Ventura IPC Instruction Manual pdf - Kuhnke

Ventura IPC Instruction Manual pdf - Kuhnke

Ventura IPC Instruction Manual pdf - Kuhnke

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Kuhnke</strong> Electronics<br />

<strong>Instruction</strong> <strong>Manual</strong><br />

<strong>Ventura</strong> <strong>IPC</strong><br />

E 674 GB 07.03.2007/ 105.745

This instruction manual is primarily intended for use by design, project and development engineers. It does not contain any availability<br />

information. Data is only given to describe the product and must not be regarded as guaranteed properties in the legal sense. Any<br />

claims for damages - on whatever legal grounds - are excluded except for instances of deliberate intent or gross negligence on our<br />

part.<br />

We reserve the rights for errors, omissions and modifications.<br />

Reproduction even of extracts only with the editor's express and written prior consent.

KUHNKE Automation Table of Contents<br />

Table of Contents<br />

1 Introduction......................................................................................................................................................7<br />

2 Reliability, Safety .............................................................................................................................................8<br />

2.1 Application............................................................................................................................................8<br />

2.2 Target Group........................................................................................................................................8<br />

2.3 Reliability..............................................................................................................................................8<br />

2.4 Symbols ...............................................................................................................................................8<br />

2.4.1 Danger................................................................................................................................................9<br />

2.4.2 Attention .............................................................................................................................................9<br />

2.4.3 Note....................................................................................................................................................9<br />

2.4.4 Under Construction ............................................................................................................................9<br />

2.4.5 <strong>Instruction</strong>...........................................................................................................................................9<br />

2.5 Safety ...................................................................................................................................................9<br />

2.5.1 Project Planning and Installation......................................................................................................10<br />

2.5.2 Maintenance and Servicing..............................................................................................................10<br />

2.6 Electromagnetic Compatibility............................................................................................................11<br />

2.6.1 Definition ..........................................................................................................................................11<br />

2.6.2 Interference Emission ......................................................................................................................11<br />

2.6.3 General Notes on Installation...........................................................................................................11<br />

2.6.4 Electrical Immission Safeguard........................................................................................................12<br />

2.6.5 Cable Routing and Wiring ................................................................................................................12<br />

2.6.6 Location of Installation .....................................................................................................................12<br />

2.6.7 Particular Sources of Interference....................................................................................................12<br />

3 <strong>Ventura</strong> <strong>IPC</strong> System Description...................................................................................................................13<br />

3.1 Overview ............................................................................................................................................13<br />

3.2 <strong>Ventura</strong> <strong>IPC</strong> + System Description ....................................................................................................14<br />

3.3 Application..........................................................................................................................................14<br />

3.4 Technical Properties ..........................................................................................................................15<br />

3.5 Model Variant.....................................................................................................................................16<br />

3.6 Physical Design..................................................................................................................................17<br />

3.7 <strong>Ventura</strong> <strong>IPC</strong> Power Supply and Ports................................................................................................18<br />

3.7.1 24 VDC Power Supply .....................................................................................................................18<br />

3.7.2 Operative Earth ................................................................................................................................18<br />

3.7.3 Serial Ports "COM1 and COM2" ......................................................................................................18<br />

3.7.4 Graphics Adapter "DVI / VGA" .........................................................................................................19<br />

3.7.5 Interface "PS / 2" ..............................................................................................................................20<br />

3.7.6 Interface "USB1","USB2" .................................................................................................................20<br />

3.7.7 Ethernet "LAN1", "LAN2"..................................................................................................................21<br />

3.7.8 Fieldbus Interface "BUS1" as CANopen Port ..................................................................................22<br />

3.8 <strong>Ventura</strong> <strong>IPC</strong> Controls .........................................................................................................................22<br />

3.8.1 "RESET" Button ...............................................................................................................................22<br />

3.9 Storage Media (Removable Disk)......................................................................................................23<br />

3.9.1 Compact Flash Card Slot "CF-CARD" .............................................................................................23<br />

3.9.2 Compact Flash Card Slot "CF-CARD" .............................................................................................23<br />

3.10 LED Indicators, <strong>Ventura</strong> <strong>IPC</strong> ..........................................................................................................23<br />

3.10.1 Status LEDs ...................................................................................................................................23<br />

3.11 External Elements, <strong>Ventura</strong> <strong>IPC</strong> + Hardware PLC.........................................................................25<br />

3.12 Power Supply and Interfaces, PLC Hardware <strong>Ventura</strong>+................................................................26<br />

3.12.1 24 VDC Power Supply ...................................................................................................................26<br />

3.12.2 Operative Earth ..............................................................................................................................26<br />

E 674 GB 3<br />

07.03.2007

Table of Contents KUHNKE Automation<br />

3.12.3 Fieldbus Interface "BUS2" as CANopen Port ................................................................................26<br />

3.12.4 Fieldbus Interface "BUS3" as PROFIBUS Port..............................................................................27<br />

3.12.5 Digital Combi I/O "DI/DO" ..............................................................................................................27<br />

3.12.6 Serial RS 232 Interface ..................................................................................................................28<br />

3.13 <strong>Ventura</strong>+ Hardware PLC Controls..................................................................................................29<br />

3.13.1 "RESET" Button .............................................................................................................................29<br />

3.14 <strong>Ventura</strong> Indicators ..........................................................................................................................29<br />

3.14.1 Status LEDs ...................................................................................................................................29<br />

3.15 Error Codes ....................................................................................................................................30<br />

4 Installation .....................................................................................................................................................31<br />

4.1 Flange Plate Installation.....................................................................................................................31<br />

4.1.1 To Install the Screw Plate Adapter (<strong>Ventura</strong> <strong>IPC</strong> 300 / 700) ...........................................................31<br />

4.1.2 To Install the Device.........................................................................................................................31<br />

4.2 Mounting on Top-hat Rail (<strong>Ventura</strong> <strong>IPC</strong> 300 / 700) ...........................................................................32<br />

4.2.1 To Attach the Rail Adapter to the Device.........................................................................................32<br />

4.2.2 To Attach the Device to the Top-hat Rail .........................................................................................32<br />

4.2.3 To Remove the Device from the Top-hat Rail..................................................................................32<br />

5 Start-up..........................................................................................................................................................33<br />

5.1 Installing CoDeSys on the Programming PC.....................................................................................33<br />

5.1.1 CoDeSys Target Installation ............................................................................................................33<br />

5.2 CoDeSys Programming PC Setup.....................................................................................................34<br />

5.2.1 Ethernet Connections of <strong>Ventura</strong> <strong>IPC</strong>..............................................................................................34<br />

5.2.2 Programming PC Interface Setup ....................................................................................................34<br />

5.2.3 CoDeSys Target System Setting on the Programming PC .............................................................35<br />

6 Windows ® XP Embedded ..............................................................................................................................36<br />

6.1 Components.......................................................................................................................................37<br />

6.1.1 General Data....................................................................................................................................37<br />

6.1.2 Breakdown of Key Components of the Windows ® XP embedded Image .......................................37<br />

6.1.3 XP embedded File System...............................................................................................................37<br />

6.2 Tools ..................................................................................................................................................38<br />

6.2.1 <strong>Ventura</strong> touch Calibration.................................................................................................................38<br />

6.2.2 Temperature Monitor........................................................................................................................38<br />

6.2.3 OPC Server......................................................................................................................................39<br />

6.3 IPHelper .............................................................................................................................................39<br />

6.3.1 USB Memory Stick ...........................................................................................................................39<br />

6.3.2 Create New SID ...............................................................................................................................40<br />

6.3.3 UltraVNC Remote Control Option ....................................................................................................41<br />

6.4 File Transfer .......................................................................................................................................42<br />

6.5 <strong>Ventura</strong> SlotPLC Gateway Driver ......................................................................................................43<br />

