Sinterizazio-atmosferaren eragina M graduko (ASP 30 ... - Euskara

Sinterizazio-atmosferaren eragina M graduko (ASP 30 ... - Euskara Sinterizazio-atmosferaren eragina M graduko (ASP 30 ... - Euskara

AVOIDING GRAIN GROWTH DURING THE SUPERSOLIDUS SINTERING OF HIGH SPEED STEELS J .I. SAN MARTIN, S .JAUREGI, LURRUTIBEASKOA, V.MARTÍNEZ, R.PALMA AND J .J.URCOLA CENTRO DE ESTUDIOS E INVESTIGACIONES TÉCNICAS DE GUIPÚZCOA (CEIT) ESCUELA SUPERIOR DE INGENIEROS INDUSTRIALES DE SAN SEBASTIÁN SAN SEBASTIÁN, (GUIPÚZCOA), BASQUE COUNTRY, SPAIN . KEY WORDS : High Speed Steel, Grain Size, Supersolidus Sintering, ABSTRACT Grain growth during supersolidus sintering of high speed tool steels in vacuum and in an atmosphere composed of N2-H2-CH4 has been investigated . An increase of temperature above the optimum for sintering (minimum temperature at which the theoretical density is reached) in vacuum causes a significant increase in the grain size, due to the dissolution of carbides and the increased amount of the liquid phase. On the other hand, oversintering in the N2-H2-CH4 atmosphere, although increasing the amount of liquid phase, results in only a small increase in the grain size . This different behaviour can be explained in terms of the formation, by reaction with the atmosphere, of very fine vanadium carbonitrides (< 1µm), which are very stable and do not dissolve even at high temperatures . This effect, responsible for better mechanical properties of high speed steels oversintered in the N2-H2-CH4 atmosphere, in comparison with vacuum, can be explained in terms of the Zener drag exerted by the fine and stable carbonitrides . INTRODUCTION It is widely known that oversintering, in vacuum, of high speed steels causes an accelerated austenite grain growth (1), also resulting in the formation of eutectic carbides during cooling (2), with the subsequent impairment of the mechanical properties (3) . In recent years investigations carried out at CEIT have shown that this grain growth during oversintering can be avoided when an atmosphere composed of N2-H2-CH4 is used (4) . In the present work a detailed analysis of the microstructural changes taking place during sintering in this atmosphere, and their effect on grain growth during the oversintering, have been carried out .

