Theater Logistician Maj. Gen. Kenneth S. Dowd - KMI Media Group

Theater Logistician Maj. Gen. Kenneth S. Dowd - KMI Media Group

Theater Logistician Maj. Gen. Kenneth S. Dowd - KMI Media Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

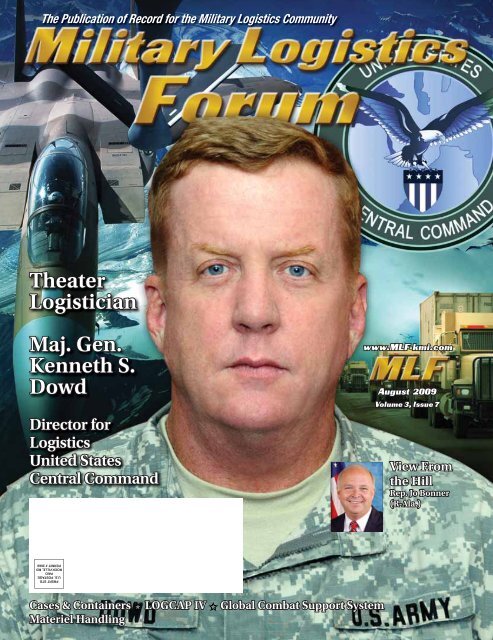

The Publication of Record for the Military Logistics Community<br />

<strong>Theater</strong><br />

<strong>Logistician</strong><br />

<strong>Maj</strong>. <strong>Gen</strong>.<br />

<strong>Kenneth</strong> S.<br />

<strong>Dowd</strong><br />

Director for<br />

Logistics<br />

United States<br />

Central Command<br />

PRSRT STD<br />

U.S. POSTAGE<br />

PAID<br />

ROCKVILLE, MD<br />

PERMIT # 2669<br />

Cases & Containers ✯ LOGCAP IV ✯ Global Combat Support System<br />

Materiel Handling<br />

www.MLF-kmi.com<br />

August 2009<br />

Volume olume 3, IIssue<br />

ssue 7<br />

View From<br />

the Hill<br />

Rep. Jo Bonner<br />

(R-Ala.)

For more information on the full range of JCB construction equipment and to find the dealer nearest you, please visit www.jcbna.com<br />

www.jcb.com<br />

Protecting those who<br />

protect our country<br />

The JCB HMEE–The World’s Toughest Backhoe Loader<br />

When the U.S. Army sought a highly mobile, self-deployable backhoe that could protect its crew in hostile environments, it turned to the company that builds<br />

more backhoes than anyone else. Three years of research, development, test and evaluation went into the JCB HMEE (High Mobility Engineer Excavator), the<br />

first purpose-built backhoe loader developed expressly for the U.S. Military. Replacing the SEE (Small Emplacement Excavator), the HMEE offers an automatic<br />

transmission, highway speeds of 60 mph, (eliminating the need for a logistical support vehicle) and an optional armored cab for enhanced crew protection.<br />

The JCB HMEE–built by the world’s best selling backhoe<br />

loader manufacturer in Savannah, Georgia USA<br />

On May 29th, 2009, a JCB HMEE digging a culvert trench near South Balad Ruz,<br />

Iraq, struck an anti-tank mine that exploded. The HMEE was immobilized, but the<br />

operator walked away from the wreckage unharmed. That’s exactly what it was<br />

designed to do – protect those who protect our country.<br />

For further information about any of our products<br />

and how they can be adapted to meet your rigorous<br />

demands, e-mail us at info@jcbamericas.com.