6.5.1 Installation ........................................................................................................................................43<br />

6.5.2 To verify correct installation of the <strong>Ventura</strong> SlotPLC gateway drivers.............................................43<br />

7 Windows ® CE.NET ........................................................................................................................................44<br />

7.1.1 Windows CE.NET File System.........................................................................................................44<br />

7.1.2 Components.....................................................................................................................................45<br />

7.1.3 <strong>Ventura</strong> touch Calibration.................................................................................................................46<br />

7.1.4 Running Applications .......................................................................................................................46<br />

7.1.5 OPC Server......................................................................................................................................47<br />

7.1.6 Printers .............................................................................................................................................47<br />

7.1.7 USB Memory Stick ...........................................................................................................................47<br />

7.1.8 Remote Control Option ....................................................................................................................47<br />

4 E 674 GB<br />

07.03.2007

KUHNKE Automation Table of Contents<br />

7.2 Connecting Using "ActiveSync" .........................................................................................................48<br />

7.3 Connecting via the Network ...............................................................................................................50<br />

7.4 Tools ..................................................................................................................................................52<br />

7.4.1 Check System Status Using "systemhealth"....................................................................................52<br />

7.4.2 ScreenRes........................................................................................................................................52<br />

7.4.3 Remote Debugging in Microsoft Visual Studio .NET 2003 ..............................................................54<br />

7.5 Connecting with <strong>Ventura</strong> <strong>IPC</strong>'s Software PLC (Windows CE)...........................................................55<br />

7.5.1 Serial Interface .................................................................................................................................55<br />

7.5.2 Ethernet Interface.............................................................................................................................57<br />

8 Troubleshooting.............................................................................................................................................60<br />

8.1 General Problems ..............................................................................................................................60<br />

9 Maintenance ..................................................................................................................................................61<br />

9.1 Replacing the Battery.........................................................................................................................61<br />

9.2 Handling of Memory Cards ................................................................................................................62<br />

10 Appendix......................................................................................................................................................63<br />

10.1 Licencing ........................................................................................................................................63<br />

10.2 Technical Data................................................................................................................................64<br />

10.2.1 Basic Data......................................................................................................................................64<br />

10.2.2 Indicators........................................................................................................................................66<br />

10.2.3 Communication ports .....................................................................................................................66<br />

10.2.4 Hardware PLC (<strong>Ventura</strong>+)..............................................................................................................66<br />

10.2.5 Integrated Inputs and Outputs (<strong>Ventura</strong> +) ....................................................................................67<br />

10.2.6 Communication Ports (<strong>Ventura</strong> +)..................................................................................................68<br />

10.2.7 Permits ...........................................................................................................................................68<br />

10.3 Dimensions, <strong>Ventura</strong> <strong>IPC</strong> ...............................................................................................................69<br />

10.3.1 Outer Dimensions, <strong>Ventura</strong> <strong>IPC</strong> 300..............................................................................................69<br />

10.3.2 <strong>Ventura</strong> <strong>IPC</strong> 300 / 700, Drilling Jig for Screw Plate Adapter..........................................................70<br />

10.3.3 <strong>Ventura</strong> <strong>IPC</strong> 300 / 700, Rail Adapter..............................................................................................71<br />

10.3.4 Outer Dimensions, <strong>Ventura</strong> <strong>IPC</strong> 800 / 1000...................................................................................72<br />

10.4 <strong>Ventura</strong> <strong>IPC</strong> 800 / 1000, Drilling Jig ...............................................................................................73<br />

10.4.1 Outer Dimensions <strong>Ventura</strong> 300+ / <strong>Ventura</strong> 300FB ........................................................................74<br />

10.4.2 <strong>Ventura</strong> <strong>IPC</strong> 300+ / 300FB / 700+ / 700FB, Drilling Jig for Screw Plate Adapter .........................75<br />

10.4.3 <strong>Ventura</strong> <strong>IPC</strong> 300+ / 300FB / 700+ / 700FB, Rail Adapter ..............................................................76<br />

10.4.4 Outer Dimensions, <strong>Ventura</strong> 800+ / 800 FB / 1000+ / 1000FB .......................................................77<br />

10.4.5 <strong>Ventura</strong> <strong>IPC</strong> 800+ / 800FB / 1000+ / 1000FB, Drilling Jig for Screw Plate Adapter .....................78<br />

10.4.6 Emergency Action ..........................................................................................................................79<br />

10.5 Taking out of Service......................................................................................................................79<br />

10.6 Disposal..........................................................................................................................................79<br />

10.7 Order Specifications .......................................................................................................................80<br />

10.7.1 Basic Units .....................................................................................................................................80<br />

10.7.2 Accessories....................................................................................................................................81<br />

10.8 References .....................................................................................................................................83<br />

10.9 Sales & Service ..............................................................................................................................84<br />

10.9.1 Main Factory in Malente.................................................................................................................84<br />

10.9.2 Sales Germany...............................................................................................................................84<br />

10.10 Index...............................................................................................................................................85<br />

E 674 GB 5<br />

07.03.2007

Table of Contents KUHNKE Automation<br />

6 E 674 GB<br />

07.03.2007

1 Introduction<br />

Performance in a nutshell<br />

Introduction<br />

The modular design and standard on-board interfaces of PC-based controller<br />

<strong>Ventura</strong> support flexible control solutions providing for future developments<br />

in automation. Its passive chiller, fanless operation and the CF cards<br />

used as mass storage media ensure advanced flexibility and speed and safety.<br />

The mechanical and electrical design of the basic <strong>Ventura</strong> <strong>IPC</strong> model provides<br />

reliable control and actuation of machines under tough everyday conditions<br />

of the industry and warrants that all data is safe even in the event of<br />

power failures. It is shock-proof and vibration-proof, features low-voltage<br />

protection and EMC compliance plus compatibility with temperatures up to<br />

50 °Celsius. Standard ports to CANopen, DVI, Ethernet, COM and USB let<br />

<strong>Ventura</strong> <strong>IPC</strong> satisfy all communication needs. Users are supported by<br />

CoDeSys, the stable and real-time control and programming system, in conjunction<br />

with the real-time operating system, Microsoft® Windows® CE and<br />

XP embedded. Two compact flash drives allow application and machine<br />

data to be separated from the operating system. The <strong>Ventura</strong> <strong>IPC</strong> platform<br />

installs or mounts either in a switching cabinet or immediately behind the<br />

new <strong>Ventura</strong> <strong>IPC</strong> Touch.<br />

E 674 GB 7<br />

07.03.2007

Reliability, Safety KUHNKE Automation<br />

2 Reliability, Safety<br />

2.1 Application<br />

2.2 Target Group<br />

2.3 Reliability<br />

2.4 Symbols<br />

<strong>Kuhnke</strong> products are designed as resources for use in industrial environments.<br />

All other applications need to be discussed with the factory first. The manufacturer<br />

shall neither be liable for any other than the intended use of our<br />

products nor for any ensuing damages. The risk shall be borne by the operator<br />

alone. The use as intended includes that you read and apply all information<br />

and instructions contained in this manual.<br />

This instruction manual contains all information necessary for the use of the<br />

described product (control device, control terminal, software, etc.) according<br />

to instructions. It is written for design, project planning, servicing and commissioning<br />

experts. For proper understanding and error-free application of<br />

technical descriptions, instructions for use and particularly of notes of danger<br />

and warning, extensive knowledge of automation technology is compulsory.<br />

Reliability of <strong>Kuhnke</strong> products is brought to the highest possible standards<br />

by extensive and cost-effective means in their design and manufacture.<br />

These include:<br />

• selecting high-quality components,<br />

• quality agreements with our suppliers,<br />

• actions to avoid static charges when handling MOS circuits,<br />

• worst case planning and design of all circuits,<br />

• visual inspections at various stages of fabrication,<br />

• computer-aided tests of all assemblies and their interaction in the circuit,<br />

