Go pro. - rymca.com

Go pro. - rymca.com

Go pro. - rymca.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Go</strong> Pro.

Who is Trojan?We are the world leader in UVtechnology, serving large cities,major water bottlers, and tensof thousands of privatehomeowners. For more than 25years we have led with technologyadvances that allow us to <strong>pro</strong>videyou with <strong>com</strong>plete waterconfidence.What is UV?Ultraviolet (UV) light is at theinvisible, violet end of the lightspectrum. The water treatmentindustry uses a high-poweredform of UV light called UV-C or“germicidal UV” to disinfect water.How does UV light work?UV-C rays penetratemicroorganisms and destroy theirability to re<strong>pro</strong>duce, effectivelyrendering them harmless.It’s a simple but effective <strong>pro</strong>cess,destroying a minimum of 99.99%of harmful microorganisms,including E. coli, Cryptosporidium,and Giardia.Not only is it safe and highlyeffective, UV does not changethe taste, color, or odor of water.It simply removes the risk ofillness caused by microbialcontamination, making water safe.Why not use chlorine?Chlorine changes the taste andodor of water. Chlorination mayalso <strong>pro</strong>duce harmful by-<strong>pro</strong>ductsthat are linked to the incidenceof cancer.Who uses UVdisinfection systems?For more than 25 years,institutions, consumers andbusinesses have relied on Trojan’senvironmentally friendly UVtechnology to disinfect theirwater supplies. Top candidatesfor UV disinfection systemsinclude:• Rural homes and cottages• Nursing homes• Hospitals• Schools• Hotels• Restaurants• Resorts and holiday camps• Community water systemsPro SeriesProfessional grade equipment that redefinesreliability with rock-solid performance under allenvironmental conditions.The new TrojanUVMax Pro Series offers aunique <strong>com</strong>bination of brains and brawn,with twice the raw power of other UV systemsand the intelligence to <strong>pro</strong>vide a real-timemeasure of the delivered dose.Most importantly, we’ve drastically im<strong>pro</strong>vedthe most critical measure of a UV system’sperformance - it’s ability to deliver a constant,reliable dose.This means you can feel <strong>com</strong>fortable treatingice-cold waters and hot water recirculation lines,in a cool basement or a hot pump house!Smarter. Stronger.Count on it.Systems tested and certified by NSFInternational against NSF/ANSI Standard55 for disinfection performance, Class A.Minimum dose of 40mJ/cm²

intuitive interfacEBecause a picture is wortha thousand words.Simple connectionsWith plug-and-play colorcoded connections, it’s aseasy as “connect the dots.”Revolutionary LampTwice the powerThe new Pro Series <strong>pro</strong>ductsuse a revolutionary lamp withtwice the output of currenthigh-output lamps, giving you<strong>com</strong>pact single-lamp systemsthat are half the size of theirpredecessors. Size does matter.Twice thelife expectancyOur revolutionary new lampslast an unprecedented twoyears, reducing maintenancerequirements.

Cooler WaterThe CoolTouchsignificantly reduceswater temperatureand does not wasteany water.IntegratedFlow RestrictorAssembly issimplified by theuse of an integralflow restrictor.Combo PortsFlexibility toconnect to either1¼” NPT or1” FNPT.Simply ShockingThe plug-and-playsolenoid is equippedwith a manualoverride to makeshocking the waterlines easy.Easy Quarter-TwistAssemblyA quarter-twist to thepositive stop and you’redone. No tools, no riskof overtightening.Test of SensorOperationWith the push ofa button you canconfirm the<strong>pro</strong>per operationof the sensor.Integrated GroundLike a standard plug -no more grounding wires!

COMMcenterInformation is powerFor the first time, you can now have a real-time displayof UV dose - and a true measure of how your systemis operating. The optional COMMcenter also displaysalarm history, lamp hours, and other performanceparameters - for up to nine systems!What's more, you can have that information presentedto you where-ever you need it. The COMMcenter canbe installed at any distance from the UV system usingstandard <strong>com</strong>puter cable. Or go wireless with anoptional FCC <strong>com</strong>pliant wireless transmitter.The optional COMMcenter displays dose inreal-time and can monitor up to 9 UV systems- that’s up to 270gpm!Set the record straightData logging allows operators to demonstrate<strong>pro</strong>per system operation to regulators andconsumers. It also <strong>pro</strong>vides valuable troubleshootinginsights and allows for scheduled, <strong>pro</strong>activemaintenance.The COMMcenter can datalog directly to a <strong>com</strong>puter.Install our free MAXtrack software and get real-timemonitoring and the ability to examine alarm anddose history for any given period of time!Alternatively, simply drop-in a standard mini-SD card,like those used in digital cameras. The informationcan be viewed and analyzed using any standardspreadsheet <strong>pro</strong>gram.MAXtrack software gives you the ultimate inreal-time monitoring and data logging.

