KCM K-TRON Product Specification K-Tron Control Module S ...

KCM K-TRON Product Specification K-Tron Control Module S ...

KCM K-TRON Product Specification K-Tron Control Module S ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

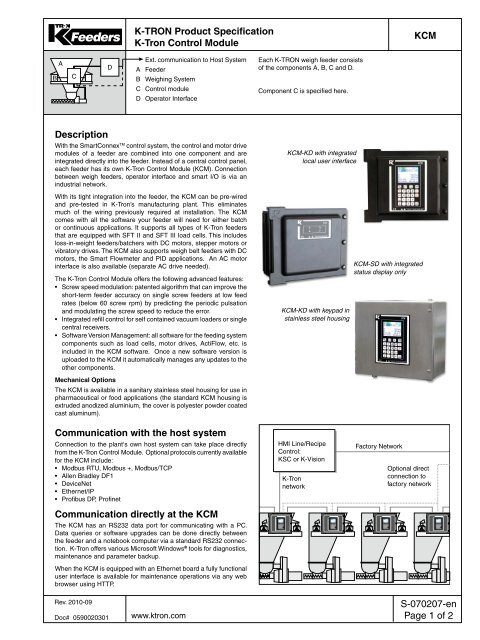

<strong>KCM</strong>CAUTION - Disconnect power before opening.115/230 VAC 50/60 HZ, 2000 Watts (Max)<strong>KCM</strong>CAUTION - Disconnect power before opening.115/230 VAC 50/60 HZ, 2000 Watts (Max)<strong>KCM</strong>CAUTION - Disconnect power before opening.115/230 VAC 50/60 HZ, 2000 Watts (Max)<strong>KCM</strong>CAUTION - Disconnect power before opening.115/230 VAC 50/60 HZ, 2000 Watts (Max)K-<strong>TRON</strong> <strong>Product</strong> <strong>Specification</strong>K-<strong>Tron</strong> <strong>Control</strong> <strong>Module</strong><strong>KCM</strong>BACDExt. communication to Host SystemA FeederB Weighing SystemC <strong>Control</strong> moduleD Operator InterfaceEach K-<strong>TRON</strong> weigh feeder consistsof the components A, B, C and D.Component C is specified here.DescriptionWith the SmartConnex TM control system, the control and motor drivemodules of a feeder are combined into one component and areintegrated directly into the feeder. Instead of a central control panel,each feeder has its own K-<strong>Tron</strong> <strong>Control</strong> <strong>Module</strong> (<strong>KCM</strong>). Connectionbetween weigh feeders, operator interface and smart I/O is via anindustrial network.With its tight integration into the feeder, the <strong>KCM</strong> can be pre-wiredand pre-tested in K-<strong>Tron</strong>’s manufacturing plant. This eliminatesmuch of the wiring previously required at installation. The <strong>KCM</strong>comes with all the software your feeder will need for either batchor continuous applications. It supports all types of K-<strong>Tron</strong> feedersthat are equipped with SFT II and SFT III load cells. This includesloss-in-weight feeders/batchers with DC motors, stepper motors orvibratory drives. The <strong>KCM</strong> also supports weigh belt feeders with DCmotors, the Smart Flowmeter and PID applications. An AC motorinterface is also available (separate AC drive needed).The K-<strong>Tron</strong> <strong>Control</strong> <strong>Module</strong> offers the following advanced features:• Screw speed modulation: patented algorithm that can improve theshort-term feeder accuracy on single screw feeders at low feedrates (below 60 screw rpm) by predicting the periodic pulsationand modulating the screw speed to reduce the error.• Integrated refill control for self contained vacuum loaders or singlecentral receivers.• Software Version Management: all software for the feeding systemcomponents such as load cells, motor drives, ActiFlow, etc. isincluded in the <strong>KCM</strong> software. Once a new software version isuploaded to the <strong>KCM</strong> it automatically manages any updates to theother components.<strong>KCM</strong>-KD with integratedlocal user interface<strong>KCM</strong>-KD with keypad instainless steel housing<strong>KCM</strong>-SD with integratedstatus display onlyMechanical OptionsThe <strong>KCM</strong> is available in a sanitary stainless steel housing for use inpharmaceutical or food applications (the standard <strong>KCM</strong> housing isextruded anodized aluminium, the cover is polyester powder coatedcast aluminum).Communication with the host systemConnection to the plant‘s own host system can take place directlyfrom the K-<strong>Tron</strong> <strong>Control</strong> <strong>Module</strong>. Optional protocols currently availablefor the <strong>KCM</strong> include:• Modbus RTU, Modbus +, Modbus/TCP• Allen Bradley DF1• DeviceNet• Ethernet/IP• Profibus DP, ProfinetHMI Line/Recipe<strong>Control</strong>:KSC or K-VisionK-<strong>Tron</strong>networkFactory NetworkOptional directconnection tofactory networkCommunication directly at the <strong>KCM</strong>The <strong>KCM</strong> has an RS232 data port for communicating with a PC.Data queries or software upgrades can be done directly betweenthe feeder and a notebook computer via a standard RS232 connection.K‐<strong>Tron</strong> offers various Microsoft Windows ® tools for diagnostics,maintenance and parameter backup.When the <strong>KCM</strong> is equipped with an Ethernet board a fully functionaluser interface is available for maintenance operations via any webbrowser using HTTP.Rev. 2010-09Doc# 0590020301www.ktron.comS-070207-enPage 1 of 2