Nike Detox Challenge 1.6 - NIKE, Inc. - The Journey

Nike Detox Challenge 1.6 - NIKE, Inc. - The Journey

Nike Detox Challenge 1.6 - NIKE, Inc. - The Journey

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

copyright® 2012 <strong>Nike</strong>, <strong>Inc</strong>.<br />

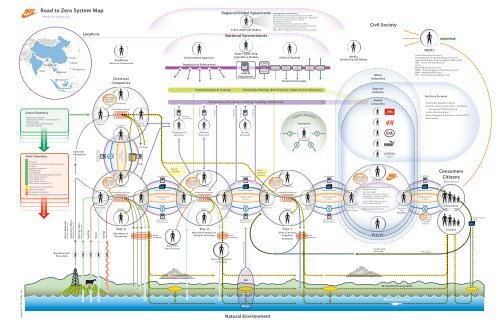

Green Chemistry<br />

Toxic Chemistry<br />

Road to Zero System Map<br />

Version 2.4 January 2012<br />

India<br />

Water-based adhesives<br />

Water-based non-PVCs non-phthalate inks<br />

Waterless dying<br />

Environmentally preferred rubber<br />

New fabric coatings<br />

Substitution<br />

Phthalates<br />

Brominated and chlorinated �ame retardants<br />

Azo Dyes<br />

Organotin compounds<br />

Chlorobenzene<br />

Chlorophenols<br />

Short-chain chlorinated para�ns (SCCPs)<br />

Heavy metals: cadmium<br />

Heavy metals: lead<br />

Heavy metals: mercury<br />

Heavy metals: chromium (VI)<br />

Per�uorinated chemicals (PFC)<br />

Chlorinated solvents<br />

Nonlyphenol ethoxylates<br />

Alkylphenols (AP) Alkylphenol Ethoxylates (APE)<br />

Elimination<br />

Bangladesh<br />

Thailand<br />

Malaysia<br />

Indonesia<br />

Other Materials<br />

Rubbers, glues, etc.<br />

Synthetic Fibers<br />

Polyester, Nylon, etc.<br />

Raw Materials<br />

Extraction<br />

China<br />

Taiwan<br />

Philippines<br />

Chemical<br />

Feedstocks<br />

Natural Fibers<br />

Cotton, Wool, etc<br />

Locations<br />

Leather<br />

Water<br />

Workers<br />

Speci�cation /<br />

Requirements<br />

Purchasing<br />

Energy<br />

Academia<br />

Research Universities<br />

Knowledge<br />

Motivation<br />

Capacity<br />

$<br />

Money<br />

Knowledge<br />

Motivation<br />

Capacity<br />

Chemical<br />

Companies<br />

Management<br />

Production Processes<br />

Purchasing<br />

Communication<br />

& Trust<br />

Management<br />

Chemical<br />

Formulations<br />

Production Processes<br />

Workers<br />

Sales &<br />

Ful�llment<br />

Discharge<br />

Certi�cation<br />

MSDS<br />

Sales &<br />

Ful�llment<br />

Speci�cation /<br />

Requirements<br />

Waste<br />

Treatment<br />

Certi�cation<br />

Finished Product<br />

Communication<br />

& Trust<br />

Money<br />

$<br />

Certi�cation<br />

Transparency<br />

Partner(s)<br />

Dying<br />

Coatings<br />

Equipment<br />

Manufacturers<br />

Bluesign<br />

Greenworks<br />

Purchasing<br />

Communication & Training<br />

Certi�cation<br />

Auditing<br />

Partner(s)<br />

Management<br />

Production Processes<br />

Workers<br />

Tier 3 Tier 2<br />

Raw Material<br />

Processing<br />

Government Agencies<br />

Regulation & Enforcement<br />

Knowledge<br />

Motivation<br />

Capacity<br />

Waste Management<br />

Companies<br />

Waste<br />

Treatment<br />

Knowledge Sharing / Best Practices / Open Source Innovation<br />

Transparency: Disclosure / Testing / Auditing / Monitoring<br />

Process<br />

Materials Production<br />

Dying & Finishing<br />

Regional/Global Agreements<br />

Sales &<br />

Ful�llment<br />

Trans-National Bodies<br />

National Governments<br />

State Leadership<br />

Legislative Bodies<br />

Outgoing<br />

Laws &<br />

Regulations<br />

Certi�cation<br />

Testing<br />

Partner(s)<br />

Certi�cation<br />

Finished Product<br />

Communication<br />

& Trust<br />

Money<br />

Speci�cation /<br />

Requirements<br />

Environmental Monitoring<br />

Air<br />

Land<br />

Water<br />

<strong>Inc</strong>oming<br />

Criminalization<br />

Regulation<br />

Glues<br />

Solvents<br />

Printing<br />

Natural Environment<br />

International Initiatives:<br />

