BEM Mar09-May09 - Board of Engineers Malaysia

BEM Mar09-May09 - Board of Engineers Malaysia

BEM Mar09-May09 - Board of Engineers Malaysia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

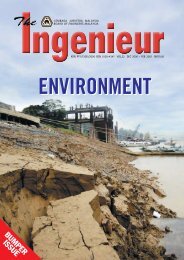

LEMBAGA JURUTERA MALAYSIA<br />

BOARD OF ENGINEERS MALAYSIA<br />

KDN PP11720/01/2010(023647) ISSN 0128-4347 VOL.41 MAR - MAY 2009 RM10.00

8<br />

16<br />

21<br />

54<br />

Volume 41 March - May 2009<br />

c o n t e n t s<br />

4 President’s Message<br />

Editor’s Note<br />

6 Announcements<br />

Cancellation Of Registration Of Registered Engineer And<br />

Removal From Register<br />

Publication Calendar<br />

Invitation To Serve In Investigating Committee<br />

Cover Feature<br />

8 Solid Waste Management: Towards Better<br />

Treatment And Disposal Facilities<br />

13 Aquaponics: The Future Of Agriculture<br />

17 Building Structures For The Future – The Green Way?<br />

Engineering & Law<br />

27 The JKR/PWD Forms (Rev. 2007): An Overview (Part 2)<br />

Feature<br />

34 Incorporating Electro-Magnetic Compatibility Design<br />

Into Mission Critical Facilities<br />

42 Riding The Economic Tsunami: Investing In Local<br />

Workforce And IBS Construction Technology<br />

46 Utilisation Of Rice Husk Waste And Its Ash (Part 1)<br />

Lighter Moments<br />

51 Sudoku : A Mental Callisthenics<br />

Engineering Nostalgia<br />

54 Bertam Valley New Village, Cameron Highlands

MEMBERS OF THE BOARD OF ENGINEERS MALAYSIA<br />

(<strong>BEM</strong>) 2009/2010<br />

President<br />

YBhg. Dato’ Sri Pr<strong>of</strong>. Ir. Dr Judin Abdul Karim<br />

Registrar<br />

Ir. Dr Mohd Johari Md. Arif<br />

Secretary<br />

Ir. Ruslan Abdul Aziz<br />

Members<br />

YBhg Tan Sri Pr<strong>of</strong>. Ir. Dr Mohd Zulkifli bin Tan Sri Mohd Ghazali<br />

YBhg Dato’ Ir. Hj. Ahmad Husaini bin Sulaiman<br />

YBhg. Dato’ Ir. Abdul Rashid Maidin<br />

YBhg. Dato’ Ir. Dr Johari bin Basri<br />

YBhg. Datuk (Dr) Ir. Abdul Rahim Hj. Hashim<br />

YBhg. Brig. Jen. Dato’ Pahlawan Ir. Abdul Nasser bin Ahmad<br />

YBhg. Dato’ Ir. Pr<strong>of</strong>. Dr Chuah Hean Teik<br />

YBhg. Datuk Ir. Anjin Hj Ajik<br />

YBhg. Datuk Ar. Dr Amer Hamzah Mohd Yunus<br />

Ir. Wong Siu Hieng<br />

Ir. Mohd Rousdin bin Hassan<br />

Ir. Pr<strong>of</strong>. Dr Ruslan bin Hassan<br />

Ir. Tan Yean Chin<br />

Ir. Vincent Chen Kim Kieong<br />

Ir. Chong Pick Eng<br />

Jaafar bin Shahidan<br />

EDITORIAL BOARD<br />

Advisor<br />

YBhg. Dato’ Sri Pr<strong>of</strong>. Ir. Dr Judin Abdul Karim<br />

Secretary<br />

Ir. Ruslan Abdul Aziz<br />

Chairman<br />

YBhg. Dato’ Ir. Abdul Rashid bin Maidin<br />

Editor<br />

Ir. Fong Tian Yong<br />

Members<br />

Pr<strong>of</strong>. Sr. Ir. Dr Suhaimi bin Abdul Talib<br />

Ir. Ishak bin Abdul Rahman<br />

Ir. Pr<strong>of</strong>. Dr K.S. Kannan<br />

Ir. Mustaza bin Salim<br />

Ir. Prem Kumar<br />

Ir. Rasid Osman<br />

Ir. Dr Zuhairi Abdul Hamid<br />

Ir. Ali Askar bin Sher Mohamad<br />

Executive Director<br />

Ir. Ashari Mohd Yakub<br />

Publication Officer<br />

Pn. Nik Kamaliah Nik Abdul Rahman<br />

Assistant Publication Officer<br />

Pn. Che Asiah Mohamad Ali<br />

Design and Production<br />

Inforeach Communications Sdn Bhd<br />

Printer<br />

Art Printing Works Sdn Bhd<br />

29 Jalan Riong, 59100 Kuala Lumpur<br />

The Ingenieur is published by the <strong>Board</strong> <strong>of</strong> <strong>Engineers</strong> <strong>Malaysia</strong><br />

(Lembaga Jurutera <strong>Malaysia</strong>) and is distributed free <strong>of</strong> charge to<br />

registered Pr<strong>of</strong>essional <strong>Engineers</strong>.<br />

The statements and opinions expressed in this<br />

publication are those <strong>of</strong> the writers.<br />

<strong>BEM</strong> invites all registered engineers to contribute articles or<br />

send their views and comments to<br />

the following address:<br />

Commnunication & IT Dept.<br />

Lembaga Jurutera <strong>Malaysia</strong>,<br />

Tingkat 17, Ibu Pejabat JKR,<br />

Jalan Sultan Salahuddin,<br />

50580 Kuala Lumpur.<br />

Tel: 03-2698 0590 Fax: 03-2692 5017<br />

E-mail: bem1@streamyx.com; publication@bem.org.my<br />

Website: http://www.bem.org.my<br />

4 THE INGENIEUR<br />

KDN PP11720/01/2010(023647)<br />

ISSN 0128-4347<br />

Vol. 41 March - May 2009<br />

Advertising<br />

Subscription Form is on page 33<br />

Advertisement Form is on page 37<br />

president’s message<br />

Industries thrive on innovation and cutting edge<br />

technology. The engineering input towards new<br />

technologies that satisfy clients’ needs which are<br />

closely related to state-<strong>of</strong>-art technology, is without<br />

doubt the most important aspect <strong>of</strong> the whole formula.<br />

However, such input has to keep up with the fast<br />

pace <strong>of</strong> innovation and discovery to stay competitive<br />

in this borderless world.<br />

As the world’s economic trend moves from<br />

agriculture, industry, ICT and then to the nanotechnology era, we<br />

expect to see more emerging technologies introduced to industrial and<br />

household products. Some <strong>of</strong> these are already at our doorsteps. If one<br />

has not been to Cameron Highlands for the last 10 years, one will be<br />

surprised to see the new trend <strong>of</strong> tomato cultivation in bags laid on top<br />

<strong>of</strong> concrete floors fed with tubes <strong>of</strong> nutrient water, called vertigation.<br />

Flower beds are lighted up at night to stop buds from blooming until<br />

ready for harvesting<br />

<strong>Malaysia</strong>, via its Science and Technology Policy for the 21 st Century,<br />

has set an objective <strong>of</strong> spending 1.5% <strong>of</strong> GDP to enhance national<br />

capacity in R&D and to achieve a competent work force <strong>of</strong> 60 RSEs<br />

(researchers, scientists and engineers) per 10,000 labour force by 2010.<br />

This should be a good platform for innovative engineers to tap into and<br />

move further up the value chain <strong>of</strong> industrial products. I hope more<br />

research groups will collaborate with locally trained engineers to move<br />

into emerging technologies as the potential is immensely beneficial to<br />

the nation.<br />

Dato’ Sri Pr<strong>of</strong> Ir. Dr. Judin bin Abdul Karim<br />

President<br />

BOARD OF ENGINEERS MALAYSIA<br />

editor’s note<br />

The increasing pace <strong>of</strong> scientific and technological<br />

innovation has kept engineers on their toes to update<br />

themselves with the latest codes <strong>of</strong> practices, technologies<br />

and scientific breakthroughs. Engineering, as an applied<br />

science, has improved the quality <strong>of</strong> life for man through<br />

the introduction <strong>of</strong> new and improved products. Emerging<br />

engineering technology holds an important place for the<br />

nation and practising engineers to stay relevant in the manufacturing<br />

and construction industry.<br />

This issue <strong>of</strong> the publication looks at green ways <strong>of</strong> building structures<br />

for the future and some <strong>of</strong> the policies towards Industralised Building<br />

