You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

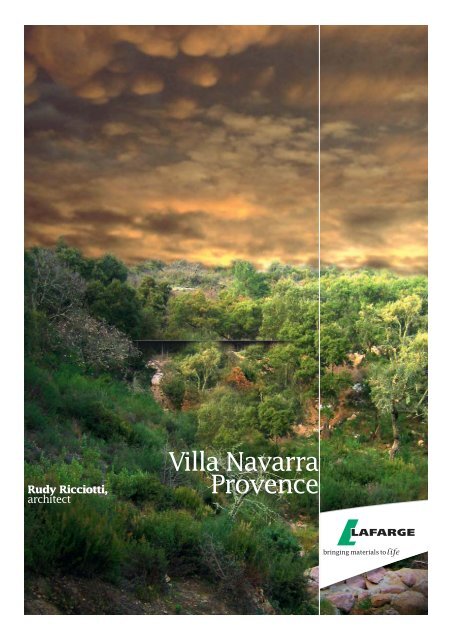

Rudy Ricciotti,<br />

architect<br />

<strong>Villa</strong> <strong>Navarra</strong><br />

Provence

03<br />

04<br />

08<br />

10<br />

13<br />

17<br />

P.02<br />

<strong>Villa</strong> <strong>Navarra</strong><br />

Rudy Ricciotti,<br />

architect<br />

Romain Ricciotti,<br />

engineer<br />

Mouloud Behloul,<br />

engineer<br />

Ductal ® ,<br />

outstanding material<br />

Rudy Ricciotti,<br />

architect<br />

An architecture of confrontation<br />

between landscape and materials<br />

Design<br />

A material used sparingly to meet the loads<br />

Prefabrication<br />

The art of moulds and pouring<br />

Assembly<br />

A traditional journeyman’s task<br />

Texts: François Lamarre. Photo credits: Philippe Ruault;<br />

Agence Ricciotti (cover, P. 08, P. 09, P. 15); Elise Sévère<br />

(P. 09, bottom). Edited by <strong>Lafarge</strong>. Design and production:<br />

External communication <strong>Lafarge</strong>;<br />

VILLA<br />

NAVARRA<br />

DUCTAL ® ,<br />

OUTSTANDING MATERIAL FOR<br />

AN ARCHITECTURE OF EXCEPTION<br />

Developed by <strong>Lafarge</strong>, Ductal ® ultra high performance fibre reinforced<br />

concrete has innovative properties which pave the way for architectural<br />

designs hitherto unheard of.<br />

Its special composition gives it exceptional compressive strength,<br />

six to eight times greater than normal concrete.<br />

For structural applications, the use of special metal fibres provides<br />

Ductal ® with ductile properties, hence the name: with flexural strength ten<br />

times that of standard concrete, it can undergo substantial working stress<br />

without shearing.<br />

Ductal ® is easy to use, and provides an infinite number of new<br />

possibilities. Its fluidity and the absence of conventional aggregates<br />

in its composition enable it to adapt to the slightest detail in the formwork<br />

and allow for the creation of extremely fine and thin forms that cannot<br />

be obtained with a traditional concrete structure. The resulting surfaces<br />

reproduce, with exceptional precision, the texture of the moulds.<br />

The surface appearance can thus adopt a range of aspects, and when<br />

polished, it can even imitate stone or marble, providing a remarkable<br />

aesthetic finish.<br />

Ductal ® is resistant to corrosion, abrasion, pollution, bad weather or<br />

shocks, making for a life span 2 to 3 times longer than that of<br />

conventional concrete.<br />

Ductal ® is an integral part of a sustainable development approach.<br />

Its mechanical performance, combined with its durability, its aesthetic<br />

qualities and its high compactness help reduce the environmental impact<br />

of construction, throughout the building's life cycle. Ductal ® requires<br />

half as much material and energy and results in CO2 emissions of up<br />

to half those induced by conventional concrete. It features the thermal<br />

mass capacity of concrete which, when optimized, helps reduce energy<br />

expenses when the building is in service.<br />

All these features make Ductal ® a high performance and sustainable<br />

construction material capable of the most impressive of architectural feats.<br />

