tool in unexpected situations.<br />

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair and<br />

clothing away from moving parts. Loose clothes, jewellery or long hair can be<br />

caught in moving parts.<br />

g) If devices are provided for the connection of dust extraction and collection<br />

facilities, ensure these are connected and properly used. Use of dust collection<br />

can reduce dustrelated hazards.<br />

4) Power tool use and care<br />

a) Do not force the power tool. Use the correct power tool for your application.<br />

The correct power tool will do the job better and safer at the rate for which it was<br />

designed.<br />

b) Do not use the power tool if the switch does not turn it on and off. Any power<br />

tool that cannot be controlled with the switch is dangerous and must be repaired.<br />

c) Disconnect the plug from the power source and/or the battery pack from<br />

the power tool before making any adjustments, changing accessories, or<br />

storing power tools. Such preventive safety measures reduce the risk of starting<br />

the power tool accidentally.<br />

d) Store idle power tools out of the reach of children and do not allow persons<br />

unfamiliar with the power tool or these instructions to operate the power<br />

eng<br />

tool. Power tools are dangerous in the hands of untrained users.<br />

e) Maintain power tools. Check for misalignment or binding of moving parts,<br />

breakage of parts and any other condition that may affect the power tool’s<br />

operation. If damaged, have the power tool repaired before use. Many<br />

accidents are caused by poorly maintained power tools.<br />

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with<br />

sharp cutting edges are less likely to bind and are easier to control.<br />

g) Use the power tool, accessories and tool bits etc. in accordance with these<br />

instructions, taking into account the working conditions and the work to<br />

be performed. Use of the power tool for operations different from those intended<br />

could result in a hazardous situation.<br />

h) Keep handles dry, clean and free from oil and grease. Slippery handles do<br />

not allow for safe handling and control of the tool in unexpected situations.<br />

5) Service<br />

a) Have your power tool serviced by a qualified repair person using only<br />

identical replacement parts. This will ensure that the safety of the power tool<br />

is maintained.<br />

Safety instructions for pipe cutting machines<br />

WARNING<br />

Read all safety warnings and all instructions. Failure to follow the warnings and<br />

instructions may result in electric shock, fire and/or serious injury.<br />

Save all warnings and instructions for future reference.<br />

● Do not overload the pipe cutting machine, the cutting wheel and the pipe<br />

by too high feeding pressure on the feed lever (6). The pipe cutting machine<br />

and the cutting wheel are subject to heavier wear by too high feeding pressure<br />

and can be damaged. At too high feeding pressure, the ends of the pipe to be<br />

cut are pressed further inwards causing constriction of the cross section. Pipes<br />

made of brittle material, e.g. cast pipes, can be fractured or broken by too high<br />

feeding pressure.<br />

● Do not reach into moving parts in the cutting and deburring area and in the<br />

area of the rollers (3) and height adjustable pipe rests (10). There is a risk<br />

of injury by crushing fingers or hands.<br />

● Use <strong>REMS</strong> Herkules 3B (Art. No. 120100), <strong>REMS</strong> Herkules Y (Art. No. 120130)<br />

material rest(s) or the height adjustable pipe rest(s) (10) to support long<br />

pipes at both ends if necessary and align these exactly to the rollers (3) of<br />

the cutting machine. This reduces off-centre running of the pipes and the cut<br />

pipes do not fall onto the floor.<br />

● Check that the pipes are running true before cutting them. Cutting pipes that<br />

are not straight causes imbalance and the pipe or pipe rest can fall over. The<br />

pipe can also slip off the material or pipe rest, the pipe cutting machine can move<br />

and the cutting wheel can be damaged. Danger of injury.<br />

● Only move or carry the <strong>REMS</strong> Due<strong>Cento</strong> by the feed lever (6) when this has<br />

been locked as described in 2.2. If the feed lever is not locked there is a danger<br />

that the feed lever (6) will come away from the spindle (8). <strong>REMS</strong> Due<strong>Cento</strong> can<br />

then fall over or fall off. Danger of injury.<br />

● Protect persons accompanying the work against the rotating pipe during<br />

cutting. Danger of injury.<br />

● Check the mains lead and any extension cables of the pipe cutting machine<br />

regularly. Have these renewed by qualified experts or an authorised <strong>REMS</strong><br />

customer service workshop in case of damage.<br />

● Only allow trained persons to use the pipe cutting machine. Apprentices<br />

may only use the pipe cutting machine when they are over 16, when this is<br />

necessary for their training and when they are supervised by a trained operative.<br />

● The pipe cutting machine is not intended for use by persons (including children)<br />

with reduced physical, sensory or mental capabilities or lack of experience and<br />

knowledge unless they have been given supervision or instruction concerning<br />

the use of the pipe cutting machine by a person responsible for their safety.<br />

Children must be supervised to ensure that they do not play with the pipe cutting<br />

machine.<br />

Explanation of symbols<br />

WARNING<br />

CAUTION<br />

NOTICE<br />

Danger with a medium degree of risk which could result in<br />

death or severe injury (irreversible) if not heeded.<br />

Danger with a low degree of risk which could result in minor<br />

injury (reversible) if not heeded.<br />

Material damage, no safety note! No danger of injury.<br />

Read the operating manual before starting<br />

Electrical device complies with protection class II<br />

Environmental friendly disposal