You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

eng<br />

<strong>REMS</strong> Due<strong>Cento</strong><br />

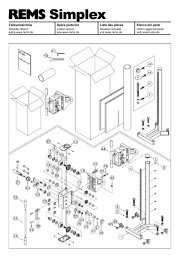

Place the pipe cutting machine on a firm, level base. Make sure that there is<br />

enough room for the pipe cutting machine, the height adjustable pipe rests and<br />

the pipe to be cut. Push the feed lever (6) onto the spindle (8). Make sure that<br />

there is a positive fit between the groove of the feed lever and the parallel pin<br />

of the spindle and push the spring plug (9) into the holes of the feed lever and<br />

the spindle (Fig. 6). Longer pipes must be supported with height adjustable<br />

pipe rests (Fig. 5) (10), on both sides of the machine if necessary. Move the<br />

cutting wheel drive (1) forwards by turning the feed lever (6) until the pipe to<br />

be cut (5) can be placed on the rollers (3). To set the height of the height adjustable<br />

rests (10), place the pipe to be cut in the centre of the rollers (3) of the<br />

pipe cutting machine. Do not allow the pipe (5) to knock against the cutting<br />

wheel (2), the cutting wheel could otherwise be damaged. Open the clamping<br />

lever (11) of the height adjustable pipe rests (10). Place the height adjustable<br />

pipe rests (10) under the pipe near the pipe cutting machine (Fig. 7), lift against<br />

the pipe and tighten the clamping lever (11). Place the preset pipe rests under<br />

each end of the pipe. Place other pipe rest(s) between the pipe cutting machine<br />

and the pipe end(s) if necessary to reduce untrue running of the pipe.<br />

Do not fasten <strong>REMS</strong> Due<strong>Cento</strong> and height adjustable pipe rests (10) to the<br />

base because otherwise a pipe running off centre could break the cutting wheel.<br />

CAUTION<br />

<strong>REMS</strong> Due<strong>Cento</strong> may only be moved or carried by the feed lever (6) when this<br />

has been locked with the spring plug (9) as described above. Otherwise there<br />

is a danger that the feed lever (6) will come away from the spindle (8). <strong>REMS</strong><br />

Due<strong>Cento</strong> can then fall over or fall off. Danger of injury!<br />

2.3. Fitting (changing) the cutting wheel (2)<br />

Pull out the mains plug! Choose suitable cutting wheel. Loosen the hexagonal<br />

nut for fastening the cutting wheel (right-hand thread) with the size 27 ring<br />

spanner provided. Insert (change) cutting wheel (2). Make sure that the driver<br />

pins of the drive shaft engage in the holes of the cutting wheel. Tighten the<br />

hexagonal nut.<br />

NOTICE<br />

An unsuitable cutting wheel will be damaged or the pipe will not be cut. Use<br />

only original <strong>REMS</strong> cutting wheels!<br />

2.4. Cutting pipes Ø 40 – 100 mm with <strong>REMS</strong> Due<strong>Cento</strong> (Fig. 8)<br />

Place roller insert for cutting pipes Ø 40 – 100 mm (14) (accessory) on the<br />

rollers (3). For pipes Ø 40 – 70 mm or for pipes Ø 70 – 100 mm, place roller<br />

insert in the rollers (3) as shown in Fig. 8. Longer pipes must be supported by<br />

height adjustable pipe rests Ø 40 – 100 mm (Art. No. 845230, accessory), on<br />

both sides of the pipe cutting machine if necessary. Cutting pipes, see 2.2.<br />

<strong>REMS</strong> Due<strong>Cento</strong>.<br />

3. Operation<br />

CAUTION<br />

Danger of injury!<br />

Wear suitable clothing. Do not wear loose clothing or jewellery. Keep hair,<br />

clothing and gloves away from moving parts. Loose clothing, jewellery or<br />

long hair can get caught in moving parts.<br />

NOTICE<br />

Make sure that the blade of the cutting wheel (2) protrudes into the groove of<br />

the <strong>REMS</strong> REG 28 – 108 (12) (Fig. 3).<br />

Deburring of outside/inside of pipes (Fig. 4)<br />

With the <strong>REMS</strong> REG 10 – 54 E (13) pipes of Ø 10 – 54 mm, Ø ½ – 2⅛” can be<br />

deburred on the outside and inside. There is a bit holder on the back of the<br />

cutting wheel shaft for driving the <strong>REMS</strong> REG 10 – 54 E. The pipes to be<br />

deburred are pressed by hand against the <strong>REMS</strong> REG 10 – 54 E set into rotation<br />

by the pipe cutting machine.<br />

NOTICE<br />

Remove <strong>REMS</strong> REG 10 – 54 E (13) for cutting pipes. The bit holder is approved<br />

only for <strong>REMS</strong> REG 10 – 54 E. Other tools with bit holder are not approved.<br />