System (IBS) construction technology. Innovations in agriculture that<br />

integrate aquaculture and hydroponics <strong>of</strong>fer wide economic potential<br />

for local industrial players and practising engineers to ponder about.<br />

Technology on incineration <strong>of</strong> solid waste is relatively new to <strong>Malaysia</strong>.<br />

The article dedicated to this technology should provide readers some<br />

insight into the wide range <strong>of</strong> technologies available to incinerate solid<br />

waste.<br />

Ir Fong Tian Yong<br />

Editor

announcement<br />

Registration Of <strong>Engineers</strong> Act 1967<br />

Cancellation Of Registration Of<br />

Registered Engineer And Removal<br />

From Register Pursuant To Section 15<br />

And Paragraph 16(c)<br />

IN ACCORDANCE with subsubparagraph 6(2)(a)(i)(B)<br />

and subparagraph 6(2)(a)(ii) <strong>of</strong> the Registration <strong>of</strong><br />

<strong>Engineers</strong> Act 1967 [Act A138], the Registrar publishes<br />

the particulars <strong>of</strong> the registered Engineer as stated in<br />

Schedule whose registration has been cancelled and<br />

removed from the Register pursuant to paragraphs<br />

15(1)(g), 15(1A)(d) and 16(c) <strong>of</strong> the Act with effect<br />

from 1 August 2008.<br />

SCHEDULE<br />

No. Name, Address and<br />

Qualification<br />

1. Leong Pui Kun<br />

No. 52 Tengkat Tong Shin<br />

50200 Kuala Lumpur<br />

BE (Civil)<br />

Dated 12 November 2008<br />

[KKR.PUU.110-1/4/3/1 Jld.2; PN(PU 2 )47/X]<br />

Registration Number<br />

4112<br />

- SGD -<br />

Ir. Dr. Mohd Johari Bin Md Arif<br />

Registrar <strong>of</strong> the <strong>Board</strong> <strong>of</strong> <strong>Engineers</strong> <strong>Malaysia</strong><br />

INVITATION TO SERVE IN<br />

INVESTIGATING COMMITTEE<br />

The <strong>Board</strong> <strong>of</strong> <strong>Engineers</strong> <strong>Malaysia</strong> would like to invite<br />

all Pr<strong>of</strong>essional <strong>Engineers</strong> <strong>of</strong> not less than ten years<br />

standing as Pr<strong>of</strong>essional <strong>Engineers</strong> to serve as members<br />

in Investigating Committee.<br />

The Committee’s prime duty is to investigate into<br />

complaints involving pr<strong>of</strong>essionalism and breach <strong>of</strong><br />

ethics <strong>of</strong> pr<strong>of</strong>essional engineers.<br />

If you are interested in serving this Committee, kindly fill<br />

in the form below and return to the Secretariat. Training<br />

would be given to potential members.<br />

To:<br />

Chairman<br />

Pr<strong>of</strong>essional Practice Committee<br />

<strong>Board</strong> <strong>of</strong> <strong>Engineers</strong> <strong>Malaysia</strong><br />

17 th Floor JKR HQ Building<br />

Jln. Sultan Salahuddin,<br />

50580 Kuala Lumpur.<br />

Tel. No: 03-26912090<br />

Fax. No: 03-26925017<br />

e-mail: ppc@bem.org.my<br />

I am interested to serve as a member <strong>of</strong><br />

Investigation Committee.<br />

Name:<br />

PE Registration:<br />

Discipline:<br />

Date Registration:<br />

Tel. No.:<br />

Fax. No.:<br />

E-mail:<br />

Office Address:<br />

Home Address:<br />

Specialization:<br />

Signature<br />

June 2009:<br />

PUBLIC AMENITIES<br />

Sept 2009:<br />

SAFETY & HEALTH<br />

Dec 2009:<br />

SUSTAINABLE DEVELOPMENT<br />

✁

cover feature<br />

Solid Waste Management:<br />

Towards Better Treatment<br />

And Disposal Facilities<br />

By Nadzri Bin Yahaya (PhD)<br />

Director-General, Department <strong>of</strong> National Solid Waste Management, Ministry <strong>of</strong> Housing and Local Government<br />