P.03

Rudy Ricciotti,<br />

architect<br />

- Officer of the Arts<br />

- Chevalier of the Legion of Honour<br />

- Laureate of the National<br />

Architecture Grand Prix 2006<br />

Projects and achievements<br />

- The Footbridge of Peace, Seoul.<br />

- National Choreography Centre,<br />

Aix-en-Provence.<br />

- ITER France headquarters<br />

(International Thermonuclear<br />

Experimental Reactor),<br />

Cadarache.<br />

- National Marine Testing and<br />

Expertise Centre, Toulon.<br />

- University of Paris VII, reuse of<br />

the great mills, Paris.<br />

P.04<br />

VILLA<br />

NAVARRA<br />

Rudy Ricciotti has the gift of transforming all his<br />

building sites into epics. He makes each one of his<br />

projects into a personal struggle, into which he<br />

soon enrols all the other actors involved in the design<br />

and implementation.<br />

Ifthe<br />

building site is par excellence the heroic moment,<br />

the struggle begins at the time of ordering, with the design<br />

work setting the scene and shaping the guiding forces. For the<br />

architect, it is quite literally a question of dominating matter<br />

by shaping it. The smallest architectural project, no matter<br />

what the scale, is thus the pretext for a conceptual joust, which<br />

takes on epic proportions visible in the final work. The<br />

challenge laid down to the laws of physics leaves its mark in<br />

the design and the material and with a little imagination one<br />

can sense the almost physical commitment of the designer.<br />

The <strong>Navarra</strong> project is no exception to the rule in spite of the<br />

relatively small proportions of the work. The building, half<br />

way between a house and an art gallery, escapes mundane<br />

domesticity through the heroic stance taken towards its<br />

location and its description. The order from the art dealer,<br />

Enrico <strong>Navarra</strong>, lends itself perfectly, justifying innovation<br />

and asking for a real feat.<br />

“The intention is for the villa to be an art<br />

gallery, which can be visited by internet”, summarises Rudy<br />

Ricciotti, “and it will not be open to the public. It’s an<br />

abstract place, whose function is to constitute an enigma.”<br />

P.05

Hidden away in the hinterland of the Var coastline, the<br />

building achieves its objective by nestling into the<br />

slope so as to blend into the natural vegetation of the Provencal<br />

landscape. The desire for discretion meets here with concern<br />

for the environment by limiting the impact of development on<br />

the site. The principle of modesty dictates the positioning and<br />

the form of the construction, which has a quiet profile.<br />

The platform, cleared beforehand for the construction, leaves<br />

the rock bare and the plot of land stripped, to be planted<br />

tomorrow with cork oaks and cypresses. As for all the private<br />

homes previously conceived by Rudy Ricciotti, the relationship<br />

with the landscape is direct and frontal, accompanied by a<br />

certain discretion, which banishes disruptive elements. The<br />

building, positioned along the contours, is by its volumes<br />

similar to a dry stone wall. Its firm horizontality often follows<br />

the horizon out at sea and at other times the green and undu -<br />

lating tide of the fronds of vegetation. Ricciotti’s houses stand<br />

guard; sometimes they even take on a camouflaged aspect. As<br />

for <strong>Villa</strong> <strong>Navarra</strong>, it resembles a watchman lying on the slope<br />

of the maquis.<br />

The confrontational attitude is accompanied by no nonsense<br />

forms: in this case, a simple rectangle of forty metres long by<br />

just ten wide, encompassing a volume built on one level and<br />

doubled by a basin in the foreground that extends out into the<br />

landscape. “The radical treatment of the house’s geometry,”<br />

which is the architect’s signature, is masterfully interpreted in<br />

the technical approach to the building’s construction. The <strong>Villa</strong><br />