• statistical assessment of the quality of fabrication and of all returned<br />

goods for the immediate taking of appropriate corrective actions.<br />

Despite the measures described in chapter 2.3 the occurrence of faults or<br />

errors in electronic control units - even if most highly improbable - must be<br />

taken into consideration.<br />

Please pay particular attention to the additional notices which we have<br />

marked by symbols throughout this instruction manual. While some of these<br />

notices make you aware of possible dangers, others are intended as a<br />

means of orientation. They are described further down below in descending<br />

order of importance.<br />

8 E 674 GB<br />

07.03.2007

KUHNKE Automation Reliability, Safety<br />

2.4.1 Danger<br />

2.4.2 Attention<br />

2.4.3 Note<br />

2.4.4 Under Construction<br />

2.4.5 <strong>Instruction</strong><br />

2.5 Safety<br />

This symbol warns you of dangers which may cause death or grievous bodily<br />

harm if operators fail to implement the precautions described.<br />

This symbol draws your attention to information you must take a look at to<br />

avoid malfunctions, possible material damage or dangerous states.<br />

This symbol draws your attention to additional information concerning the<br />

use of the described product. This may include cross references to information<br />

found elsewhere (e.g. in other manuals).<br />

This symbol tells you that the function described was not or not fully available<br />

at the time this document went to press.<br />

Wherever you see these symbols in the left margin, you will find a list of<br />

steps instructing you to take the appropriate computer or hardware actions.<br />

They are intended as a means of orientation wherever working steps and<br />

background information alternate (e.g. in tutorials).<br />

Our products normally become part of larger systems or installations. The information<br />

below is intended to help you integrate the product into its environment<br />

without dangers to humans or material/equipment.<br />

To achieve a high degree of conceptual safety in planning and installing an<br />

electronic controller, it is essential to exactly follow the instructions given in<br />

the manual because wrong handling could lead to rendering measures against<br />

dangers ineffective or to creating additional dangers.<br />

E 674 GB 9<br />

07.03.2007

Reliability, Safety KUHNKE Automation<br />

2.5.1 Project Planning and Installation<br />

2.5.2 Maintenance and Servicing<br />

• 24 VDC power supply: generate as electrically safely separated low<br />

voltage. Suitable devices are, for example, split transformers constructed<br />

in compliance with European Standard EN 60742 (corresponds<br />

to VDE 0551).<br />

• Power breakdowns or power fades: the program structure is to ensure<br />

that a defined state at restart excludes all dangerous states.<br />

• Emergency switch-off installations must comply with EN 60204/IEC 204<br />

(VDE 0113). They must be effective at any time.<br />

• Safety and precautions regulations for qualified applications have to be<br />

complied with.<br />

• Please pay particular attention to the notices of warning which, at relevant<br />

places, will make you aware of possible sources of dangerous mistakes<br />

or faults.<br />

• Relevant standards and VDE regulations are to be complied with in<br />

every case.<br />

• Control elements are to be installed in such a way as to exclude unintended<br />

operation.<br />

• Control cables are to be laid in such a way as to exclude interference<br />

(inductive or capacitive) which could influence controller operation or its<br />

functionality.<br />

• Precautions regulation VBG 4.0 must be observed when measuring or<br />

checking a controller in a power-up condition. This applies to section 8<br />

(Admissible deviations when working on parts) in particular.<br />

• Repairs must be carried out by specially trained <strong>Kuhnke</strong> staff only (usually<br />

in the main factory in Malente). Warranty expires in every other<br />

case.<br />

• Spare parts:<br />

• Only use parts approved of by <strong>Kuhnke</strong>. Only genuine <strong>Kuhnke</strong> modules<br />

must be used in modular controllers.<br />

• Modular systems: always plug or unplug modules in a power-down state.<br />

You might otherwise damage the modules or (possibly not immediately<br />

recognisably!) inhibit their functionality.<br />

• Always dispose of any batteries and accumulators as hazardous waste.<br />

10 E 674 GB<br />

07.03.2007

KUHNKE Automation Reliability, Safety<br />

2.6 Electromagnetic Compatibility<br />

2.6.1 Definition<br />

2.6.2 Interference Emission<br />

2.6.3 General Notes on Installation<br />

Electromagnetic compatibility is the ability of a device to function satisfactorily<br />

in its electromagnetic environment without itself causing any electromagnetic<br />

interference that would be intolerable to other devices in this environment.<br />

Of all known phenomena of electromagnetic noise, only a certain range occurs<br />

at the location of a given device. These kinds of noise are specified in<br />

the applicable product standards.<br />

The design and immunity to interference of programmable logic controllers<br />

are internationally governed by standard<br />

IEC 61131-2 which, in Europe, has been the basis for European Standard<br />

EN 61131-2.<br />

Refer to IEC 61131-4, User's Guideline, for general installation instructions<br />

to be complied with to ensure that hardware interface factors and the ensuing<br />

noise voltages are limited to tolerable levels.<br />

Interfering emission of electromagnetic fields, HF<br />

compliant to EN 55011, limiting value class A, Group 1<br />

If the controller is designed for use in residential areas, high-frequency emissions<br />

must comply with limiting value class B as described in EN 55011.<br />

Fitting the controller into earthed metal cabinets and in-stalling filters in the<br />

supply lines may produce a shielding compliant to the above standard.<br />

As component parts of machines, facilities and systems, electronic control<br />

systems must comply with valid rules and regulations, depending on their<br />

field of application.<br />

General requirements concerning the electrical equipment of machines and<br />

aiming at the safety of these machines are contained in Part 1 of European<br />

Standard EN 60204 (corresponds to VDE 0113).<br />

For safe installation of our control system please observe the information<br />

contained in the next chapters (� 2.6.4 ff).<br />

E 674 GB 11<br />

07.03.2007

Reliability, Safety KUHNKE Automation<br />

2.6.4 Electrical Immission Safeguard<br />

2.6.5 Cable Routing and Wiring<br />

2.6.6 Location of Installation<br />

2.6.6.1 Temperature<br />

2.6.6.2 Contamination<br />

2.6.6.3 Impact and Vibration<br />

2.6.6.4 Electromagnetic Interference<br />

Connect the control system to the protective earth conductor to eliminate electromagnetic<br />

interference. Practice best cable routing.<br />

Keep power circuits separate from control circuits:<br />

• DC voltages 60 V ... 400 V<br />

• AC voltages 25 V ... 400 V<br />

Joint laying of control circuits is allowed for:<br />

• shielded data signals<br />

• shielded analogue signals<br />

• unshielded digital I/O lines<br />

• unshielded DC voltages < 60 V<br />

• unshielded AC voltages < 25 V<br />

2.6.7 Particular Sources of Interference<br />

2.6.7.1 Inductive Actuators<br />

Ensure that temperatures, contaminations, impact, vibration or electromagnetic<br />

interference are no impediment to the installation.<br />

Consider heat sources such as general heating of rooms, sunlight, heat accumulation<br />

in assembly rooms or control cabinets.<br />

Use suitable casings to avoid possible negative influences due to humidity,<br />

corrosive gas, liquid or conducting dust.<br />

Consider possible influences caused by motors, compressors, transfer lines,<br />

presses, ramming machines and vehicles.<br />

Consider electromagnetic interference from various local sources: motors,<br />

switching devices, switching thyristors, radio-controlled devices, welding equipment,<br />

arcing, switched-mode power supplies, converters / inverters.<br />

Switching off inductances (such as from relays, contactors, solenoids or<br />

switching magnets) produces surge voltages. It is necessary to reduce these<br />

extra voltages to a minimum. Throttling elements could be diodes, Z diodes,<br />

varistors or RC elements. To find the best adapted elements, we recommend<br />

that you contact the manufacturer or supplier of the corresponding actuators<br />