GeneralColour-coded plug and play connectionsUV intensity monitor with diagnostic testCoolTouch fanDynamic flow restrictorCommunications ports (two, RJ45)COMMcenter control packageSolenoid valveChamber materialRated service life of lampInlet and outletYesYesYesYesYesOptionalOptional316L SST2 yearsCombo1 1 /4" NPT, 1" FNPTPro20Rated flow 20 GPMat dose of (75.7 LPM)40 mJ/cm 2Electrical30 GPM(113.5 LPM)Voltage 99-264V AC 99-264V ACFrequency 50-60Hz 50-60HzMax. current 1.6 Amp 2.4 AmpMax. powerconsumptionLamp powerconsumptionPro20Pro30160 Watts 230 Watts140 Watts 200 WattsControlsAudible alarm mute buttonNew lamp buttonLamp age indicatorLamp operation indicatorBallast operation indicatorSolenoid operation indicatorFan operation indicatorSensor reading indicatorYesYesYesYesYesYesYesYesOperating ParametersMaximum operating presureMinimum operating pressure100 PSI (689 kPa)10 PSI (69 kPa)Maximum ambient air temperature 104 0 F (40 0 C)Minimum ambient air temperature 32 0 F (0 0 C)Maximum humidity 100%Maximum hardnessMaximum iron120 ppm(7 grains per gallon)0.3 ppmMinimum UVT 75%NSF/ANSI certification Standard 55Class AOther certifications3020 <strong>Go</strong>re Road London, Ontario, Canada N5V 4T7 T 519.457.3400 F 519.457.3030 www.trojanuv.<strong>com</strong>CA0015-0107 Printed in Canada. Copyright ©2007 Trojan Technologies, London, Ontario, Canada.No part of this publication may be re<strong>pro</strong>duced, stored in a retrieval system, or transmitted in any form or by any means without the written permission of Trojan Technologies. Products may be covered by one or more patents.

Application OverviewG E N E RAL I N DUSTR IALTrojan UV systems<strong>pro</strong>vide efficientdisinfection, TOCreduction, ozone &chlorine destructionfor <strong>pro</strong>cess, utilityand ultrapure waterUltraviolet Solutions for Industrial ApplicationsFull digital instrumentation <strong>pro</strong>videsinstant, at-a-glance status of keysystem information in an easy-touse,menu-driven interface. Therevolutionary “L-shaped” reactorof the TrojanUVLogic deliversmaximum efficiency. Sophisticated3-D CFD <strong>com</strong>puter modeling wasused to optimize the hydraulicsand dose delivery of the system.Ultraviolet (UV) light is well established asa fast acting, point-of-contact disinfectiontechnology for water treatment. UV, at the254 nm wavelength, penetrates the cellwalls of microorganisms and permanentlyalters their DNA structure – renderingthem inactive and unable to re<strong>pro</strong>duce.UV is also effective for reducingozone (O 3 ), chlorine and chloramines<strong>com</strong>pounds, and total organic carbon(TOC) <strong>com</strong>pounds to required levels.Comprehensive UV Product LineThe TrojanUVLogic series addresses thediverse needs of the food and beveragesector, and many other industries,including ultrapure water applications.The <strong>pro</strong>duct line includes models rangingfrom 1 to 30 lamps, with disinfectioncapabilities from 40 to 8,000 GPM(9 to 2,044 m 3 /hr) from a single reactorat 95% UVT. The TrojanUVLogicalso <strong>pro</strong>vides effective TOC reductionand ozone and chlorine/chloraminesdestruction.Sophisticated Digital InstrumentationA key feature of the TrojanUVLogic isits user-friendly, micro<strong>pro</strong>cessor-basedcontroller. The robust, versatile systemfeatures a menu-driven, digital interfaceand keypad for easy configuration, andis housed in a NEMA 4X/IP65 stainlesssteel cabinet with UL, NEN, and CErating. The sophisticated controller offers:• Discreet alarm outputs for rapid identificationand correction of system faults• Programmable inputs/outputs andremote ON/OFF control• Ability to be linked to plant SCADAsystems for integrated plant operationand monitoring• Built-in memory for data acquisition,logging, and trending analysis of UVintensity and alarm conditions• Easy-to-read, real time visual displayfor at-a-glance assessment of systemperformanceHigh-Output, Amalgam LampsTrojan’s low-pressure, high-output (LPHO)amalgam lamps deliver significantly higherUV output than conventional systems. As aresult, TrojanUVLogic systems require onlyone-third the number of lamps to deliveran equivalent dose – and also draw lesspower – than other systems. The singleendedlamps are rated for 9,000-hours and<strong>pro</strong>vide flat UV output in operating watertemperatures of 41 ° to 104 ° F (5 ° to40 ° C). Trojan TOC reduction lampsdeliver a full 25% of their UV output at185 nm – almost four times that ofconventional 185 nm lamps.Unsurpassed HydraulicEfficiency & Installation FlexibilityTrojan’s “L-shaped” reactor was developedusing advanced 3-D <strong>com</strong>puter modeling,resulting in 40% greater hydraulicefficiency than conventional “U-shaped”systems. Its <strong>com</strong>pact size and abilityto be mounted inline, horizontally orvertically, maximizes installation flexibilityand preserves precious floor space.Designed for Fast, Easy MaintenanceTrojan offers optional manual or automatedsleeve cleaning that can be operatedwhile the reactor is online. Single-endedlamps and quartz sleeves allow fastlamp change-outs without tools. Oneperson can replace a lamp in less than5 minutes.Fully Equipped, Tested andPre-AssembledIn addition to a <strong>com</strong>prehensive listof standard features, every systemundergoes rigorous quality checks, andelectronic and hydrostatic pressuretesting before leaving our facility.Systems are shipped in a wood crate,ready for installation – arriving fullyassembled, including quartz sleeves,lamps and seals.TROJANUV.COM

