KESSEL-Kleinkläranlagen INNO-CLEAN® - Kessel Design

KESSEL-Kleinkläranlagen INNO-CLEAN® - Kessel Design

KESSEL-Kleinkläranlagen INNO-CLEAN® - Kessel Design

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4. Installation and assembly<br />

During the intermediate storage of the small sewage treatment<br />

plant and until completion of the installation<br />

work, suitable safeguarding measures must be taken at<br />

the building site to prevent accidents and damage to the<br />

small sewage treatment plant.<br />

The maximum clearance for plants with several tanks amounts<br />

to 3.0 m. Should this clearance be exceeded, additional<br />

hoses will be necessary.<br />

The chapter "Safety instructions" must be heeded.<br />

Installation requirements<br />

Installation must only be carried out by companies who are<br />

in possession of the technical experience, suitable implements<br />

and equipment as well as adequately trained personnel.<br />

A measurement of the soil conditions with a view to<br />

its structural suitability must have been carried out (soil classification<br />

for structural purposes DIN 18196). The maximum<br />

occurring ground water level must also be determined before<br />

the start of construction work. A sufficient drainage of<br />

seepage water is compulsory for soils that are impermeable<br />

to water. The types of loads occurring such as maximum travelling<br />

loads and installation depth must have been clarified.<br />

Brief overview installation steps (see also 4.1 to 4.12)<br />

1. Deciding on the place of installation.<br />

2. Excavating the excavation pit.<br />

3. Preparing the blinding layer (tank bed) .<br />

4. Placing the tank into the excavation pit..<br />

5. Filling all chambers of the tank halfway up with water to<br />

guarantee stability.<br />

6. Backfilling the excavation pit with gravel in layers (to<br />

below the outlet) and compacting.<br />

7. Pipe installation for the inlets and drains as well as the<br />

ventilation line and cable conduit lines.<br />

8. Laying the ventilation hose and control line inside the<br />

cable conduit.<br />

9. Attaching the attachment piece and fastening with clamping<br />

ring.<br />

10. Concluding filling of the tank.<br />

11. Installing and connecting wall bracket, compressor and<br />

control.<br />

12. Commissioning the plant (see chapter 5).<br />

4.1 Place of installation<br />

Immediately before placing the tank into the excavation pit,<br />

the technical expert of the company that has been commissioned<br />

to carry out the installation has to check and certify<br />

the following:<br />

- The sound condition of the tank wall;<br />

- The proper condition of the excavation pit with a view to<br />

its dimensions and base bedding;<br />

- Consistence of the filling material graining.<br />

The clearance between control unit and tank may amount<br />

to a maximum of 12.6 m (option: 30 m - hose package =<br />

clearance 27.5 m). If this proves to be insufficient, the control<br />

unit and the compressor can be installed inside an optional<br />

control cabinet.<br />

➁<br />

➀<br />

➁<br />

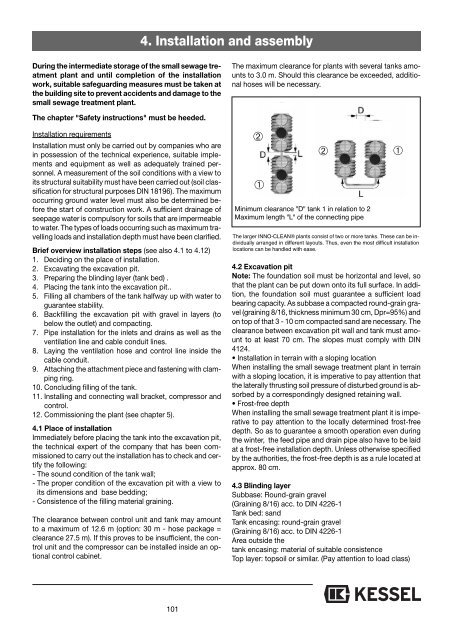

Minimum clearance "D" tank 1 in relation to 2<br />

Maximum length "L" of the connecting pipe<br />

➀<br />

The larger <strong>INNO</strong>-<strong>CLEAN®</strong> plants consist of two or more tanks. These can be individually<br />

arranged in different layouts. Thus, even the most difficult installation<br />

locations can be handled with ease.<br />

4.2 Excavation pit<br />

Note: The foundation soil must be horizontal and level, so<br />

that the plant can be put down onto its full surface. In addition,<br />

the foundation soil must guarantee a sufficient load<br />

bearing capacity. As subbase a compacted round-grain gravel<br />

(graining 8/16, thickness minimum 30 cm, Dpr=95%) and<br />

on top of that 3 - 10 cm compacted sand are necessary. The<br />

clearance between excavation pit wall and tank must amount<br />

to at least 70 cm. The slopes must comply with DIN<br />

4124.<br />

• Installation in terrain with a sloping location<br />

When installing the small sewage treatment plant in terrain<br />

with a sloping location, it is imperative to pay attention that<br />

the laterally thrusting soil pressure of disturbed ground is absorbed<br />

by a correspondingly designed retaining wall.<br />

• Frost-free depth<br />

When installing the small sewage treatment plant it is imperative<br />

to pay attention to the locally determined frost-free<br />

depth. So as to guarantee a smooth operation even during<br />

the winter, the feed pipe and drain pipe also have to be laid<br />

at a frost-free installation depth. Unless otherwise specified<br />

by the authorities, the frost-free depth is as a rule located at<br />

approx. 80 cm.<br />

4.3 Blinding layer<br />

Subbase: Round-grain gravel<br />

(Graining 8/16) acc. to DIN 4226-1<br />

Tank bed: sand<br />

Tank encasing: round-grain gravel<br />

(Graining 8/16) acc. to DIN 4226-1<br />

Area outside the<br />

tank encasing: material of suitable consistence<br />

Top layer: topsoil or similar. (Pay attention to load class)<br />

101