Solid Waste Management<br />

(SWM) in <strong>Malaysia</strong>, as in<br />

most countries worldwide,<br />

has traditionally been a task for<br />

Local Authorities (LA). It falls<br />

under sanitation which is listed<br />

as an item under the concurrent<br />

list <strong>of</strong> the Federal Constitution.<br />

Items listed in the concurrent list<br />

indicate that both the State and<br />

the Federal Governments have<br />

jurisdiction over it.<br />

RDF Plant in Semenyih<br />

8 THE INGENIEUR<br />

In this regard, The Local<br />

G o v e r n m e n t A c t ( A c t 1 7 1 )<br />

empowers the LAs to establish,<br />

maintain and carry out sanitary<br />

services with regard to solid<br />

waste and public cleansing for<br />

areas within their jurisdiction.<br />

Another piece <strong>of</strong> legislation that<br />

empowered the LAs relating to<br />

the maintenance, repair and<br />

provision <strong>of</strong> ash pits, dustbin<br />

and like receptacles is the Street,<br />

Drainage and Building Act, 1974<br />

(Act 133).<br />

The Federal Government’s<br />

engagement in the sector is<br />

traditionally restricted to financing<br />

<strong>of</strong> facilities, equipment and<br />

collection vehicles, based on<br />

applications from local authorities,<br />

and establishing policies and<br />

awareness. In addition, the States<br />

play an important role as the<br />

authority on land and hence<br />

responsible for the allocation<br />

<strong>of</strong> land for landfills and other<br />

facilities.<br />

The management <strong>of</strong> solid<br />

waste by LAs has given rise to<br />

increasing criticism from the<br />

public, due to poor quality in<br />

some places. The quality <strong>of</strong> the<br />

service to a large degree depends<br />

on financial resources. LAs are<br />

also handicapped in handling the<br />

latest technologies for disposal<br />

and treatment <strong>of</strong> solid waste. Lack<br />

<strong>of</strong> human resources also hamper<br />

good quality enforcement. All<br />

these factors contributed to the<br />

deterioration in the quality <strong>of</strong><br />

the environment, in particular,<br />

those surrounding the landfill<br />

sites. In its effort to ensure a coordinated,<br />

effective and efficient<br />

solid waste management, the<br />

Federal Government embarked on

a two-prong strategy; federalising<br />

the SWM through the enactment<br />

<strong>of</strong> the Solid Waste and Public<br />

Cleansing Management Act 2007<br />

and privatising the collection and<br />

transportation <strong>of</strong> the household<br />

solid waste to reduce financial<br />

pressure on LAs. The enactment<br />

<strong>of</strong> the Act saw the establishment<br />

<strong>of</strong> the Department <strong>of</strong> National<br />

Solid Waste Management and the<br />

Corporation on Solid Waste and<br />

Public Cleansing Management as<br />

dedicated agencies to manage<br />

solid waste in the country.<br />

Policy and National<br />

Strategic Plan on Waste<br />

Management<br />

The importance <strong>of</strong> technologies<br />

in the management <strong>of</strong> solid waste<br />

in the country was clearly defined<br />

by the 3 rd Outline Perspective Plan<br />

(2001-2010). The 3 rd OPP reported<br />

that the Government will install<br />

incinerators for safe and efficient<br />

disposal <strong>of</strong> solid waste. The<br />

National Policy on Solid Waste<br />

Management which was approved<br />

by Cabinet in 2006 as well as the<br />

National Strategic Plan on Solid<br />

Waste Management which was<br />

approved by Cabinet in 2005 put<br />

great emphasis on the importance<br />

<strong>of</strong> technologies to improve the<br />

quality <strong>of</strong> solid waste management.<br />

The National Strategic Plan laid<br />

down the provision <strong>of</strong> sustainable<br />

technologies as its fourth strategy<br />

to achieve the Plan’s objectives<br />

among which is to adopt an<br />

integrated management <strong>of</strong> solid<br />

wa s t e . Th e N a t i o n a l Po l i cy<br />

provides clear guidance on the<br />

criteria <strong>of</strong> technologies to be<br />

used. Its 5 th thrust emphasizes<br />

that only technologies which<br />

are environmental-friendly, cost<br />

effective and proven should be<br />

adopted for use in this country.<br />

Another criterion is that local<br />

Mini incinerator in Pulau Tioman<br />

t e ch n o l o g i e s w i l l b e g iven<br />

priority.<br />

To ensure that solid waste<br />

management technologies which<br />

are proposed for implementation<br />

in the county comply with the<br />

criteria laid down by the National<br />

Policy and National Strategic Plan,<br />

a National Committee to evaluate<br />

solid waste technologies was<br />

formed under the Chairmanship <strong>of</strong><br />

the Secretary-General <strong>of</strong> Ministry<br />

<strong>of</strong> Housing and Local Government.<br />

Its members among others consist<br />

<strong>of</strong> pr<strong>of</strong>essionals and academicians<br />

from various universities and<br />

research institutions that are well<br />

versed in solid waste management<br />

technologies. The Committee will<br />

analyse not only the technical<br />

and technological features <strong>of</strong> the<br />

proposed facilities, but also the<br />

economic and financial aspects.<br />

Cost which includes capital and<br />

operating expenditure remains a<br />

crucial criterion in any proposal<br />

to built solid waste management<br />

cover feature<br />

facilities in the country. Hence,<br />

the reason behind the termination<br />

<strong>of</strong> the Broga’s Incinerator as<br />

announced by the Deputy Prime<br />

Minister in 2007. He cited high<br />

cost as the main reason for the<br />

cancellation <strong>of</strong> the project.<br />

Provision on technologies<br />

in the Solid Waste and<br />

Public Cleansing Act 2007<br />

The Act besides laying down<br />

the various provisions on general<br />

management <strong>of</strong> solid waste has<br />

also recognized the importance<br />

<strong>of</strong> standards and specifications<br />

in the building <strong>of</strong> facilities to<br />

treat and dispose solid waste.<br />

Under Section 108 <strong>of</strong> the Act,<br />

the Minister may prescribe the<br />

standards and specifications for<br />

the design, construction, operation<br />

and maintenance <strong>of</strong> any prescribed<br />

solid waste management facilities.<br />

The Minister also may order any<br />

solid waste generator to reduce<br />

THE INGENIEUR 9

cover feature<br />

the generation <strong>of</strong> solid waste, to<br />

use environment-friendly materials<br />

as well as use specified amount<br />

<strong>of</strong> recycled materials. All the<br />

requirements as laid down by<br />

the Act can only be achieved if<br />

research and development activities<br />

are carried out in search <strong>of</strong><br />

emerging environmentally sound<br />

technologies as well as new<br />

approaches in production processes.<br />

Best available technology (BAT) and<br />

‘Best available technology not at<br />

excessive cost’ (BATNEC) will be<br />

the main guiding principle in the<br />

search for emerging technologies<br />

under the new National Solid<br />

Waste Management Department.<br />

Strategies towards<br />

sustainable solid waste<br />

management<br />

As reported by the 9 th <strong>Malaysia</strong><br />

Plan, 17,000 tonnes <strong>of</strong> solid waste<br />

were generated each day in 2002<br />

<strong>of</strong> which 45% is food waste, 24%<br />

plastics, 7% paper and 6% iron. The<br />

Plan forecasted that in 2020, we<br />

will generate about 30,000 tonnes<br />

per day if no new effort is put in<br />

place to address the ever increasing<br />

generation <strong>of</strong> solid waste. In this<br />

regard, the Department <strong>of</strong> National<br />

Solid Waste Management has put in<br />

place two strategies: prevention at<br />

source and providing facilities for<br />

solid waste management treatment<br />

and disposal. To address this<br />

menace, high priority is given to<br />

reducing, reusing and recycling<br />

(3R) solid waste. Whilst lifestyle<br />

can largely contribute to the<br />

reduction <strong>of</strong> household solid<br />

waste, manufacturing process and<br />

technologies play a key role in the<br />

reduction <strong>of</strong> other types <strong>of</strong> solid<br />

waste, in particular, industrial and<br />

commercial waste as well as in<br />

recycling activities.<br />

Facilities under the solid waste<br />

management concept include<br />

10 THE INGENIEUR<br />

Composting process<br />

the various thermal treatment<br />

technologies such as incineration,<br />

p y r o l y s i s a n d g a s i f i c a t i o n<br />

technologies as well as material<br />

recovery facilities and mechanical<br />

and biological treatment, mechanical<br />

heat treatment; renewable energy<br />

and waste technologies. Sanitary<br />

landfill is still the most common<br />

disposal facility in the country.<br />

I n c i n e ra t i o n i s t h e m o s t<br />

established and matured thermal<br />

treatment technology whereas<br />

p y r o l y s i s a n d g a s i f i c a t i o n<br />

technologies are termed as the<br />

emerging, advance technologies in<br />

solid waste treatment and disposal.<br />

Incineration usually involves the<br />

combustion <strong>of</strong> mingled solid<br />

waste with the presence <strong>of</strong> air or<br />

sufficient oxygen. Typically, the<br />

temperature in the incinerator is<br />

more than 850ºC and the waste<br />

is converted into carbon dioxide<br />

and water. Dioxin is the main<br />

concern but is destroyed with<br />

high temperature. An incinerator<br />

will give rise to two types <strong>of</strong><br />

ash; fly ash and bottom ash. Fly<br />

ash is categorised as scheduled<br />

waste and controlled under<br />

the Environmental Quality Act<br />

1974 and can only be disposed<br />

<strong>of</strong>f at prescribed facilities as<br />

designated by the Department<br />

<strong>of</strong> Environment. The bottom ash<br />

consist <strong>of</strong> any non-combustible<br />

materials that contain a small<br />

amount <strong>of</strong> residual carbon. This<br />

can be used as materials in road<br />

making as well brick making.<br />