United Nations Environment Programme (UNEP)<br />

UN Division for Sustainable Development - Agenda 21<br />

EU Commission Environment - REACH<br />

Rotterdam Convention<br />

Asia-Paci�c Economic Cooperation (APEC) –<br />

Sustainable Development and Chemical Dialogue<br />

EPA - China Environmental Law Initiative<br />

EPA's O�ce of Pollution Prevention and Toxics (OPPT)<br />

Education &<br />

Convening<br />

Knowledge<br />

Motivation<br />

Capacity<br />

Judicial System<br />

Market<br />

Creation<br />

Management<br />

Production Processes<br />

Sales &<br />

Waste<br />

Treatment<br />

Certi�cation<br />

Finished Product<br />

Communication<br />

& Trust<br />

Money<br />

Speci�cation /<br />

Requirements<br />

Other<br />

Industries<br />

Apparel<br />

Industry<br />

Brand<br />

Consortia<br />

Management<br />

<strong>Nike</strong> Material Sustainability Index<br />

Considered Index<br />

<strong>Nike</strong> RSL & MRSL<br />

<strong>Nike</strong> Green Chemistry Program<br />

Sustainable Chemistry Guidance<br />

List of Positive Chemistries<br />

Global Water Quality Program<br />

H2O-Insight Water Tool<br />

GC3 Data Exchange Pilot Project<br />

Material Traceability Pilot<br />

Purchasing<br />

Designers<br />

$ Workers<br />

Ful�llment<br />

Marketing<br />

$<br />

$<br />

Tier 1<br />

Direct Contract<br />

Suppliers<br />

Assembly<br />

Trade<br />

Policy<br />

Government Levers<br />

$<br />

Taxes &<br />

Fees<br />

Investors<br />

$ $<br />

Funding &<br />

Subsidies<br />

$<br />

Media<br />

Online/Social Media<br />

Buying Teams<br />

Knowledge<br />

Motivation<br />

Capacity<br />

Civil Society<br />

Brands<br />

ReUSE A SHOE<br />

<strong>NIKE</strong> GRIND<br />

Sales<br />

Retailers<br />

Terrestrial Ecosystems<br />

Marine Ecosystems<br />

NGO’s<br />

Green Chemistry Institute<br />

China National Textile and Apparel Council<br />

Institute of Public & Environmental A�airs (IPE)<br />

BSR – China Training Institute<br />

Ceres<br />

World Resources Institute<br />

NRDC - National Resources Defense Council<br />

WWF - World Wildlife Fund<br />

EDF - Environmental Defense Fund<br />

3rd Party Partners<br />

Labeling<br />

Finished Product<br />

Communication<br />

& Trust<br />

Money<br />

Sustainable Apparel Coalition<br />

Outdoor Industry Association - Chemicals<br />

Management Working Group<br />

Leather Working Group<br />

Green Chemistry & Commerce Council (GC3 )<br />

A�rm Group<br />

Wants<br />

Needs<br />

Desires<br />

Demand<br />

Recycling<br />

Consumers<br />

Citizens<br />

Market Demand<br />

Consumers<br />

Citizens<br />

Post-consumer<br />

Waste

Other<br />

Industries<br />

Communication & Training<br />

Knowledge Sharing / Best Practices / Open Source Innovation<br />

Apparel<br />

Industry<br />

Brand<br />

Consortia<br />

3rd Party Partners<br />

Sustainable Apparel Coalition<br />

Outdoor Industry Association - Chemicals<br />

Management Working Group<br />

Leather Working Group<br />

Green Chemistry & Commerce Council (GC3 International Initiatives:<br />

United Nations Environment Programme (UNEP)<br />

Version 2.4 January 2012<br />

Where and how to engage with the governments of supplier countries?<br />

UN Division for Sustainable Development - Agenda 21<br />

Dealing with country/culture norms and regulations<br />

Global harmonization of regulations EU Commission Fitting Environment the detox - REACHissue<br />

into the context of the full GA remit:<br />

Rotterdam Convention<br />

What are the levers of in�uence in sourcing countries? REACH as a model to follow?<br />

