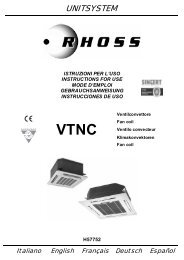

SPLIT-SYSTEM - Rhoss

SPLIT-SYSTEM - Rhoss

SPLIT-SYSTEM - Rhoss

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

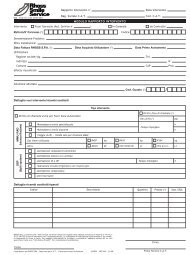

SECTION II: INSTALLATION AND MAINTENANCE<br />

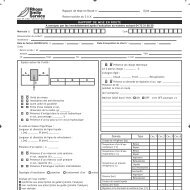

Left<br />

Back<br />

centre<br />

Back<br />

left<br />

Towards the<br />

bottom left<br />

Use the support<br />

brackets.<br />

Fig. 7<br />

Right<br />

Back<br />

right<br />

• make the refrigerant, electric and condensation drain connections as<br />

specified in the “Refrigerant connections” and “Electric connections”<br />

paragraphs;<br />

• before removing the casing, check that the condensation drain is<br />

working properly.<br />

II.2.4<br />

Towards the<br />

bottom right<br />

EXTERNAL UNIT INSTALLATION<br />

Fig. 4<br />

Secure the unit to the support plate,<br />

making sure that the refrigerant lines, the<br />

electric cables and the condensation drain<br />

pipe run through the hole in the wall.<br />

Fig. 5<br />

The external unit must be installed outdoors, respecting the minimum<br />

technical clearance distances in order to allow the passage of air and<br />

the execution of any necessary maintenance operations.<br />

Water is produced in heat pump models, during the heating mode<br />

defrosting phase. This water needs to be collected and channelled to<br />

the drain.<br />

II.2.5<br />

REFRIGERANT CONNECTIONS<br />

IMPORTANT!<br />

The refrigerant connections must be made by<br />

specialist personnel in compliance with laws and<br />

regulations in force in the country of installation.<br />

RHOSS S.p.A. shall not be held liable for damage<br />

to persons or property caused by incorrect<br />

connections.<br />

Copper pipes for cooling systems must be used for refrigerant lines,<br />

respecting the lengths and diameters recommended in the enclosed<br />

documents. Make sure there are no impurities or moisture inside the<br />

pipes as this is extremely harmful for the refrigerant circuit. The<br />

refrigerant lines must each be insulated individually with lagging of<br />

closed-cell expanded material.<br />

A 65 mm hole is sufficient for the passage of the pipes through the<br />

walls.<br />

Proceed as follows to prepare the pipes.<br />

Cut the connection pipes at the set distance, leaving a certain safety<br />

margin and bearing in mind the tips indicated in Fig. 8.<br />

Right<br />

Wrong<br />

Make sure that the unit is<br />

level.<br />

Fig. 6<br />

Eliminate any cutting burr while keeping the pipe opening facing<br />

downwards to prevent the ingress of debris.<br />

Fig. 8<br />

The consistency of the wall must be sufficient for the weight of the unit<br />

and must not permit the transmission of noise or vibrations.<br />

Particular care must be taken when selecting the area, so that the air<br />

flow does not disturb the neighbours.<br />

Cover the refrigerant lines with suitable<br />

insulation and then insert the nozzles which<br />

had previously been removed from the unit<br />

connections.<br />

Fig. 9<br />

32