for the relevant information.<br />

12 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

3 <strong>Ventura</strong> <strong>IPC</strong> System Description<br />

3.1 Overview<br />

<strong>Ventura</strong> <strong>IPC</strong> is<br />

• compact<br />

• reliable due to fanless operation up to 50 °C<br />

• a safe place for data due to its retentive NV-RAM w/o battery<br />

• compatible due to CoDeSys (to IEC 61131-1 standard)<br />

• flexible due to modular PC hardware<br />

• scalable in its price and performance<br />

• a PC-based controller<br />

available in the long term<br />

PLC power supply<br />

CANopen<br />

easy to install<br />

E 674 GB 13<br />

07.03.2007

Hardware KUHNKE Automation<br />

3.2 <strong>Ventura</strong> <strong>IPC</strong> + System Description<br />

3.3 Application<br />

A scalable price and performance also means to only use the <strong>Ventura</strong> <strong>IPC</strong><br />

building blocks you really need for a given application.<br />

<strong>Ventura</strong> <strong>IPC</strong> + is a variant with an integrated slot PLC. Actually, it consists of<br />

two separate components built into the same housing and communicating<br />

via a dual-port RAM. Although the slot PLC resides in the same housing, it<br />

still has its own power supply and, to give extra safety to the system, the deterministic<br />

control process is entirely independent from the "<strong>Ventura</strong> <strong>IPC</strong><br />

host PC".<br />

For further information on the slot PLC inside <strong>Ventura</strong> <strong>IPC</strong> +, please read<br />

instruction manual E 697 GB "<strong>Ventura</strong> SlotPLC, PLC, PROFIBUS-DP and<br />

CANopen Master"<br />

<strong>Ventura</strong> <strong>IPC</strong> installs on a top-hat rail to provide a scalable, PC-based control<br />

platform for switching cabinets or terminal boxes.<br />

With this range of products you get a powerful and flexible industry PC system<br />

for a wide range of practical applications, specifically in the fields of mechanical<br />

engineering and switching cabinet construction:<br />

• open and closed loop control using standardised software tools for all<br />

areas of mechanical engineering<br />

• operation and visualisation with the display terminal taken down for use<br />

in automatic machines and info terminals<br />

• a single unit for the visualisation and real-time control of generalpurpose<br />

machine systems<br />

14 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

3.4 Technical Properties<br />

<strong>Ventura</strong> <strong>IPC</strong> 300 <strong>Ventura</strong> <strong>IPC</strong> 700 <strong>Ventura</strong> <strong>IPC</strong> 800/1000<br />

Design Cabinet-mounted <strong>IPC</strong> Cabinet-mounted <strong>IPC</strong> Cabinet-mounted <strong>IPC</strong><br />

Installation<br />

Universal rail or with<br />

screws<br />

Universal rail or with<br />

screws<br />

Cooling Passive Passive Passive<br />

Processor<br />

Controls<br />

Status indication by LEDs<br />

266 MHz<br />

Geode<br />

Reset button on front<br />

panel<br />

Run,<br />

Stop,<br />

Error (PLC),<br />

HDD,<br />

Bus (CANopen),<br />

DVI,<br />

USB<br />

Main memory Min. 128 Mbyte SD-RAM<br />

733 MHz<br />

Celeron®<br />

Reset button on front<br />

panel<br />

Run,<br />

Stop,<br />

Error (PLC),<br />

HDD,<br />

Bus (CANopen),<br />

DVI,<br />

USB<br />

Min. 128 Mbyte SD-<br />

RAM<br />

Integrated screw plate<br />

adapter<br />

800 MHz / 1.0 GHz<br />

Celeron® M<br />

Reset button on front panel<br />

Run,<br />

Stop,<br />

Error (PLC),<br />

HDD,<br />

Bus (CANopen),<br />

DVI,<br />

USB<br />

Min. 256 Mbyte DDR-Ram<br />

NV-RAM 32 kbyte 32 kbyte 32 kbyte<br />

Working memory size Max. 512 Mbyte Max. 512 Mbyte Max. 1024 Mbyte<br />

Compact flash card<br />

Ethernet<br />

Type I, boot-enabled,<br />

1x at front,<br />

1x at back<br />

2x 10/100 Base-T<br />

RJ-45 jack<br />

Type I, boot-enabled,<br />

1x at front,<br />

1x at back<br />

2x 10/100 Base-T<br />

RJ-45 jack<br />

Type I, boot-enabled,<br />

1x at front,<br />

1x at back<br />

2x 10/100 Base-T<br />

RJ-45 jack<br />

USB 2x USB 1.1 2x USB 2.0 2x USB 2.0<br />

Serial interface, 2x COM 2x COM 2x COM<br />

Graphics adapter DVI / VGA (combined) DVI / VGA (combined) DVI / VGA (combined)<br />

Resolution (DVI) Max. 1024 x 768 Max. 1024 x 768 Max. 1024 x 768<br />

Resolution (VGA) Max. 1024 x 768 Max. 1280x1024 Max. 2048x1536<br />

Keyboard/mouse PS/2 PS/2 PS/2<br />

CANopen Max. 1 Mbps Max. 1 Mbpss Max. 1 Mbpss<br />

Supply voltage 24 VDC -15%+20% 24 VDC -15%+20% 24 VDC -15%+20%<br />

Ambient temperature 0 ... 50 °C 0 ... 50 °C 0 ... 50 °C<br />

Housing made of Stainless steel/aluminium Stainless<br />

steel/aluminium<br />

Stainless steel/aluminium<br />

Protection IP20 IP20 IP20<br />

Dimensions (HxWxD) 222 x 63 x 141mm<br />

222 x 81 x 141 mm incl.<br />

heat sink<br />

222 x 69 x 135 mm incl.<br />

heat sink<br />

E 674 GB 15<br />

07.03.2007

Hardware KUHNKE Automation<br />

3.5 Model Variant<br />

KUHNKE <strong>Ventura</strong> <strong>IPC</strong><br />

Processor<br />

PC-RAM<br />

Add-on assembly<br />

CF card<br />

Operating system/<br />

software<br />

To perfectly adapt <strong>Ventura</strong> <strong>IPC</strong> to a given application, there is a range of<br />

hardware and software options to choose from. The model variant of your<br />

unit can be derived from the part no. (Order-No.) you order it by. The name<br />

