KESSEL-Kleinkläranlagen INNO-CLEAN® - Kessel Design

KESSEL-Kleinkläranlagen INNO-CLEAN® - Kessel Design

KESSEL-Kleinkläranlagen INNO-CLEAN® - Kessel Design

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

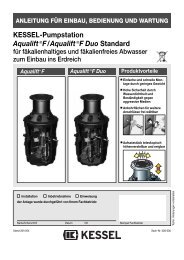

4. Installation and assembly<br />

<br />

<br />

<br />

≤ 20cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

≥ 50cm<br />

<br />

≥ 50cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

β nach<br />

DIN 4124<br />

<br />

<br />

≤ 30cm<br />

3-10cm<br />

≥ 30cm<br />

≥ 70cm<br />

Subbase: round-grain gravel (max. graining 8/16) according<br />

to DIN 4226-1 compacted with Dpr=95%<br />

Tank bed: compacted sand<br />

Tank<br />

Tank encasing: round-grain gravel (max. graining 8/16)<br />

<br />

<br />

≥ 70cm<br />

according to DIN 4226-1 compacted with Dpr=95%<br />

Area outside tank encasing: material of suitable<br />

consistence<br />

Top layer: topsoil, road surface, concrete or similar<br />

4.4 Placing<br />

The tank must be placed shock-free into the excavation pit<br />

with the aid of suitable equipment and put down onto the<br />

base bedding (see also chapter "Transport").<br />

Pay attention to direction of flow and direction of flow arrows<br />

on the tank!<br />

4.5 Filling the tank<br />

Fill tanks in both chambers with clear water (approx. 80 cm)<br />

to achieve an improved stability.<br />

4.6 Backfilling the excavation pit<br />

In general, filling the tank and backfilling the excavation pit<br />

should be carried out in parallel. The excavation pit is backfilled<br />

up to the bottom edge of inlet and drain, as well as the<br />

ventilation line and cable conduit line. The tank encasing<br />

must be produced in a width of at least 50 cm. The individual<br />

layers of the backfilling material should not exceed a<br />

height of 30 cm. They must be compacted using light compacting<br />

equipment (minimum Dpr=95%). Damage to the<br />

tank wall and a dislocation of the tanks during and after installation<br />

must be ruled out.<br />

4.7 Pipework<br />

The inlet/drain lines as well as connecting lines must be laid<br />

in a frost-free manner (see 4.2) and connected as soon as<br />

the excavation pit has been backfilled and compacted up to<br />

the bottom edge of inlet and drain line.<br />

The transition from penstocks to horizontal lines must be<br />

executed with two 45° curved fittings and an at least 250<br />

mm long connecting piece. A stilling section, the length of<br />

which corresponds to at least the tenfold of the pipeline's<br />

nominal width, must be provided upstream of the <strong>INNO</strong>-<br />

CLEAN ® tank.<br />

A cable conduit (KG pipe made of PVC-U in the dimension<br />

DN 100) must be laid as line link between control unit/ compressor<br />

and valve block /<strong>INNO</strong>-CLEAN ® tank. The empty<br />

conduit should exhibit a constant gradient of ≥ 2° in relation<br />

to the tank along its entire length. <strong>KESSEL</strong> recommends to<br />

execute the duct through the building wall in the manner of<br />

wall ducts customary in trade (see illustration).<br />

In order to seal the cable conduit inside the building the<br />

<strong>KESSEL</strong> cover (cable conduit sealing, item No. 97711)<br />

should be installed as protection against unpleasant odours.<br />

102