Asia-Paci�c Economic Cooperation (APEC) –<br />

And the rest of the world<br />

International trade<br />

Sustainable Development and Chemical Dialogue<br />

Opportunity for countries to move up the value chain<br />

Civil Society<br />

EPA - China Environmental Licence to Law operate<br />

Initiative<br />

Trans-National Bodies<br />

EPA's O�ce of Pollution Prevention and Toxics (OPPT)<br />

Fear of competitive disadvantage<br />

Labor issues<br />

Locations<br />

National Governments<br />

Tax and trading company issues<br />

Insu�cient & uneven regulations<br />

Priorities<br />

Environmental issues Aligning with green economy initiatives<br />

Allies or Adversaries?<br />

Opportunity for investment<br />

Insu�cient & uneven enforcement<br />

Motivation<br />

Support for research chair in green chemistry<br />

Opportunity for alignment<br />

Public awareness<br />

Campaign locally for a shared vision of green<br />

Expertise<br />

Legal Issues<br />

Research on hazard assessment<br />

Role of Government?<br />

Good or bad press<br />

manufacturing, and a healthy planet, by all actors<br />

Resources<br />

Making commitments<br />

NGO’s<br />

Research on green chemistry<br />

What is the ask ?<br />

Use social media proactively<br />

State Leadership<br />

Restraint of trade / anti-competitive actions<br />

Research on process improvements<br />

De�ne R2X friendly policies<br />

Green Chemistry Institute<br />

Lack of consistent Chinarules<br />

Government Agencies<br />

Legislative Bodies<br />

Judicial Costs / Prices System<br />

Media<br />

China National Textile and Apparel Council<br />

Training Academia green chemists<br />

What regulations/actions will further the R2Z goals?<br />

Online/Social Media<br />

Find other Institute partners of Public beyond & Environmental Greenpeace A�airs (IPE)<br />

Lack of level playing Taiwan�eld<br />

Undue in�uence<br />

and Research industrial Universities process engineers<br />

Criminal-<br />

BSR – China Training Institute<br />

Bangladesh<br />

Regulation & Enforcement<br />

Invite Greenpeace to be more collaborative<br />

Country prioritization<br />

ization<br />

IP / con�dentiality vs. disclosure / transparency<br />

Ceres<br />

Education & Market Trade Taxes & Funding &<br />

Convening Creation Policy<br />

Fees Subsidies<br />

- so other World brands Resources will Institute join<br />

Country sequencing Philippines<br />

India<br />

Regulation<br />

NRDC - National Resources Defense Council<br />

Thailand<br />

Sustainable consumption + GDP<br />

<strong>Inc</strong>rease<br />

Laws &<br />

WWF collaborative - World Wildlife relationships Fund with other NGOs<br />

Set standards with<br />

metrics in�uence capital markets<br />

Regulations<br />

- with specialized EDF - Environmental capabilities Defense Fund<br />

chemical companies<br />

Malaysia<br />

Chemical<br />

Collaboration / partnership with chemical companies<br />

Opportunity to talk Government with a consistent Levers voice and uni�ed voice,<br />

Companies<br />

Big di�erence in chemical company’s performance standards<br />

Commitment to driving the demand curve for green chemistry within and beyond the apparel industry<br />

Expand to include other industries<br />

Indonesia Map the scope of the chemical company suppliers<br />

New model for R&D investment into green chemistry<br />

More communication on what’s in and what’s out<br />

Percentage of chemical company business to apparel / footwear<br />

Translate innovation throughout the supply chain<br />

Speci�c instructions from customers esp. re traceability Identify NGOs that in�uence / collaborate with chemical companies Expand on 3rd party collaboration<br />

Generic disclosure vs. apparel industry Knowledge speci�c disclosure?<br />

Motivation<br />

Capacity<br />

Management<br />

Lack Transparency: of Transparency Disclosure / Testing / Auditing / Monitoring<br />