In contrast to incineration,<br />

pyrolysis is the thermal degradation<br />

<strong>of</strong> a substance in the absence <strong>of</strong><br />

oxygen. This process requires an<br />

external heat source to maintain<br />

the temperature required. Typically,<br />

relatively low temperatures <strong>of</strong><br />

between 300ºC and 850ºC are<br />

used during pyrolysis <strong>of</strong> materials<br />

such as solid waste. The products<br />

produced from pyrolysing materials<br />

are a solid residue and a synthetic<br />

gas (syngas). The solid residue

(sometimes described as char) is<br />

a combination <strong>of</strong> non-combustible<br />

materials and carbon. The syngas<br />

is a mixture <strong>of</strong> gases (combustible<br />

constituents include carbon<br />

monoxide, hydrogen, methane<br />

and a broad range <strong>of</strong> other VOCs).<br />

A proportion <strong>of</strong> these can be<br />

condensed to produce oils, waxes<br />

and tars. The syngas typically has<br />

a net calorific value (NCV) <strong>of</strong><br />

between 10 and 20 MJ/Nm3.<br />

Gasification can be seen as<br />

between pyrolysis and incineration<br />

(combustion) in that it involves the<br />

partial oxidation <strong>of</strong> a substance.<br />

This means that oxygen is added<br />

but the amounts are not sufficient<br />

to allow the fuel to be completely<br />

oxidised and full combustion to<br />

occur. The temperatures employed<br />

are typically above 650°C. The<br />

process is largely exothermic but<br />

some heat may be required to<br />

initialise and sustain the gasification<br />

process. The main product is a<br />

syngas, which contains carbon<br />

monoxide, hydrogen and methane.<br />

Typically, the gas generated from<br />

Mini incinerator in Denmark<br />

gasification will have a net calorific<br />

value (NCV) <strong>of</strong> 4 - 10 MJ/Nm3.<br />

While we are engaged in<br />

thermal treatment technologies, we<br />

are concerned with the existing<br />

method <strong>of</strong> disposal; the landfills.<br />

At present, we have about 261<br />

landfills all over the country, 111<br />

<strong>of</strong> these are no longer in operation<br />

and only 10 <strong>of</strong> the 150 operating<br />

landfills are sanitary landfills.<br />

Thus, the Department’s strategies<br />

on landfill management are laid<br />

down as follows:<br />

(i) Decide location, types and size<br />

<strong>of</strong> landfills and coverage area<br />

<strong>of</strong> each landfill;<br />

(ii) Build regional landfills with<br />

centralised treatment plant;<br />

(iii) Safe closure <strong>of</strong> landfills in<br />

sensitive areas<br />

(iv) Safe closure <strong>of</strong> the nonsanitary<br />

landfills which are<br />

no longer operating;<br />

(v) Upgrade non-sanitary landfills<br />

that are still operating; and<br />

(vi) Build new sanitary landfills<br />

with Recycling Facilities<br />

A l t h o u g h t h e t e c h n i c a l<br />

specifications <strong>of</strong> sanitary landfill is<br />

not new, materials used for lining<br />

<strong>of</strong> landfill is now undergoing<br />

va r i o u s ch a n g e s , t h a n k s t o<br />

research and development to find<br />

better materials. Traditionally,<br />

lining material is made <strong>of</strong> High-<br />

Density Poly Ethylene (HDPE). But<br />

new technologies have emerged<br />

suggesting other materials as<br />

alternatives. These new materials<br />

are expected to better prevent<br />

the leakages <strong>of</strong> leachate into<br />

the surrounding environment<br />

thus preventing pollution, in<br />

particular, <strong>of</strong> underground water,<br />

rivers and soil.<br />

Waste to Energies<br />

Facilities<br />

Waste to energies facilities in<br />

solid waste management is quite<br />

new in <strong>Malaysia</strong>. Although this has<br />

caught on in the palm oil sector<br />

where waste from the industries<br />

are converted to energy, in solid<br />

waste management it has some<br />

hurdles to overcome before it can<br />

be made viable. The characteristics<br />

<strong>of</strong> waste which has high moisture<br />

content and its co-mingling nature<br />

make it difficult to harness its<br />

potential. Furthermore, incentives<br />

to encourage the private sector to<br />

venture into renewable energy are<br />

not very lucrative. In Europe, most<br />

solid waste treatment facilities are<br />

also power plants. They generate<br />

electricity and steam for central<br />

heating facilities.<br />

Conclusion<br />

cover feature<br />

S o l i d wa s t e m a n a g e m e n t<br />

in <strong>Malaysia</strong> is undergoing a<br />

paradigm shift from being a local<br />

authority concern to a Federal<br />

Government responsibility. A<br />

structured approach has been<br />

established with policy, strategic<br />

THE INGENIEUR 11

� ��� ���� ���� ����� ����� ����������� ����������� ���� ���� �������������� �������������� ����� �����<br />

����������� ����������� ���� ���� �������������� �������������� ������� �������<br />

���������� ���������� ��� ��� �������� ��������<br />

�� �� � ���� � ���� �������� �������� ����� ����� ��������� ��������� ���� ���� ����� ����� ���������� ����������<br />

����� ����� � ����� � ����� �������� �������� �������� �������� ������ ������<br />

�� �� � ����������� � ����������� ��������� ��������� ������� ������� ����� ����� ��������� ��������� ���� ����<br />

������ ������<br />

�� �� ����������� ����������� ����� ����� ������������ ������������ ������������� ������������� ���� ����<br />

������������� ������������� ��� ��� ���� ����<br />

�� �� � ��������� � ��������� ���� ���� ���� ���� ����� ����� �������� �������� ������ ������ ���� ���� ����������� �����������<br />

���������� ����������<br />

�� �� � ����� � ����� ��� ��� ������� �������<br />

�� �� � ����� � ����� ��������� ���������<br />

� � �� �� �� �� �� ��<br />

� �<br />

�������� �������� �������������� �������������� ����� ����� ���� ���� ���� ���� � �<br />

���� ���� ������ ������ �������� �������� ������� ������� �������� �������� ���� ����<br />

����� ����� ����� ����� ������� ������� ��������� ��������� ������ ������ ������� ������� �������� ��������<br />

����� ����� ��� ��� ��� ��� ����� ����� ������ ������ � � ����� � � ����� � ��� � ��� ��� ��� ����� ����� ���� ����<br />

��������� ��������� ���������������<br />

���������������<br />

� �<br />

Sanitary landfill in <strong>Malaysia</strong><br />

plan and legislation in place as well as dedicated<br />

agencies. The policy will provide the general<br />

principles and guidance for management <strong>of</strong> solid<br />

waste. The law will provide the catalyst for the<br />

policy and strategic plan to be implemented in<br />

an integrated manner. However, the much needed<br />

push to ensure that solid waste being treated<br />

and disposed in an environment-friendly manner,<br />

cost effective and feasible depends on technology<br />

and technical know-how. Without expert and<br />

pr<strong>of</strong>essional human resources, all the best policies<br />

and plans to ensure that solid waste management<br />

is carried out effectively and efficiently will not<br />

be successfully implemented. <strong>BEM</strong><br />

REFERENCE<br />

cover feature<br />

1. Federalising Solid Waste Management In<br />

Peninsula <strong>Malaysia</strong>: Dr. Nadzri Bin Yahaya 1 and<br />

Ib Larsen 2<br />

1 Director General, Department <strong>of</strong> National<br />

Solid Waste Management, Ministry <strong>of</strong><br />

Housing and Local Government, Level 2 &<br />

4, Block B North, Pusat Bandar Damansara,<br />

50644 Kuala Lumpur, <strong>Malaysia</strong><br />

2 Chief Technical Advisor, Danish International<br />

Development Assistance (DANIDA) Solid<br />

Waste Management Component (SWMC),<br />

Level 4, Block B North, Pusat Bandar<br />

Damansara 50644 Kuala Lumpur<br />

2. Advance Thermal Treatment <strong>of</strong> Municipal<br />

Solid Waste: Defra- Department for Environment,<br />

Food and Rural Affairs, UK

cover feature<br />

AQUAPONICS:<br />

The Future Of Agriculture<br />

By Lim Keng Tee<br />

INSAP<br />

Figure 1: Overview <strong>of</strong> Aquaponics System<br />

Arecent report from Farmer’s<br />

Organisation Authority<br />

(FOA) <strong>Malaysia</strong> stating that<br />

the maximum potential marine<br />

capture fisheries has probably<br />

been reached, triggered increased<br />

attention on aquaculture, which<br />

will soon account for half <strong>of</strong><br />

fish consumed. Based on world<br />

population growth projection to<br />

2030, an extra 27 million tonnes <strong>of</strong><br />

fish will be needed to maintain the<br />

current consumption rate <strong>of</strong> 16.7kg<br />

per person per year.<br />

Fish farming or aquaculture<br />

is a system where commercial<br />

fishes are reared in a contained<br />

system e.g. ponds or tanks. The<br />

water quality <strong>of</strong> the contained<br />

system will directly affect the<br />

growth rate as well as the feed<br />

conversion rate (weight <strong>of</strong> feed<br />

needed to convert a kilogramme<br />

<strong>of</strong> fish meat). Hence, aquaculture<br />

is said to be a highly polluting<br />

system due to the discharge <strong>of</strong><br />

polluted water into the surrounding<br />

THE INGENIEUR 13

cover feature<br />

Figure 2: Aquaculture portion<br />

environment in order to improve<br />

water quality. However, over<br />

time many techniques have been<br />

invented to reduce the pollution,<br />

one <strong>of</strong> them is the AQUAPONIC<br />

system.<br />

Aquaponics is the combination<br />

<strong>of</strong> Aquaculture and Hydroponic<br />

systems whereby nutrient rich waste<br />

water from the Aquaculture system<br />

14 THE INGENIEUR<br />

Figure 3: Filtering system <strong>of</strong> the Aquaponics System<br />

is directed into the Hydroponic<br />

system. Plants will absorb the<br />

nutrient from the waste water<br />

and improve or purify the water<br />

quality for the aquaculture system.<br />

This provides an eco-friendly as<br />

well as sustainable system for the<br />

agriculture sector.<br />

This fantastic integrated farming<br />

system was invented by Dr James<br />

The UVI Aquaponic System<br />

Tank dimensions<br />

Rearing tanks: Diameter: 10 ft, height: 4 ft, Water volume:<br />

2,060 gal each<br />

Clarifiers: Diameter: 6 ft, Height <strong>of</strong> cylinder: 4 ft, Depth <strong>of</strong> cone:<br />

