LSB german_french_english 771076129 - Water Solutions

LSB german_french_english 771076129 - Water Solutions

LSB german_french_english 771076129 - Water Solutions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

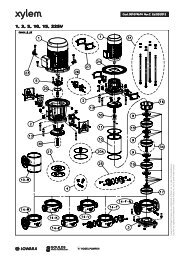

Installation, Operation and Maintenance InstructionModel <strong>LSB</strong>3. Removal of mech. sealFor that purpose use the appropriate sectional drawingand the enclosed data sheet of the mech. seal.Remove and disassemble the pump acc. to theInstallation, Operation and MaintenanceInstructions including chapter 8.6.Remove fixing ring (527) (if existing) and rotatingpart of the mech. seal (433) from shaft (210).Refer to the enclosed data sheet of the mech.seal, if set screws are to be loosened at the mech.seal at first. Remove stationary part of the mech. seal (433)out of the casing cover (161).4. Installation of a mech. sealFor that purpose use the sectional drawing and datasheet of the mech. seal.It is only allowed to install mech. seals, whichhave a certificate of Conformity acc. theDirective 94/9/EG.On changing the mech. seal type resp. themech. seal manufacturer the data regardingmax. operating temperature of the pumpedmedium and temperature class must bechecked again.Pay attention to the utmost cleanness!Especially the seal faces must be clean, dry andundamaged. Don´t apply lubrication on the sealfaces of the mech. seal.If a lubricant is provided with the replacementmech. seal, you should use this.Use mineral grease or oil only, if you arecompletely sure that the elastomers of themech. seal are oil resistant. Use no silicone.Use only lubricants when you are sure thatthere can´t occur any dangerous reactionsbetween the pumpage and the lubricant.Make all required parts available, so thatassembly can be completed quickly. Thelubricants are only effective for a short time.After that the axial movability and, thus, theautomatic adjustment of the elastomeres is lost.Don´t push elastomers over sharp edges. Ifnecessary use mounting devices.Clean drilling for stationary seal rng (∅d 7 ) in thecasing cover (161) and surface of shaft (210).The reuse of mech. seals, which have alreadybeen used for a longer time, can lead to leakingat the seal faces after reinstallation. Thereforethe replacement of the mech. seal through anew one is recommended. The dismountedmechanical seal can be reconditioned by themanufacturer and serve as a replacementmech.seal.Push the rotating unit of the mech. seal on theshaft (210).Complete the face on the impeller side of themech. seal exactly with the shaft (measure l 1K ).For mech. seals without own set screws the fixingring (527) serves as a stop.Push mech. seals with bellows in such a way,that the bellow is compressed and not stretched(danger of tearing apart!).Further mounting and installation of the pumpreferring to the repair instructions.Press the stationary part of the mech. seal in thecasing cover (161). For this you can eventuallyuse a stamp with a soft surface. Unequal load canlead to cracking of the seal face.Don´t damage seal face!Pay attention that the stationary ring is in solidcontact with the casing cover. The seal face mustbe installed perpendicular to the shaft.If a pin (560) is existing, be careful that it fits intothe slot of the mech. sealing, without touching themech. seal.<strong>LSB</strong> 100-<strong>english</strong> page 91 Revision 02Artikel Nr. <strong>771076129</strong> Ausgabe 01/2010