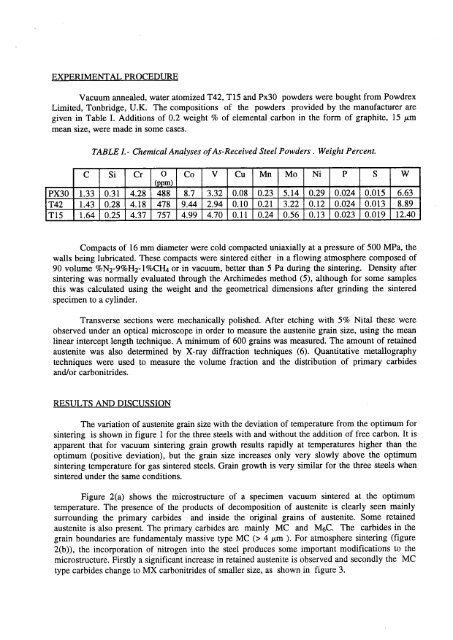

EXPERIMENTAL PROCEDURE Vacuum annealed, water atomized T42, T15 and Px30 powders were bought from Powdrex Limited, Tonbridge, U .K. The compositions of the powders provided by the manufacturer are given in Table I . Additions of 0 .2 weight % of elemental carbon in the form of graphite, 15 µm mean size, were made in some cases . TABLE 1.- Chemical Analyses of As-Received Steel Powders . Weight Percent . C Si Cr a (PPm) Compacts of 16 mm diameter were cold compacted uniaxially at a pressure of 500 MPa, the walls being lubricated . These compacts were sintered either in a flowing atmosphere composed of 90 volume %N2-9%H2-1%CH4 or in vacuum, better than 5 Pa during the sintering . Density after sintering was normally evaluated through the Archimedes method (5), although for some samples this was calculated using the weight and the geometrical dimensions after grinding the sintered specimen to a cylinder . Transverse sections were mechanically polished . After etching with 5% Nital these were observed under an optical microscope in order to measure the austenite grain size, using the mean linear intercept length technique . A minimum of 600 grains was measured . The amount of retained austenite was also determined by X-ray diffraction techniques (6) . Quantitative metallography techniques were used to measure the volume fraction and the distribution of primary carbides and/or carbonitrides . RESULTS AND DISCUSSION Co V Cu Mn Mo Ni p S W PX30 1 .33 0 .31 4 .28 488 8 .7 3 .32 0 .08 0 .23 5 .14 0 .29 0 .024 0 .015 6 .63 T42 1 .43 0 .28 4 .18 478 9 .44 2 .94 0 .10 0 .21 3 .22 0 .12 0 .024 0 .013 8 .89 T15 1 .64 0 .25 4.37 757 4 .99 4 .70 0 .11 0 .24 0 .56 0 .13 0 .023 0 .019 12 .40 The variation of austenite grain size with the deviation of temperature from the optimum for sintering is shown in figure 1 for the three steels with and without the addition of free carbon . It is apparent that for vacuum sintering grain growth results rapidly at temperatures higher than the optimum (positive deviation), but the grain size increases only very slowly above the optimum sintering temperature for gas sintered steels. Grain growth is very similar for the three steels when sintered under the same conditions . Figure 2(a) shows the microstructure of a specimen vacuum sintered at the optimum temperature . The presence of the products of decomposition of austenite is clearly seen mainly surrounding the primary carbides and inside the original grains of austenite . Some retained austenite is also present . The primary carbides are mainly MC and M6C . The carbides in the grain boundaries are fundamentaly massive type MC (> 4 gm ) . For atmosphere sintering (figure 2(b)), the incorporation of nitrogen into the steel produces some important modifications to the microstructure . Firstly a significant increase in retained austenite is observed and secondly the MC type carbides change to MX carbonitrides of smaller size, as shown in figure 3 .

- Page 272: IRUDIAK FIGURAS

- Page 275 and 276: Frecuency (%) 100 90 80 70 60 50 40

- Page 277 and 278: 100 80 ó ' 60 .J W H Z 40 w '< 20

- Page 279 and 280: 1 .4 1 0 .8 0 .4 • 1 0 20 Hondar-

- Page 282 and 283: 6 . ONDORIOAK 1 . % 90 N2-% 9 H2-%

- Page 284: 7. ATALA: IRADOKIZUNAK . CAPÍTULO

- Page 287 and 288: 7 . SUGERENCIAS 1 . Explorar hasta

- Page 290 and 291: BIBLIOGRAFÍA (1) P. Payson ; "The

- Page 292 and 293: (39) V .P. Martínez, R .H . Palma,

- Page 294 and 295: (77) H . Takigawa, H . Manto, N. Ka

- Page 296: ARGITARAPENAK . PUBLICACIONES .

- Page 299: PUBLICACIONES . Publicaciones gener

- Page 303 and 304: 306 Urr uibeaskoa et al . Metallogr

- Page 305 and 306: 308 Urrutibeaskoa et al . Metallogr

- Page 307 and 308: 310 Urrutibeaskoa et al . Metallogr

- Page 309: 312 Urrutibeaskoa et al . Metallogr

- Page 314 and 315: Figure 1 Microstructure of T42 + 0.

- Page 316 and 317: Figure 3 Microstructure of T15 (1 .

- Page 318 and 319: . . . 4 --s-- r a- 10 im Figure 5 M

- Page 320 and 321: TABLE V Chemical analysis of M 23 C

- Page 326 and 327: 90 o GT42 80 o e GT42C VT42 * VT42C

- Page 328 and 329: The presence of these MX carbonitri

- Page 332 and 333: Publishing & Editorial The Institut

- Page 334 and 335: INTRODUCTION Work carried out in th

- Page 336 and 337: etter than 5 Pa during the sinterin

- Page 338 and 339: gas atmosphere (see Table IV for qu

- Page 340 and 341: - Needle type : observed only at hi

- Page 342 and 343: -1o- (18) . These values would give

- Page 344 and 345: Chemical composition of primary car

- Page 346 and 347: CONCLUSIONS 1 . Addition of free ca

- Page 348 and 349: Vasco, 1987, Bilbao, España . 13 .

