Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

7 Troubleshooting<br />

7 Troubleshooting<br />

<br />

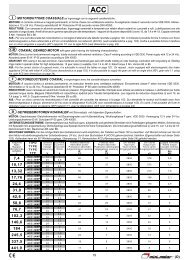

General Fault and Alarms<br />

Faults and alarms indicate problems in the drive or in the machine.<br />

An alarm is indicated by a code on the data display and the flashing ALM LED. The drive output is not necessarily switched off.<br />

A fault is indicated by a code on the data display and the ALM LED is on. The drive output is always switched off immediately and the motor coast<br />

to stop.<br />

To remove an alarm or reset a fault, trace the cause, remove it and reset the drive by pushing the Reset key on the operator or cycling the power<br />

supply.<br />

This lists up the most important alarms and faults only. Please refer to the Technical Manual for a complete list.<br />

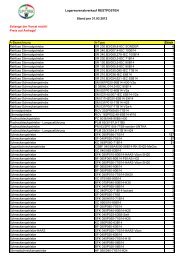

LED Display ALM FLT Cause Corrective Action<br />

Base Block<br />

The software base block function is assigned to one of the digital inputs and • Check the digital inputs function selection.<br />

<br />

the input is off. The drive does not accept Run commands.<br />

• Check the upper controller sequence.<br />

Control Fault<br />

Control Circuit Fault<br />

to<br />

Control Circuit Fault<br />

Cannot Reset<br />

<br />

<br />

<br />

The torque limit was reached during deceleration for longer than 3 sec.<br />

when in Open Loop Vector control<br />

• The load inertia is too big.<br />

• The torque limit is too low.<br />

• The motor parameters are wrong.<br />

There is a problem in the drive’s control circuit.<br />

There is no terminal board connected to the control board or the connection<br />

is broken.<br />

• Check the load.<br />

• Set the torque limit to the most appropriate setting (L7-01 through L7-<br />

04).<br />

• Check the motor parameters.<br />

• Cycle the drive power supply.<br />

• Initialize the drive.<br />

• Replace the drive if the fault occurs again.<br />

• Check if the terminal board is installed properly.<br />

• Uninstall and Reapply the terminal board.<br />

• Change the drive.<br />

Fault reset was input when a Run command was active. Turn off the Run command and reset the drive.<br />

Option External Fault<br />

External Fault<br />

External Faults<br />

to<br />

Internal Fan Alarm<br />

Ground Fault<br />

<strong>Drive</strong> Disable<br />

<strong>Drive</strong> Disable Fault<br />

Output Phase Loss<br />

Overcurrent<br />

Heatsink Overheat<br />

or<br />

Motor Overload<br />

<strong>Drive</strong> Overload<br />

DC Overvoltage<br />

An external fault was tripped by the upper controller via an option card.<br />

<br />

<br />

<br />

A forward and reverse command were input simultaneously for longer than<br />

500 ms. This alarm stops a running motor.<br />

• An external fault was triggered by an external device via one of the<br />

digital inputs S1 to S6.<br />

• The digital inputs are set up incorrectly.<br />

• Internal stirring fan does not work<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Ground leakage current has exceeded 50% of the drives rated output<br />

current.<br />

• Cable or motor insulation is broken.<br />

• Excessive stray capacitance at drive output.<br />

Both <strong>Drive</strong> Disable inputs are open. The drive output is safely disabled and<br />

the motor can not be started.<br />

<strong>Drive</strong> output is disabled while only one of the <strong>Drive</strong> Disable inputs is open.<br />

(normally both input signals H1 and H2 should be open)<br />

• One channel is internally broken and does not switch off, even if the<br />

external signal is removed.<br />

• Only one channel is switched off by the upper controller.<br />

• Output cable is disconnected or the motor winding is damaged.<br />

• Loose wires at the drive output.<br />

• Motor is too small (less than 5% of drive current).<br />

• Short circuit or ground fault on the drive output side<br />

• The load is too heavy.<br />

• The accel./decel. times are too short.<br />

• Wrong motor data or V/f pattern settings.<br />

• A magnetic contactor was switched at the output.<br />

• Surrounding temperature is too high.<br />

• The cooling fan has stopped. <br />

• The heatsink is dirty.<br />

• The airflow to the heatsink is restricted.<br />

• The motor load is too heavy.<br />

• The motor is operated at low speed with heavy load.<br />

• Cycle times of accel./ decel. are too short.<br />

• Incorrect motor rated current has been set.<br />

• The load is too heavy.<br />

• The drive capacity is too small.<br />

• Too much torque at low speed.<br />

DC bus voltage rose too high.<br />

• The deceleration time is too short.<br />

• Stall prevention is disabled.<br />

• Braking chopper / resistor broken.<br />

• Unstable motor control in OLV.<br />

• Too high input voltage.<br />

• Remove the fault cause, reset the fault and restart the drive.<br />

• Check the upper controller program.<br />

Check the sequence and make sure that the forward and reverse input are<br />

not set at the same time.<br />

• Find out why the device tripped the EF. Remove the cause and reset the<br />

fault.<br />

• Check the functions assigned to the digital inputs.<br />

• Replace internal fan (see fig. Replacing the Internal Stirring Fan on<br />

page 27)<br />

• Check the output wiring and the motor for short circuits or broken<br />

insulation. Replace any broken parts.<br />

• Reduce the carrier frequency.<br />

• Check why the upper controller’s safety device disabled the drive.<br />

Remove the cause and restart.<br />

• Check the wiring. If the <strong>Drive</strong> Disable function is not utilized for<br />

EN60204-1, stop cat. 0 or for disabling the drive, the terminals HC, H1,<br />

H2 must be linked.<br />

• Check the wiring from the upper controller and make sure that both<br />

signals are set correctly by the controller.<br />

• If the signals are set correctly and the alarm does not disappear, replace<br />

the drive.<br />

• Check the motor wiring.<br />

• Make sure all terminal screws in the drive and motor are properly<br />

tightened.<br />

• Check the motor and drive capacity.<br />

• Check the output wiring and the motor for short circuits or broken<br />

insulation. Replace the broken parts.<br />

• Check the machine for damages (gears, etc.) and repair any broken parts.<br />

• Check the drive parameter settings.<br />

• Check the output contactor sequence.<br />

• Check the surrounding temperature and install cooling devices if<br />

necessary.<br />

• Check the drive cooling fan.<br />

• Clean the heatsink.<br />

• Check the airflow around the heatsink.<br />

• Reduce the motor load.<br />

• Use a motor with external cooling and set the correct motor in parameter<br />

L1-01<br />

• Check the sequence.<br />

• Check the rated current setting.<br />

• Check the load.<br />

• Make sure that the drive is big enough to handle the load.<br />

• The overload capability is reduced at low speeds. Reduce the load or<br />

increase the drive size.<br />

• Increase the deceleration time.<br />

• Enable stall prevention by parameter L3-04.<br />

• Make sure the braking resistor and braking chopper are working<br />

correctly.<br />

• Check motor parameter settings and adjust torque and slip compensation,<br />

AFR and hunting prevention as needed.<br />

• Make sure that the power supply voltage meets the drives specifications.<br />

EN 24<br />

<strong>YASKAWA</strong> Europe TOMP_C710606_75A <strong>V1000</strong> <strong>IP66</strong> - Quick Start Guide