SPECI FICATIONSModel: TrojanUVLogic 01AM10 01AM15 02AM15 02AM20 03AM20 03AS20 04AS20 03AL20 06AS20 04AL20 08AS20 06AL20 08AL20Flow Rate:Disinfection (@ 95% UVT) GPM (m 3 /hr)* 40 (9) 65 (15) 110 (25) 155 (35) 230 (52) 350 (80) 480 (110) 560 (130) 695 (160) 780 (189) 875 (200) 1120 (255) 1345 (306)Disinfection (@ 99% UVT) GPM (m 3 /hr)* 44 (10) 75 (17) 128 (29) 195 (44) 280 (63) 430 (97) 585 (133) 690 (156) 835 (189) 935 (212) 1010 (229) 1340 (304) 1620 (367)TOC/Ozone Destruction (@ 99% UVT) GPM (m 3 /hr)** 15 (3) 25 (5) 45 (10) 65 (14) 95 (21) 145 (32) 195 (44) 235 (53) 280 (63) 320 (72) 345 (78) 455 (103) 555 (126)Number of Lamps: 1 1 2 2 3 3 4 3 6 4 8 6 8Electrical Requirements:Voltage 120V/60Hz or 220-240V/50Hz, 1Φ 2W+GND 240/120V 1Φ 3W+GND 60HzPower (VA) 197 197 334 334 471 534 692 849 1007 1113 1323 1639 2165Internal System Fuse @ 240V 5 5 5 5 5 6 7.5 6 10 7.5 15 10 15Ballast TypeElectronic, High FrequencyControl Panel:RatingNEMA 4X/IP65Materials of Construction304 Stainless SteelMax. Cable Length ft (m) 15 (5)Water Chamber:Materials of Construction316L Stainless SteelNozzles (ANSI Flange) inches 1.5 2 2 4 4 4 6 6 6 6 6 6 6Nozzles (Metric) mm 38 50 50 100 100 100 150 150 150 150 150 150 150Max. Operating Pressure PSIG (Bar) 150 (10)Max. Operating Temperature ˚F (˚C) 120 (49)Hot Water Sanitizable with Sensor ˚F (˚C) 185 (85)Ap<strong>pro</strong>x. Dimensions (L x H) - inches 37 x 11 37 x 11 37 x 11 37 x 11 37 x 13 50 x 14 50 x 14 71 x 14 50 x 14 71 x 14 50 x 14 71 x 14 71 x 14- mm 94 x 28 94 x 28 94 x 28 94 x 28 94 x 33 127 x 36 127 x 36 180 x 36 127 x 36 180 x 36 127 x 36 180 x 36 180 x 36Standard Features:Ra 40/Ra

Trojan UV3000PTPTechnology you can trust from the industry leaderTrojan Technologies Inc. is an ISO 9001 registered <strong>com</strong>panyand for more than 25 years has set the standard for <strong>pro</strong>venUV technology and ongoing innovation. With unmatchedscientific and technical expertise, and a global network ofspecialists, representatives and technicians, Trojan is trustedmore than any other firm as the best choice for municipalUV solutions – worldwide.The Trojan UV3000PTP (Packaged Treatment Plant) isone of the reasons why. First introduced in 1991, it is anenhancement to the very successful UV2000, which pioneeredultraviolet disinfection in wastewater plants with the first-everopen channel design. Over the past decade, the UV3000PTPhas be<strong>com</strong>e recognized as the standard for UV systemdesign. Today, there are more than 3,000 Trojan UV Municipalsystems installed worldwide. The UV3000PTP is ideally suitedfor wastewater disinfection applications up to 1.4 MGD.

An ‘off-the-shelf’ solution designed for economical disinfectionElectronic BallastThe electronic ballast is mountedwithin its own Type 4 (IP65)-ratedwatertight enclosure within the moduleframe.System MonitorThe optional system monitor includesa submersible sensor that monitorslamp hours and UV intensity at eachbank. Elapsed time display <strong>pro</strong>videscontinuous readout of actual hours ofoperation. Display is visible throughthe panel door. A dry contact enablesa remote low UV intensity alarm.Power Distribution Recepticles(PDRs)Each optional PDR powers 2 UVmodules and allows for quick andsafe electrical disconnect. Groundfault <strong>pro</strong>tected for operator safety.The duplex ground fault interrupterreceptacles are mounted insideType 3R rain shield boxes.Fixed WeirMaintains the correct channel effluentdepth over different flow rates, withmaximum height of 1.5 inches(3.8 cm) of effluent at peak flow.Equipped with a drain for easychannel cleaning. Weirs are usedwith concrete channel and stainlesssteel channel option.UV ModulesUV lamps are mounted on modulesinstalled in open channels. The lampsare enclosed in quartz sleeves, andpositioned horizontally and parallel towater flow. A bank is made up ofmultiple modules placed in parallelpositions. All ballast, lamp and sensorwiring runs inside the module frame.Effluent ChannelAn optional Type 304 stainless steelchannel, <strong>com</strong>plete with UV ModuleSupport Rack, can be used. Channelcan be set into a poured concretechannel or installed as a freestandingstructure connected to flanged pipesusing the optional transition boxes.Gravity flow eliminates need forpumps, pipe valves or fittings.Transition BoxesThe optional transition boxes arepositioned at the channel’s inlet andoutlet points to create a plug flowcondition throughout the UV system.This enhances disinfection efficiency.Boxes feature hinged, stainless steellids with handles for easy access anddrain plugs for ease of cleaning.For stainless steel channels only.