Invite more brands to join<br />

More trust and collaboration<br />

Trust & collaboration Activities, Projects<br />

and momentum<br />

Bring more suppliers into SAC<br />

Green Green Chemical Chemistry Substitution<br />

Precautionary Water-based adhesivesprinciple<br />

on substitutions<br />

Water-based non-PVCs non-phthalate inks<br />

Product Waterless dying performance impacts?<br />

Environmentally preferred rubber<br />

New fabric coatings<br />

Inspire innovation on greener<br />

chemistries and materials<br />

Green chemistry/materials X-prise(s)<br />

Standardized speci�cations<br />

for acceptable chemistries<br />

Production Processes<br />

Chemical<br />

Innovation<br />

Bluesign<br />

Greenworks<br />

Workers<br />

Sales &<br />

Purchasing<br />

Ful�llment<br />

<strong>Inc</strong>reased visibility into the chemical industry<br />

Transparency<br />

Auditing<br />

Proprietary formulations<br />

Partner(s)<br />

Partner(s)<br />

More BlueSign-like partners<br />

Fear of losing IP<br />

How to scale BlueSign-like process?<br />

Fear of exclusion<br />

- due to toxic/poor formulation Discharge<br />

Analytic Capacity?<br />

Testing<br />

Partner(s)<br />

Testing / compliance partners provide<br />

visibility into the supply chain<br />

Engage with Wallstreet - and make the case<br />

for sustainability Investors and the costs involved<br />

An opportunity to engage work with other<br />

leading industries $ to change the $<br />

expectations/conversation re sustainability<br />

and short vs long-term returns<br />

$ $<br />

Knowledge Sharing<br />

Capacity Sharing<br />

Disclosure issues<br />

Education<br />

Margin Pressure<br />

Who will pay?<br />

Organization<br />

Management<br />

)<br />

Resources Cost to join? A�rm Group<br />

Moving to<br />

public industry<br />

standards<br />

Building marketing, consumer and citizen awareness<br />

Chemical<br />

Complex formulations<br />

Training on chemicals management<br />

Quantify the costs involved<br />

Feedstocks<br />

Shared pro�tability model?<br />

Toxic Chemistry<br />

Unknown formulations<br />

Unsophisticated Chemistry<br />

Diversity of supplier performance<br />

Quantify and build-in lifecycle cost savings<br />

Common industry standards<br />

Phthalates<br />

Best vs. worst practices<br />

How to internalize the externalities?<br />

Standardization Brominated and chlorinated of RSL’s �ame retardants<br />

Poor Quality / Residuals & MSDS Impurities<br />

Azo Dyes<br />

Capital cost of waterless dying(?)<br />

Carrots or Sticks?<br />

<strong>Inc</strong>orporate Organotin compounds other RSLs:<br />

Concentration reporting limits<br />

Dying<br />

Making better products with attributes<br />

Chlorobenzene<br />

Glues<br />

Other Brands, REACH,<br />

Sanctions or Cooperation?<br />

Management commitment<br />

Coatings<br />

Chlorophenols<br />

Lack of resources<br />

Solvents Lack of resources<br />

recognized by consumers Consumers<br />

ChemSec’s Short-chain SIN chlorinated List, para�ns IRAC (SCCPs) groups,<br />

Cost sensitivity<br />

Engineering support<br />

Consequences for Non-compliance? Internal engagement<br />

Printing<br />

Heavy metals: cadmium<br />

Certi�cation<br />

(low-margin business)<br />

Certi�cation<br />

(low-margin business)<br />

Certi�cation<br />

Labeling<br />

Knowledge<br />

Labeling standards?<br />

GOTS, Citizens<br />

Heavy Bluesign<br />

metals: lead<br />

from the chemical co’s<br />

Supply capacity constraints<br />

Be recognized as a global leader<br />

Motivation<br />

Heavy metals: mercury<br />

Knowledge<br />

Knowledge Lack of transparency<br />

Knowledge Lack of transparency<br />

Capacity<br />

Management<br />

OIA / SAC Index<br />

on these issues<br />

Market Demand<br />

Heavy metals: chromium (VI)<br />

Motivation<br />

Motivation<br />

Motivation<br />

Certi�ed across which metrics?<br />

Capacity<br />

Capacity<br />

Capacity<br />

Per�uorinated chemicals (PFC)<br />

Management<br />

Management<br />

Management<br />

Exploiting <strong>Nike</strong> Material Sustainability / extending Index<br />

• toxics<br />

Chlorinated solvents<br />

Considered Index<br />

Finished Product<br />

Finished Product<br />

Finished Product<br />

• Finished carbon Product footprint<br />

Nonlyphenol ethoxylates<br />

Supplier Churn<br />

existing Production Processes<br />

Production Processes<br />

Production Processes<br />

<strong>Nike</strong> RSL & MRSL work/programs<br />

Demand for clean products?<br />

Alkylphenols (AP) Alkylphenol Ethoxylates (APE)<br />

Process<br />

<strong>Nike</strong> Green Chemistry Program<br />

• organic<br />

Communication<br />

Communication<br />

Communication<br />

Sustainable Chemistry Guidance<br />

Brand loyalty & trust<br />

Innovation<br />

SB&I Lab fastrack solutions<br />

Communication<br />

& Trust<br />

Declining & Trust In�uence<br />

Nurture and strengthen long-term<br />

& Trust<br />

List of Positive Chemistries<br />

• low-water<br />

& Trust<br />

Turn consumers into advocates<br />

supplier relationships<br />

Internal Global Water venture Quality Program investments<br />

Better de�ne the scope of ‘hazardous’<br />

• fair labor<br />

H2O-Insight Water Tool<br />

Understanding consumer demand<br />

Money<br />

Money<br />

Money<br />

Money<br />

Hazard Assessment<br />

GC3 Data Exchange Pilot Project<br />

• animal care Consumers<br />

Purchasing<br />

Sales &<br />

Purchasing<br />

Sales &<br />

Purchasing<br />

Sales &<br />

Designers<br />

Workers<br />

Ful�llment Sharing the $ true costs<br />

Workers<br />

Ful�llment<br />

$ Workers<br />

Ful�llment Sharing the $ true costs Cost sensitivity Material Traceability Pilot<br />