3.6 ft, Slope: 45 o , Water volume: 1,000 gal<br />

Filter and degassing tanks: Length: 6 ft, Width: 2.5 ft, Depth:<br />

2 ft, Water volume: 185 gal<br />

Hydroponics tanks: Length: 100 ft, Width: 4 ft, Depth: 16 in,<br />

Water volume: 3,000 gal, Growing area: 2,304 ft 2<br />

Figure 4: Basic Layout <strong>of</strong> the Aquaponics System<br />

Rakocy from the University <strong>of</strong> Virgin<br />

Island (UVI). Over time this system<br />

has been improved from a test<br />

system to an improved commercial<br />

system. UVI continuously improves<br />

its system with the focus on<br />

effective model design, which<br />

improves and optimizes water<br />

turnover rates. Figure 1, 2 and 3<br />

show the actual site pictures <strong>of</strong><br />

Sump: Diameter: 4 ft, Height: 3 ft, Water volume: 160 gal<br />

Base addition tank: Diameter: 2 ft, Height: 3 ft, Water<br />

volume: 50 gal<br />

Total system water volume: 29,375 gal<br />

Flow rate: 100 GPM<br />

Water pump: !s hp<br />

Blowers: 1 !s hp (fish) and 1 hp (plants)<br />

Total land area: Qi acre

the UVI Aquaponics System, while<br />

Figure 4 shows the basic layout<br />

<strong>of</strong> the UVI Aquaponics system.<br />

(Source: Rakocy et al, 2006)<br />

From the above figures, it can<br />

be seen that water is recirculating<br />

within the contained aquaponics<br />

system. Hence water wastage<br />

can be minimized, compared to<br />

the aquaculture system (frequent<br />

changing <strong>of</strong> fish water to ensure<br />

water quality) or plant cultivation<br />

on soil (roughly 10% <strong>of</strong> the water<br />

is absorbed by the plant, while<br />

90% <strong>of</strong> the water is wasted). Along<br />

with saving water, the fertilizer<br />

and pesticide needed for plants<br />

can be further reduced, which<br />

directly contributes to operational<br />

cost savings. Besides that, labour<br />

needed is also reduced, as several<br />

operations such as watering plants,<br />

spraying fertilizer or pesticides can<br />

be minimized accordingly.<br />

In order to prevent solid sludge<br />

from clotting the system, a filtration<br />

system is installed between the<br />

aquaculture portion and the<br />

hydroponic portion. UVI has even<br />

improved the effectiveness by<br />

modifying the clarifier. Sludge will<br />

slowly sink to the bottom, whereby<br />

the operator can easily suck out<br />

A<br />

Figure 6: Geotexile Technology used in extracting the solid sludge<br />

cover feature<br />

Figure 5: Cross-sectional view <strong>of</strong> modified UVI clarifier. (Source: Rakocy<br />

et al, 2006)<br />

the sludge without disturbing the<br />

system. Figure 5 shows the crosssection<br />

<strong>of</strong> a modified clarifier<br />

which is easy to clean.<br />

Besides that, the filtrating<br />

system also plays a crucial role<br />

to allow the growth <strong>of</strong> beneficial<br />

bacteria which converts ammonia<br />

(waste from the fish) to nitrate<br />

and nitrite that plants are able<br />

to utilize for growth, as well<br />

as control the fruiting period.<br />

B<br />

C<br />

D<br />

E<br />

Moreover, the solid sludge filtered<br />

out can be further processed to<br />

become bio-fertilizer. Figure 6<br />

shows the Geotexile Technology/<br />

Geotube ® used to extract the<br />

solid sludge from the system.<br />

(Source: Danahar J, 2008)<br />

Land scarcity is a common<br />

issue for the agricultural sector,<br />

and cultivatable land is even more<br />

scarce. However this system does<br />

not require soil for cultivation.<br />

THE INGENIEUR 15

cover feature<br />

Figure 7: Multilayer cultivation <strong>of</strong> plants under the Aquaponic system.<br />

Hence, soil fertility is not an<br />

issue. Furthermore, plants can<br />

even be cultivated in multilayers<br />

to maximize the utilization <strong>of</strong><br />

land as shown in Figure 7. The<br />

critical point <strong>of</strong> this system is to<br />

maintain the correct balance, so<br />

that one does not deviate from the<br />

optimized ratio. (Source: Ramos,<br />

2009)<br />

A n o t h e r b e a u t y i n t h i s<br />

aquaponics system is scaleability,<br />

whereby the unit system can be<br />

scaled up to commercial sizes<br />

by retaining the same ratios <strong>of</strong><br />

16 THE INGENIEUR<br />

each component. However, it is<br />

advisable to multiply the model<br />

units when scaling up as this<br />

allows flexibility in controlling the<br />

production rate, and gives constant<br />

supplies as well as standard<br />

produce.<br />

In a nutshell, the benefits <strong>of</strong><br />

the Aquaponics system can be<br />

summarized below:<br />

(i) Operational cost will be<br />

reduced<br />

(a) Wa s t a g e o f wa t e r i s<br />

minimized.<br />

(b) Less pesticide as well as<br />

fertilizer is needed.<br />

(c) Less labour needed.<br />

(ii) Intensive production and<br />

maximizing space utilization.<br />

(iii) Scaleable and applicable to<br />

both ornamental and food fish/<br />

plant.<br />

(iv) Environment-friendly system<br />

which produces healthy products.<br />

(v) No wastage <strong>of</strong> valuable byproducts<br />

(biomass and fertilizer).<br />

In view <strong>of</strong> the need for<br />

eco-friendly systems, scientist,<br />

agriculturalist as well as engineers<br />

should cooperate to invent and<br />

improve integrated agricultural<br />

systems. <strong>BEM</strong><br />

REFERENCE<br />

Danaher, J. (2008). Evaluating<br />

Geotexile Technology To<br />

Enhance Sustainability Of<br />

Agricultural Production<br />

Systems In The U.S. Virgin<br />

Island. Aquaponic Journal,<br />

50, 18-20.<br />

James E. Rakocy, M. P.<br />

(2006). Recirculating<br />

Aquaculture Tank Production<br />

System: Aquaponics -<br />

Intergrating Fish and Plant<br />

Culture. Southern Region<br />

Aquaculture Centre, 454.<br />

Ramos, C. L. (2009).<br />

Aquaponic Development in<br />

Mexico. Aquaponic Journal,<br />

52, 32-35.

cover feature<br />

Building Structures For<br />

The Future – The Green Way?<br />

By Ir. Chen Thiam Leong<br />

The need and urgency <strong>of</strong> sustainable development for the built industry is beyond the deliberation<br />

stage (or at least we hope so). Energy Efficiency can be deemed to be the prelude to Sustainability,<br />

and locally we did not fare too tardily having developed our MS1525 in 2001. It is only unfortunate<br />

that the incorporation <strong>of</strong> MS1525 into our Uniform Building By-laws (UBBL) has been delayed<br />

since 2003.<br />

However, <strong>of</strong> more significant concern (and damage) is our local modus operandi where Energy<br />

Efficiency (and now Sustainability) issues are more than <strong>of</strong>ten regarded as the sole responsibility<br />

<strong>of</strong> M&E <strong>Engineers</strong>. The sad reality is that not many Architects in <strong>Malaysia</strong> are conversant or have<br />

taken the lead role in sustainable design. Hence, it is not at all surprising that most Structural<br />

(Civil) <strong>Engineers</strong> have hardly heard <strong>of</strong> or have participated in sustainable structural designs.<br />

This paper will serve to highlight the role Structural (Civil) <strong>Engineers</strong> can and should play to<br />

realize the Sustainable (Green) agenda and the need for a holistic design approach by all relevant<br />

players. An introduction to the proposed <strong>Malaysia</strong>n Green Building Rating tool will be included.<br />