Key Benefits of the TrojanUV3000PTP• Cost-effective disinfection solution due to its simple, easy-to-maintaindesign.• Bioassay validated dose delivery <strong>pro</strong>vides peace of mind. Trojan'sbioassay testing demonstrates the system’s disinfection performance inreal-world conditions; you don’t have to rely on theoretical calculations.• Reduced installation costs. The entire UV3000PTP can be quicklyand inexpensively installed into existing channels or chlorine contact basins.• Reduced capital costs. The <strong>com</strong>plete UV3000 TM PTP system can beinstalled outdoors, eliminating the need and capital costs of a building,shelter or air conditioning.• Reduced space requirements since ballasts are housed within themodule instead of in external cabinets, resulting in a smaller footprint.• Reduced operating costs. Gravity-fed design eliminates costs ofpressurized vessels, piping and pumps.• Enhanced <strong>com</strong>ponent performance. UV Modules are constructed ofType 316 stainless steel with excellent corrosion resistance to cleaningsolutions.• Easy expansion as your needs grow thanks to its modular design.• Reduced maintenance requirements due to design features like tripleseal lamp-sockets which <strong>pro</strong>tect against moisture entry and algae growthwithin channel and transition connections.• Easy cleaning. Modules are electrically separated from each other,allowing for one module to be removed for cleaning or repair. A sparemodule can quickly be inserted to maintain maximum performance.• Increased operator safety and no disinfection by-<strong>pro</strong>ducts. Trojan'sUV3000PTP uses environmentally safe ultraviolet light – not chlorine.• Comprehensive warranty <strong>pro</strong>tection for your investment.

Open-Channel Architecture Designed for Outdoor InstallationCost-effective to install and expandBenefits:• Compact, open channel designallows cost-effective installationin existing effluent channels andchlorine tank basins• Gravity-fed design eliminatescosts of pressurized vessels,piping and pumps• System can be installedoutdoors to reduce capitalcosts – no building, shelter orair conditioning is required• Open channel allows for easiercleaning and maintenance• Redundancy requirements are minimized byallowing disinfection to continue whileperforming maintenance on UV modules andchannel• The system offers a true off-the-shelf solutionfor operators with restricted budgets and basicdisinfection requirementsThe Trojan UV3000PTP system delivers flexibility and cost savings through its simpleinstallation in existing channels and chlorine contact tanks. The system is <strong>com</strong>pletely stand-aloneand can be situated outdoors with no additional building, shelter or cooling requirements.Modular Design Simplifies System ExpansionProvides maximum flexibility for changing needsBenefits:• Trojan’s modular ap<strong>pro</strong>ach isthe building block for maximumflexibility and efficiency• The number of modules can beeasily increased to suit differentflowrates and disinfection needs• Modular design is readilyexpandable to meet newregulatory or capacityrequirements• Trojan’s design ap<strong>pro</strong>ach ensures effluentquality, upstream treatment <strong>pro</strong>cesses, and O&Mneeds are addressed in system configuration• Horizontal lamp mounting delivers optimalhydraulic performance. This induces turbulenceand dispersion and maximizes wastewaterexposure to UV output.

Advanced, Self-Contained UV ModuleDramatically reduces footprint size and eliminates costs of air conditioningBenefits:• Lamps are <strong>pro</strong>tected in afully-submersible, Type 316stainless steel frame• Water<strong>pro</strong>of module frame<strong>pro</strong>tects cables from effluentand UV light• Space-saving electronic ballastsare housed right in the module,not separate external cabinets,to minimize footprint size, andinstallation time and costs• The electronic ballast is mounted within its ownType 4 (IP65)-rated airtight enclosure within themodule frame• Convection cooling of the ballast eliminatescost associated with air conditioning orforced-air coolingAll wiring and cables are safely enclosed inside the water<strong>pro</strong>of module frame.• Modules are electrically separated from eachother, allowing for one module to be removedfor maintenance. A spare module can quickly beinserted to maintain maximum performance.• Streamlined module minimizes head loss andprevents build-up of debris• All module wiring is pre-installed andfactory-testedTrojan’s Innovative Ballasts and Enclosures Provide Significant AdvantagesTrojan UV3000PTP ballasts are housed • This takes up less space and footprint, reducing installation time and costswithin the module, rather than in external cabinetsTrojan UV3000PTP utilizes convection cooling • Housing the ballasts in the module allows for convection cooling to dissipate the heatof the ballasts into the air• The ballasts are kept sealed and <strong>pro</strong>tected• No air conditioning or forced-air cooling requiredTrojan UV3000PTP ballast enclosure • Some suppliers use external cabinets, with forced-air cooling. This introduces dust<strong>pro</strong>vides a clean, <strong>pro</strong>tected environmentand moisture onto circuit boards and other electronic <strong>com</strong>ponents greatly reducingthe life of these <strong>com</strong>ponents• By housing the module internally the <strong>com</strong>ponents remain dry and cleanTrojan UV3000PTP utilizes internal cabling • All lamp-ballast wiring is contained within the module frame. This configuration<strong>pro</strong>tects wires and cables from exposure to effluent and UV light• Internal cabling allows all electrical connections within the module to be factory tested

High Efficiency Electronic BallastsConserve energy and <strong>pro</strong>long lamp lifeBenefits:• Electronic ballasts are more<strong>com</strong>pact, generate less heat,and are more efficient thanelectromagnetic ballasts• In a multi-unit system, banks ofUV lamps can be turned offmanually to conserve energywhen flow rates are minimal• Ballasts operate on standard 120V A/C,minimizing electrical requirements andinstallation costsTrojan’s electronic ballasts generate less heat and are more <strong>com</strong>pact than electromagneticballasts.Designed for Easy MaintenanceSimplicity of design allows for fast cleaning and upkeep• Lamps are available from more than one source,and are easily replaced without tools. One lampcan be replaced in 3-5 minutes on average• Trojan lamps are guaranteed for 12,000 hours ofoperation• 1 module can be unplugged and removedwithout disrupting flow or system performanceCleaning Options• Maintenance Rack – a mobile, stainless steelrack holds 1 UV module. Allows operator toclean and change lamps as required.Trojan’s mobile stainless steel rack allows for fast cleaning and quick lamp replacement.