Marketing<br />

What to else to eliminate?<br />

Opportunity for process innovation<br />

Buying Teams<br />

Sales<br />

• etc. $<br />

Retailers<br />

Many chemical untested<br />

Worker RWB funding health<br />

Leverage existing platforms<br />

Design<br />

Wants<br />

Consumer<br />

Needs<br />

Post-consumer<br />

Comprehensive hazardous chemical inventory<br />

EHS standards & practices that engage tier 1 & tier 2<br />

Worker turnover<br />

Contracting implications<br />

Speci�cation /<br />

Speci�cation /<br />

Speci�cation /<br />

Innovation<br />

Desires<br />

Local<br />

desires?<br />

Waste<br />

Screening tools e.g. GreenScreen<br />

Requirements<br />

Requirements<br />

Consistent Requirements global requirements<br />

environmental<br />

Demand<br />

Licensees and agents are a black box<br />

activism<br />

Tier 3 Tier 2<br />

Tier 1<br />

In-source solutions<br />

Citizens<br />

Raw Material<br />

Materials Production<br />

An opportunity Direct Contract to restructure the supply chain<br />

Zero toxics<br />

Pollution control<br />

Facility by facility<br />

Motivate<br />

Waste<br />

Dying & Finishing<br />

Waste<br />

Waste<br />

Processing<br />

Suppliers<br />

Brands to innovate: get employees engaged<br />

for greatly reduced environmental impact<br />

vs<br />

programs/technology Treatment<br />

wastewater treatment<br />

Treatment<br />

Treatment<br />

Assembly<br />

Design standards and simpli�cation<br />

An opportunity to create a framework for<br />

EPM - Environmentally Preferred Materials<br />

IT Systems<br />

Environmental<br />

Industrial engineers<br />

addressing other challenges:<br />

Wholistic understanding of LCA impacts<br />

Equipment<br />

damage<br />

Application engineers<br />

environmental, EH&S, labor<br />

across the supply chain<br />

Manufacturers<br />

ReUSE A SHOE<br />

Driving process control and innovation<br />

Re-structuring the supply chain:<br />

<strong>NIKE</strong> GRINDSources<br />

of recycled materialsRecycling<br />

Raw Materials<br />

Carbon<br />

Simpli�cation, fewer suppliers, vertical integration<br />

Extraction<br />

Footprint<br />

Amount of<br />

Waste Management<br />

water used<br />

Companies Environmental monitoring<br />

Shared vision of green manufacturing, and a healthy planet, by all actors<br />

Substitution<br />

Elimination<br />

Questions/unknowns<br />

Barrier / Issues<br />

Action item<br />

copyright® 2012 <strong>Nike</strong>, <strong>Inc</strong>.<br />

Road to Zero System Map: Strategic Issues<br />

Other Materials<br />

Rubbers, glues, etc.<br />

Synthetic Fibers<br />

Polyester, Nylon, etc.<br />

Natural Fibers<br />

Cotton, Wool, etc<br />

Leather<br />

Water<br />

Speci�cation /<br />

Requirements<br />

Energy<br />

Environmental Footprint<br />

of Raw Material Production<br />

Water Scarcity<br />

$<br />

Money<br />

Communication<br />

& Trust<br />

Chemical<br />

Formulations<br />

Certi�cation<br />

Certi�cation<br />

Water Scarcity<br />

Certi�cation<br />

Process<br />

Regional/Global Agreements<br />

Outgoing<br />

across the supply chain<br />

De�ning ‘zero’<br />

Zero discharge or zero use?<br />

Certi�cation<br />

Environmental Monitoring<br />

Opportunity to reduce storage costs<br />

Air<br />

Storage Integrity<br />

Land<br />

Toxic metabolites<br />

Water<br />

<strong>Inc</strong>oming<br />

Natural Environment<br />

Government A�airs<br />

Distance & Disconnection<br />

EP&L Accounting<br />

Terrestrial Ecosystems<br />

Marine Ecosystems

copyright® 2012 <strong>Nike</strong>, <strong>Inc</strong>.<br />

