SPLIT-SYSTEM - Rhoss

SPLIT-SYSTEM - Rhoss

SPLIT-SYSTEM - Rhoss

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

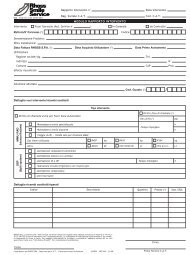

SECTION II: INSTALLATION AND MAINTENANCE<br />

II.2.6<br />

ELECTRICAL CONNECTIONS<br />

IMPORTANT!<br />

The electrical connections must be made by<br />

specialist personnel in compliance with laws and<br />

regulations in force in the country of installation.<br />

RHOSS shall not be held liable for damage to<br />

persons or property caused by incorrect electrical<br />

connection.<br />

DANGER!<br />

Always install an automatic main switch (IG) in a<br />

protected area near the appliance with a<br />

characteristic delayed curve, with sufficient<br />

capacity and breaking power. There should be a<br />

minimum distance of 3 mm between the contacts.<br />

The automatic main switch (IG) must be placed up<br />

the line from the entire system in order to cut off<br />

the electrical power supply to the main unit and to<br />

all the accessories connected to it which make up<br />

the entire system.<br />

Earth connection is compulsory by law to ensure<br />

user safety while the machine is in use.<br />

Strip off the sheathing only in the immediate area of the terminals. Use<br />

suitable cable-ends for the terminals involved.<br />

After inserting the cable-end into the terminal, tighten the screws with a<br />

screwdriver without applying excessive force: at the end of the<br />

operation, pull gently on the cables to check that they are properly tight.<br />

Use the cable clamp inside the electronic board compartment to lock<br />

the cables.<br />

II.2.6.1<br />

Connecting the power supply<br />

Check that the voltage and the frequency of the electrical supply<br />

correspond to 230V (±10%) single phase at 50 Hz; that the available<br />

power is sufficient for the running the equipment; and that the supply<br />

cables are of adequate section for the maximum current which will be<br />

required.<br />

Make sure that the electrical supply system complies with current<br />

national safety regulations.<br />

When connecting the unit to the electricity network, use flexible bipolar<br />

wiring + earth, 1.5 mm² section with polychloroprene sheath of no<br />

lighter than H05RN-F. The earth conductor must be longer than the<br />

other conductors in order to ensure that in the event of the cable<br />

clamping device becoming slack, it will be the last to come under strain.<br />

The electrical connection wires must be made to pass through conduits<br />

with a sufficient level of protection, which must be firmly secured to the<br />

floor or the walls.<br />

Special attention must be given to any sharp edges, burrs, rough<br />

surfaces in general or threads so as to guarantee that the conductor<br />

insulation is not damaged.<br />

When making connections, removing the internal unit casing and the<br />

external unit side door (refrigerant connections side), insert the electric<br />

wires into the terminals in keeping with the wiring diagrams applied on<br />

the<br />

air conditioning units themselves.<br />

In the event that the unit is mounted on a metal surface, earth<br />

connections must be made in compliance with local regulations.<br />

The connections must be made in compliance with the wiring diagrams<br />

in the enclosed documents.<br />

The electrical line is normally around 2 m longer than the refrigerant<br />

line.<br />

Each internal unit is fitted with a power supply cable with plug.<br />

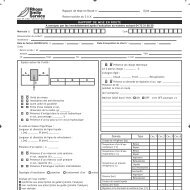

II.3<br />

START-UP INSTRUCTIONS<br />

IMPORTANT!<br />

Machine commissioning or the first start up (where<br />

required) must be carried out by skilled personnel<br />

qualified to work on this type of product.<br />

DANGER!<br />

Before starting up, make sure that the installation<br />

and electrical connections have been carried out in<br />

accordance with the instructions in this manual.<br />

Also make sure that there are no unauthorised<br />

persons in the vicinity of the machine during the<br />

above operations.<br />

4. the electrical connections are correct;<br />

5. the screws holding the cables are well tightened;<br />

6. the supply voltage is as required;<br />

It is advisable to run the unit at maximum speed for several hours.<br />

II.4<br />

II.4.1<br />

EXTRAORDINARY MAINTENANCE<br />

DANGER!<br />

Maintenance work must only be carried out by<br />

qualified technicians authorised to work on airconditioning<br />

and refrigerant systems.<br />

Use suitable work gloves.<br />

DANGER!<br />

Always turn off the automatic main switch (IG) for<br />

the protection of the entire system before doing any<br />

maintenance work, even if it is only an inspection.<br />

Make sure that no one accidentally supplies power<br />

to the machine – lock the automatic main switch in<br />

the off position.<br />

DANGER!<br />

Beware of the hot surfaces inside the machine.<br />

Do not introduce pointed objects through the air<br />

delivery intake grilles.<br />

REFRIGERANT FLUID CHARGE CONTROL<br />

Fit a pressure gauge on the test point on the outlet side and another on<br />

the test point on the suction side. Start up the unit and check both<br />

pressure readings once the pressure has stabilised.<br />

II.4.2<br />

CHECKING FOR ABSENCE OF<br />

REFRIGERANT FLUID LEAKS<br />

Use a specific leak detector or soapy water to check the refrigerant<br />

circuit and make sure that leaks do not exceed 5 g/year.<br />

II.4.3<br />

CHECKING HEAT EXCHANGER<br />

CLEANLINESS<br />

Switch off the unit, check the heat exchanger and, depending on its<br />

condition, proceed as follows:<br />

• remove any foreign bodies from the finned surface which may<br />

obstruct air flow;<br />

• clean off the dust with a jet of compressed air;<br />

• wash and brush, gently, with water;<br />

• dry with a jet of compressed air;<br />

II.4.4<br />

CHECKING CONDENSATION DRAIN<br />

CLEANLINESS<br />

With the unit switched off, check the cleanliness of the condensation<br />

drain tube.<br />

II.4.5<br />

CHECKING THE ELECTRIC CIRCUIT<br />

The following checks are recommended on the electrical circuit:<br />

• check the unit power absorption using a clip-on meter and compare<br />

the reading with the values shown in Appendix A1;<br />

• inspect and, if necessary, tighten the electrical contacts and<br />

terminals.<br />

II.4.6<br />

COMPONENT REPLACEMENT<br />

INSTRUCTIONS<br />

Before replacing components, discharge coolant from both the high and<br />

low-pressure sides. If the coolant is discharged from the high-pressure<br />

side only, the compressor may close the circuit thereby preventing<br />

pressure equalisation. In this way, the low-pressure side of the casing<br />

and the suction line may remain pressurised. If that happens, if you<br />

apply a brazing torch to one of the low-pressure components of the<br />

system, the pressurised mixture of refrigerant and oil could blow out of<br />

the circuit and ignite on contact with the brazing torch. To avoid this<br />

hazard, make sure both the high and low pressure sides of the circuit<br />

have been correctly depressurised before applying brazing torches.<br />

Any topping up of the system on units with R410A refrigerant must be<br />

carried out in the liquid phase, piping it from a cylinder so as not to alter<br />

its composition.<br />

II.3.1<br />

CONTROLS BEFORE START-UP<br />

Before starting up the unit, make sure that:<br />

1. the unit is positioned correctly;<br />

2. the system flow, return and condensation drainage pipes are<br />

correctly connected;<br />

3. the exchanger is clean;<br />

34