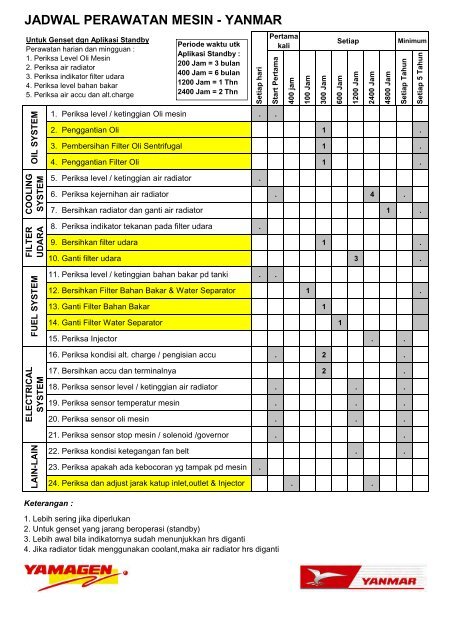

JADWAL PERAWATAN MESIN - YANMAR

JADWAL PERAWATAN MESIN - YANMAR

JADWAL PERAWATAN MESIN - YANMAR

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>JADWAL</strong> <strong>PERAWATAN</strong> <strong>MESIN</strong> - <strong>YANMAR</strong><br />