plate is located on the right-hand side of the housing.<br />

Part Number<br />

Model variants Part Number<br />

Control PC 639<br />

100 MHz STPC eLite 00<br />

266 MHz Geode 10<br />

733 MHz Celeron 20<br />

800 MHz Celeron® M 41<br />

1 GHz Celeron® M 40<br />

128 Mbyte 0<br />

256 Mbyte 1<br />

512 Mbyte 2<br />

none 00<br />

<strong>Ventura</strong> <strong>IPC</strong>+ (CAN, PROFIBUS, 5 I/O) 01<br />

<strong>Ventura</strong> <strong>IPC</strong> FB (PROFIBUS) 02<br />

<strong>Ventura</strong> <strong>IPC</strong> ASI 30<br />

<strong>Ventura</strong> <strong>IPC</strong> ASI FB (PROFIBUS)<br />

UPS<br />

32<br />

128 Mbyte 0<br />

256 Mbyte 1<br />

512 Mbyte 2<br />

1024 Mbyte 3<br />

2048 Mbyte 4<br />

HDD 8<br />

none 00<br />

Win CE.net 01<br />

Win CE.net + CoDeSys RT 02<br />

Win CE.net + CoDeSys RT + Target Visualisation 03<br />

Win CE.net plus<br />

+ CoDeSys RT + Target Visualisation<br />

04<br />

Win XP embedded<br />

Win XP embedded + CoDeSys RTE<br />

Win XP embedded + .net framework<br />

20<br />

16 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

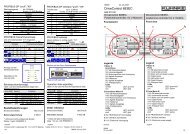

3.6 Physical Design<br />

mouse/keyboard adapter<br />

for Y cable<br />

Ethernet<br />

CANopen<br />

DVI/VGA<br />

serial port COM1<br />

24 VDC power supply<br />

protective earth<br />

heat sink for <strong>Ventura</strong> <strong>IPC</strong><br />

700/800/1000<br />

see dimensions<br />

protective earth<br />

status LEDs<br />

reset button<br />

CF card (front)<br />

CF card ejector<br />

USB1 (USB 2.5)<br />

USB2 (USB 2.5)<br />

serial port COM2<br />

E 674 GB 17<br />

07.03.2007

Hardware KUHNKE Automation<br />

3.7 <strong>Ventura</strong> <strong>IPC</strong> Power Supply and Ports<br />

3.7.1 24 VDC Power Supply<br />

3.7.2 Operative Earth<br />

3.7.3 Serial Ports "COM1 and COM2"<br />

1<br />

6<br />

2<br />

7<br />

3<br />

8<br />

4<br />

9<br />

5<br />

Only attach the unit to a 24 VDC power supply source if the source is guaranteed<br />

to meet safe extra low voltage requirements (SELV).<br />

Please use the connector from the package to attach the unit to the power<br />

supply.<br />

The admissible diameter of the cord connecting the 24 VDC power is between<br />

0.75 mm 2 and 2.5 mm 2 .<br />

Connector 2-pin, male, 2.5 mm 2<br />

Pin Function<br />

L+ Supply voltage +24 VDC<br />

L GND<br />

Connect operative earth to the protective earth conductor of the switching<br />

cabinet or the system that the PC is installed in. Use the flat plug (6.3 mm x<br />

0.8 mm) on the bottom side of the unit.<br />

The minimum cross section must be no less than 2.5 mm 2 . Try to keep the<br />

lead to the cabinet terminal as short as possible.<br />

A low-impedance earth conductor improves the dissipation of interference<br />

received via external power supply cables, signal cables or cables of peripheral<br />

units.<br />

<strong>Ventura</strong> <strong>IPC</strong> has two serial COM ports for communication with peripherals<br />

such as terminals, modems, etc. A 9-pin D-Sub connector is used to attach<br />

peripherals with a suitable cable.<br />

Connector 9-pin D-SUB, male<br />

Pin Function<br />

1 -<br />

2 TxD<br />

3 RxD<br />

4 -<br />

5 GND<br />

6 -<br />

7 CTS<br />

8 RTS<br />

9 -<br />

18 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

3.7.4 Graphics Adapter "DVI / VGA"<br />

The DVI-I adapter transfers analogue and digital monitor data (DVI-I integrated,<br />

analogue and digital) and can therefore be used for both monitors<br />

with a digital DVI port and monitors with an analogue VGA input.<br />

If a <strong>Ventura</strong> <strong>IPC</strong> touch-series monitor is attached, the cable can be up to 25<br />

m long (800x600 resolution). To bridge larger gaps, a DVI signal repeater<br />

can be installed somewhere along the line.<br />

Since the DVI port outputs VGA signals, VGA monitors can be attached using<br />

a DVI-to-VGA adapter.<br />

Pin Signal Function<br />

1 TMDS Data2- DVI data line (A)<br />

2 TMDS Data2+ DVI data line (A)<br />

3 TMDS Data2/4 shield shield<br />

4 NC*<br />

5 NC<br />

6 DDC clock (SCL) display data channel clock (I/O)<br />

7 DDC data (SDA) display data channel data (I/O)<br />

8 analogue vertical sync (VSYNC) analogue vertical sync signal (A)<br />

9 TMDS Data1- DVI data line (A)<br />

10 TMDS Data1+ DVI data line (A)<br />

11 TMDS Data1/3 shield shield<br />

12 NC<br />

13 NC<br />

14 +5V power (VCC) +5V power for DCC (A)<br />

15 Ground<br />

(return for V, Hsync and Vsync)<br />

analogue ground (GND)<br />

16 Hot plug detect<br />

17 TMDS Data 0- DVI data line (A)<br />

18 TMDS Data 0+ DVI data line (A)<br />

19 TMDS Data0/5 shield shield<br />

20 NC<br />

21 NC<br />

22 TMDS clock shield shield<br />

23 TMDS clock+ DVI clock line (A)<br />

24 TMDS clock- DVI clock line (A)<br />

C1 Analogue red (R) analogue red signal (A)<br />

C2 Analogue green (G) analogue green signal (A)<br />

C3 Analogue blue (B) analogue blue signal (A)<br />

C4 Analogue horizontal sync<br />

(HSYNC)<br />

analogue horizontal sync signal (A)<br />

C5 Analogue ground (analogue R, G,<br />

& return)<br />

analogue ground (GND)<br />

To allow the PC BIOS and operating system to properly detect and operate<br />

the DVI or CRT monitor, we recommend that you attach the monitor prior to<br />

starting the PC (automatic terminal detect).<br />

E 674 GB 19<br />

07.03.2007

Hardware KUHNKE Automation<br />

3.7.5 Interface "PS / 2"<br />

2<br />

1<br />

4<br />

3<br />

6<br />

5<br />

3.7.6 Interface "USB1","USB2"<br />

<strong>Ventura</strong> <strong>IPC</strong> features a PS / 2 interface that an external keyboard and/or an<br />

external mouse can be attached to.<br />

Connector 6-pin mini-DIN, female<br />

Pin Signal Function<br />

1 DAT (mouse) Data line (mouse)<br />

2 DAT (keyboard) Data line (keyboard)<br />

3 GND Earth<br />

4 P5VFK +5 V (fused)<br />

5 CLK (mouse) Clock line (mouse)<br />

6 CLK (keyboard) Clock line (keyboard)<br />

Shell Shield shielding<br />

To attach a keyboard or a mouse or both to the interface, a PS2 splitter (Y<br />

cable) is required.<br />

The USB adapter is the port for external peripherals such as CD-ROM<br />

drives, printers, modems or mouse and keyboard. The power supply unit for<br />

the USB peripherals supplies up to 500 mA output current and is fused by<br />

means of a maintenance-free "USB current-limiting circuit breaker". A short<br />

circuit or overload thus switches off the power supply and the "USB" status<br />

indicator lights up red.<br />

Connector type A, male<br />

Pin Signal Function<br />

1 VBUS (5 VDC) +5V (fused) for external USB port<br />

2 D- data+, USB channel 0<br />

3 D+ data-, USB channel 0<br />

4 GND GND for external USB port<br />

Shell Shield shielding<br />

The USB interfaces are made for attaching USB peripherals to. Due to the<br />

wide range of commercially available USB units and operating systems,<br />

KUHNKE cannot warrant that they will function properly.<br />

The standard demands 5m as the warranted length of line. Putting in a USB<br />

repeater you can extend lines to a maximum of 20m.<br />

Hot Plug-ready peripherals can be attached to the USB port while the PC is<br />

running.<br />

To comply with the noise immunity demanded by standard IEC 61131, the<br />

use of suitable USB cables is recommended. The accessory cables supplied<br />

by KUHNKE Automation GmbH & Co. ( 10.7.2 Accessories) are tested for<br />

compliance.<br />

Wiring of all installations should bear IT-specific needs in mind.<br />

20 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

3.7.7 Ethernet "LAN1", "LAN2"<br />

Ethernet is a commonly used, vendor-independent data transfer technology<br />

for Local Area Networks (LAN). Transfer rates are 10 million or 100 million<br />

bits per second (Mbps). Refer to standard IEEE802.3 to find specifications<br />

for the RJ 45 jack used in this device.<br />

Connector RJ 45 (female):<br />

Pin Signal Function<br />

1 TD + Transmit +<br />

2 TD - Transmit -<br />

3 RD + Receive +<br />

4 - -<br />

5 - -<br />

6 RD - Receive -<br />

7 - -<br />

8 - -<br />

Assuming you wish to attach <strong>Ventura</strong> <strong>IPC</strong> to a second network component<br />