Road to Zero System Map<br />

Version 2.4 January 2012<br />

Joint Roadmap Projects<br />

India<br />

Bluesign<br />

Water-based adhesives<br />

Greenworks<br />

Water-based non-PVCs non-phthalate inks<br />

Expand Waterless our dyingcurrent<br />

e�orts of prescribing alternative (greener) chemistries to be used on our products.<br />

Environmentally preferred rubber<br />

Workers<br />

Sales &<br />

Con�rm, New fabric or coatings set timelines for the elimination of products that are associated with PFOA Purchasing and PFOS by replacing Ful�llment C8 �uorinated water repellent chemistry<br />

with alternative technologies including short-chain �uorochemical water repellents approved by global regulators.<br />

Transparency<br />

In early 2012, we will initiate a project with chemical suppliers to identify a ‘positive list’ of APEO/NPE-free detergents.<br />

Partner(s)<br />

We will expand our current e�orts of prescribing alternative (greener) chemistries to be used on our products. Current examples include water-based<br />

adhesives and water-based inks.<br />

Substitution<br />

Elimination<br />

Bangladesh<br />

Thailand<br />

Malaysia<br />

Indonesia<br />

Other Materials<br />

Rubbers, glues, etc.<br />

Synthetic Fibers<br />

Polyester, Nylon, etc.<br />

Raw Materials<br />

Extraction<br />

China<br />

Taiwan<br />

Philippines<br />

Chemical<br />

Feedstocks<br />

Natural Fibers<br />

Cotton, Wool, etc<br />

Locations<br />

Leather<br />

Water<br />

Speci�cation /<br />

Requirements<br />

Energy<br />

Knowledge<br />

Motivation<br />

Capacity<br />

$<br />

Chemical<br />

Companies<br />

Production Processes<br />

Money<br />

Management<br />

Green Chemistry<br />

Green Chemistry / Substitution<br />

Toxic Chemistry<br />

Hazard Assessment<br />

Phthalates<br />

Brominated and chlorinated �ame retardants<br />

MSDS<br />

Azo Dyes<br />

Identify and agree to a cross-industry screening tool for chemical hazards.<br />

Organotin compounds<br />

Dying<br />

Beginning Chlorobenzene in early 2013, we will determine a plan to evaluate the chemical inventory by intrinsic hazard and establish a sector wide list Coatings of hazardous chemicals.<br />

Chlorophenols<br />

This Short-chain list will chlorinated be used para�ns to do a (SCCPs) gap analysis and identify the alternative (greener) chemical formulations that are needed.<br />

Heavy metals: cadmium<br />

Certi�cation<br />

Heavy metals: lead<br />

Heavy metals: mercury<br />

Knowledge<br />

Knowledge<br />

Toxic Heavy metals: chromium Chemistry<br />

(VI)<br />

Motivation<br />

Motivation<br />

Capacity<br />

Capacity<br />

Per�uorinated chemicals (PFC)<br />

Management<br />

Develop a comprehensive, generic inventory of chemicals used in textile manufacturing.<br />

Chlorinated solvents<br />

Continue Nonlyphenol expansion ethoxylates of individual/collective RSLs and MRSLs.<br />

Alkylphenols (AP) Alkylphenol Ethoxylates (APE)<br />

Production Processes<br />

Finished Product<br />

Communication<br />

& Trust<br />

Chemical<br />

Formulations<br />

We will develop a joint generic audit approach for environmental<br />

Communication<br />

performance<br />

&<br />

(including<br />

Training<br />

chemicals management)<br />

Knowledge<br />

with<br />

Sharing<br />

the possibility<br />

/ Best Practices<br />

for brands<br />

/ Open<br />

to, within<br />

Source<br />

legal con�nes,<br />

Innovation<br />

share supplier results between brands.<br />

By the end of 2013, we will develop a shared dye house and printer audit protocol with a competent third party.<br />