<strong>Navarra</strong> practically boils down to its roof: an immense visor<br />

stretching forty metres between the trees, a distinctive sign of<br />

the watchman hiding deep in the woods. This cantilevered<br />

surface of 7.80 metres opens up the house to the wild Var<br />

landscape. Only a thin line of façade gives away its hidden<br />

presence: an added line, blackened by coal.<br />

P.06<br />

FRONTAL ATTITUDE<br />

A simple rectangle defines a volume,<br />

established over a single level,<br />

and doubled by a basin that extends<br />

out into the landscape.<br />

VILLA<br />

NAVARRA<br />

"The "<strong>Villa</strong> <strong>Navarra</strong>" can be summed up by<br />

its roof structure: an immense visor stretching 40 m between<br />

the trees, a distinctive sign of the watcher<br />

in the shadows."<br />

P.07

P.08<br />

An architecture of<br />

confrontation<br />

between landscape<br />

and materials<br />

VILLA<br />

NAVARRA<br />

If discretion is the order of the day and the planned use virtual<br />

via internet, the construction itself is not at all virtual! The work<br />

is very real; it is even highly concrete and reeks of effort and<br />

applied physicality, as the architect is wont to say in imaginative<br />

terms.<br />

Under his leadership, the project took on an innovative dimension,<br />

which made the undertaking exciting: an exploration of<br />

materials, namely ultra-high performance fibered concrete<br />

Ductal® developed by <strong>Lafarge</strong>. By concentrating on the roof,<br />

the project gave itself a structural challenge, going beyond the<br />

dimensions of the plan to take on the status of a work of art.<br />

Applying civil engineering to this scale of project is the first<br />

achievement of the architect; the second lies in the way he<br />

ROMAIN RICCIOTTI<br />

Structural engineer.<br />

MOULOUD BEHLOUL<br />

Concrete engineer at <strong>Lafarge</strong> .<br />

executed it. The art dealer was clearly inviting the architect to<br />

indulge in a veritable creative act. This is how a work of art will<br />

tomorrow house other works of art, going beyond a question<br />

of format by the nature of the questions posed and the intensity<br />

of the thinking. The creative spirit which took over the<br />

construction makes architecture the reflection of the arts and<br />

broadens the builder’s scope, both in and calling the tune.<br />

The project, as executed, is thus almost a prototype and its<br />

execution a case study. Mouloud Behloul, the engineer in charge<br />

of the Ductal® development at <strong>Lafarge</strong>, points out that “the roof<br />

was the opportunity for all of us to think about a structure<br />

working mainly through flexing, due to the cantilever which<br />

typifies it and with no pre-stressing, the engineer’s normal<br />

approach, in order to thoroughly test the qualities of the<br />

material.” An approach even more unheard of and singular than<br />

that of the footbridge in Seoul, the architect’s first project<br />

undertaken with Ductal®, of which the single 130 metre arch<br />

naturally only works by pressure and makes use of pre-stressing<br />

to reinforce its voussoirs and optimise performance. At<br />

<strong>Villa</strong> <strong>Navarra</strong>, the 7.80 metre cantilever makes the roof one of<br />

a kind and its execution in Ductal© is a world first.<br />

P.09

DUCTAL ®<br />

The material was used 100%<br />

for the roof structure, making the most<br />

of all its properties.<br />

P.10<br />

DESIGN<br />

A material used<br />

sparingly to meet<br />

the loads<br />

VILLA<br />

NAVARRA<br />

Composed of 17 juxtaposed panels, the roof of the<br />

<strong>Villa</strong> <strong>Navarra</strong> makes full use of Ductal®’s qualities. The<br />