(PC �� PC), but there is no uplink port, you can use a crossover cable to<br />

still establish the connection.<br />

A crossover cable X-links the two Receive and Transmit lines of the two<br />

interconnecting network components.<br />

E 674 GB 21<br />

07.03.2007

Hardware KUHNKE Automation<br />

3.7.8 Fieldbus Interface "BUS1" as CANopen Port<br />

1<br />

6<br />

2<br />

7<br />

3<br />

8<br />

4<br />

9<br />

5<br />

3.8 <strong>Ventura</strong> <strong>IPC</strong> Controls<br />

3.8.1 "RESET" Button<br />

RUN<br />

STOP<br />

ERROR<br />

HDD<br />

BUS<br />

DVI<br />

USB<br />

RESET<br />

<strong>Ventura</strong> <strong>IPC</strong> is a control PC with an integrated CANopen fieldbus interface.<br />

To connect to a CANopen network, attach a 9-pin female Sub-D connector<br />

to the male Sub-D CAN port on the unit. Its address is set at the configuration<br />

stage.<br />

Connector 9-pin D-SUB, male<br />

Pin Function<br />

1 -<br />

2 CAN-L<br />

3 CAN-GND<br />

4 -<br />

5 -<br />

6 -<br />

7 CAN-H<br />

8 -<br />

9 -<br />

Housing frame ground (cable shield)<br />

Please note that the CAN BUS must be properly terminated at both ends of<br />

the bus cable.<br />

For details on how to install the bus cable, on shielding, connectors, bus<br />

nodes and bus termination refer to instruction manual E 615 GB "CANopen“.<br />

The Reset button is located on the front of the device, underneath the <strong>Ventura</strong><br />

<strong>IPC</strong>'s status indicators. To avoid unintended actuation, you need a tool<br />

to operate it.<br />

Use a pointed object (pen, screwdriver) to press the Reset button. Pressing<br />

the button performs a hardware reset. The <strong>IPC</strong> reboots (cold boot).<br />

22 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

3.9 Storage Media (Removable Disk)<br />

3.9.1 Compact Flash Card Slot "CF-CARD"<br />

ejector mechanism<br />

Look at the back of the <strong>Ventura</strong> <strong>IPC</strong> housing to find the Compact Flash slot.<br />

The card stores the monitor program and the user program. Push the CF<br />

card into the slot until it is flush with the housing. You need a narrow or pointed<br />

object (screwdriver, pen) to actuate the ejector mechanism. You cannot<br />

remove the CF card while <strong>Ventura</strong> <strong>IPC</strong> is in the switching cabinet.<br />

Model variants <strong>Ventura</strong> <strong>IPC</strong> 300 and <strong>Ventura</strong> <strong>IPC</strong> 300 + feature a second<br />

compact flash slot at the front of the unit. The second CF card can be used<br />

for storing extra data, e.g. recipes.<br />

The ejector will mechanically push out the card until you can pull it out with<br />

your fingers. When you slot in the card, the ejector mechanism audibly<br />

snaps in.<br />

CompactFlash cards are susceptible to electrostatic discharge (ESD). Improper<br />

handling may lead to temporary or complete failure.<br />

Please take account of the instructions on how to handle memory cards.<br />

The compact flash card (CF card) is a non-volatile memory. The data stored<br />

on it will be retained even in the event of a power failure.<br />

We recommend to only use CF cards designed for industrial applications<br />

because these cards have an extended temperature range and can be rewritten<br />

more often.<br />

Compact flash cards (CF cards) of various volume capacities are sold as separate<br />

accessory options.<br />

3.9.2 Compact Flash Card Slot "CF-CARD"<br />

ejector mechanism<br />

3.10 LED Indicators, <strong>Ventura</strong> <strong>IPC</strong><br />

3.10.1 Status LEDs<br />

Look at the front of the <strong>Ventura</strong> <strong>IPC</strong> 300 housing to find a second Compact<br />

Flash slot which allows you to operate an additional storage volume of compact<br />

flash type I.<br />

CompactFlash cards are susceptible to electrostatic discharge (ESD).<br />

Improper handling may lead to temporary or complete failure.<br />

Please take account of the instructions on how to handle memory cards.<br />

Name LED Description<br />

E 674 GB 23<br />

07.03.2007

Hardware KUHNKE Automation<br />

RUN<br />

STOP<br />

ERROR<br />

HDD<br />

BUS<br />

DVI<br />

USB<br />

RUN OFF<br />

GREE<br />

N<br />

STOP OFF<br />

RED<br />

ERROR OFF<br />

RED<br />

HDD OFF<br />

YEL-<br />

LOW<br />

BUS OFF<br />

YEL-<br />

LOW<br />

OFF<br />

YEL-<br />

LOW<br />

DVI OFF<br />

YEL-<br />

LOW<br />

USB OFF<br />

RED<br />

PLC program not loaded, not started<br />

PLC program runs cyclically<br />

PLC program runs cyclically<br />

PLC program not loaded, not started<br />

No system error<br />

Operative controller problem<br />

Shows that the CF card is being accessed<br />

Data traffic on the fieldbus<br />

No function<br />

DVI display active<br />

USB station short circuit<br />

24 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

3.11 External Elements, <strong>Ventura</strong> <strong>IPC</strong> + Hardware PLC<br />

Industry PC connectors<br />

mouse/keyboard<br />

status LEDs<br />

<strong>IPC</strong> reset button<br />

Ethernet<br />

CF card (front)<br />

field bus interface 1<br />

CF card ejector<br />

DVI/VGA<br />

USB<br />

serial interfaces<br />

COM1<br />

COM2<br />

<strong>IPC</strong> power supply<br />

heat sink for<br />

<strong>Ventura</strong> <strong>IPC</strong> 700/800/1000<br />

see dimensions<br />

protective earth<br />

Hardware PLC<br />

connectors<br />

status LEDs<br />

PLC hardware<br />

reset button<br />

field bus interface 2<br />

field bus interface 3<br />

digital combi I/Os<br />

RS 232<br />

power supply to hardware<br />

PLC<br />

E 674 GB 25<br />

07.03.2007

Hardware KUHNKE Automation<br />

3.12 Power Supply and Interfaces, PLC Hardware <strong>Ventura</strong>+<br />

3.12.1 24 VDC Power Supply<br />

3.12.2 Operative Earth<br />

Only attach the unit to a 24 VDC power supply source if the source is guaranteed<br />

to meet safe extra low voltage requirements (SELV).<br />

Please use the connector from the package to attach the unit to the power<br />

supply.<br />

The admissible diameter of the cord connecting the 24 VDC power is between<br />

0.2 mm 2 and 2.5 mm 2 .<br />

Connector 2-pin, male, 2.5 mm 2<br />

Pin Function<br />

L+ Supply voltage +24 VDC<br />

L GND<br />

Connect <strong>Ventura</strong>'s operative earth connector to the protective earth conductor<br />

of the cabinet or system / machine element. Use the flat plug (6.3 mm x<br />

0.8 mm) at the back of the unit.<br />

The minimum cross section must be no less than 2.5 mm 2 . Try to keep the<br />

lead to the earthing terminal as short as possible.<br />

A low-impedance earth conductor improves the dissipation of interference<br />

received via external power supply cables, signal cables or cables of peripheral<br />

units.<br />

3.12.3 Fieldbus Interface "BUS2" as CANopen Port<br />

1<br />

6<br />

2<br />

7<br />

3<br />

8<br />

4<br />

9<br />

5<br />

Hardware PLC <strong>Ventura</strong> <strong>IPC</strong> + is an embedded controller with integrated<br />