MILITARY LOGISTICS FORUM<br />

AUGUST 2009<br />

VOLUME 3 • ISSUE 7<br />

FEATURES COVER / Q&A<br />

9<br />

10<br />

15<br />

25<br />

30<br />

33<br />

View From the Hill<br />

Rep. Jo Bonner (R-Ala.) shares his view on the Air Force tanker<br />

programs and what they think is necessary.<br />

Materiel Handling<br />

Loading and unloading military gear can be heavy and awkward.<br />

Specialized equipment makes the job of moving that gear from<br />

one type of transport to another quicker and easier.<br />

By J.J. Smith<br />

Tactical Logistics Support<br />

A roundtable on the status of the Global Combat Support System<br />

and what it will deliver to the warfighter—and when! Army, Air<br />

Force and Marine Corps GCSS officers come together and share<br />

their visions.<br />

Pack It Up<br />

From hand-carried rugged cases to large shipping containers, the<br />

shipping process is made easier with the use of ruggedized and<br />

purpose-built boxes. Whether big or little, innovation has increased<br />

their utility.<br />

By Steve Goodman<br />

LOGCAP IV<br />

The LOGCAP IV contracting office looks at the newest task orders<br />

and contractors for operations in Afghanistan.<br />

By Jon Connor<br />

Executing the Task Orders<br />

Military Logistics Forum recently had the opportunity to talk with<br />

senior representatives from Fluor Government <strong>Group</strong>, DynCorp<br />

International and KBR Government and Infrastructure, the three<br />

primes of the Logistics Civil Augmentation Program IV (LOGCAP<br />

IV), about how they are positioned to execute those orders.<br />

21<br />

<strong>Maj</strong>or <strong>Gen</strong>eral <strong>Kenneth</strong> S. <strong>Dowd</strong><br />

Director for Logistics<br />

United States Central Command<br />

DEPARTMENTS<br />

2<br />

4<br />

5<br />

6, 8<br />

18<br />

35<br />

Editor’s Perspective<br />

Log Ops/People<br />

Log Leadership Lessons<br />

PEO EIS Enterprise LOG<br />

Supply Chain<br />

Calendar, Directory<br />

INDUSTRY INTERVIEW<br />

36<br />

Katell Thielemann<br />

Director of Platform Logistics<br />

Honeywell Technology Solutions Inc.

MILITARY LOGISTICS<br />

FORUM<br />

VOLUME 3, ISSUE 7 AUGUST 2009<br />

Publication of Record for the<br />

Military Logistics Community<br />

EDITORIAL<br />

Editor<br />

Jeff McKaughan jeffm@kmimediagroup.com<br />

Managing Editor<br />

Harrison Donnelly harrisond@kmimediagroup.com<br />

Copy Editors<br />

Regina Kerrigan reginak@kmimediagroup.com<br />

Diana McGonigle dianam@kmimediagroup.com<br />

Correspondents<br />

Christian Bourge Peter Buxbaum Kelly Fodel<br />

Marty Kauchak Tom Marlowe Kenya McCullum<br />

Christian Sheehy J.J. Smith Karen E. Thuermer<br />

ART & DESIGN<br />

Art Director<br />

Anna Druzcz anna@kmimediagroup.com<br />

Graphic Designers<br />

Scott Morris scottm@kmimediagroup.com<br />

Anthony Pender anthonyp@kmimediagroup.com<br />

Jittima Saiwongnuan jittimas@kmimediagroup.com<br />

ADVERTISING<br />

Associate Publisher<br />

Jane Engel jane@kmimediagroup.com<br />

<strong>KMI</strong> MEDIA GROUP<br />

President and CEO<br />

Jack Kerrigan jack@kmimediagroup.com<br />

Executive Vice President<br />

David Leaf davidl@kmimediagroup.com<br />

Vice President of Sales and Marketing<br />

Kirk Brown kirkb@kmimediagroup.com<br />

Editor-In-Chief<br />

Jeff McKaughan jeffm@kmimediagroup.com<br />

Controller<br />

Gigi Castro gcastro@kmimediagroup.com<br />

Publisher’s Assistant<br />

Carol Ann Barnes carolannb@kmimediagroup.com<br />

OPERATIONS, CIRCULATION & PRODUCTION<br />

Circulation Specialists<br />

Dena Granderson denag@kmimediagroup.com<br />

Davette Posten davettep@kmimediagroup.com<br />

MARKETING & ONLINE<br />

Marketing & Online Director<br />

Amy Stark astark@kmimediagroup.com<br />

Trade Show Coordinator<br />

Holly Foster hollyf@kmimediagroup.com<br />

A PROUD MEMBER OF:<br />

SUBSCRIPTION INFORMATION<br />

Military Logistics Forum<br />

ISSN 1937-9315<br />

is published 10 times a year by <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong>.<br />