material is used 100%, as if left to its own devices, with<br />

no other assistance than traditional reinforcing placed at the<br />

upper part of the ribs. Even then the reinforcing is mechanically<br />

redundant, used in the end as a safety measure, just as the<br />

safety net protects the performing acrobat.<br />

The roof, of optimal design and structure, makes use of a design<br />

that faithfully follows the load lines with great economy of<br />

means. “The material is placed exactly where needed in order<br />

to be able to express itself,” enthuses Mouloud Behloul.<br />

The architect’s son, the engineer Romain Ricciotti arrived at the<br />

form through painstaking drafting, dictated by all manner of<br />

constraints, starting with the most pressing: getting all the<br />

materials to the building site in the middle of the countryside.<br />

The road network is, therefore, the first factor behind the dimensions<br />

of the roof, composed of modular, pre-fabricated parts.<br />

The final module is a panel measuring 9.25 m x 2.35 m, whose<br />

design is suitable for the spreading of the load in the planned<br />

structure, which is made up of a plate of a constant thickness<br />

edged by two lateral progressive inertia ribs, higher at the<br />

supports and becoming gradually thinner, meeting the thickness<br />

of the plate at the far ends. The ends have a clever open<br />

design to save weight and to allow the light to enter this part<br />

opened up as a porch. “The design produces an optimal<br />

mechanic, which is not without similarities to steel forms, comprising<br />

a web, wings or a purlin,” comments Romain Ricciotti, “and<br />

this form is not the result of any particular design feature.”<br />

A specialist in mathematical modelling, the young civil works<br />

engineer almost goes on the defensive about having held the<br />

pencil. “Structures behave as conceived and calculated,” points<br />

out Mouloud Behloul, who accepts the pre-defining of the shape,<br />

namely a plate edged by lateral ribs, “in as much as a structure<br />

never imposes itself and is always a matter of choice,” so says<br />

the engineer!<br />

The decisive factors behind the size of the roof panel are, therefore,<br />

its own weight, the allowable overload due to weather,<br />

wind resistance and heat expansion, which it is likely to suffer<br />

in a region subject to high amplitudes linked to sunshine and<br />

high winds. These amplitudes are all the greater, as the surface<br />

of the un-insulated roof is left bare, benefiting from the finished<br />

look and the waterproof qualities of the Ductal® panels.<br />

PRE-CASTED MODULES<br />

The extremity of the modules<br />

is open to add weight and make use the<br />

light in this part with an open top.<br />

“The aim to<br />

reduce the impact<br />

of the villa<br />

on the site led<br />

to the use of an<br />

ultra-thin roof<br />

made of Ductal®<br />

which comes<br />

to a thickness of<br />

3 cm at its tip.”<br />

P.11

THE LINE OF EFFORT<br />

The module is formed by a panel<br />

whose design matches the distribution<br />

of effort in the structure.<br />

THE DESIGN<br />

The design produces optimal<br />

mechanics, which recalls the design<br />

of steel profiles.<br />

P.12<br />

“Ductal®, as a<br />

new material,<br />

challenges<br />

all the usual<br />

methods of<br />

calculation.”<br />

VILLA<br />

NAVARRA<br />

Heat expansion is by far the most difficult to predict. The<br />

highest expansion recorded due to variations in temperature<br />

can be as much as 5 mm and, when the calculations give a<br />

theoretically doubled value, as much as one centimetre. Ductal®,<br />

as a new material, challenges all the usual methods of calculation.<br />

The delicate lines made possible by the material mean that<br />

the engineer must ask himself all manner of questions never<br />

heard of with buildings in traditional concrete, particularly<br />

questions about expansion and twisting. “The calculations<br />

themselves are ordinary” says Mouloud Behloul, “but it’s the<br />

approach that is not, above all for concrete.” The thickness of<br />

the slab to resolve the problem of twisting has been measured<br />

at 35 mm, “a sheet of paper in terms of concrete!<br />