It is no more a matter <strong>of</strong> WHY<br />

we need to build green but<br />

rather HOW we can build<br />

green and it should be starting<br />

NOW.<br />

Unless we remain closeted<br />

(somehow), the effects <strong>of</strong> Global<br />

Warming (GW) cannot be unknown.<br />

GW has been attributed to the<br />

Ozone Hole; given gradual rise in<br />

the earth’s temperature; and leading<br />

to the Greenhouse Effect. The<br />

frightening statistic is temperatures<br />

in the far north have increased 5-<br />

7 0 C in the last 50 years, and as<br />

the temperatures get warmer, the<br />

sea level rises causing a difference<br />

in the amount <strong>of</strong> precipitation.<br />

This in turn causes extreme<br />

weather conditions to develop<br />

resulting in excessive storms with<br />

heavier rainfall. The ecosystem is<br />

then affected with difference in<br />

agricultural growth and harvest,<br />

leading to extinction <strong>of</strong> certain<br />

animal and plant species.<br />

The main Green House Gases<br />

(GHG) are CO 2 , methane and water<br />

vapour. While water vapour and<br />

methane are not present for very<br />

long in the earth’s atmosphere, CO 2<br />

can remain in the atmosphere for<br />

many years and when combined<br />

with the water vapour can escalate<br />

the rate at which GW takes place.<br />

Therein lies the need to stop GW<br />

by removing CO 2 present in the<br />

atmosphere or at least not add<br />

more to it. The Montreal Protocol<br />

and Kyoto Protocol are aimed at<br />

arresting or at least mitigating this<br />

man-made disaster.<br />

So what can we do about<br />

GW? Plenty! We can reduce<br />

consumption <strong>of</strong> energy to decrease<br />

GHG, starting with reducing use<br />

<strong>of</strong> electricity. It is amazing to<br />

know that about 11% <strong>of</strong> electricity<br />

is consumed by phantom loads<br />

alone. We are ready and have the<br />

capacity to use more efficient light<br />

bulbs. For instance, in US alone,<br />

if every household were to apply<br />

a compact florescent bulb instead<br />

<strong>of</strong> a glowing light bulb, we can<br />

realize a staggering reduction <strong>of</strong> 90<br />

billion pounds <strong>of</strong> CO 2 emission!<br />

THE INGENIEUR 17

cover feature<br />

In terms <strong>of</strong> Climate Change,<br />

apart from the great financial<br />

impact, the human impact is<br />

already being felt. Millions are<br />

starving throughout the globe,<br />

and with the World’s population<br />

increasing steadily, the situation<br />

will continue to deteriorate if<br />

temperature and climate changes<br />

are allowed to continue unimpeded.<br />

It will take years if not decades<br />

to put an end to the emission <strong>of</strong><br />

GHG. This can only be achieved<br />

through a gradual transition to<br />

cleaner energy. In the meantime,<br />

mankind will have to live with<br />

the catastrophic effects that these<br />

temperature and climate changes<br />

are bringing upon us.<br />

Global GHG emissions have<br />

increased by 70% between 1970<br />

and 2004 and the largest growth<br />

<strong>of</strong> this emission has come from<br />

the energy supply sector.<br />

So where do we stand locally?<br />

<strong>Malaysia</strong>’s population grew at a<br />

rate <strong>of</strong> about 2.8% from 23 million<br />

in 2000 to 27 million today.<br />

Rising population and changes<br />

in life style have accelerated the<br />

demand for energy. The <strong>Malaysia</strong>n<br />

energy sector is still heavily<br />

dependant on non-renewable<br />

fuels. These non-renewable fuels<br />

are finite, gradually depleting and<br />

contributing significantly to the<br />

emission <strong>of</strong> GHG.<br />

What is meant by building<br />

Green?<br />

A Green or Sustainable building<br />

is one which is designed:<br />

● To save energy and resources,<br />

recycle materials and minimise<br />

the emission <strong>of</strong> toxic substances<br />

throughout its life cycle,<br />

● To harmonise with local<br />

climate, traditions, culture and the<br />

surrounding environment, and<br />

● To be able to sustain and<br />

improve the quality <strong>of</strong> human life<br />

18 THE INGENIEUR<br />

Pusat Tenaga <strong>Malaysia</strong> - Zero Energy Office (ZEO) building<br />

while maintaining the capacity <strong>of</strong><br />

the ecosystem at local and global<br />

levels<br />

Building Green in the future<br />

is a necessity and not an option<br />

as the following statistics will<br />

attest;<br />

● Buildings consume 40% <strong>of</strong> our<br />

planet's materials and 30% <strong>of</strong> its<br />

energy<br />

● Their construction uses up<br />

to three million tonnes <strong>of</strong> raw<br />

materials a year and generates<br />

20% <strong>of</strong> the solid waste stream<br />

Therefore, if we want to survive<br />

our urban future, there is no option<br />

but to build in ways which improve<br />

the health <strong>of</strong> ecosystems.<br />

Understanding the concept<br />

<strong>of</strong> ecological sustainability and<br />

translating it into practice as<br />

sustainable development is a<br />

key challenge for today's built<br />

environment pr<strong>of</strong>essionals<br />

To quote Peter Graham;<br />

The skill and vision <strong>of</strong> those<br />

w h o s h a p e o u r c i t i e s a n d<br />

homes is vital to achieving<br />

sustainable solutions to the many<br />

environmental, economic and<br />

social problems we face on a<br />

local, national and global scale<br />

How to build Green?<br />

The term ‘Green building’<br />

is a loosely defined collection<br />

<strong>of</strong> land-use, building design,<br />

and construction strategies that<br />

reduce the environmental impact<br />

that buildings have on their<br />

surroundings. Traditional building<br />

practices <strong>of</strong>ten overlook the<br />

inter-relationships between a<br />

building, its components, its<br />

surroundings, and its occupants.<br />

Typical buildings consume more<br />

<strong>of</strong> our resources than necessary<br />

and generate large amounts <strong>of</strong><br />

waste. Green buildings have<br />

many benefits, such as better use<br />

<strong>of</strong> building resources, significant<br />

operational savings, and increased<br />

workplace productivity. Building<br />

green sends the right message<br />

about a company or organisation<br />

- that it’s well run, responsible,<br />

and committed to the future.