EPA-Endorsed Bioassay Validated PerformanceReal-world testing ensures accurate dose deliveryBenefits:• Performance data is generatedfrom real-world testing over arange of flows, effluent quality,and UVTs• Provides physical verificationthat system will perform asexpected; ensures public andenvironmental safety• Provides accurate assessmentof equipment sizing needsBasing System Design on Theoretical Dose CalculationsCan Result In Undersizing of Equipment and UnderdosingThe variance betweenbioassay validatedperformance andcalculated performancecan lead to inaccurateassessments of systemsizing requirementsand delivered dose.• The Trojan UV3000PTP has been thoroughlyvalidated through real-world bioassay testingunder a wide range of operating conditions• Real-world bioassay testing offers the peace ofmind and im<strong>pro</strong>ved public and environmentalsafety of verified dose delivery, not theoreticalcalculations• The U.S. Environmental Protection Agency (EPA)has endorsed bioassays as the standard forassessment and <strong>com</strong>parison of UV technologies• The disinfection performance ratings for theTrojan UV3000PTP are <strong>pro</strong>of that what you seeis what you actually getStainless Steel Channels and Transition BoxesFaster, easier and less expensive to install versus concreteBenefits• Stainless steel is easier to workwith, especially on small <strong>pro</strong>jects• It takes less time to installstainless steel channels• The UV3000PTP channel is constructed fromType 304 stainless steel and <strong>com</strong>es <strong>com</strong>pletewith UV module support rack and downstreamserpentine weir• Stainless steel transition boxes at the UVchannel’s inlet and outlet points permitconnection to flanged pipes• The transition box connections enhancedisinfection efficiency by creating a plug flowcondition throughout the UV systemTrojan’s stainless steel transition box enhances disinfection efficiency and is easily connectedto flanged pipes.

System SpecificationsModel #TypicalPeak FlowsRatedPowerRe<strong>com</strong>mended Spare PartsAp<strong>pro</strong>ximate Dimensions for reference value only(inches /cm)US gal/day cu m/hr Requirementsx 1000(Watts) L1 L2 H1 H2 H3 H4 W1 W2 WD E DIA3025K-PTP 40 6 90 48 / 122 84 / 213 15 / 38 19 / 48 5.5 / 14 9 / 23 3 / 8 9 / 23 5-6.5 / 13-16 4 / 103050K-PTP 80 13 180 48 / 122 84 / 213 15 / 38 19 / 48 5.5 / 14 9 / 23 6 / 15 12 / 30 5-6.5 / 13-16 6 / 153075K-PTP 120 19 270 48 / 122 84 / 213 15 / 38 19 / 48 5.5 / 14 9 / 23 9 / 23 14 / 36 5-6.5 / 13-16 6 / 153100K-PTP 140 22 350 96 / 244 132 / 335 15 / 38 22 / 56 8 /20 12 / 30 6 / 15 14 / 36 5-6.5 / 13-16 8 /203150K-PTP 210 33 525 96 / 244 132 / 335 15 / 38 22 / 56 8 /20 12 / 30 9 / 23 15 / 38 5-6.5 / 13-16 8 /203200K-PTP 280 44 700 96 / 244 132 / 335 15 / 38 22 / 56 8 /20 12 / 30 12 / 30 16 / 41 5-6.5 / 13-16 8 /203250K-PTP 350 55 875 96 / 244 132 / 335 15 / 38 22 / 56 9 / 23 13 / 33 15 / 38 19 / 48 5-6.5 / 13-16 10 / 253300K-PTP 420 66 1050 96 / 244 132 / 335 15 / 38 22 / 56 9 / 23 13 / 33 18 / 46 22 / 56 5-6.5 / 13-16 10 / 253350K-PTP 490 77 1225 96 / 244 132 / 335 15 / 38 22 / 56 9 / 23 13 / 33 21 / 53 25 / 64 5-6.5 / 13-16 10 / 253400K-PTP 560 88 1400 115 / 292 163 / 414 21 / 53 33.5 / 85 10 / 25 16.5 / 42 12 / 30 19 / 48 11-12.5 / 28-32 12 / 303500K-PTP 700 110 1750 115 / 292 163 / 414 21 / 53 33.5 / 85 10 / 25 16.5 / 42 15 / 38 19 / 48 11-12.5 / 28-32 12 / 303600K-PTP 840 133 2100 115 / 292 163 / 414 21 / 53 33.5 / 85 10 / 25 16.5 / 42 18 / 46 22 / 56 11-12.5 / 28-32 12 / 303700K-PTP 980 155 2450 115 / 292 163 / 414 21 / 53 33.5 / 85 10 / 25 16.5 / 42 21 / 53 25 / 64 11-12.5 / 28-32 12 / 303800K-PTP 1120 177 2800 115 / 292 163 / 414 21 / 53 33.5 / 85 10 / 25 16.5 / 42 24 / 61 28 / 71 11-12.5 / 28-32 12 / 303900K-PTP 1260 199 3150 115 / 292 163 / 414 21 / 53 33.5 / 85 10 / 25 16.5 / 42 27 / 69 31 / 79 11-12.5 / 28-32 12 / 303001M-PTP 1400 221 3500 115 / 292 163 / 414 21 / 53 33.5 / 85 10 / 25 16.5 / 42 30 / 76 34 / 86 11-12.5 / 28-32 12 / 30* Please consult factory for dimensions applicable to a poured concrete channel and for exact dimensions of stainless steel channels.Products in this brochure may be covered by one or more of the following patents:CA 1,327,877 US 4,872,980US 5,006,244Other Patents pending.To facilitate easyand timelymaintenance, it isre<strong>com</strong>mendedthat the followingequipment beordered at thetime of systempurchase:• 4 lamps• 4 sleeves• 4 lamp holders(seal socketassemblies)Find out how your wastewater treatment plant can benefit from Trojan UV3000PTP – call us today.Printed in Canada. ©2002 Trojan Technologies Inc., London, Ontario, Canada.No part of this publication may be re<strong>pro</strong>duced, stored in a retrieval system, or transmitted in anyform or by any means without the written permission of Trojan Technologies Inc.OA-W-M&S-5.2-BR-CA0005-0902Head Office (Canada)3020 <strong>Go</strong>re RoadLondon, OntarioCanada N5V 4T7Telephone: (519) 457-3400Fax: (519) 457-3030www.trojanuv.<strong>com</strong>Trojan Technologies is a publicly traded <strong>com</strong>pany on theToronto Stock Exchange under the symbol TUV.