Originally designed for post-stressing, the panels would not<br />

have been very different, apart from necessarily being firmly<br />

anchored, as dictated by post-stressing. Entirely made of UHPFC<br />

Ductal® and reliant on this one type of material (except for the<br />

fixed reinforcing which was eventually placed in the ribs), the<br />

panels lie in a more traditional fashion on two longitudinal<br />

beams, placed 1.50 metre apart, forming a technical gallery.<br />

Supporting braces, made up of a rod inserted in a socket<br />

injected with resin and bolted at the surface with a wing nut<br />

holding in place a load spreading plate, are placed along the<br />

back beam. For the second beam, simple neoprene cushions<br />

form the support.<br />

PREFABRICATION<br />

The art of<br />

moulds<br />

and pouring<br />

This choice, apart from the experimentation with<br />

materials that it affords, corresponds to a conscious<br />

choice of building method. Rudy Ricciotti is enthusiastic<br />

about the combination of a high tech product, as represented<br />

by Ductal® and industrial prefabrication, with traditional<br />

fitting without the constraints of the sophisticated processes<br />

necessitated by pre-stressing. If the formulation of Ductal®<br />

belongs to the world of the very latest highly sophisticated<br />

technology, its use is gradually becoming less dependent on<br />

laboratory culture, becoming known for real operational performance<br />

on the bulding site. Traditional fitting gives this innovative<br />

product, the result of ten years of research, a shared and<br />

mass appeal, which finally allows one to foresee mass usage in<br />

the short term. This “schizophrenic” relationship between<br />

production and fitting fuels the architect’s hope of seeing this<br />

family of concretes quickly becoming a material used by masons.<br />

The first stage in the process, prefabrication, still relies<br />

on the experimental culture necessitated by the material.<br />

The theory is already tainted by empiricism, having benefited<br />

from the expertise of the precaster, namely the Bonna Sabla<br />

company, located near Montpellier, France. The production of<br />

the mould and the method of pouring are determining factors<br />

for the production of these parts with elaborate and complex<br />

shapes, which also have a finished surface. The technological<br />

requirements are satisfied by the metal moulds which are<br />

produced by an aeronautics industry supplier. “In this way, two<br />

different industrial worlds, which normally are not aware of<br />

each other, are brought together in the manufacturing process,”<br />

notes the architect.<br />

TECHNOLOGICAL REQUIREMENTS<br />

The manufacture of the metallic<br />

moulds was performed by a supplier<br />

from the aeronautical industry.<br />

P.13

“The direction of the metallic fibres<br />

used in Ductal® requires a methodical<br />

and skilled approach.”<br />

P.14<br />

VILLA<br />

NAVARRA<br />

THE EXPERTISE OF THE PRE-CASTER<br />

The pouring method is vital in obtaining<br />

the elaborate and complex forms.<br />

Neither is it by chance that the next steps have something in<br />

common with aeronautics, notably through the run-off of<br />

liquids. The direction of the metallic fibres that make up Ductal®<br />

is not the least mysterious of the phenomena observed when<br />

manipulating the material, requiring a methodical and skilled<br />

approach. The mechanical performance being dependent on the<br />

direction of the fibres, it is essential to determine the pouring<br />

process which will align the needles in the direction of the flow<br />

of liquid. The extremely fine texture of these concretes, of which<br />

the largest particles reach only 0.5 mm, facilitates this hydraulic<br />

behaviour, which conditions the mechanical direction of the<br />

needles carried by the flow.<br />

“Proportionate to the other constituent parts which make<br />

up UHPFC’s, including silica fume, these fibres play the<br />

same role as reinforcements in traditional concretes,” notes<br />

Mouloud Behloul to explain the extraordinary resistance obtained<br />

by these clever formulations of which certain components are<br />

kept secret. For the production of the <strong>Villa</strong> <strong>Navarra</strong> panels, the<br />