All Rights Reserved. Reproduction without permission is<br />

strictly forbidden. © Copyright 2009.<br />

Military Logistics Forum is free to members of the<br />

U.S. military, employees of the U.S. government and<br />

non-U.S. foreign service based in the U.S.<br />

All others: $65 per year.<br />

Foreign: $149 per year.<br />

Corporate Offices<br />

<strong>KMI</strong> <strong>Media</strong> <strong>Group</strong><br />

15800 Crabbs Branch Way, Suite 300<br />

Rockville, MD 20855-2604 USA<br />

Telephone: (301) 670-5700<br />

Fax: (301) 670-5701<br />

Web: www.MLF-kmi.com<br />

In early 1998, the Army Materiel Command began the<br />

Logistics Modernization Program (LMP), designed to replace<br />

its existing material management systems—the Commodity<br />

Command Standard Systems and the Standard Depot System.<br />

The LMP transformed what it was to bring logistics operations—<br />

specifically in six core areas: order fulfillment; demand and<br />

supply planning; procurement; asset management; material<br />

management; and financial management. Still considered a<br />

work in progress, LMP is reported to manage goods and services<br />

valued at about $40 billion, including 6 million Army inventory<br />

items. As of September 2008, approximately $880 million has<br />

been invested by the Army in LMP.<br />

The Government Accountability Office (GAO) recently issued a report on the Army’s reporting<br />

of its progress, the implementation at Army depots and the expected capabilities of LMP when fully<br />

implemented. One aspect of LMP is that the House of Representatives has directed the secretary of the<br />

Army to issue a status report to the House and the Senate as well as the GAO. In general the report<br />

found the Army has satisfied the reporting requirements and has acted on most of the GAO’s previous<br />

recommendations. While there is always room for improvement, the Army seems well on the way to<br />

meeting its obligations and seeing the benefits from the system.<br />

This issue has a very interesting round table discussion with Global Combat Support System<br />

offices from the Army, Air Force and Marine perspectives. As with the LMP,<br />

this too is a work in progress that has delivered results, but its potential<br />

is just being realized. Read the answers from each service and see how<br />

they relate to your field or fulfillment activities. I would be interested<br />

in hearing from others involved either within the systems or on the<br />

receiving end.<br />

As always, please feel free to call or e-mail me with any comments<br />

or suggestions.<br />

Jeffrey D. McKaughan<br />

301-670-5700<br />

<strong>KMI</strong> MEDIA GROUP FAMILY OF MAGAZINES AND WEBSITES<br />

Military Medical/<br />

CBRN Technology<br />

www.MMT-kmi.com<br />

Special Operations<br />

Technology<br />

Geospatial<br />

Intelligence Forum<br />

www.GIF-kmi.com<br />

Military Information<br />

Technology<br />

Military Logistics<br />

Forum<br />

www.MLF-kmi.com<br />

Military Training<br />

Technology<br />

Military Space &<br />

Missile Forum<br />

www.MSMF-kmi.com<br />

Military Advanced<br />

Education<br />

www.SOTECH-kmi.com www.MIT-kmi.com www.MT2-kmi.com<br />

www.MAE-kmi.com

Fight proud. Work proud.<br />

“I feel proud to be a part of the troop deployments and all<br />

the other aircraft that support our military operations.”<br />

– AbilityOne employee Ira Huddleston<br />

Ira works in Airfield Alert Support Services at Ft. Hood Army Base,<br />

TX and is just one example of how AbilityOne supports the mission of<br />

America’s warfighters.<br />

From serving meals to troops and delivering mail from home, to<br />

receiving and storing supplies and maintaining fleet operations, the<br />

AbilityOne Program provides quality products and services at fair<br />

market pricing to the DoD. In turn, AbilityOne helps people who are<br />

blind or have other severe disabilities join the ranks of independent,<br />

productive, tax-paying citizens.<br />

AbilityOneDoD.org<br />

Soldier photo courtesy of U.S. Army.