Filtración y Tratamiento de Agua3SISTEMAS deMEMBRANASSha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Membranas>>Industria, Sector Público y AgriculturaLos sistemas de membranas de YAMIT E.L.I. son usados por clientes en un amplio rango desoluciones en toda la industria, el sector público y la agricultura, incluyendo:SiderurgiaIndustria petroquímicaIndustria plásticaIndustria químicaIndustria electrónicaIndustria de generación de fuerza<strong>Go</strong>bierno y <strong>pro</strong>yectos nacionalesMunicipalidadesHoteles y <strong>com</strong>plejos turísticosCentros de conferencias y exposicionesIndustria turísticaProducción alimenticiaProducción de granos y forrajeProducción de flores y plantasSoluciones Globales para Tratamiento y Filtración de AguaYAMIT E.L.I. diseña, fabrica e implementa soluciones para:Tratamiento, filtración y reciclado de aguas industrialesTratamiento de agua potable para el sector público y el privadoTratamiento de aguas servidas industrialesTratamiento <strong>com</strong>pacto público y privado de aguas servidasFiltración para regado en agricultura e invernaderosAdemás, la <strong>pro</strong>fundidad y amplitud de nuestros sistemas y nuestra experiencia en aplicacionesnos permiten ofrecer gestión de <strong>pro</strong>yectos, adiestramiento y transferencia deconocimientos.18Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Membranas

Sistemas de Membranas>Micro-FiltraciónFiltración de hasta 1 micrón para quitar sólidos en suspensión.Su aplicación primaria es pre-tratamiento para hiper-filtración (sistemas RO), y filtración deagua potable.Ultra-Filtración a Membrana (Filtración Hasta Tamaño de Virus)Su uso primario es en <strong>pro</strong>ceso de agua potable y en la industria de alimentos y bebidas.Nano-Filtración a MembranaUsada para quitar del agua valores duales de iones tales <strong>com</strong>o Fe++ calcio, magnesio.Su aplicación primaria es tratamiento de sistemas de agua para calefacción, sistemas de tratamientode termosifones, <strong>com</strong>idas y bebidas, <strong>pro</strong>ceso de agua y aplicaciones de torres derefrigeración de alto rendimiento.Hiper-Filtración – Membrana ROSistemas a membrana para tratamiento de agua de mar, agua semisalada y agua desionizadaen industrias petroquímica y alimenticia.Todos los sistemas a membrana incluyen membranas de alta presión, bombas de alta presión,controlador de <strong>com</strong>pensación de temperatura, y pre-tratamiento obligatorio.20Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Membranas

Sistemas de MembranasSistemas de Membranas y Sistemas a Ósmosis Inversa>>Sistemas Integrados Aplicaciones de Tratamiento de Agua Municipales e IndustrialesSistemas de tratamiento de agua potable.Sistemas de eliminación de hierro con filtros de material o a membrana.Tratamiento de agua reciclada.Tratamiento de agua de marAgua ultra pura.Desinfección.Dosificación química.Sistemas ultravioletas.Sistemas de dosificación de ozono.Sistemas de Tratamiento Integrados22Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Membranas

Filtración y Tratamiento de AguaSha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>3

Filtración y Tratamiento de AguaSISTEMAS deTRATAMIENTOULTRAVIOLETASha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Purificación Ultravioleta>>Industria, Sector Público y AgriculturaLos Sistemas de Ablandadores e Intercambio Iónico de YAMIT E.L.I. son usados por clientesen un amplio rango de soluciones en toda la industria, el sector público y la agricultura,incluyendo:SiderurgiaIndustria petroquímicaIndustria plásticaIndustria químicaIndustria electrónicaIndustria de generación de fuerza<strong>Go</strong>bierno y <strong>pro</strong>yectos nacionalesMunicipalidadesHoteles y <strong>com</strong>plejos turísticosCentros de conferencias y exposicionesIndustria turísticaProducción alimenticiaProducción de granos y forrajeProducción de flores y plantasSoluciones Globales para Tratamiento y Filtración de AguaYAMIT E.L.I. diseña, fabrica e implementa soluciones para:Tratamiento, filtración y reciclado de aguas industrialesTratamiento de agua potable para el sector público y el privadoTratamiento de aguas servidas industrialesTratamiento <strong>com</strong>pacto público y privado de aguas servidasFiltración para regado de agricultura e invernaderosAdemás, la <strong>pro</strong>fundidad y amplitud de nuestros sistemas y nuestra experiencia en aplicacionesnos permiten ofrecer gestión de <strong>pro</strong>yectos, adiestramiento y transferencia de conocimientos.86Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Purificación Ultravioleta