moulds were set up back to front, pouring was carried out longitudinally<br />

for the profiled ribs on the edges and transversally for<br />

the plate, as witnessed by the oblong gaps retained at the ends.<br />

The checks carried out on the first prototypes showed the well<br />

founded basis for this method, with the fibres always correctly<br />

aligned. “This is choreography for materials,” notes Rudy<br />

Ricciotti, who is in wonderment over the “huge gap that exists<br />

between the minuscule scale of the fibres and the 7.80 metre<br />

cantilever that the calculations allow for.”<br />

The turning out of the mould carried out next happens after<br />

steaming at 90 °C for a more rapid curing of the concrete. It gives<br />

a smooth and shiny surface, of which the burnishing is accentuated<br />

by the darker tones caused by the fines used in the formulation<br />

of the concrete.<br />

P.15

P.16<br />

VILLA<br />

NAVARRA<br />

ASSEMBLY<br />

A traditional<br />

journeyman’s<br />

task<br />

With the on site assembly of the panels, the epic<br />

story of the roof runs into the traditional world<br />

of construction, its ups and downs and its constraints.<br />

The architect is in his element, caught between his fascination<br />

for the latest technology in materials and his ancestral attraction<br />

for the building site and the men who work there.<br />

The magic of this roof with its pronounced cantilever was not<br />

immediately obvious. Apart from the opinions sought after<br />

beforehand from experts in the field, in particular Jacques<br />

Resplendino, the Setra engineer who compiled the standard for<br />

UHPFCs, the assembly was subject to a methodological<br />

approach also involving the stone mason Ortunio. The installation<br />

of these panels weighing approximately 3 tonnes each<br />

and brought by lorry to the plot, was at times epic, “similar to<br />

the passage of the ship over the hill in the film Fitzcaraldo by<br />

Werner Herzog,” comments the architect with hindsight. “Mutual<br />

trust was created from one end to the other of the chain, making<br />

the operation a story of fellowship,” he likes to say.<br />

Lifted by a field crane, the panels were positioned on the two<br />

supporting beams, then pushed against the preceding one by<br />

being slid sideways and finally propped. They are joined by<br />

mortise and tenon at the bulge in the ribs by the positioning of<br />

a socket subsequently injected with resin. The fixture to the back<br />

beam is achieved by the previously mentioned sunken braces,<br />

LESS IS MORE<br />

The precast and the work site are forgotten;<br />

the roof structure dominates the landscape<br />

and is reflected in the water.<br />

P.17

working in traction, whereas support is provided entirely by the<br />

interior beam, equipped with neoprene.<br />

In order to avoid any tapping in the façade between these juxtaposed<br />

panels, similar to giant tiles placed edge to edge, a system<br />

of transversal axes in the form of a steel rod anchored in the<br />

lifting points at the ends of the panels and sealed by a resin,<br />

reinforces them. A silicon joint, placed later, guarantees waterproofing<br />

of the upper part of the ribs, which are thus joined and<br />

reinforced.<br />

The old fashioned part of the procedure and the fixing by simple<br />

metal bolts contrast with the sophisticated technology which<br />

preceded the development of this new type of plastic material<br />

and the manufacturing of the panels in elaborate shapes.<br />

It is in the ability to express these two worlds, of industry<br />

and of tradition, that the greatest sources of innovation<br />

for Ductal® reside, as for those builders who choose to allow<br />

this strange material to “talk”.<br />

The major work finished and the landscape growing back around<br />

it, there are no signs of this epic undertaking. The epic moments<br />

of the prefabrication and the building site are forgotten, leaving<br />

the roof to reign over the landscape and to reflect in the waters<br />

of the pond, henceforth frozen in harmony, still and as if at peace.<br />

P.18<br />

VILLA<br />

NAVARRA<br />

A VIRTUAL TOUR<br />

The structure is quite real;<br />

a strong materiality which exudes<br />

the effort and physics applied,<br />

as the architect puts it.<br />

"Mutual trust<br />

was created<br />

from one end<br />

to the other of<br />

the chain, making<br />

the operation<br />

a story<br />

of fellowship."<br />

P.19

<strong>Lafarge</strong><br />

61, rue des Belles Feuilles - BP 40<br />

75782 Paris Cedex 16 - France<br />

Phone: +33 1 44 34 11 11<br />

External Communications<br />

Phone: +33 1 44 34 58 30<br />

Fax: + 33 1 44 34 12 00<br />

www.lafarge.com