4 | MLF 3.7<br />

<strong>Gen</strong>eral Dynamics Land Systems, a business unit of <strong>Gen</strong>eral<br />

Dynamics, has been awarded a contract by the U.S. Army Tankautomotive<br />

and Armaments Command to reset 330 Stryker infantry<br />

combat vehicles. The contract has a maximum potential value<br />

of $55.2 million. Through the contract, the company will service,<br />

repair and modify Strykers that are returning from Operation Iraqi<br />

Freedom, restoring them to a pre-combat, like-new condition in<br />

people<br />

Lieutenant Colonel Cary<br />

V. Ferguson is the new PEO<br />

EIS product manager for the<br />

Joint–Automatic Identification<br />

Technology (PM J-AIT). In<br />

this assignment, Ferguson is<br />

responsible for the acquisition<br />

and integration of the<br />

Army’s Automatic Identification<br />

Technology and Radio Frequency<br />

Identification equipment and<br />

services.<br />

Rear Admiral (lower half)<br />

Paul A. Grosklags will be<br />

assigned as vice commander,<br />

Naval Air Systems Command,<br />

Patuxent River, Md. Grosklags is<br />

currently serving as commander,<br />

Fleet Readiness Centers,<br />

Patuxent River, Md.<br />

Captain<br />

Kurt L. Kunkel<br />

Captain Kurt L. Kunkel, who<br />

has been selected for promotion to<br />

rear admiral (lower half), will be<br />

assigned as chief of staff, Defense<br />

Logistics Agency, Fort Belvoir, Va.<br />

Kunkel is currently serving as<br />

deputy director for joint logistics,<br />

J4, Joint Staff, Washington, D.C.<br />

Captain Kevin R. Slates, who<br />

has been selected for promotion<br />

to rear admiral (lower half), will<br />

be assigned as commander, Naval<br />

USS New York<br />

The future USS New York (LPD 21) was put to<br />

sea for the first time June 27, transiting down the<br />

Mississippi River to conduct builder’s trials.<br />

Named for the state of New York, the ship and<br />

its motto “Never Forget” honor the victims and first<br />

responders of the September 11, 2001, World Trade<br />

Center attacks. Constructed in Avondale, La., the ship<br />

contains 24 tons of steel salvaged from the World<br />

Trade Center within the 311-ton bow unit.<br />

During the four-day trial, Northrop Grumman<br />

Shipbuilding conducted comprehensive tests intended<br />

to demonstrate the performance of the combat<br />

and communication systems, propulsion plant,<br />

Stryker Reset<br />

Facilities Engineering Command<br />

Atlantic, Norfolk, Va. Slates is<br />

currently serving as chief of staff,<br />

Naval Facilities Engineering<br />

Command, Washington, D.C.<br />

Captain<br />

Jonathan A. Yuen<br />

Captain Jonathan A. Yuen, who<br />

has been selected for promotion<br />

to rear admiral (lower half),<br />

will be assigned as deputy chief<br />

of staff for logistics, fl eet supply<br />

and ordnance, N4, U.S. Pacifi c<br />

Fleet, Pearl Harbor, Hawaii. Yuen<br />

Compiled by <strong>KMI</strong> <strong>Media</strong> <strong>Group</strong> staff<br />

ship-handling, damage control capabilities and<br />

auxiliary systems. <strong>Maj</strong>or events included full-power<br />

demonstrations during ahead and astern maneuvers,<br />

main ballasting, steering drills and combat system<br />

evolutions—all of which were successful.<br />

The ship is scheduled for commissioning in<br />

November 2009, and her homeport will be Norfolk,<br />

Va.<br />

“The LPD 17 class represents a revolution<br />

in amphibious ship design,” said class program<br />

manager Captain Bill Galinis. “These ships provide<br />

a much-needed capability for our country and our<br />

Navy/Marine Corps team.”<br />

advance of reissuing the vehicles prior to their next deployment.<br />

To date, <strong>Gen</strong>eral Dynamics has delivered 2,852 new vehicles<br />