CANopen fieldbus interface. To connect to a CANopen network, attach a 9pin<br />

female Sub-D connector to the male Sub-D CAN port on the unit. Its address<br />

is set at the configuration stage.<br />

Connector 9-pin D-SUB, male<br />

Pin Function<br />

1 -<br />

2 CAN-L<br />

3 CAN-GND<br />

4, 5, 6 -<br />

7 CAN-H<br />

8, 9 -<br />

Housing frame ground (cable shield)<br />

Please note that the CAN BUS must be properly terminated at both ends of<br />

the bus cable.<br />

For details on how to install the bus cable, on shielding, connectors, bus<br />

nodes and bus termination refer to instruction manual E 615 GB "CANopen“.<br />

26 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

3.12.4 Fieldbus Interface "BUS3" as PROFIBUS Port<br />

5<br />

9<br />

4<br />

8<br />

3<br />

7<br />

2<br />

6<br />

1<br />

3.12.5 Digital Combi I/O "DI/DO"<br />

1<br />

2<br />

4<br />

Hardware PLC <strong>Ventura</strong> <strong>IPC</strong> + can be optionally equipped with a PROFIBUS<br />

DP master port. To connect to a bus, attach a 9-pin male Sub-D PROFIBUS<br />

connector to the female PROFIBUS port on the unit.<br />

Run the bus configuration utility to set the network's baud rate and address,<br />

then transfer the hardware parameters to the hardware PLC. It is not necessary<br />

to change any bus parameter settings at the device hardware.<br />

Connector 9-pin D-SUB, male<br />

Pin Function<br />

1 (attached to housing frame)<br />

2 -<br />

3 RxD/TxD-P (Data +)<br />

4 -<br />

5 DGnd<br />

6 VP (+5 V power, max. 100 mA)<br />

7 -<br />

8 RxD/TxD-N (Data -)<br />

9 -<br />

Housing frame ground (connected with pin 1)<br />

Attach the cable shield to the connector housing.<br />

Please note that the PROFIBUS must be properly terminated at both ends of<br />

the bus cable. The PROFIBUS jack of hardware PLC <strong>Ventura</strong> <strong>IPC</strong> + supplies<br />

the required voltage.<br />

For details on how to install the bus cable, on shielding, connectors, bus<br />

nodes and bus termination refer to instruction manual E 611 GB "PROFI-<br />

BUS-DP“.<br />

Hardware PLC <strong>Ventura</strong>+ features 5 digital combi I/Os "DI/DO 0 ... 4" which<br />

can be set to act as inputs, special-function inputs or as outputs.<br />

Connector 5-pin, male, 2.5 mm 2<br />

Pin Function<br />

Input Output (short-circuit-proof)<br />

0 Interrupt A1 track counter, 24 VDC/0.5 A<br />

1 Interrupt B1 track - 24 VDC/0.5 A<br />

2 Interrupt A2 track counter, 24 VDC/0.5 A<br />

3 Interrupt A3 track - 24 VDC/0.5 A<br />

4 Interrupt Ref track - -<br />

If used as inputs, DI/DO 0 to DI/DO 4 are marked by their very short rising<br />

delay. User programs can read them just like normal inputs. To be able to<br />

immediately react to events, they are capable of requested processor interrupts.<br />

LEDs lighting up green show that there is either an input signal or that the<br />

output is active. Active outputs can be checked via the input address.<br />

Optional<br />

E 674 GB 27<br />

07.03.2007

Hardware KUHNKE Automation<br />

3.12.6 Serial RS 232 Interface<br />

5<br />

9<br />

4<br />

8<br />

3<br />

7<br />

22<br />

6<br />

1<br />

Combi I/Os DI/DO 0 and DI/DO 2 are designed to also act as event counters<br />

up to 10 kHz. If combined with a 24V incremental encoder, these combi I/Os<br />

also provide A, B, Ref counter functions.<br />

Their actual function is set at the configuration stage.<br />

The maximum nominal current of every combi I/O output is 0.5 A.<br />

If a combi I/O is used as an output, mind that no external input signal must<br />

go through that port at the same time.<br />

The main practical use of the RS 232 port is to attach an external programming<br />

device to it. However, you could also use it for exchanging data with<br />

dialog terminals, PCs and other such devices.<br />

Connector 9-pin D-SUB, female<br />

Pin Function<br />

1 -<br />

2 TxD<br />

3 RxD<br />

4 -<br />

5 GND<br />

6 -<br />

7 -<br />

8 -<br />

9 -<br />

Housing shielding<br />

If the interface is used for communication with a CoDeSys programming<br />

system, choose menu item "Communication Parameters" to set its baud rate<br />

to 38400 baud.<br />

The normal programming cable from the accessories range connects the<br />

<strong>Ventura</strong>+ hardware PLC with the programming device.<br />

Part number 691.151.09<br />

Length 3.0 m<br />

Assignment 1 : 1<br />

28 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

3.13 <strong>Ventura</strong>+ Hardware PLC Controls<br />

3.13.1 "RESET" Button<br />

RUN<br />

STOP<br />

ERROR<br />

BUS2<br />

BUS3<br />

RESET<br />

3.14 <strong>Ventura</strong> Indicators<br />

3.14.1 Status LEDs<br />

RUN<br />

STOP<br />

ERROR<br />

BUS2<br />

BUS3<br />

RESET<br />

The Reset button is located on the front of the device, underneath the <strong>Ventura</strong>'s<br />

status indicators. The reset / cold boot will affect the <strong>Ventura</strong>+ hardware<br />

PLC only, but not the PC.<br />

To avoid it being pushed unintentionally, the Reset button can be operated<br />

using a pointed object (pen, screwdriver) only.<br />

Label LED Description<br />

RUN OFF<br />

GREE<br />

N<br />

STOP OFF<br />

RED<br />

ERROR OFF<br />

RED<br />

BUS2 OFF<br />

YEL-<br />

LOW<br />

BUS3 OFF<br />

YEL-<br />

LOW<br />

FLASHI<br />

NG<br />

PLC program not loaded, not started<br />

PLC program runs cyclically<br />

PLC program runs cyclically<br />

PLC program not loaded, not started<br />

No system error<br />

Operative controller problem<br />

Ready<br />

OK, all stations connected to bus<br />

Warning, station missing<br />

Flash code imitates address of missing station<br />

E 674 GB 29<br />

07.03.2007

Hardware KUHNKE Automation<br />

3.15 Error Codes<br />

RUN<br />

STOP<br />

ERROR<br />

HDD<br />

BUS<br />

DVI<br />

USB<br />

RESET<br />

LEDs "RUN“, "STOP“ and "ERROR“ exclusively refer to functions of soft-<br />

PLC CoDeSys SP. If CoDeSys SP if off these LEDs have no function.<br />

LEDs "RUN" and "STOP", PLC op. modes<br />

RUN STOP Operating mode<br />

Off On PLC program not loaded<br />

Off On PLC program loaded but not started<br />

On Off PLC program loaded and started<br />

Flashing On PLC program loaded and started but stopped at<br />

breakpoint (DEBUG)<br />

LED "ERROR"<br />

Whereas LED "ERROR" indicates serious operative problems, it is not indicative<br />

of any PLC program errors. The following classify a serious operative<br />

problems: watchdog, low voltage, short circuit.<br />

If applicable, these problems are indicated by KUHNKE's well-known flash<br />

codes. Every flash pulse lasts 500 ms (250 ms on, 250 ms off), every flash<br />

sequence consists of n flash pulses (e.g. watchdog: n = 3), flash sequences<br />

are interrupted by 1 s breaks (off).<br />

30 E 674 GB<br />

07.03.2007

KUHNKE Automation Hardware<br />

4 Installation<br />

4.1 Flange Plate Installation<br />

Control PC <strong>Ventura</strong> <strong>IPC</strong> is designed for front panel installation. However,<br />

