9. Schaltgerät - Kessel

9. Schaltgerät - Kessel

9. Schaltgerät - Kessel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

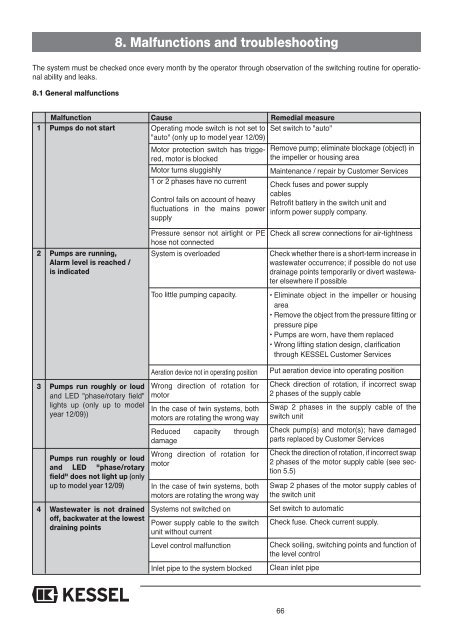

8. Malfunctions and troubleshootingThe system must be checked once every month by the operator through observation of the switching routine for operationalability and leaks.8.1 General malfunctionsMalfunction Cause Remedial measure1 Pumps do not start Operating mode switch is not set to Set switch to "auto""auto" (only up to model year 12/09)Motor protection switch has triggered,motor is blockedMotor turns sluggishly1 or 2 phases have no currentControl fails on account of heavyfluctuations in the mains powersupplyRemove pump; eliminate blockage (object) inthe impeller or housing areaMaintenance / repair by Customer ServicesCheck fuses and power supplycablesRetrofit battery in the switch unit andinform power supply company.2 Pumps are running,Alarm level is reached /is indicatedPressure sensor not airtight or PEhose not connectedSystem is overloadedToo little pumping capacity.Check all screw connections for air-tightnessCheck whether there is a short-term increase inwastewater occurrence; if possible do not usedrainage points temporarily or divert wastewaterelsewhere if possible• Eliminate object in the impeller or housingarea• Remove the object from the pressure fitting orpressure pipe• Pumps are worn, have them replaced• Wrong lifting station design, clarificationthrough KESSEL Customer Services3 Pumps run roughly or loudand LED "phase/rotary field"lights up (only up to modelyear 12/09))3 Pumps run roughly or loudand LED "phase/rotaryfield" does not light up (onlyup to model year 12/09)4 Wastewater is not drainedoff, backwater at the lowestdraining pointsAeration device not in operating positionWrong direction of rotation formotorIn the case of twin systems, bothmotors are rotating the wrong wayReduced capacity throughdamageWrong direction of rotation formotorIn the case of twin systems, bothmotors are rotating the wrong waySystems not switched onPower supply cable to the switchunit without currentLevel control malfunctionInlet pipe to the system blockedPut aeration device into operating positionCheck direction of rotation, if incorrect swap2 phases of the supply cableSwap 2 phases in the supply cable of theswitch unitCheck pump(s) and motor(s); have damagedparts replaced by Customer ServicesCheck the direction of rotation, if incorrect swap2 phases of the motor supply cable (see section5.5)Swap 2 phases of the motor supply cables ofthe switch unitSet switch to automaticCheck fuse. Check current supply.Check soiling, switching points and function ofthe level controlClean inlet pipe66