By the end of 2014, within legal con�nes, we will develop a program to incentivize suppliers to ful�ll the dye house and printer audit protocol (e.g. Leather Working Group (LWG)).<br />

Discharge<br />

By the end of 2012, we will con�rm, or set timelines for the elimination of products that are associated with PFOA and PFOS<br />

In 2012 we will develop a comprehensive inventory of chemicals used in textile manufacturing.<br />

By mid-2012, we will identify and agree to a cross industry-screening tool for chemical hazards.<br />

Purchasing<br />

Sales &<br />

By the end of 2011, we will communicate to all suppliers the requirement to source preparations Workers that are APEO/NPE free.<br />

Ful�llment<br />

Certi�cation<br />

Communication<br />

& Trust<br />

Speci�cation /<br />

Requirements<br />

Waste<br />

Treatment<br />

Money<br />

$<br />

Certi�cation<br />

Purchasing<br />

Certi�cation<br />

Auditing<br />

Partner(s)<br />

Management<br />

Production Processes<br />

Workers<br />

Tier 3 Tier 2<br />

Raw Material<br />

Processing<br />

Communication & Training<br />

Transparency: Disclosure / Testing / Auditing / Monitoring<br />

Process<br />

Materials Production<br />

Dying & Finishing<br />

Regional/Global Agreements<br />

We will collaborate on joint training e�orts and knowledge transfer (e.g., Leather Working Group (LWG), Apparel & Footwear International EPA - China Environmental RSL Management Law Initiative Group (AFIRM),<br />

Trans-National Bodies<br />

EPA's O�ce of Pollution Prevention and Toxics (OPPT)<br />

Outdoor Industry Association (OIA) Chemicals Management Working Group (CMWG), Sustainable Apparel Coalition, SAC).<br />

Sales &<br />

Ful�llment<br />

National Governments<br />

Outgoing<br />

Waste<br />

Treatment<br />

Testing<br />

Partner(s)<br />

Certi�cation<br />

Speci�cation /<br />

Requirements<br />

By mid-2013, we will develop an action plan to address phase-out of any of the Air nine chemicals that are found from this benchmarking study.<br />

Certi�cation<br />

Finished Product<br />

Communication<br />

& Trust<br />

Money<br />

Environmental Monitoring<br />

Land<br />

Water<br />

Glues<br />

Solvents<br />

Printing<br />

Natural Environment<br />

Waste<br />

Treatment<br />

Certi�cation<br />

Speci�cation /<br />

Requirements<br />

Equipment<br />

Manufacturers<br />

Benchmark study whether 9 classes of chemicals not in discharge to water or sludge using on-site visits and audits, inventories, and analytics where appropriate.<br />

Develop action plan to address phase-out of any 9 chemical classes found in benchmark study.<br />

Conduct follow-up study at selection of facilities Waste that Management<br />

have converted to APEO/NPE free detergents to identify remaining sources.<br />

Companies<br />

By the end of 2012, we will benchmark and verify whether the above nine classes of chemicals are not in discharge to water or sludge through a carefully designed<br />

process of on-site visits and audits, inventories, and analytics where appropriate.<br />

<strong>Inc</strong>oming<br />

Criminalization<br />

Regulation<br />

International Initiatives:<br />

United Nations Environment Programme (UNEP)<br />

UN Division for Sustainable Development - Agenda 21<br />

EU Commission Environment - REACH<br />

Rotterdam Convention<br />

Asia-Paci�c Economic Cooperation (APEC) –<br />

Sustainable Development and Chemical Dialogue<br />

On an on-going basis, we will disclose the results of all studies undertaken as part of this initiative (without reference to speci�c facilities).<br />

In 2012, we will provide joint quarterly updates to projects/programs, and from 2013 publish annual State performance Leadershipupdates<br />

on the roadmap. Each end of year update will be open for comment and feedback from key stakeholders.<br />

Academia<br />

In 2012, we will publish an up dated roadmap, based Government on the experience Agencies we have gathered throughout Legislative 2012 Bodies and on input from all stakeholders. Judicial System<br />

Media<br />

Online/Social Media<br />

Research Universities<br />

Regulation & Enforcement<br />

Transparency / Disclosure<br />

We will continue to update the individual brands Restricted Substances Lists (RSL) and Manufacturing RSL (black list) and associated testing protocols.<br />

