- Page 1 and 2: TPE, TPED Series 2000 Installation

- Page 3 and 4: Декларация о соотв

- Page 5 and 6: TPE, TPED Series 2000 Installation

- Page 7 and 8: 1. Symbols used in this document (

- Page 9 and 10: 5.1.9 Connections Note If no extern

- Page 11 and 12: 5.2.8 Start/stop of pump Caution Wh

- Page 13 and 14: • Two protective earth conductors

- Page 15: 5.4 Signal cables • Use screened

- Page 19 and 20: 8. Setting by means of control pane

- Page 21 and 22: 0. GENERAL 1. OPERATION 2. STATUS 3

- Page 23 and 24: 9.1.4 Fault log For both fault type

- Page 25 and 26: 9.3.4 Buttons on pump The operating

- Page 27 and 28: 13. External setpoint signal The se

- Page 29 and 30: The functions of the two indicator

- Page 31 and 32: 19. Maintenance and service 19.1 Cl

- Page 33 and 34: 23. Other technical data EMC (elect

- Page 35 and 36: INHALTSVERZEICHNIS 1. Sicherheitshi

- Page 37 and 38: 2. Allgemeine Informationen Die vor

- Page 39 and 40: 5.1.9 Anschlüsse Hinweis Wird kein

- Page 41 and 42: Arten von Netzen Dreiphasige E-Pump

- Page 43 and 44: Abb. 11 Anschluss eines einzelnen S

- Page 45 and 46: Gruppe 2 Gruppe 4 Gruppe 3 1: Digit

- Page 47 and 48: 6. Betriebs- und Regelungsarten Die

- Page 49 and 50: 7. Einstellungen über das Bedienfe

- Page 51 and 52: 8.4 Einstellen auf Betrieb mit MIN-

- Page 53 and 54: 9.1 Menü BETRIEB In diesem Menü e

- Page 55 and 56: 9.2.7 Anzeige des Schmierstatus der

- Page 57 and 58: 10. Einstellungen über das PC Tool

- Page 59 and 60: 15. Andere Bus-Protokolle Grundfos

- Page 61 and 62: 18. Notbetrieb (nur 11-22 kW) Warnu

- Page 63 and 64: 21. Technische Daten - dreiphasige

- Page 65 and 66: Schalldruckpegel Einphasige Pumpen:

- Page 67 and 68:

22. Caractéristiques techniques -

- Page 69 and 70:

5.1.9 Raccordements Nota Si aucun i

- Page 71 and 72:

5.2.8 Marche/arrêt de la pompe Pr

- Page 73 and 74:

• Deux conducteurs de protection

- Page 75 and 76:

5.4 Câbles de signaux • Utiliser

- Page 77 and 78:

Mode courbe constante : La pompe n'

- Page 79 and 80:

8. Réglage au moyen du panneau de

- Page 81 and 82:

0. GENERAL 1. FONCTIONNEMENT 2. ETA

- Page 83 and 84:

9.1.4 Journal des défauts Le R100

- Page 85 and 86:

9.3.4 Touches de la pompe Les touch

- Page 87 and 88:

13. Signal externe du point de cons

- Page 89 and 90:

Les fonctions des deux voyants et d

- Page 91 and 92:

19. Maintenance et entretien 19.1 N

- Page 93 and 94:

23. Autres caractéristiques techni

- Page 95 and 96:

INDICE 1. Simboli utilizzati in que

- Page 97 and 98:

5.1 Collegamento elettrico - pompe

- Page 99 and 100:

5.2 Collegamento elettrico- pompe t

- Page 101 and 102:

Gruppo 4 Fig. 9 Morsetti di conness

- Page 103 and 104:

Gruppo 2: Uscita (segnale del relè

- Page 105 and 106:

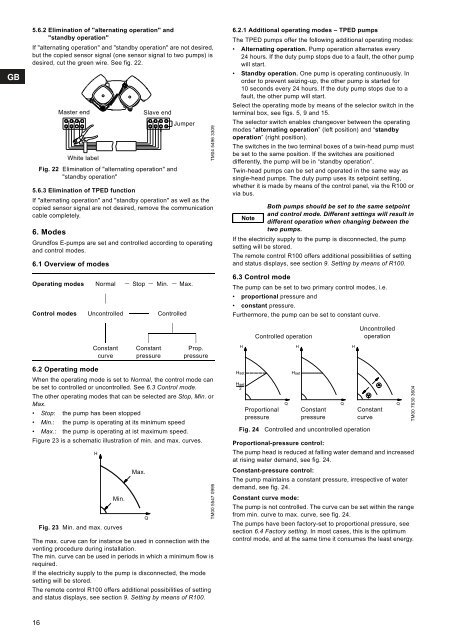

5.6.2 Eliminazione del "funzionamen

- Page 107 and 108:

7. Impostazione dal pannello di con

- Page 109 and 110:

8.4 Impostazione del funzionamento

- Page 111 and 112:

9.1 Menu FUNZIONAMENTO La prima sch

- Page 113 and 114:

9.2.7 Stato della lubrificazione de

- Page 115 and 116:

10. Impostazione tramite l'PC Tool

- Page 117 and 118:

14. Segnale di bus La pompa support

- Page 119 and 120:

18. Funzionamento di emergenza (sol

- Page 121 and 122:

21. Dati tecnici - pompe trifase, 0

- Page 123 and 124:

Livello di pressione acustica Pompe

- Page 125 and 126:

1. Símbolos utilizados en este doc

- Page 127 and 128:

5.1.9 Conexiones Nota Si no se cone

- Page 129 and 130:

5.2.8 Arranque/parada de la bomba P

- Page 131 and 132:

• Dos conductores de tierra de pr

- Page 133 and 134:

5.4 Cables de señal • Utilizar c

- Page 135 and 136:

6.3.1 Guía de selección del modo

- Page 137 and 138:

8. Ajuste mediante el panel de cont

- Page 139 and 140:

0. GENERAL 1. FUNCIONAMIENTO 2. EST

- Page 141 and 142:

9.1.4 Registro de fallos Para ambos

- Page 143 and 144:

9.3.4 Botones de la bomba Los boton

- Page 145 and 146:

13. Señal externa del punto de aju

- Page 147 and 148:

Las funciones de las dos luces test

- Page 149 and 150:

19. Mantenimiento y reparación 19.

- Page 151 and 152:

23. Otros datos técnicos EMC (comp

- Page 153 and 154:

ÍNDICE 1. Símbolos utilizados nes

- Page 155 and 156:

5.1 Ligação eléctrica - bombas m

- Page 157 and 158:

5.2 Ligação eléctrica - bombas t

- Page 159 and 160:

Grupo 4 Fig. 9 Terminais de ligaç

- Page 161 and 162:

Grupo 2: Saída (sinal de relé, te

- Page 163 and 164:

5.6.2 Eliminação da "operação a

- Page 165 and 166:

7. Configuração através do paine

- Page 167 and 168:

8.4 Configuração para funcionamen

- Page 169 and 170:

9.1 Menu FUNCIONAMENTO O primeiro v

- Page 171 and 172:

9.2.7 Estado da lubrificação dos

- Page 173 and 174:

10. Configuração através do PC T

- Page 175 and 176:

14. Sinal bus A bomba suporta comun

- Page 177 and 178:

18. Funcionamento de emergência (a

- Page 179 and 180:

21. Características técnicas - bo

- Page 181 and 182:

Bombas trifásicas: 24. Eliminaçã

- Page 183 and 184:

23. Άλλα τεχνικά χαρ

- Page 185 and 186:

5.1.8 Εκκίνηση/παύση

- Page 187 and 188:

5.2.8 Εκκίνηση/παύση

- Page 189 and 190:

• Δύο προστατευτικ

- Page 191 and 192:

5.4 Καλώδια σήματος

- Page 193 and 194:

Πρόγραμμα σταθερής

- Page 195 and 196:

8. Ρύθμιση μέσω του

- Page 197 and 198:

0. ΓΕΝΙΚΑ 1. ΛΕΙΤΟΥΡΓ

- Page 199 and 200:

9.1.4 Ημερολόγιο βλαβ

- Page 201 and 202:

Σημείωση Οι ενδείξ

- Page 203 and 204:

13. Εξωτερικό σήμα σ

- Page 205 and 206:

Οι λειτουργίες των

- Page 207 and 208:

Χρησιμοποιήστε τις

- Page 209 and 210:

22. Τεχνικά χαρακτηρ

- Page 211 and 212:

24. Απόρριψη Το προϊ

- Page 213 and 214:

1. Symbolen die in dit document geb

- Page 215 and 216:

5.1.9 Aansluitingen N.B. Verbind kl

- Page 217 and 218:

5.2.8 In- en uitschakelen van de po

- Page 219 and 220:

• Twee aarddraden met dezelfde ad

- Page 221 and 222:

5.4 Signaalkabels • Gebruik afges

- Page 223 and 224:

6.3.1 Richtlijn voor de keuze van r

- Page 225 and 226:

8. Instelling d.m.v. bedieningspane

- Page 227 and 228:

0. ALGEMEEN 1. BEDRIJF 2. STATUS 3.

- Page 229 and 230:

9.1.4 Overzicht van storingen en wa

- Page 231 and 232:

N.B. Storing omvat activiteiten die

- Page 233 and 234:

13. Signaal van externe gewenste wa

- Page 235 and 236:

De onderstaande tabel geeft een ove

- Page 237 and 238:

19. Onderhoud en service 19.1 Reini

- Page 239 and 240:

23. Overige technische gegevens EMC

- Page 241 and 242:

INNEHÅLLSFÖRTECKNING 1. Symboler

- Page 243 and 244:

5.1 Elanslutning: 1-faspumpar Varni

- Page 245 and 246:

5.2 Elanslutning: 3-faspumpar, 0,75

- Page 247 and 248:

Grupp 4 Fig. 9 Anslutningsplintar -

- Page 249 and 250:

Grupp 4: Kommunikationskabel (8-sti

- Page 251 and 252:

5.6.2 Eliminering av "alternerande

- Page 253 and 254:

7. Inställning från manöverpanel

- Page 255 and 256:

8.4 Inställning av drift på min.k

- Page 257 and 258:

9.1 Menyn DRIFT Detta är den förs

- Page 259 and 260:

9.2.7 Motorlagrens smörjningsstatu

- Page 261 and 262:

10. Inställning med hjälp av Grun

- Page 263 and 264:

16. Indikeringslampor och meddeland

- Page 265 and 266:

18. Nöddrift (endast 11-22 kW) Var

- Page 267 and 268:

21. Tekniska data - 3-faspumpar, 0,

- Page 269 and 270:

Ljudtrycksnivå 1-faspumpar: < 70 d

- Page 271 and 272:

1. Tässä julkaisussa käytettäv

- Page 273 and 274:

5.1.9 Liitännät Huomaa Jos ulkois

- Page 275 and 276:

5.2.8 Pumpun käynnistys/pysäytys

- Page 277 and 278:

• Käytetään kahta suojamaadoit

- Page 279 and 280:

5.4 Signaalikaapelit • Käytä ul

- Page 281 and 282:

6.3.1 Säätötavan valintaohje jä

- Page 283 and 284:

8. Asetusten tekeminen ohjauspaneel

- Page 285 and 286:

0. YLEISTÄ 1. KÄYTTÖ 2. OLOTILA

- Page 287 and 288:

9.1.4 Vikaloki R100:ssa on lokitoim

- Page 289 and 290:

9.3.4 Painikkeet pumpussa Ohjauspan

- Page 291 and 292:

13. Ulkoinen asetuspistesignaali As

- Page 293 and 294:

Merkkivalojen ja signaalireleen toi

- Page 295 and 296:

19. Kunnossapito ja huolto 19.1 Moo

- Page 297 and 298:

23. Muut tekniset tiedot EMC (sähk

- Page 299 and 300:

INDHOLDSFORTEGNELSE 1. Symboler bru

- Page 301 and 302:

5.1 El-tilslutning af 1-fasede pump

- Page 303 and 304:

5.2 El-tilslutning af 3-fasede pump

- Page 305 and 306:

Gruppe 4 Fig. 9 Tilslutningsklemmer

- Page 307 and 308:

Gruppe 3: Netforsyning (klemme L1,

- Page 309 and 310:

5.6.3 Sådan fjernes TPED-funktione

- Page 311 and 312:

7. Indstilling ved hjælp af betjen

- Page 313 and 314:

8.4 Sådan indstilles min. kurve-dr

- Page 315 and 316:

9.1 Menu DRIFT Dette er det første

- Page 317 and 318:

9.2.7 Smørestatus for motorens lej

- Page 319 and 320:

10. Indstilling ved hjælp af PC To

- Page 321 and 322:

16. Signallamper og melderelæ Pump

- Page 323 and 324:

18. Nøddrift (kun 11-22 kW) Advars

- Page 325 and 326:

21. Tekniske data - 3-fasede pumper

- Page 327 and 328:

Lydtryksniveau 1-fasede pumper: < 7

- Page 329 and 330:

21. Dane techniczne - pompy 3-fazow

- Page 331 and 332:

5.1 Podłączenie elektryczne - pom

- Page 333 and 334:

5.2 Podłączenie elektryczne - pom

- Page 335 and 336:

Grupa 4 Rys. 9 Zaciski przyłączen

- Page 337 and 338:

Grupa 2: Wyjścia (przekaźnik sygn

- Page 339 and 340:

5.6.2 Rezygnacja z "pracy naprzemie

- Page 341 and 342:

7. Nastawy z poziomu panelu steruj

- Page 343 and 344:

8.4 Ustawienie charakterystyki Min.

- Page 345 and 346:

9.1 Menu PRACA Pierwszym ekranem te

- Page 347 and 348:

9.2.7 Stan nasmarowania łożysk si

- Page 349 and 350:

10. Ustawienia przy pomocy PC Tool

- Page 351 and 352:

14. Sygnał bus Pompa zapewnia moż

- Page 353 and 354:

18. Praca awaryjna (tylko 11-22 kW)

- Page 355 and 356:

21. Dane techniczne - pompy 3-fazow

- Page 357 and 358:

Poziom ciśnienia akustycznego Pomp

- Page 359 and 360:

16. Другие стандарты

- Page 361 and 362:

6.1 Подключение элек

- Page 363 and 364:

6.2 Подключение элек

- Page 365 and 366:

Группа 4 Рис. 9 Клемм

- Page 367 and 368:

Группа 1: Входы • ВК

- Page 369 and 370:

7. Способы регулиро

- Page 371 and 372:

8. Установка параме

- Page 373 and 374:

9.2 Установка значен

- Page 375 and 376:

10.1 Меню ЭКСПЛУАТАЦ

- Page 377 and 378:

10.2.6 Часы эксплуата

- Page 379 and 380:

10.3.8 Подтверждение

- Page 381 and 382:

При регулировании

- Page 383 and 384:

Функции двух свето

- Page 385 and 386:

Используйте винты

- Page 387 and 388:

Используются станд

- Page 389 and 390:

25. Утилизация отход

- Page 391 and 392:

22. Műszaki adatok - háromfázis

- Page 393 and 394:

5.1 Elektromos bekötés - egyfázi

- Page 395 and 396:

5.2 Elektromos bekötés - háromf

- Page 397 and 398:

4. csoport 9. ábra Csatlakozó sor

- Page 399 and 400:

3. csoport: Hálózati feszültség

- Page 401 and 402:

5.6.2 A "váltott üzemmód" és a

- Page 403 and 404:

7. Beállítás a kezelőpanelen, e

- Page 405 and 406:

8.4 Min. görbe beállítása Tarts

- Page 407 and 408:

9.1 ÜZEMELTETÉS menü Ez az első

- Page 409 and 410:

9.2.7 Motor csapágyak kenési áll

- Page 411 and 412:

10. Beállítások a PC Tool E-prod

- Page 413 and 414:

16. Jelzőfények és jelzőrelé A

- Page 415 and 416:

18. Szükségüzem (csak 11-22 kW)

- Page 417 and 418:

21. Műszaki adatok - háromfázis

- Page 419 and 420:

Zajszint Egyfázisú szivattyúk: <

- Page 421 and 422:

21. Tehnični podatki - trifazne č

- Page 423 and 424:

5.1 Električna priključitev - eno

- Page 425 and 426:

5.2 Električna priključitev - tri

- Page 427 and 428:

Skupina 4 Slika 9 Priključki - TPE

- Page 429 and 430:

Skupina 4: Komunikacijski kabel (8-

- Page 431 and 432:

5.6.2 Preprečevanje "izmenjujočeg

- Page 433 and 434:

7. Nastavljanje preko kontrolnega p

- Page 435 and 436:

8.4 Nastavitev na delovanje na min.

- Page 437 and 438:

9.1 Meni DELOVANJE Prvi prikaz v te

- Page 439 and 440:

9.2.7 Status podmazanosti ležajev

- Page 441 and 442:

10. Nastavljanje s pomočjo "PC Too

- Page 443 and 444:

14. Bus signal Črpalka podpira ser

- Page 445 and 446:

18. Delovanje v sili - bypass (samo

- Page 447 and 448:

21. Tehnični podatki - trifazne č

- Page 449 and 450:

Trifazne črpalke: 24. Odstranitev

- Page 451 and 452:

22. Tehnički podaci - trofazne crp

- Page 453 and 454:

5.1 Električno spajanje - jednofaz

- Page 455 and 456:

5.2 Električno spajanje - trofazne

- Page 457 and 458:

Grupa 4 Slika 9 Stezaljke - TPED se

- Page 459 and 460:

Grupa 2: Izlaz (signal za relej, st

- Page 461 and 462:

5.6.2 Uklanjanje "izmjeničnog rada

- Page 463 and 464:

7. Podešavanje putem upravljačke

- Page 465 and 466:

8.4 Podešavanje na minimalnu krivu

- Page 467 and 468:

9.1 Izbornik RAD Prva ekranska slik

- Page 469 and 470:

9.2.7 Status podmazivanja ležajeva

- Page 471 and 472:

10. Postavljanje pomoću alata PC T

- Page 473 and 474:

14. Sabirnički signal Crpka podrž

- Page 475 and 476:

18. Rad u slučaju nužde (samo 11-

- Page 477 and 478:

21. Tehnički podaci - trofazne crp

- Page 479 and 480:

Razina zvučnog tlaka Jednofazne cr

- Page 481 and 482:

21. Tehnički podaci - trofazne pum

- Page 483 and 484:

5.1 Elektro povezivanja - monofazne

- Page 485 and 486:

5.2 Elektro povezivanje - trofazne

- Page 487 and 488:

Grupa 4 Slika 9 Terminali - TPED se

- Page 489 and 490:

Grupa 3: Glavno napajanje (terminal

- Page 491 and 492:

5.6.2 Uklanjanje "naizmeničnog rad

- Page 493 and 494:

7. Podešavanje preko kontrolne plo

- Page 495 and 496:

8.4 Podešavanje na minimalnu radnu

- Page 497 and 498:

9.1 Meni RAD Prvi displej u ovom me

- Page 499 and 500:

9.2.7 Status podmazivanja motornih

- Page 501 and 502:

10. Podešavanje preko PC Tool E-pr

- Page 503 and 504:

16. Indikacione lampice i signalni

- Page 505 and 506:

18. Pomoćni rad (samo 11-22 kW) Up

- Page 507 and 508:

21. Tehnički podaci - trofazne pum

- Page 509 and 510:

Nivo pritiska buke Monofazne pumpe:

- Page 511 and 512:

1. Simboluri folosite în acest doc

- Page 513 and 514:

5.1.9 Conexiuni Notă Dacă nu este

- Page 515 and 516:

5.2.8 Pornirea/oprirea pompei Aten

- Page 517 and 518:

• Doi conductori de împământar

- Page 519 and 520:

5.4 Cabluri de semnal • Utilizaţ

- Page 521 and 522:

6.3.1 Ghid pentru alegerea modului

- Page 523 and 524:

8. Setarea cu ajutorul panoului de

- Page 525 and 526:

0. GENERALITĂŢI 1. FUNCŢIONARE 2

- Page 527 and 528:

9.1.4 Jurnal de avarii Pentru ambel

- Page 529 and 530:

9.3.4 Butoanele pompei Butoanele de

- Page 531 and 532:

13. Semnal extern prag programat Pr

- Page 533 and 534:

Funcţiile celor doi indicatori lum

- Page 535 and 536:

19. Întreţinere şi reparaţii 19

- Page 537 and 538:

23. Alte date tehnice EMC (compatib

- Page 539 and 540:

СЪДЪРЖАНИЕ 1. Мерки

- Page 541 and 542:

2. Обща информация Т

- Page 543 and 544:

5.1.8 Старт/стоп на по

- Page 545 and 546:

Типове мрежи Трифа

- Page 547 and 548:

Фиг. 12 Свързване на

- Page 549 and 550:

5.4 Кабели за сигнал

- Page 551 and 552:

Режим Константна к

- Page 553 and 554:

7.4 Старт/стоп на пом

- Page 555 and 556:

0. ОБЩИ 1. РАБОТА 2. СТ

- Page 557 and 558:

9.1.4 Регистър на неи

- Page 559 and 560:

9.3.3 Сигнално реле (с

- Page 561 and 562:

Приоритет на настр

- Page 563 and 564:

16. Светлинни индика

- Page 565 and 566:

17. Изолационно съпр

- Page 567 and 568:

20. Технически данни

- Page 569 and 570:

Като се инсталира п

- Page 571 and 572:

OBSAH 1. Bezpečnostní pokyny Stra

- Page 573 and 574:

4. Mechanická instalace Pokyn K z

- Page 575 and 576:

Skupina 4 0-10 V 0/4-20 mA 4-20 mA

- Page 577 and 578:

NC C NO L1 L2 L3 0-10 V 0/4-20 mA 4

- Page 579 and 580:

5.3.5 Motorová ochrana Čerpadlo n

- Page 581 and 582:

5.4 Signální kabely • Pro exter

- Page 583 and 584:

6.3.1 Návod k volbě druhu regulac

- Page 585 and 586:

8. Nastavování na ovládacím pan

- Page 587 and 588:

0. OBECNĚ 1. PROVOZ 2. PROVOZNÍ S

- Page 589 and 590:

9.1.4 Poruchové hlášení Pro oba

- Page 591 and 592:

Pokyn Možnosti Porucha a Alarm se

- Page 593 and 594:

13. Externí signál požadované h

- Page 595 and 596:

Funkce obou signálních světel a

- Page 597 and 598:

19. Údržba a servis 19.1 Čiště

- Page 599 and 600:

23. Jiné technické údaje EMC (el

- Page 601 and 602:

OBSAH 1. Bezpečnostné pokyny Stra

- Page 603 and 604:

2. Všeobecné informácie Tento mo

- Page 605 and 606:

5.1.9 Prípojky Dôležité Ak nie

- Page 607 and 608:

5.2.8 Štart/stop čerpadla Pozor A

- Page 609 and 610:

Obr. 11 Pripojenie jednotlivého oc

- Page 611 and 612:

Skupina 2 Skupina 4 Skupina 3 1: Di

- Page 613 and 614:

6. Režimy E-čerpadlá Grundfos s

- Page 615 and 616:

7. Nastavovanie na ovládacom panel

- Page 617 and 618:

8.4 Nastavenie režimu prevádzky p

- Page 619 and 620:

9.1 Menu PREVÁDZKA Prvé displejov

- Page 621 and 622:

9.2.7 Stav mazania motorových lož

- Page 623 and 624:

10. Nastavenie pomocou 'PC Tool E-p

- Page 625 and 626:

14. Bus signál Čerpadlo podporuje

- Page 627 and 628:

18. Núdzová prevádzka (len 11-22

- Page 629 and 630:

21. Technické údaje - trojfázov

- Page 631 and 632:

Trojfázové čerpadlá: 24. Likvid

- Page 633 and 634:

1. Bu dokümanda kullanılan sembol

- Page 635 and 636:

5.1.9 Bağlantılar Not Harici açm

- Page 637 and 638:

5.2.8 Pompanın çalıştırılmas

- Page 639 and 640:

• Bir iletken terminal kutusundak

- Page 641 and 642:

5.4 Sinyal kabloları • Harici a

- Page 643 and 644:

6.3.1 Sistem türüne göre kontrol

- Page 645 and 646:

8. Üç-fazlı pompalar, kontrol pa

- Page 647 and 648:

0. GENEL 1. ÇALIŞMA 2. DURUM 3. K

- Page 649 and 650:

9.1.4 Arıza kaydı Alarm ve uyarı

- Page 651 and 652:

9.3.4 Pompa üzerindeki düğmeler

- Page 653 and 654:

13. Harici ayar noktası sinyali Ay

- Page 655 and 656:

İki gösterge ışığının ve si

- Page 657 and 658:

19. Bakım ve servis 19.1 Motorun t

- Page 659 and 660:

23. Diğer teknik veriler EMC (EN 6

- Page 661 and 662:

YETKİLİ GRUNDFOS SERVİSLERİ SER

- Page 663 and 664:

1. Selles dokumendis kasutatud süm

- Page 665 and 666:

5.1.9 Ühendused Märkus Kui välis

- Page 667 and 668:

5.2.8 Pumba käivitamine/peatamine

- Page 669 and 670:

5.3.3 Reservkaitsmed Soovitatavad k

- Page 671 and 672:

5.4 Signaalikaablid • Kasuta väl

- Page 673 and 674:

6.3.1 Juhend juhtimisrežiimi valik

- Page 675 and 676:

8. Seadistamine juhtimispaneelilt,

- Page 677 and 678:

0. ÜLDMENÜÜ 1. TÖÖMENÜÜ 2. S

- Page 679 and 680:

9.1.4 Vealogi Mõlemale vigade tü

- Page 681 and 682:

9.3.4 Pumba nupud Juhtimispaneelil

- Page 683 and 684:

13. Välise seadeväärtuse signaal

- Page 685 and 686:

Kahe indikaatortule ja signaalrelee

- Page 687 and 688:

19. Ekspluatatsioon ja hooldus 19.1

- Page 689 and 690:

23. Teised tehnilised andmed EMC (e

- Page 691 and 692:

TURINYS 1. Šiame dokumente naudoja

- Page 693 and 694:

5.1 Vienfazių siurblių elektros j

- Page 695 and 696:

5.2 Trifazių 0,75-7,5 kW siurblių

- Page 697 and 698:

Grupė 4 9 pav. TPED serija 2000 gn

- Page 699 and 700:

Grupė 4: Ryšio kabelis (8 kaište

- Page 701 and 702:

5.6.2 Darbo pakaitomis režimo ir r

- Page 703 and 704:

7. Nustatymas valdymo skydeliu, vie

- Page 705 and 706:

8.4 Min. kreivės režimo įjungima

- Page 707 and 708:

9.1 Meniu DARBAS Pirmasis ekranas

- Page 709 and 710:

9.2.7 Variklio guolių tepimo būkl

- Page 711 and 712:

10. Nustatymas naudojantis programa

- Page 713 and 714:

14. Magistralės signalas Siurblys

- Page 715 and 716:

18. Avarinis darbas (tik 11-22 kW)

- Page 717 and 718:

21. 0,75-7,5 kW trifazių siurblių

- Page 719 and 720:

Trifaziai siurbliai: 24. Atliekų t

- Page 721 and 722:

1. Šajā dokumentā lietotie simbo

- Page 723 and 724:

5.1.9. Savienojumi Piezīme Ja nav

- Page 725 and 726:

5.2.8. Sūkņa ieslēgšana/izslēg

- Page 727 and 728:

5.3.3. Rezerves drošinātāji Iete

- Page 729 and 730:

5.4. Signālkabeļi • Jālieto ek

- Page 731 and 732:

6.3.1. Vadības režīma izvēle sa

- Page 733 and 734:

8. Iestatīšana ar vadības pults

- Page 735 and 736:

0. GALVENĀ IZVĒLNE 1. DARBĪBA 2.

- Page 737 and 738:

9.1.4. Bojājumu reģistrs Abiem bo

- Page 739 and 740:

9.3.4. Sūkņa pogas Darba pogām u

- Page 741 and 742:

13. Ārējās uzdotās vērtības s

- Page 743 and 744:

Divu indikatora kontrollampiņu un

- Page 745 and 746:

19. Tehniskā apkope 19.1. Motora t

- Page 747 and 748:

23. Citi tehniskie dati EMC (elektr

- Page 749 and 750:

ЗМIСТ 1. Значення си

- Page 751 and 752:

5.1 Електричне під'є

- Page 753 and 754:

5.2 Електричне під'є

- Page 755 and 756:

Група 4 Рис. 9 З'єдну

- Page 757 and 758:

Група 2: Вихід (сигн

- Page 759 and 760:

5.6.2 Видалення "змін

- Page 761 and 762:

7. Введення установ

- Page 763 and 764:

8.4 Установка в режи

- Page 765 and 766:

9.1 Меню РОБОТА Перш

- Page 767 and 768:

9.2.7 Стан змащення п

- Page 769 and 770:

10. Задання установо

- Page 771 and 772:

14. Сигнал по шині На

- Page 773 and 774:

17. Опір ізоляції Ув

- Page 775 and 776:

20. Технічна інформа

- Page 777 and 778:

23. Інші технічні да

- Page 779 and 780:

1. Installation in the USA and Cana

- Page 781:

96782378 0110 Repl. 96782378 0109 w