Elements <strong>of</strong> a Green Building<br />

There is not any one single<br />

technique for designing and<br />

building a green building, but<br />

green buildings <strong>of</strong>ten:<br />

● Preserve natural vegetation<br />

● Contain non-toxic or recycledcontent<br />

building materials<br />

● Maintain good indoor airquality<br />

● U s e w a t e r a n d e n e r g y<br />

efficiently<br />

● Conserve natural resources<br />

● Feature natural lighting<br />

● Include recycling facilities<br />

throughout<br />

● Include access to public<br />

transportation<br />

● Feature flexible interiors; and<br />

● Recycle construction and<br />

demolition waste.<br />

Who are involved in Green<br />

Buildings?<br />

A truly green building can only<br />

materialize and thereafter sustain<br />

itself when all parties involved<br />

with its birth are involved. Notice<br />

the choice <strong>of</strong> word – birth and not<br />

construction. If involvement by all<br />

commence only at the construction<br />

stage, then the end result would<br />

definitely be a tainted green at<br />

most.<br />

Obviously the starting point is<br />

the particular piece <strong>of</strong> land on<br />

which the building will stand.<br />

Hence, it starts with the owner/<br />

developer who will probably consult<br />

the advice <strong>of</strong> the relevant experts<br />

which includes the pr<strong>of</strong>essional<br />

architect or engineer (as the case<br />

maybe). It is at this stage that<br />

issues such as developing on a<br />

protected green lung, brown field<br />

and green field are relevant and<br />

decisive on achieving a green<br />

building.<br />

After the initial hurdle (which<br />

i n c l u d e s t h e s o c i a l i m p a c t<br />

assessment) is successfully (and<br />

greenly) navigated, the design team<br />

will be next to play their full role.<br />

From there on, the need to strike<br />

a balance between ‘company’s<br />

green policy’, value engineering,<br />

life cycle cost et al will determine<br />

the success or otherwise <strong>of</strong> the<br />

project.<br />

Nowadays when we talk about<br />

green buildings, the project team<br />

(helmed by the owner) will have<br />

to determine which Green Building<br />

Rating system to adopt. There is no<br />

right or wrong tool but rather the<br />

most appropriate tool to choose<br />

from.<br />

A l l g r e e n r a t i n g t o o l s<br />

incorporate basically similar<br />

criteria <strong>of</strong> assessments (albeit with<br />

differing weightings) and these<br />

criteria require the entire team’s<br />

participation. For instance, the<br />

owner will have to agree to pay to<br />

save the environment and commit<br />

that the end users will procure<br />

energy efficient appliances. The<br />

cover feature<br />

designers will need to write into<br />

the contract conditions for the<br />

builder to undertake the protection<br />

<strong>of</strong> the environment (in terms<br />

<strong>of</strong> air and waste pollution) at<br />

commencement <strong>of</strong> construction.<br />

Vendors have to supply products<br />

that are environmental-friendly<br />

and so on. The simple chart<br />

below summarizes this integrated<br />

approach to achieving green.<br />

Local Design Consultants/<br />

Pr<strong>of</strong>essionals<br />

The notorious modus operandi<br />

<strong>of</strong> the local consultant team needs<br />

to be highlighted at this juncture.<br />

We have to admit that it is an<br />

exception rather than the rule<br />

to experience a fully integrated<br />

design team working together in<br />

<strong>Malaysia</strong> (for a green project).<br />

With the advent <strong>of</strong> green<br />

buildings, the design team leader<br />

(architect for majority <strong>of</strong> building<br />

THE INGENIEUR 19

cover feature<br />

Comparison <strong>of</strong> Selected Green Rating Tools<br />

Name<br />

Country<br />

Year<br />

Assessment Criteria<br />

types and civil engineer for<br />

industrial type buildings) must<br />

take the role to lead the whole<br />

team, failing which they can<br />

only blame themselves if they<br />

are subsequently made irrelevant<br />

in green matters by other allied<br />

pr<strong>of</strong>essionals. A simple case in<br />

point would be architects not<br />

interested (or not conversant) in<br />

dictating the design development<br />

and calculations for Overall<br />

Thermal Transfer Value (OTTV) <strong>of</strong><br />

building envelopes.<br />

Local Civil (and Structural)<br />

engineers are similarly notorious<br />

in not venturing beyond their<br />

self-defined field, with many<br />

not being aware <strong>of</strong> their role<br />

in green building designs in the<br />

fields <strong>of</strong> construction process,<br />

material selection, innovation and<br />

so forth.<br />

Local Mechanical & Electrical<br />

engineers are also not spared this<br />

criticism with more than a handful<br />

<strong>of</strong> them contented to merely churn<br />

out basic fundamental designs and<br />

not bothering to catch up with<br />

technological advances.<br />

It is Author’s fervent hope<br />

that such a critical comment<br />

will elicit reaction from the local<br />

pr<strong>of</strong>essional fraternity to practice<br />

20 THE INGENIEUR<br />

BREEAM<br />

UK<br />

Bldg Research Establishment<br />

Environmental Assessmt Method<br />

1990<br />

1. Management<br />

2. Health & Comfort<br />

3. Energy<br />

4. Transportation<br />

5. Water Consumption<br />

6. Materials<br />

7. Land Use<br />

8. Ecology<br />

9. Pollution<br />

LEED<br />

USA<br />

Leadership in Energy and<br />

Environmental Design<br />

1996<br />

1. Sustainable site<br />

2. Water Efficiency<br />

3. Energy & Atmosphere<br />

4. Materials & Resources<br />

5. Indoor Environmental<br />

Quality<br />

6. Innovation & Design /<br />

Construction Process<br />

an integrated design approach to<br />

achieve beyond green buildings.<br />

Green Building<br />

Rating Tools<br />

● Advent <strong>of</strong> Green Tools<br />

In 1990, the Building Research<br />

Establishment <strong>of</strong> UK came out<br />

with the first Green Building<br />

Rating Tool or Assessment Method<br />

called BREEAM. This was quickly<br />

followed by other countries,<br />

and in the past year or so, this<br />

awareness has finally come to<br />

<strong>Malaysia</strong>’s shore. The following<br />

table depicts a comparison <strong>of</strong><br />

selected established assessment<br />

methods.<br />

● Proposed <strong>Malaysia</strong> Green<br />

Building Index<br />

It is inevitable that some<br />

p a s s i o n a t e a n d c o n c e r n e d<br />

individuals will eventually band<br />

together to initiate our own<br />

local Green Building Rating<br />

tool. Hence, after a few years <strong>of</strong><br />

false starts, the <strong>Malaysia</strong>n Green<br />

Building Council will soon be up<br />

and running and together with<br />

a parallel group from PAM and<br />

ACEM, the target <strong>of</strong> getting our<br />

tool ready should hopefully be<br />

GREEN STAR<br />

Australia<br />

2003<br />

1. Management<br />

2. Transport<br />

3. Ecology<br />

4. Emissions<br />

5. Water<br />

6. Energy<br />

7. Materials<br />

8. Indoor Environmental<br />

Quality<br />

9. Innovation<br />

GREEN MARK<br />

Singapore<br />

2005<br />

1. Energy Efficiency<br />

2. Water Efficiency<br />

3. Environmental<br />

Protection<br />

4. Indoor Environmental<br />

Quality<br />

5. Other Green Features<br />

realized by the second quarter<br />

<strong>of</strong> 2009.<br />

As highlighted at the onset,<br />

meeting the assessment criteria<br />

for any green building rating tool<br />

will involve all members <strong>of</strong> the<br />

building team. For the Green<br />

Building Index, the structural<br />

engineer’s input likewise will<br />

cover all the six criteria, but<br />

probably with more emphasis on;<br />

Sustainable Site & Management;<br />

and Materials & Resources;<br />

Role <strong>of</strong> Structural <strong>Engineers</strong><br />

in Building Green<br />

This section is extracted/reproduced<br />

from various website<br />

a r t i c l e s b y e m i n e n t g r e e n<br />

pr<strong>of</strong>essionals/organisations (See<br />

Reference).<br />

● Structural Engineering Best<br />

‘Green’ Practice<br />

Structural engineering ‘best<br />

practices’ incorporates strategies<br />

that embrace the tenets <strong>of</strong><br />

sustainable design. Sustainable<br />

design is not a novelty; it is a<br />

mainstream approach that reflects<br />

good design.<br />

The necessity and importance<br />

<strong>of</strong> design integration, in general,

Comparison <strong>of</strong> <strong>Malaysia</strong> Green Building Index with other selected Tools<br />