Filtración y Tratamiento de AguaSha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Filtración y Tratamiento de AguaSISTEMAS deABLANDADORESe INTERCAMBIO IÓNICOSha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Ablandadores e Intercambio Iónico>>Industria, Sector Público y AgriculturaLos Sistemas de Ablandadores e Intercambio Iónico de YAMIT E.L.I. son usados por clientesen un amplio rango de soluciones en toda la industria, el sector público y la agricultura,incluyendo:SiderurgiaIndustria petroquímicaIndustria plásticaIndustria químicaIndustria electrónicaIndustria de generación de fuerza<strong>Go</strong>bierno y <strong>pro</strong>yectos nacionalesMunicipalidadesHoteles y <strong>com</strong>plejos turísticosCentros de conferencias y exposicionesIndustria turísticaProducción alimenticiaProducción de granos y forrajeProducción de flores y plantasSoluciones Globales para Tratamiento y Filtración de AguaYAMIT E.L.I. diseña, fabrica e implementa soluciones para:Tratamiento, filtración y reciclado de aguas industrialesTratamiento de agua potable para el sector público y el privadoTratamiento de aguas servidas industrialesTratamiento <strong>com</strong>pacto público y privado de aguas servidasFiltración para regado de agricultura e invernaderosAdemás, la <strong>pro</strong>fundidad y amplitud de nuestros sistemas y nuestra experiencia en aplicacionesnos permiten ofrecer gestión de <strong>pro</strong>yectos, adiestramiento y transferencia de conocimientos.78Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Ablandadores e Intercambio Iónico< >Muchas fuentes de agua contienen minerales duros, calcio y magnesio. Cuando se hallanpresentes en tu agua pueden incrustarse y crear <strong>pro</strong>blemas en máquinas de lavar, calentadores,lavaplatos, máquinas de café, humidificadores y sistemas de plomería. Es posibledetener los efectos dañosos de dichos minerales duros por medio del uso de un sistema deablandamiento de agua. Este sistema quita el calcio y el magnesio del abastecimiento de agua,filtrándola por un material ablandador de resina. Se usa periódicamente sal para revitalizarel sistema y asegurar el abastecimiento de agua blanda.Descripción de la Tecnología de Intercambio IónicoEl intercambio iónico es una reacción química en la que un ión de una solución acuosa esintercambiado por un ión de carga similar unido a una partícula sólida inmóvil (por ejemplo,resina de intercambio iónico). Las reacciones de intercambio iónico son estequiométricas (osea basadas en relaciones químicas) y reversibles.Las resinas están generalmente contenidas en recipientes llamados columnas. La soluciónpasa por las columnas y entonces se realiza el intercambio.Luego, cuando se llega a la capacidad máxima de las resinas, los iones de interés que estánacoplados a la resina son quitados durante una etapa de regeneración, en la que pasa por ellecho una fuerte solución que contiene los iones originalmente acoplados a la resina.La estrategia usada en esta tecnología es intercambiar iones más o menos inocuos (porej., iones de hidrógeno e hidróxilo), que se hallan en las resinas, por iones interesantes enla solución (por ej., cobre). En el más básico sentido, los materiales de intercambio iónicoson clasificados <strong>com</strong>o catiónicos o aniónicos. Las resinas catiónicas intercambian iones dehidrógeno por iones cargados positivamente, <strong>com</strong>o cobre, níquel y sodio.Resinas aniónicas intercambian iones de hidróxilo por iones cargados negativamente <strong>com</strong>osulfatos, cromatos y cianuro. La columna básica de intercambio iónico consiste de un lechode resina que es mantenido en la columna con cedazos de entrada y de salida, y distribuidoresde flujo de servicio y regeneración.Se requiere tubería y válvulas para redirigir el flujo e instrumentación para controlar la sincronizaciónde la regeneración.Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>79

Sistemas de Ablandadores e Intercambio Iónico

Sistemas de Ablandadores e Intercambio Iónico

Filtración y Tratamiento de AguaSha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Filtración y Tratamiento de AguaSISTEMAS deTRATAMIENTOULTRAVIOLETASha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Purificación Ultravioleta>>Industria, Sector Público y AgriculturaLos Sistemas de Ablandadores e Intercambio Iónico de YAMIT E.L.I. son usados por clientesen un amplio rango de soluciones en toda la industria, el sector público y la agricultura,incluyendo:SiderurgiaIndustria petroquímicaIndustria plásticaIndustria químicaIndustria electrónicaIndustria de generación de fuerza<strong>Go</strong>bierno y <strong>pro</strong>yectos nacionalesMunicipalidadesHoteles y <strong>com</strong>plejos turísticosCentros de conferencias y exposicionesIndustria turísticaProducción alimenticiaProducción de granos y forrajeProducción de flores y plantasSoluciones Globales para Tratamiento y Filtración de AguaYAMIT E.L.I. diseña, fabrica e implementa soluciones para:Tratamiento, filtración y reciclado de aguas industrialesTratamiento de agua potable para el sector público y el privadoTratamiento de aguas servidas industrialesTratamiento <strong>com</strong>pacto público y privado de aguas servidasFiltración para regado en agricultura e invernaderosAdemás, la <strong>pro</strong>fundidad y amplitud de nuestros sistemas y nuestra experiencia en aplicacionesnos permiten ofrecer gestión de <strong>pro</strong>yectos, adiestramiento y transferencia de conocimientos.86Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Sistemas de Purificación Ultravioleta