for seven separate Stryker brigades to the Army. With more than<br />

6 million miles accumulated through two completed Operation<br />

Iraqi Freedom rotations since October 2003, the Stryker vehicle has<br />

demonstrated a combined fleet operational-readiness rate of 96<br />

percent.<br />

is currently serving as deputy<br />

commander/chief of staff, Joint<br />

Contracting Command Iraq/<br />

Afghanistan.<br />

Brigadier <strong>Gen</strong>eral Thomas A.<br />

Harvey, deputy assistant chief<br />

of staff, C/J-4, U.N. Command/<br />

Combined Forces Command/U.S.<br />

Forces Korea, has been assigned<br />

as commanding general, 19th<br />

Sustainment Command (expeditionary),<br />

Korea.<br />

Brigadier <strong>Gen</strong>eral Xavier P.<br />

Lobeto, commanding general,<br />

19th Sustainment Command<br />

(expeditionary), Korea, has been<br />

assigned as deputy commanding<br />

general, 1st <strong>Theater</strong> Sustainment<br />

Command, Camp Arifjan, Kuwait.<br />

www.MLF-kmi.com

By Keith Lippert<br />

Vice Admiral<br />

Keith Lippert (Ret.)<br />

www.MLF-kmi.com<br />

During my almost 38 years of active Navy duty, I<br />

experienced logistics support from my early days of<br />

serving on a nuclear submarine to much later when I<br />

became director of the Defense Logistics Agency. Military<br />

logistics changed dramatically during my active duty<br />

time, and will continue to evolve. What remains constant<br />

is that the people providing the logistics support to our<br />

warfighters worldwide 24 hours a day work very hard<br />

for its success.<br />

In terms of the military logistics system becoming<br />

more effective and efficient, I will address three areas:<br />

•<br />

•<br />

•<br />

Vice Admiral Keith Lippert (Ret.) started working as chief strategy officer for the Accenture Defense group<br />

in October 2006. His last tour on active duty was as the 14th director of the Defense Logistics Agency (DLA).<br />

The longest-serving director in DLA’s history, Lippert served in this capacity from July 2001 to July 2006. Prior<br />

to DLA, he was the commander, Naval Supply Systems Command, and 41st chief of Supply Corps from August<br />

1999 to July 2001. He also served as vice commander, Naval Supply Systems Command from August 1999 to<br />

July 2001.<br />

Lippert earned his commission through the regular U.S. Navy ROTC program, graduating from Miami<br />

University, Oxford, Ohio, with a B.A. in mathematics in 1968. Additionally, he holds master’s degrees from the<br />