Name<br />

Country<br />

Year<br />

Assessment Criteria<br />

LEED<br />

USA<br />

1996<br />

1. Sustainable site<br />

2. Water Efficiency<br />

3. Energy & Atmosphere<br />

4. Materials & Resources<br />

5. Indoor Environmental<br />

Quality<br />

6. Innovation & Design /<br />

Construction Process<br />

LEED,<br />

USA<br />

is not a new idea. For decades,<br />

structural engineers have seen<br />

how close collaboration with other<br />

project team members has led to<br />

the creation <strong>of</strong> some very unique<br />

buildings. Unfortunately, design<br />

integration is <strong>of</strong>ten overlooked<br />

when teams collaborate on more<br />

typical structures. Structural<br />

engineers have traditionally been<br />

limited to providing input only<br />

after the core building concepts<br />

have been decided. However,<br />

structural engineers should not<br />

limit themselves to the perceived<br />

boundaries <strong>of</strong> their expertise.<br />

Sustainable design integration<br />

is a call to action for structural<br />

engineers to become more involved<br />

with the early conceptualization <strong>of</strong><br />

a building project.<br />

Structural engineers need to be<br />

reminded <strong>of</strong> the significance <strong>of</strong><br />

sustainable design with increased<br />

awareness <strong>of</strong> considerations<br />

GREEN STAR<br />

Australia<br />

2003<br />

1. Management<br />

2. Transport<br />

3. Ecology<br />

4. Emissions<br />

5. Water<br />

6. Energy<br />

7. Materials<br />

8. Indoor Environmental<br />

Quality<br />

9. Innovation<br />

Green Star,<br />

Australia<br />

GREEN MARK<br />

Singapore<br />

2005<br />

1. Energy Efficiency<br />

2. Water Efficiency<br />

3. Environmental Protection<br />

4. Indoor Environmental<br />

Quality<br />

5. Other Green Features<br />

Green Mark,<br />

Singapore<br />

associated with it. The following<br />

issues are presented in cursory form<br />

as is appropriate to generate interest:<br />

materials, resource conservation in<br />

design and construction, structural<br />

systems and performance based<br />

engineering, and collaboration<br />

opportunities with other design<br />

pr<strong>of</strong>essions.<br />

● Materials<br />

Structural materials provide<br />

the structural engineer with<br />

real opportunities to contribute<br />

to a project’s sustainability.<br />

Th e s t r u c t u ral e n g i n e e r, i n<br />

using the traditional criteria<br />

for material selection such as<br />

economy and appropriateness to<br />

project structural requirements,<br />

has already been an active<br />

participant in sustainable design.<br />

The structural engineer can<br />

further contribute to the overall<br />

sustainability <strong>of</strong> a project by<br />

cover feature<br />

GREEN BUILDING INDEX<br />

<strong>Malaysia</strong><br />

2008<br />

1. Energy Efficiency<br />

2. Indoor Environmental<br />

Quality<br />

3. Sustainable Site &<br />

Management<br />

4. Materials & Resources<br />

5. Water Efficiency<br />

6. Innovation<br />

Green Building Index,<br />

<strong>Malaysia</strong><br />

considering and exploiting the<br />

efficiency, availability, recycled<br />

content, reuse, and impact a<br />

material has on the environment.<br />

Consideration <strong>of</strong> benefits and<br />

disadvantages <strong>of</strong> some <strong>of</strong> the<br />

major building materials such<br />

as concrete, masonry, steel, and<br />

timber, are briefly outlined.<br />

Concrete<br />

Concrete consists primarily<br />

<strong>of</strong> cement paste binder and<br />

aggregate. While concrete is an<br />

essential and structural material,<br />

cement production contributes<br />

approximately 1.5% <strong>of</strong> annual (US)<br />

carbon dioxide emissions, and as<br />

much as 7% <strong>of</strong> worldwide annual<br />

emissions. Cement production<br />

produces approximately one pound<br />

<strong>of</strong> CO 2 for each pound <strong>of</strong> cement.<br />

Reducing the amount <strong>of</strong> cement<br />

used in concrete will reduce<br />

carbon dioxide emissions.<br />

THE INGENIEUR 21

cover feature<br />

The amount <strong>of</strong> cement in<br />

concrete can be reduced by<br />

substituting fly ash or ground<br />

granulated blast furnace slag,<br />

or slag for short, for cement.<br />

Fly ash is a by-product <strong>of</strong> the<br />

combustion <strong>of</strong> coal in electric<br />

power generating plants, and slag<br />

is made from iron blast-furnace<br />

slag. Fly ash has less embodied<br />

energy than Portland cement.<br />

Typically, fly ash replaces cement<br />

at 15% to 25% by weight, and slag<br />

replaces cement at 15% to 40%<br />

by weight, with little effect on<br />

concrete mix design, placement,<br />

curing, and finishing. However,<br />

the following considerations are<br />

applicable:<br />

- Minimal cost impact<br />

- Improved workability<br />

- Less bleeding<br />

- Improved finishability<br />

- Improved pumpability<br />

- No change in plastic<br />

shrinkage<br />

- No change in abrasion<br />

resistance<br />

High Volume Fly Ash (HVFA)<br />

concrete mixes replace cement<br />

binder with fly ash at rates <strong>of</strong><br />

50% to 55% by weight. These<br />

mixes have been developed<br />

in recent years and have the<br />

advantage <strong>of</strong> reducing cement<br />

requirements while producing<br />

concrete with low permeability<br />

and lower heat <strong>of</strong> hydration.<br />

Masonry<br />

The use <strong>of</strong> concrete masonry<br />

has many sustainable benefits<br />

throughout the life <strong>of</strong> the structure.<br />

It is <strong>of</strong>ten obtained from local<br />

suppliers, and its thermal mass can<br />

be used for night time heat purge.<br />

Unlike light framed construction,<br />

masonry remains cool long after<br />

the air-conditioning has shut<br />

<strong>of</strong>f, reducing cooling loads.<br />

Masonry also <strong>of</strong>fers improved<br />

22 THE INGENIEUR<br />

indoor environmental quality by<br />

eliminating plaster or paint if an<br />

architectural finish is desired. The<br />

use <strong>of</strong> masonry construction also<br />

reduces the potential for mold<br />

growth because masonry does<br />

not provide a ready food source<br />

for mould. Additional benefits are<br />

gained by specifying lightweight<br />

or aerated concrete masonry<br />

units whenever feasible. These<br />

units decrease resource depletion,<br />

reduce transportation energy<br />

impact, and increase concrete<br />

unit masonry wall insulation<br />

values.<br />

Masonry construction also<br />

has benefits <strong>of</strong> recycled content<br />

including fly ash, slag cement,<br />

silica fume and recycled or<br />

salvaged aggregates, for all the<br />

same reasons cited for concrete<br />

[www.greenbuilder.com].<br />

In addition to traditional<br />

concrete and clay masonry units,<br />

there are many alternative forms<br />

<strong>of</strong> masonry available today. Adobe<br />

is an especially environmentfriendly<br />

masonry product, using<br />

less than one-sixth the production<br />

e n e r g y o f c o n c r e t e b l o c k .<br />

Interlocking concrete masonry<br />

units for landscape retaining<br />

walls do not require mortar and<br />

are easy to disassemble and<br />

reuse or recycle. Use <strong>of</strong> salvaged<br />

marble reduces demand on nonrenewable<br />

virgin resources. Other<br />

salvaged materials such as brick<br />

and stone are readily available.<br />

Sound reflecting <strong>of</strong> the s<strong>of</strong>fit Sound reflecting <strong>of</strong> the flat s<strong>of</strong>fit<br />

Sound tansmiiting between<br />

work-cells<br />

Absorption control noise<br />

levels within work-cell<br />

TRADITIONAL CEILING SOFFIT<br />

Acoustic screen making privacy<br />

between work-cells<br />

C<strong>of</strong>fers preventing shallow reflection<br />

propagating over distance<br />

THERMOCAST COFFERED SOFFIT

Steel structure<br />

Steel<br />

Steel is the most recycled<br />

material used in modern building<br />

construction. In 2005 alone,<br />

almost 76 million tons <strong>of</strong> steel<br />

were recycled which corresponds<br />

to a recycling rate <strong>of</strong> 75.7%<br />

[www.recycle-steel.org]. Steel<br />

in all forms including cans,<br />

automobile parts and structural<br />

shapes is continually salvaged by<br />

various mills throughout the globe<br />

and can be made into new steel<br />

products <strong>of</strong> any form through<br />

one <strong>of</strong> two new technologies:<br />

the electric arc furnace (EAF) and<br />

the basic oxygen furnace (BOF).<br />

The primary method used in the<br />

production <strong>of</strong> structural shapes<br />

and bars is the EAF which uses<br />

95-100% [www.aisc.org] old steel<br />

to make new. With this process,<br />

producers <strong>of</strong> structural steel are<br />

able to achieve up to 97.5%<br />

recycled content for beams and<br />

plates, 65% [www.recycle-steel.<br />

org] for reinforcing bars and<br />

66% [www.aiacolorado.org] for<br />

steel deck. Total recycled content<br />

varies from mill to mill. Steel for<br />

products such as soup cans, pails,<br />

drums and automotive fenders is<br />

produced using the BOF process<br />

which uses 25-35% [www.aisc.<br />

org] old steel to make new.<br />

In addition to the recyclability<br />

and percent recycled content <strong>of</strong><br />

the materials used in building<br />

construction, the deconstructability<br />

<strong>of</strong> a building can be considered<br />

when evaluating its sustainability.<br />

For instance, using all-bolted<br />

connections in the structural<br />

framing system is one method for<br />

facilitating ease <strong>of</strong> deconstruction.<br />

As another example, the use <strong>of</strong><br />

butted steel deck under concrete<br />

fill as opposed to lapped and<br />

welded metal deck also aids in<br />

deconstruction.<br />

Wood<br />

Of the many material choices<br />

designers have at their disposal,<br />

timber at first glance may appear<br />

the least sustainable. Discussions<br />

Wood ro<strong>of</strong> trust<br />

cover feature<br />

<strong>of</strong> timber harvesting conjure<br />

images <strong>of</strong> clear cutting and global<br />

de-forestation. However, timber<br />

holds the distinction <strong>of</strong> being the<br />

only conventional building material<br />

that is renewable. Additionally, it<br />

is biodegradable, non-toxic, energy<br />

efficient, recyclable, and reusable.<br />

With more than one quarter <strong>of</strong><br />

the world’s consumption <strong>of</strong> wood<br />

used in building products such<br />

as lumber, plywood, veneer, and<br />

particleboard, a shift in the way<br />

structural engineers utilize timber<br />

could have far reaching ecological<br />

effects. The three primary areas the<br />

structural engineer can promote<br />

the sustainable use <strong>of</strong> wood<br />

are: efficient framing, alternative<br />

products, and sustainable material<br />

suppliers. Conventional wood<br />

framing practice can be reexamined<br />

so that it is more efficient<br />

and less wasteful. Rethinking the<br />

way we detail light framed wood<br />

construction can significantly<br />

reduce a project’s wood waste.<br />

● Resource Conservation<br />

Resource conservation can<br />

be considered in all stages <strong>of</strong><br />

a project. These considerations<br />

include, but are not limited to<br />

material use, material source,<br />

construction process, and the<br />

end <strong>of</strong> a building’s useful life.<br />

Material, design and construction<br />

THE INGENIEUR 23

cover feature<br />

decisions have an enormous<br />

impact on the sustainability <strong>of</strong><br />

buildings. The structural engineer<br />

has the opportunity to weigh<br />

these decisions with respect to<br />

the beauty, efficiency, function,<br />

constructability and budget <strong>of</strong> a<br />

building project.<br />

Design<br />

During the design phase <strong>of</strong> a<br />

project, the structural engineer<br />

can affect the sustainability <strong>of</strong> a<br />

project through<br />

(i) the choice <strong>of</strong> locally available<br />

resources,<br />

(ii) t h e r e c y c l a b i l i t y a n d<br />

reusability <strong>of</strong> materials and<br />

systems,<br />

(iii) the efficiency <strong>of</strong> structural<br />

systems, and<br />

(iv) informed choices about<br />

demolition and preservation.<br />

R e s o u r c e l o c a t i o n i s a<br />

determining factor in material<br />

choice. Local resources minimize<br />

the use <strong>of</strong> fossil fuels in truck<br />

transportation and potentially<br />

increase the efficiency <strong>of</strong> the<br />

building process. The structural<br />

engineer should be aware <strong>of</strong><br />

locally available materials, and<br />

make effort to design using these<br />

materials. These materials would<br />

ideally be both harvested and<br />

manufactured in the local area.<br />

During construction, using local<br />

materials can result in shorter lead<br />

times, which can simplify logistics<br />

and speed up the construction<br />

process. Choices concerning<br />

labour resources should be made<br />

similarly, though in fact the<br />