Filtración y Tratamiento de AguaSha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Filtración y Tratamiento de AguaFILTROS deMATERIALFILTRANTESha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Filtros de Material Filtrante>>Industria, Sector Público y AgriculturaLos Filtros de Material de YAMIT E.L.I. son usados por clientes en un vasto rango de solucionesen toda la industria, el sector público y la agricultura, incluyendo:SiderurgiaIndustria petroleraIndustria plásticaIndustria químicaIndustria electrónicaIndustria de <strong>pro</strong>ducción de energía<strong>Go</strong>bierno y <strong>pro</strong>yectos nacionalesMunicipalidadesHoteles y <strong>com</strong>plejos turísticosCentros de conferencias y exposicionesIndustria turísticaProducción alimenticiaProducción de granos y forrajeProducción de flores y plantasAgriculturas – campos abiertosSoluciones Globales para Tratamiento y Fltración de AguaYAMIT E.L.I. diseña, fabrica e implementa soluciones para:Tratamiento, filtración y reciclado de aguas industrialesTratamiento de agua potable para el sector público y el privadoTratamiento de aguas servidas industrialesTratamiento <strong>com</strong>pacto público y privado de aguas servidasFiltración para regado de agricultura e invernaderosAdemás, la <strong>pro</strong>fundidad y amplitud de nuestros sistemas y nuestra experiencia en aplicacionesnos permiten ofrecer gestión de <strong>pro</strong>yectos, adiestramiento y transferencia de conocimientos.Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>11

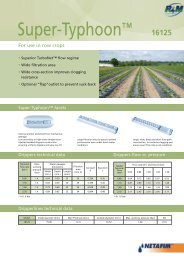

Filtros de Material FiltranteFiltros de Material Filtrante - “Multimedia”>>Materiales de FiltraciónModelode filtroTamaño deconexiónDiámetro delcuerpoÁrea defiltraciónTasa de flujo re<strong>com</strong>endadaPulgada mm Pulgada mm m2 pie2 m3/h L/sec gpmmin max min max min maxF6020 HM 1.5 40 20 500 0.20 2.15 1 3 0.3 0.8 4.4 13.2F6025 HM 1.5 40 25 625 0.30 3.23 2 4 0.6 1.4 8.8 17.6F6030 HM 2 50 30 750 0.44 4.73 3 6 0.8 1.7 13.2 26.4F6036 HM 2 50 36 900 0.63 6.46 4 9 1.1 2.5 17.6 39.6F6048 HM 2 50 48 1200 1.13 12.16 6 17 1.7 4.7 26.4 74.9F6064 HM 3 80 64 1600 2.00 21.52 10 30 2.8 8.3 44.0 132.2F6080 HM 4 100 80 2000 3.14 33.79 16 47 4.5 13.0 70.5 207.0F6088 HM 4 100 88 2200 3.80 40.90 19 57 5.3 15.8 84.0 251.0F6100 HM 4 100 100 2500 4.90 52.70 25 74 6.9 20.5 110.0 326.0F6120 HM 6 150 120 3000 7.06 75.60 36 107 10.0 29.7 159.0 471.0Tipos de Materiales (Medios) FiltrantesArena de cuarzoGrava volcánica: tamaños entre 1 mm – 20 mm.Antracita: <strong>com</strong>o <strong>com</strong>ponente de filtros duales o de material múltiple para agua potableconjuntamente con arena (y posiblemente granate). La inclusión de una capa de antracita encima de la arena asegura tiempo de acción de filtración más largo. Esta capa deantra cita puede <strong>pro</strong>ducir una tasa de filtración más alta que la de los filtros sin ella, asíreduci endo el peso de las partículas bastas sobre la arena.Material catalítico: cedazo de dióxido de manganeso lavado y secado. Usos: eliminaciónde hierro catalítico y de manganeso del agua potable.Carbón activo: para absorber cloro y otros minerales del agua.12Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Filtros de Material FiltranteProceso de Filtración por Medio Filtrante>>Pasos y ComponentesControl de pH• Pre-desinfecciónDosificación de floculantesMezclador/es estático/s serán instalados luego de cada punto de inyección química.Filtración lenta de material en filtros de material múltiple.Los materiales de filtración serán grava volcánica, arena de cuarzo y antracita.Filtración opcional de carbón activo.Filtros de reflujo opcionales.Monitoreo de calidad de agua: turbiedad y desinfección.Control PLC automático, dosificación, filtración y bomba, control para aseguraroperaciones precisas, automáticas y sin <strong>pro</strong>blemas.Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>13

Filtros de Material FiltranteAplicaciones>>Eliminación de HierroEl <strong>pro</strong>ceso de eliminación de hierro del agua incluye:- Control de pH, oxidación con aire, cloro u otro aditivo oxidante- Filtración con material con arena <strong>pro</strong>funda o un me dio catalítico.- Velocidad de filtración de 5 a 15 m/h.LeyendaBomba de dosificación para desinfecciónSM = Mezclador estáticoAnalizador de cloro libreBomba de dosificación para floculaciónMaterial de filtroEntrada de agua crudaSalida de agua del drenaje (retro lavado)Salidas de agua <strong>pro</strong>ducidaEntrada de agua externaSalida de agua tratada14Sha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>

Filtros de Material Filtrante>>Tanque de Material Filtrante “Multimedia”Apertura superior para servicioEntrada de filtroCapa de antracitaApertura lateral para servicioCapa de arena finaCapa de arena gruesaCapa de grava de soporteSalida de filtroElemento de filtroSistema Compacto para Agua PotableVálvula de aire de 1”Cuerpo del filtroPanel de control eléctricoDescargaAntracita de 2 mmArena n° 0Tamaño 0.5 – 0.8 mmArena n° 1Tamaño 0.8 – 1.2 mmGravaTamaño 0.8 – 1.2 mmVálvula de descarga(retro lavado) de 2”Bomba de aguapara retro lavadoBomba de dosificación de cloroMedidor de agua 3⁄4”Modelo ventiladorBomba de dosificaciónpara floculaciónBomba de descargaFiltro de malla semiautomático 2”Bomba de entradade agua crudaSalidaSha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>15

Filtración y Tratamiento de AguaSha’ar Efráim 42855 ISRAEL Tel: +972-46220006 Fax: +972-46220042 Correo-E: yamit@yamit-f.<strong>com</strong>