Naval Postgraduate School in management and in operations research.<br />

Improving the Effectiveness and Effi ciency<br />

of Military Logistics<br />

civilian management and leadership expertise;<br />

knowledge of commercial off-the-shelf information<br />

technology systems; and<br />

joint logistics solutions.<br />

Throughout my career and continuing today, I have<br />

observed a lack of emphasis on the proper education<br />

and training of the Department of Defense’s civilian<br />

logistics work force. While some of the education and<br />

training is well thought out, structured and effective,<br />

most is not. This problem is not unique to DoD,<br />

but prevalent throughout the federal government. The<br />

Annenberg Leadership Institute commenced leadership<br />

training for mid-level civilians from many departments<br />

of the federal government to address this issue. I believe<br />

programs like these—either internal to the departments<br />

of the federal government or like the Annenberg<br />

Leadership Institute—will result in a more effective and<br />

efficient federal government. This must be a priority for<br />

DoD logistics organizations.<br />

The military services and the Defense Logistics<br />

Agency are in various stages of implementing Enterprise<br />

Resource Planning (ERP) systems. These systems will<br />

improve the effectiveness and efficiency of the military<br />

logistics system by reducing logistics response time,<br />

requiring data integrity, improving financial accountability<br />

and reducing inventories. The ERP systems<br />

are large and complex, requiring expertise to take<br />

full advantage of their benefits. Military and civilian<br />

logisticians must become very knowledgeable on these<br />

systems and develop new approaches to solving problems.<br />

Change management training also is essential for<br />

these systems to reach full potential. For example, there<br />

are extensive inventory savings as a result of improved<br />

demand forecasting from these ERP systems.<br />

Finally, I have had the opportunity to participate in<br />

a red team effort with the joint staff, which describes the<br />

ideal logistics system in 2016–2028. Obviously, much<br />

needs to be accomplished to achieve this goal. Certainly<br />

a renewed emphasis on “jointness” is required. IT<br />

systems that address total asset visibility, integrated data<br />

environment and an enterprise approach, to name a<br />

few, should be implemented where practical from a joint<br />

perspective, to speed implementation and reduce costs.<br />

The bottom line is that DoD must renew its efforts on<br />

leadership and management skills of the civilian logistics<br />

work force. The organic expertise of the COTS ERP<br />

systems must be improved, and joint IT solutions should<br />

be implemented where practical.<br />

For more information, contact Keith Lippert at<br />

keith.w.lippert@accenture.com.<br />

MLF 3.7 | 5

A Regular Feature of Logistics News and Information Directly From PEO EIS<br />

PM J-AIT Awards AIT-IV Contract to<br />

Five Vendors By Darci Hunt<br />

The Product Manager for Joint–<br />

Automatic Identification Technology<br />

(PM J-AIT) recently announced the<br />

award of the Automatic Identification<br />

Technology (AIT)-IV indefinite delivery/<br />

indefinite quantity (IDIQ) contracts to<br />

the following contractors: GTSI Corp.,<br />

Intermec Technologies Corp., Northrop<br />

Grumman Information Technology, CDO<br />

Technologies Inc., and Lowry Holding<br />

Company Inc.<br />

“This is an important milestone in<br />

that with the award of AIT-IV, all the<br />

single award IDIQ contracts managed<br />

under PM J-AIT have migrated to multivendor<br />

IDIQ contracts,” stated Lieutenant<br />

Colonel Cary Ferguson, PM J-AIT. “The<br />

AIT-IV contract provides an opportunity<br />

for more companies to provide DoD and<br />

federal agencies best-value solutions at<br />

competitive prices across the globe. We<br />

look forward to working with the AIT-IV<br />

contractors.”<br />

The firm fixed price IDIQ contract<br />

for Commercial AIT hardware, software<br />

and services has a ceiling value of<br />

$418.52 million. The term of the contract<br />

is nine years consisting of a three-year<br />

6 | MLF 3.7<br />