<strong>The</strong> expansion of individual/collective RSLs and MRSLs will continue inde�nitely based on our work above, and nothing in this roadmap is intended to restrict<br />

the ability of the companies to separately implement individual discharge plans, as may be required by legislation or regulation or otherwise.<br />

Collaborate on joint training e�orts and knowledge transfer and deliver a joint training program in one or more countries.<br />

Beginning in 2011, we (the undersigned group of brands will) communicate the mission of zero discharge of all hazardous chemicals to all factories and material suppliers (including licensees).<br />

Beginning in 2011, we will initiate continual education of the supply chain regarding hazardous chemicals to all factories and material suppliers (including licensees).<br />

By the end of 2012, we will deliver a joint pilot training program in one or more of the countries named above.<br />

Laws &<br />

Regulations<br />

In 2012, we will convene a cross sector group to explore the best ways to encourage sector wide supplier chemical disclosure. We will also Government deliver a study Levers based on data collection from a select group of facilities.<br />

In 2012 we will explore platform options for suppliers to disclose their chemical inventory under the assumption that disclosing their inventory will have a positive e�ect.<br />

Testing & Benchmarking<br />

Education &<br />

Convening<br />

Knowledge<br />

Motivation<br />

Capacity<br />

Market<br />

Creation<br />

$<br />

Management<br />

Production Processes<br />

Sales &<br />

Finished Product<br />

Communication<br />

& Trust<br />

Money<br />

Other<br />

Industries<br />

Apparel<br />

Industry<br />

Brand<br />

Consortia<br />

Management<br />

<strong>Nike</strong> Material Sustainability Index<br />

Considered Index<br />

<strong>Nike</strong> RSL & MRSL<br />

<strong>Nike</strong> Green Chemistry Program<br />

Sustainable Chemistry Guidance<br />

List of Positive Chemistries<br />

Global Water Quality Program<br />

H2O-Insight Water Tool<br />

GC3 Data Exchange Pilot Project<br />

Material Traceability Pilot<br />

Purchasing<br />

Designers<br />

$ Workers<br />

Ful�llment<br />

Marketing<br />

$<br />

$<br />

Tier 1<br />

Direct Contract<br />

Suppliers<br />

Assembly<br />

Trade<br />

Policy<br />

Taxes &<br />

Fees<br />

Investors<br />

$ $<br />

In 2012, we will conduct a follow-up study at a selection of facilities that have converted to APEO/NPE-free detergents to evaluate if there are remaining sources<br />

including non-intentional uses etc. of these chemicals.<br />

Funding &<br />

Subsidies<br />

Broader work<br />

$<br />

Buying Teams<br />

Knowledge<br />

Motivation<br />

Capacity<br />

Civil Society<br />

Brands<br />

ReUSE A SHOE<br />

<strong>NIKE</strong> GRIND<br />

Sales<br />

Retailers<br />

Terrestrial Ecosystems<br />

Marine Ecosystems<br />

NGO’s<br />

Green Chemistry Institute<br />

China National Textile and Apparel Council<br />

Institute of Public & Environmental A�airs (IPE)<br />

BSR – China Training Institute<br />

Ceres<br />

World Resources Institute<br />

NRDC - National Resources Defense Council<br />

WWF - World Wildlife Fund<br />

EDF - Environmental Defense Fund<br />

3rd Party Partners<br />

Labeling<br />

Finished Product<br />

Communication<br />

& Trust<br />

Money<br />

Sustainable Apparel Coalition<br />

Outdoor Industry Association - Chemicals<br />

Management Working Group<br />

Leather Working Group<br />

Green Chemistry & Commerce Council (GC3 )<br />

A�rm Group<br />

Beginning in 2012, based on knowledge gained from the pilot projects, we will extend chemical management programs to the full supply chain.<br />

We will begin elements of chemical management (e.g. education, communication on restrictions) in 2011 and expand and improve through 2020.<br />

Beginning in 2012, we will commence pilot projects to gain greater knowledge of hazardous chemical use and discharge in the supply chain.<br />

We will continue to engage our supply chains via wider initiatives on raw materials such as cotton and leather.<br />

Wants<br />

Needs<br />

Desires<br />

Demand<br />

Recycling<br />

Consumers<br />

Citizens<br />

Market Demand<br />

Consumers<br />

Citizens<br />

Post-consumer<br />

Waste