4. Maintenance<br />

eng<br />

4.1. Maintenance<br />

WARNING<br />

Pull out the mains plug before maintenance work!<br />

Keep the rollers (3) of the pipe cutting machine and the roller insert (14) clean.<br />

Clean the spindle (8) and guides of the cutting wheel drive (1) from time to time<br />

and grease lightly with machine oil. Clean heavily soiled metal parts with the<br />

<strong>REMS</strong> CleanM (Art. No. 140119) cleaner, for example, and then protect against<br />

rust.<br />

Clean plastic parts (e.g. housing) only with the <strong>REMS</strong> CleanM machine cleaner<br />

(Art. No. 140119) or a mild soap and a damp cloth. Do not use household<br />

cleaners. These often contain chemicals which can damage the plastic parts.<br />

Never use petrol, turpentine, thinner or similar products to clean plastic parts.<br />

Make sure that liquids never get inside the pipe cutting machine.<br />

4.2. Inspection / maintenance<br />

WARNING<br />

Pull out the mains plug before carrying out maintenance or repair work!<br />

This work may only be performed by qualified personnel.<br />

The gear of <strong>REMS</strong> <strong>Cento</strong> and <strong>REMS</strong> Due<strong>Cento</strong> is maintenance-free. It runs<br />

in a life-long grease filling and therefore needs no lubrication. The motor has<br />

carbon brushes. These are subject to wear and must therefore by checked and<br />

changed by qualified specialists or an authorised customer service workshop<br />

from time to time. Only use original <strong>REMS</strong> carbon brushes. See also page 5.<br />

Behaviour in the event of faults.<br />

3.1. Work procedure<br />

CAUTION<br />

Support longer pipes (see 2.2)! The cut pipe sections can fall to the floor<br />

immediately after being cut!<br />

Move the cutting wheel drive (1) forwards by turning the feed lever (6) until the<br />

pipe to be cut (5) can be placed on the rollers (3). Outside burr (sawing burr)<br />

must be removed from the pipe otherwise the rollers will be damaged. Make<br />

sure that the <strong>REMS</strong> cutting wheel (2) suitable for the pipe to be cut is selected/<br />

fitted. Do not allow the pipe (5) to knock against the cutting wheel (2) when<br />

inserting, the cutting wheel could be damaged. Mark the cutting point on the<br />

pipe and position it to the cutting wheel. Press the safety foot switch (7). Turn<br />

the feed lever (6) until the cutting wheel sets the pipe in rotation. Then turn the<br />

feed lever (6) approx. 30° further (corresponds to the hour distance on the dial<br />

of a clock). Let the pipe turn about another 2 turns without further feeding before<br />

re-engaging by a 30° turn of the feed lever. Repeat the process.<br />

NOTICE<br />

If the cutting wheel breaks during cutting, the same groove in the pipe to be<br />

cut may not be used after changing the cutting wheel. The changed cutting<br />

wheel will be damaged by fragments left in the groove.<br />

3.2. Supporting the material<br />

Longer pipes must be supported, on both sides of the pipe cutting machine if<br />

necessary (see 2.2).<br />

3.3. Deburring<br />

Deburring of inside of pipe<br />

With the <strong>REMS</strong> REG 28 – 108 (12) pipes of Ø 28 – 108 mm, Ø ¾ – 4” can be<br />

deburred on the inside. The <strong>REMS</strong> REG 28 – 108 is driven by a cutting wheel<br />

(Fig. 3). The cutting wheels <strong>REMS</strong> cutting wheel Cu-INOX (Art. No. 845050),<br />

<strong>REMS</strong> cutting wheel Cu (Art. No. 845053) and <strong>REMS</strong> cutting wheel RF (Art.<br />

No. 845054) can be used for driving. Use one or more <strong>REMS</strong> Herkules 3B (Art.<br />

No. 120100), <strong>REMS</strong> Herkules Y (Art. No. 120130) or height adjustable pipe<br />

rest(s) (10) for deburring longer pipes.