Untuk Genset dgn Aplikasi Standby<br />

Perawatan harian dan mingguan :<br />

1. Periksa Level Oli Mesin<br />

2. Periksa air radiator<br />

3. Periksa indikator filter udara<br />

4. Periksa level bahan bakar<br />

5. Periksa air accu dan alt.charge<br />

Periode waktu utk<br />

Aplikasi Standby :<br />

200 Jam = 3 bulan<br />

400 Jam = 6 bulan<br />

1200 Jam = 1 Thn<br />

2400 Jam = 2 Thn<br />

Setiap hari<br />

Pertama<br />

kali<br />

Start Pertama<br />

400 jam<br />

100 Jam<br />

300 Jam<br />

Setiap<br />

600 Jam<br />

1200 Jam<br />

2400 Jam<br />

4800 Jam<br />

Minimum<br />

Setiap Tahun<br />

Setiap 5 Tahun<br />

OIL SYSTEM<br />

COOLING<br />

SYSTEM<br />

1. Periksa level / ketinggian Oli mesin . .<br />

2. Penggantian Oli 1 .<br />

3. Pembersihan Filter Oli Sentrifugal 1 .<br />

4. Penggantian Filter Oli 1 .<br />

5. Periksa level / ketinggian air radiator .<br />

6. Periksa kejernihan air radiator . 4 .<br />

7. Bersihkan radiator dan ganti air radiator 1 .<br />

FILTER<br />

UDARA<br />

8. Periksa indikator tekanan pada filter udara .<br />

9. Bersihkan filter udara 1 .<br />

10. Ganti filter udara 3 .<br />

FUEL SYSTEM<br />

11. Periksa level / ketinggian bahan bakar pd tanki . .<br />

12. Bersihkan Filter Bahan Bakar & Water Separator 1 .<br />

13. Ganti Filter Bahan Bakar 1<br />

14. Ganti Filter Water Separator 1<br />

15. Periksa Injector . .<br />

16. Periksa kondisi alt. charge / pengisian accu . 2 .<br />

ELECTRICAL<br />

SYSTEM<br />

17. Bersihkan accu dan terminalnya 2 .<br />

18. Periksa sensor level / ketinggian air radiator . . .<br />

19. Periksa sensor temperatur mesin . . .<br />

20. Periksa sensor oli mesin . . .<br />

21. Periksa sensor stop mesin / solenoid /governor . .<br />

LAIN-LAIN<br />

22. Periksa kondisi ketegangan fan belt . .<br />

23. Periksa apakah ada kebocoran yg tampak pd mesin .<br />

24. Periksa dan adjust jarak katup inlet,outlet & Injector . .<br />

Keterangan :<br />

1. Lebih sering jika diperlukan<br />

2. Untuk genset yang jarang beroperasi (standby)<br />

3. Lebih awal bila indikatornya sudah menunjukkan hrs diganti<br />

4. Jika radiator tidak menggunakan coolant,maka air radiator hrs diganti

MAINTENANCE SCHEDULE<br />

First<br />

time at<br />

Interval<br />

At least<br />

LUBRICATING OIL SYSTEM, page 30<br />

1. Checking oil level • •<br />

2. Oil change •1 •<br />

3. Cleaning oil cleaner •1 •<br />

4. Changing the oil filter and filter for closed crankcase<br />

•1 •<br />

ventilation<br />

COOLING SYSTEM, page 36<br />

5. Checking coolant level •<br />

6. Checking coolant • •3 •<br />

7. Cleaning cooling system •1 •<br />

AIR CLEANER, page 42<br />

8. Test reading low pressure indicator •<br />

9. Cleaning the coarse cleaner •1 •<br />

10. Cleaning or changing filter element •2 •<br />

11. Changing safety cartridge • •<br />

FUEL SYSTEM, page 44<br />

12. Checking fuel level • •<br />

13. Changing the main filter and water separating filter •1 •<br />

ELECTRICAL SYSTEM, page 46<br />

14. Checking electrolyte level in batteries • • •<br />

15. Checking state of charge in batteries • • •<br />

16. Cleaning batteries • •<br />

17. Checking coolant level monitor • •<br />

MISCELLANEOUS, page 48<br />

18. Checking drive belt • •<br />

19. Look for leakage, rectify as necessary •<br />

20. Checking/adjusting valve clearances • •<br />

21. Checking/adjusting PDE injector rocker arms • •<br />

Daily<br />

First start<br />

400 h<br />

200 h<br />

400 h<br />

1200 h<br />

2400 h<br />

4800 h<br />

Annually<br />

Every 5th year<br />

1. More often if required.<br />

2. Earlier if low pressure indicator shows red.<br />

3. If inhibitor has not been topped up for five years, the coolant should be changed.

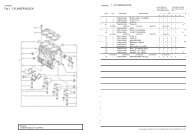

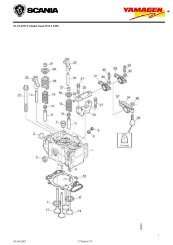

Lepaskan mur dan angkat<br />

cover oil cleaner.<br />

Perhatian : Hati-hati pada saat<br />

membuka tutup, kemungkinan<br />

oli masih panas.<br />

Cuci semua part tersebut<br />

didalam solar.<br />

Pasangkan kembali O-ring ke<br />

mangkuk rotor.<br />

Pastikan O-ring tidak rusak.<br />

Ganti jika memang diperlukan.<br />

Tarik rotor dan longgarkan<br />

mur pada mangkuk rotor<br />

sebanyak 3 putaran.<br />

Memasang rotor kembali.<br />

Kencangkan kembali mur<br />

pelan-pelan dengan tangan.<br />

Jika mur macet : jepitkan<br />

mur (bukan rotornya) pada<br />

ragum dan putar rotor<br />

sebanyak 3 putaran<br />

menggunakan tangan atau<br />

dengan memakai obeng.<br />

Sesuaikan kembali posisi<br />

rotor.<br />

Pastikan bahwa rotor dapat<br />

berputar dengan mudah.<br />

Ketuk mur pelan-pelan dengan<br />

menggunakan tangan atau<br />

palu plastik, untuk<br />

melepaskan mangkuk rotor<br />

dari Bottom plate.<br />

Lepaskan mur dan angkat<br />

mangkuk rotor.<br />

Ungkit pelan-pelan untuk<br />

melepaskan saringan dari<br />

Bottom plate.<br />

Bersihkan endapan kotoran di<br />

dalam mangkuk rotor. Jika tidak<br />

ada endapan, hal ini menandakan<br />

bahwa cleaner tidak berfungsi<br />

dengan baik.<br />

Jika tebal endapan melebihi 20mm :<br />

Harus lebih sering dibersihkan !<br />

Pastikan O-ring mangkuk rotor<br />

tidak rusak. Ganti jika O-ring<br />

mengeras atau rusak.<br />

Tutup mangkuk dan kencangkan<br />

mur.<br />

Jika mur dikencangkan<br />

memakai alat, hal ini dapat<br />

merusak shaft rotor, mur dan<br />

mangkuk rotor.<br />

Rotor akan terus berputar<br />

beberapa saat setelah mesin<br />

dimatikan.<br />

Matikan mesin jika suhu rotor<br />

memanas.<br />

Dengarkan suara desingan dari<br />

rotor atau rasakan getaran dari<br />

bagian luar cleaner.<br />

Rotor normalnya terus berputar<br />

selama 30-60 detik setelah mesin<br />

dihentikan.<br />

Jika tidak, bongkar dan periksa !<br />

PERHATIAN : BERSIHKAN OIL CLEANER SECARA RUTIN BERSAMAAN DENGAN PENGGANTIAN OLI

3. Every 400 hours:<br />

CLEANING THE OIL CLEANER<br />

(at same time as an oil change)<br />

- Clean the cover. Unscrew the nut and remove the cover.<br />

Open the cap carefully.<br />

The oil may be hot.<br />

- Lift out the rotor and loosen the nut on the rotor bowl three turns.<br />

- If the nut is jammed:<br />

Clamp the nut, absolutely not the rotor, in a vice and turn the rotor three<br />

turns by hand or with a screwdriver.<br />

- Tap the nut lightly with your hand or a plastic hammer, to detach the<br />

rotor bowl from the bottom plate.<br />

- Unscrew the nut and remove the rotor bowl.<br />

- Remove the strainer located on the rotor. If the strainer is stuck, you can<br />

prise its bottom edge carefully until it comes loose from the bottom<br />

plate.<br />

- Scrape off the deposits from the inside of the rotor bowl. If there are no<br />

deposits, this indicates that the cleaner is not working properly.<br />

- If the deposits are thicker than 20 mm: clean more often.

- Wash all parts in diesel oil.<br />

- Make sure the nozzles on the rotor are not blocked or damaged.<br />

- Make sure the bearings are not damaged.<br />

- Fit the O-ring in the rotor bowl. Make sure it is not damaged.<br />

Change if necessary.<br />

- Reassemble the rotor.<br />

- Tighten the rotor nut firmly by hand.<br />

- Make sure the shaft is not loose. If it is loose, use locking compound<br />

561 200 and tighten it to a torque of 34 Nm.<br />

- Refit the rotor.<br />

- Check that it rotates easily by rotating it manually.<br />

- Check that the O-ring in the bowl is undamaged.<br />

A hardened or damaged O-ring must be changed.<br />

- Screw on the bowl and tighten the lock nut to 15 Nm.<br />

Tighten the nut carefully so as not to damage the rotor shaft, nut or bowl.<br />

Functional inspection<br />

The rotor rotates very fast and should continue to rotate when the engine has<br />

stopped.<br />

- Stop the engine when it is warm.<br />

- Listen for a whirring sound from the rotor or feel whether the cleaner<br />

housing is vibrating.<br />

The rotor normally continues spinning for 30 - 60 seconds after the engine<br />

has stopped.<br />

If it does not: dismantle it and inspect the component parts.