base period; and one two-year option<br />

for products, services and maintenance;<br />

and one four-year option for maintenance<br />

only. In addition, PM J-AIT will<br />

offer site surveys, installation, integration,<br />

implementation and training for<br />

turnkey AIT solutions to DoD, U.S. Coast<br />

Guard, NATO, federal agencies, coalition<br />

partners, and other foreign military sales<br />

(FMS). Individuals interested in additional<br />

information on the AIT products<br />

and services offered should contact the<br />

contracting officer representative, Sally J.<br />

Ewing, sally.j.ewing@us.army.mil.<br />

PM J-AIT is the DoD AIT and radio<br />

frequency identification leader providing<br />

global asset tracking, Web-based radio<br />

frequency in-transit visibility (RF-ITV)<br />

services, and complete program life cycle<br />

support. PM J-AIT products and services<br />

are customer-driven, easily accessible,<br />

and capable of being updated. PM J-AIT<br />

serves as the executive agent for the<br />

RF-ITV infrastructure to DoD and coalition<br />

partners in support of expeditionary<br />

logistics and the joint warfighter. For<br />

more information about PM J-AIT, please<br />

visit www.eis.army.mil/ait.<br />

Lieutenant Colonel Cary V. Ferguson is the new product<br />

manager for Joint–Automatic Identification Technology (PM<br />

J-AIT), effective June 24, 2009. In this assignment, Ferguson is<br />

responsible for the acquisition and integration of the Army’s<br />

automatic identification technology and radio frequency<br />

identification equipment and services.<br />

“It is an exciting opportunity to lead the PM J-AIT team,”<br />

said Ferguson. “PM J-AIT has an outstanding reputation as<br />

the DoD’s leading provider of innovative AIT products and<br />

services. I look forward to continuing Colonel Burden’s legacy<br />

of providing state-of-the-art technologies to our soldiers and<br />

their mission.”<br />

Ferguson joins the PM J-AIT office with 19 years of military<br />

experience. He previously served as the assistant project<br />

manager and the military deputy for the Project Manager<br />

Global Combat Support System–Army (GCSS-Army) at Fort<br />

Lee, Va.<br />

Change of Charter at PM Acquisition Business By Tricia May<br />

In the photo (from left): PEO Gary Winkler, outgoing PM AcqBusiness Lt. Col. Matthew Riordan,<br />

incoming PM Lt. Col. Anthony Sanchez and Assistant Secretary of the Army for Acquisition,<br />

Logistics & Technology Dean Popps. [Photo by William Hitchcock, 2009]<br />

PM J-AIT Welcomes a New<br />

Product Manager<br />

By Darci Hunt<br />

(J-AIT PHOTO CREDIT AND CAPTION)<br />

In the photo (from left): Outgoing PM J-AIT Col. Patrick Burden, program executive<br />

officer (PEO) Gary Winkler and incoming Lt. Col. Cary Ferguson. [Photo by William<br />

Hitchcock, 2009]<br />

Lieutenant Colonel Maurice Stewart assumed the charter of product<br />

manager Acquisition Business (AcqBusiness), July 10, 2009, from former PM,<br />

Lieutenant Colonel Matthew Riordan. Stewart comes to AcqBusiness from the<br />

Office of Assistant Secretary of the Army (Acquisition, Logistics and Technology)<br />

in Washington, D.C., where he served as the executive officer to the acting assistant<br />

secretary of the Army (Acquisition, Logistics and Technology) and Army<br />

Acquisition Executive Dean Popps.<br />

Chartered in August 2006, PM AcqBusiness (formerly known as Future<br />

Business Systems) provides the Army acquisition community with tools and<br />

capabilities through a suite of enterprise business services. PM AcqBusiness<br />

recently delivered a new financial and decision support tool to assist with Army<br />

Force <strong>Gen</strong>eration (ARFORGEN). AcqReadiness provides users with improved<br />

visibility and access to soldier equipment issue and financial requirements. For<br />

a complete list of services, please visit https://acqbiz.army.mil.<br />

www.MLF-kmi.com

........................................<br />

“A is not an option”<br />

Go ahead, challenge us.<br />

Give Agility an impossible task and we’ll<br />

make it happen, regardless of what stands in<br />

the way. When it comes to moving essential<br />

supplies through hostile environments without<br />

turning back, you can count on us to deliver.

