KESSEL-Kleinkläranlagen INNO-CLEAN® - Kessel Design

KESSEL-Kleinkläranlagen INNO-CLEAN® - Kessel Design

KESSEL-Kleinkläranlagen INNO-CLEAN® - Kessel Design

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

7. Maintenance<br />

7.1 Maintenance Preliminary sedimentation + aeration<br />

Note: Please find out who is responsible for the maintenance<br />

of small sewage treatment plants in your area.<br />

For maintenance purposes, work and inspections must be<br />

carried out by the service staff at intervals of approx. 6<br />

months (at least twice every year). The plant components inside<br />

the tank are easy to maintain. The examination results<br />

of the purified sewage are requested by the Lower Water<br />

Authority as proof of the purification performance (operations<br />

diary).<br />

We recommend to at least carry out the following tasks:<br />

• Inspection of the operations diary for regular entry of the<br />

operating times.<br />

• Checking the plant's state of repair, e.g.: accessibility, ventilation,<br />

screw connections, hoses.<br />

• Checking the free mobility of the floater.<br />

• Function check of all mechanical, electrical and other plant<br />

parts, in particular of the compressor and ventilation facilities.<br />

• Function check of the alarm function and control for possible<br />

faults or incidents.<br />

• Inspection of the air syphons (clear water, feeding and<br />

sludge syphon) for clogging. For this purpose it may be necessary<br />

to remove and clean the air syphons. To do so,<br />

unlock the snap closing on the syphon and pull out the<br />

grey air hose. Afterwards open the red locking lever and<br />

pull the air syphon out of the purification tower. Thus, the<br />

syphon incl. the inside hose can be cleaned of any dirt. Afterwards<br />

return the lever into the appropriate position and<br />

connect it correctly.<br />

• If an inadequate ventilation pattern makes it necessary to<br />

clean or replace the aerator spark plug, the latter can be<br />

removed via the integrated guide rail on the purification<br />

tower. The aerator spark plug is located underneath the<br />

outlet pipe on the bottom of the tank. Pull out the aerator<br />

spark plug by means of the pertinent air hose. When inserting<br />

the aerator spark plug, pay attention that the integrated<br />

guide claw is placed back into the guide rail on the<br />

purification tower. The aerator spark plug must be let down<br />

to the bottom of the tank.<br />

• Performance of general cleaning work such as e.g.: removal<br />

of deposits, removal of foreign matter.<br />

• Pay attention that the floating switch is clean and free floating.<br />

• Setting optimum performance data (see table page 29) e.g.<br />

oxygen supply (~ 2 mg/l), sludge volume (300 - 500 ml/l).<br />

• Determining the sludge level inside the sludge storage and<br />

possibly initiating the sludge removal.<br />

The maintenance that is carried out must be recorded in the<br />

operations diary.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

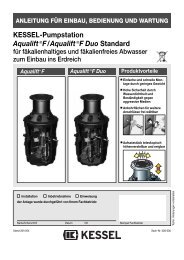

Sampling vessel<br />

Clear water syphon<br />

Feed syphon<br />

Sludge syphon<br />

Discharge pipe<br />

Snap closing<br />

Locking lever<br />

Valve block<br />

Floating switch<br />

113