- Page 350 and 351: TABLE I Chemical analysis of as-rec

- Page 352 and 353: TABLE IV Austenite grain size and p

- Page 354 and 355: TABLE VII Chemical composition of C

- Page 356 and 357: 8 .5 8 `/ U) 7 c o 6 .5 6 5 .5 1 1

- Page 358 and 359: Fig . 3 : Microstructure at the opt

- Page 360 and 361: L Ú y i3 70 60 30 - L 2 0 r- i Q L

- Page 362 and 363: Frecuency (%) 100 90 - 80 70 - 60 -

- Page 364 and 365: Frecuency (%) 100 90 - 80 - 70 - 60

- Page 366 and 367: Fig. 8 a) Eutectic type carbides .

- Page 369 and 370: March 10, 1992 Mr . J . J . Urcola

- Page 371 and 372: INTRODUCTION Work carried out in th

EXPERIMENTAL PROCEDURE<br />

Vacuum annealed, water atomized T42, T15 and Px<strong>30</strong> powders were bought from Powdrex<br />

Limited, Tonbridge, U .K. The compositions of the powders provided by the manufacturer are<br />

given in Table I . Additions of 0 .2 weight % of elemental carbon in the form of graphite, 15 µm<br />

mean size, were made in some cases .<br />

TABLE 1.- Chemical Analyses of As-Received Steel Powders . Weight Percent .<br />

C Si Cr a<br />

(PPm)<br />

Compacts of 16 mm diameter were cold compacted uniaxially at a pressure of 500 MPa, the<br />

walls being lubricated . These compacts were sintered either in a flowing atmosphere composed of<br />

90 volume %N2-9%H2-1%CH4 or in vacuum, better than 5 Pa during the sintering . Density after<br />

sintering was normally evaluated through the Archimedes method (5), although for some samples<br />

this was calculated using the weight and the geometrical dimensions after grinding the sintered<br />

specimen to a cylinder .<br />

Transverse sections were mechanically polished . After etching with 5% Nital these were<br />

observed under an optical microscope in order to measure the austenite grain size, using the mean<br />

linear intercept length technique . A minimum of 600 grains was measured . The amount of retained<br />

austenite was also determined by X-ray diffraction techniques (6) . Quantitative metallography<br />

techniques were used to measure the volume fraction and the distribution of primary carbides<br />

and/or carbonitrides .<br />

RESULTS AND DISCUSSION<br />

Co V Cu Mn Mo Ni p S W<br />

PX<strong>30</strong> 1 .33 0 .31 4 .28 488 8 .7 3 .32 0 .08 0 .23 5 .14 0 .29 0 .024 0 .015 6 .63<br />

T42 1 .43 0 .28 4 .18 478 9 .44 2 .94 0 .10 0 .21 3 .22 0 .12 0 .024 0 .013 8 .89<br />

T15 1 .64 0 .25 4.37 757 4 .99 4 .70 0 .11 0 .24 0 .56 0 .13 0 .023 0 .019 12 .40<br />

The variation of austenite grain size with the deviation of temperature from the optimum for<br />

sintering is shown in figure 1 for the three steels with and without the addition of free carbon . It is<br />

apparent that for vacuum sintering grain growth results rapidly at temperatures higher than the<br />

optimum (positive deviation), but the grain size increases only very slowly above the optimum<br />

sintering temperature for gas sintered steels. Grain growth is very similar for the three steels when<br />

sintered under the same conditions .<br />

Figure 2(a) shows the microstructure of a specimen vacuum sintered at the optimum<br />

temperature . The presence of the products of decomposition of austenite is clearly seen mainly<br />

surrounding the primary carbides and inside the original grains of austenite . Some retained<br />

austenite is also present . The primary carbides are mainly MC and M6C . The carbides in the<br />

grain boundaries are fundamentaly massive type MC (> 4 gm ) . For atmosphere sintering (figure<br />

2(b)), the incorporation of nitrogen into the steel produces some important modifications to the<br />

microstructure . Firstly a significant increase in retained austenite is observed and secondly the MC<br />

type carbides change to MX carbonitrides of smaller size, as shown in figure 3 .