you can also choose to install the unit on any other even surface using the<br />

flange fitting. Please take note of the admissible ambient conditions during<br />

storage and operation as summarised in the Technical Data tables.<br />

A flange for installing the device at the rear wall of a switching cabinet or on<br />

any other even surface can be ordered as a separate accessory option. The<br />

<strong>Ventura</strong> 800 / 1000 series has the flange fitting as a component part of the<br />

housing. In these cases, the flange plate need not be ordered separately.<br />

4.1.1 To Install the Screw Plate Adapter (<strong>Ventura</strong> <strong>IPC</strong> 300 / 700)<br />

4.1.2 To Install the Device<br />

• Use screws (2) to attach the flange plate (1) to the back of the unit.<br />

• Drill holes into the mounting surface as shown on the illustration.<br />

• Turn all but approx. 5 mm of the screws into the holes drilled into the<br />

mounting surface.<br />

• Put on the device and push down.<br />

• Turn in the screws until tight.<br />

Please remember that the plate and screws must not only be able to sustain<br />

the weight of the device but also that of the cables.<br />

E 674 GB 31<br />

07.03.2007

Hardware KUHNKE Automation<br />

4.2 Mounting on Top-hat Rail (<strong>Ventura</strong> <strong>IPC</strong> 300 / 700)<br />

4.2.1 To Attach the Rail Adapter to the Device<br />

• Use screws (2) to attach snap-on adapter (1) to the back of the unit.<br />

4.2.2 To Attach the Device to the Top-hat Rail<br />

• Place the device on the upper top-hat rail guide, holding it at a slant.<br />

• Tip the device down onto the top-hat rail until the bracket of the adapter<br />

snaps onto the bottom top-hat rail guide.<br />

4.2.3 To Remove the Device from the Top-hat Rail<br />

• Pull down the strap at the bottom side of the device. Use a flat screwdriver<br />

and turn it slightly.<br />

• This will unlock the mechanism holding the unit firmly in place on the<br />

top-hat rail.<br />

• You can now remove the device.<br />

32 E 674 GB<br />

07.03.2007

KUHNKE Automation Software<br />

5 Start-up<br />

Various variants of the <strong>Ventura</strong> industial PC (<strong>IPC</strong>) are available. For the exact<br />

system configuration of your device, please refer to the name plate and<br />

the coded part number on it.<br />

To allow the BIOS and operating system to properly detect the DVI or CRT<br />

monitor at boot-up, we recommend that you attach the monitor prior to attaching<br />

the device to the power supply.<br />

Danger of damage to the unit!<br />

If the device was exposed to condensation, allow it to rest for about 12 hours<br />

before you start to use it.<br />

5.1 Installing CoDeSys on the Programming PC<br />

5.1.1 CoDeSys Target Installation<br />

To install the CoDeSys software on your programming<br />

PC:<br />

• Select CoDeSys...exe either from Windows Explorer or via 'Run' from<br />

the Windows Start menu.<br />

• Run the program.<br />

• The CoDeSys installer runs to request your preferred settings and install<br />

the application in the target system.<br />

To obtain an installation copy of the CoDeSys programming system either<br />

ask for the up-to-date CD-ROM 'Software & Information, E 627 D / GB' or<br />

browse for www.3s-software.com and find the download page of that company<br />

To create a CoDeSys project for target system "<strong>Ventura</strong> <strong>IPC</strong>", you must install<br />

the Target Support Package (TSP) "<strong>Ventura</strong>CE_TV.tnf" prior to running<br />

the program by running the installer called InstallTarget.<br />

A TSP contains all configuration and extension files required to use an application<br />

for operating a certain controller (target system).<br />

A configuration includes the code generator, the memory layout, the set of<br />

functions provided by the controller and the I/O modules.<br />

The libraries, gateway drivers, error and ini files for the PLC browser etc. are<br />

also installed.<br />

• Run the target installer delivered with your CoDeSys package.<br />

• Click on "Open" to open the folder containing TSP "KUHNKE PC Control<br />

<strong>Ventura</strong>", then choose "<strong>Ventura</strong>CE_TV.tnf".<br />

• Click to select "KUHNKE PC Control <strong>Ventura</strong>" and "Install" it.<br />

E 674 GB 33<br />

07.03.2007

Software KUHNKE Automation<br />

5.2 CoDeSys Programming PC Setup<br />

5.2.1 Ethernet Connections of <strong>Ventura</strong> <strong>IPC</strong><br />

5.2.2 Programming PC Interface Setup<br />

Following successful installation, "KUHNKE PC Control <strong>Ventura</strong>" appears in<br />

column "Installed target systems. The programming system can now access<br />

the <strong>Ventura</strong> controller.<br />

• To directly connect the <strong>IPC</strong> with the programming PC, please use a<br />

CAT5 crossover cable.<br />

• To operate the <strong>Ventura</strong> <strong>IPC</strong> in a network, please use a CAT5 patch<br />

cable.<br />

• CoDeSys communication should go through the <strong>Ventura</strong> <strong>IPC</strong>'s<br />

LAN2 port if at all possible.<br />

• Establish the connection before turning on the <strong>IPC</strong>'s 24 V power<br />

supply.<br />

Network connection<br />

No settings should have to be made or changed to program the <strong>IPC</strong> via a<br />

network.<br />

Windows 98, direct connection<br />

• Go to Windows Start and choose<br />

Start – Settings – Control Panels: "Network" – pick "TCP/IP" from the<br />

list, then "Properties".<br />

• Go to tab "IP address", choose "Set IP address" and enter any IP address<br />

as appropriate,<br />

e.g.: "169.254.112.85", subnet mask "255.255.255.0".<br />

34 E 674 GB<br />

07.03.2007

KUHNKE Automation Software<br />

Windows XP, direct connection<br />

• Go to Windows Start and choose<br />

Start – Settings – Network Connections: pick LAN connection from list,<br />

Properties<br />

• Go to tab "General", find the list of elements, choose "Internet protocol<br />

(TCP/IP)" and click on Properties.<br />

• Still on tab "General" choose "Use this IP address" and enter any IP<br />

address as appropriate,<br />

e.g.: "169.254.112.85", subnet mask "255.255.255.0"<br />

A direct connection requires the "File and printer release" to be ticked and a<br />

firewall, if any, to be disabled at least for the time of this connection.<br />

5.2.3 CoDeSys Target System Setting on the Programming PC<br />

• Run PLCWinCE on the <strong>Ventura</strong> <strong>IPC</strong><br />

(Start – Programs – KUHNKE – PLCWinCE)<br />

• Create a new CoDeSys project and choose "KUHNKE PC Control <strong>Ventura</strong>"<br />

as its target system<br />

• Choose "Online – Communication Parameters" to set up a TCP/IP connection<br />

using the IP address you previously specified for the <strong>Ventura</strong><br />

<strong>IPC</strong>.<br />

E 674 GB 35<br />

07.03.2007

Software KUHNKE Automation<br />

6 Windows ® XP Embedded<br />

Windows ® XP Embedded is based on the functionality of Windows ® XP Professional<br />

plus that it contains a set of predefined system configurations and<br />

more than 10,000 separate components that hardware developers can<br />

choose from. The space required by the installation (i.e., its footprint) can be<br />

minimised to make the operating system fit onto flash media.<br />

Windows ® XP Embedded is marked by its high level of reliability, safety and<br />

performance. It runs even on "small" x86 systems.<br />

Windows ® XP Embedded thus provides all properties for perfect interaction<br />

with industrial PCs to be trusted with industrial control tasks while still having<br />

the whole range of Windows ® communication and software features at hand.<br />

36 E 674 GB<br />

07.03.2007

KUHNKE Automation Software<br />

6.1 Components<br />