8 | MLF 3.7<br />

Transition Progresses Smoothly and On Schedule<br />

All transition-related activities are<br />

continuing smoothly, and no issues are expected<br />

to prevent its completion during FY09. Phase I of<br />

the transition, which was completed in January,<br />

transferred operational control of the STAMIS<br />

legacy systems consisting of the Standard Army<br />

Retail Supply System (SARSS) family (SARSS-1,<br />

SARSS 2AC/B, SARSS-Gateway, and SARSS-CTASC<br />

II), a portion of the Standard Army Maintenance<br />

System (SAMS) family (SAMS-1, SAMS-2, and<br />

SAMS-I/TDA), some of the Unit Level Logistics<br />

System (ULLS) family (ULLS-G and ULLS-A)<br />

and the Standard Army Ammunition System-<br />

Modernization (SAAS-MOD).<br />

Phase II of this transition will transfer<br />

complete sustainment management responsibility<br />

for the remaining STAMIS bridging<br />

systems: Property Book Unit Supply Enhanced,<br />

Standard Army Maintenance System-Enhanced,<br />

Standard Army Maintenance System-Installation<br />

Enhanced, Financial Management Tactical<br />

Platform and the Unit Level Logistics System-<br />

SEC-Lee is Strongly Committed<br />

to the Transition<br />

As one of the largest centralized software engineering centers<br />

within the Army, SEC-Lee develops and supports logistics, engineering,<br />

procurement and subsistence systems for numerous<br />

customers, including: Headquarters Department of Army G4;<br />

PEO EIS; Project Manager Global Combat Support Systems-<br />

Army; Defense Commissary Agency; Army Procurement, Research<br />

and Analysis Office; HQDA deputy chief of staff for logistics;<br />

HQDA assistant chief of staff for Installation Management; and<br />

the assistant secretary of the Army (Acquisition, Logistics and<br />

Technology).<br />

“The entire SEC-Lee force is ecstatic about the STAMIS<br />

sustainment mission,” declared Gary Lichvar, SEC Business<br />

Mission Area director. “They feel that the systems have gone full<br />

circle and are now returning home. In many cases, for SARSS,<br />

SAAS, SAMS and ULLS, the original functional and technical<br />

personnel still work on the system today. There is a unique<br />

bond among the systems, the personnel and the soldiers they<br />

support.”<br />

Ricky Daniels, SEC-Lee director, sees this new mission as<br />

the first of many in the system-support arena as PEOs transition<br />

systems after achieving full operational capability. “Our<br />

mission is to provide life cycle software products and services<br />

that enhance Army and joint war fighting and management and<br />

support capabilities and to ensure that America’s warfighters<br />

continue to own the decisive edge from the battlespace through<br />

the sustaining base,” remarked Daniels.<br />

“SEC’s commitment to the PM LIS transition is real; it is<br />

personal; and it is borne out in the actions and performance<br />

demonstrated throughout the years,” stated Daniels. “By fostering<br />

strong teamwork and a dedication to software engineering excellence,<br />

SEC-Lee has established an enviable record of delivering<br />

solutions and supporting systems that are customer-focused,<br />

state-of-the-art and value-driven.”<br />

Aviation (Enhanced). This phase of the transition<br />

is expected to be completed by the end of<br />

August.<br />

The Product Management Office for<br />

Movement Tracking System (PM MTS), which<br />

was one of the logistics information systems<br />

under PM LIS, is not transitioning to SEC-Lee.<br />

PM MTS, instead, has become a stand-alone,<br />

direct report to PEO EIS and will continue to<br />

develop and field its critical logistic information<br />

system through FY15.<br />

PM LIS Sustainment and<br />

Management Transfer to<br />

SEC-Lee<br />

By Jeffrey Davis<br />

The Army’s logistics information systems are essential to<br />

increasing combat effectiveness. They play a vital, time-sensitive<br />

role in managing supplies, equipment and ammunition, which<br />

enables the rapid reallocation of resources needed to sustain<br />

troops in theater.<br />

Since the early 1990s, the project manager for Logistics<br />

Information Systems (PM LIS) has been committed to providing<br />

the warfighter with the most up-to-date logistics management<br />

and information systems available. Now, as these systems<br />

move into a sustainment mode, management responsibility<br />

for the systems is also shifting from the Program Executive<br />

Office Enterprise Information Systems (PEO EIS) to the<br />

Communications-Electronics Life Cycle Management Command<br />

Software Engineering Center, Fort Lee, Va. (SEC-Lee).<br />

Coordination between PEO EIS, Army G-4, the Army Material<br />

Command and the Combined Arms Support Command resulted<br />

in establishing a two-phase transition, which was approved in<br />

December 2008. The effort formally began in January, and by<br />

April, the transition plan was staffed, coordinated, approved and<br />

signed by PEO EIS and SEC-Lee. The transition is projected to be<br />

fully completed by October 2009.<br />

Gaining efficiencies for contracting efforts, testing facilities,<br />

information assurance and Customer Assistance Office support<br />

were key factors in the decision. Additionally, the change enables<br />

PEO EIS to focus its resources on future systems such as GCSS-<br />

Army.<br />

More than 120,000 combat service support soldiers are<br />

using these critical systems on a daily basis, and the Logistics<br />

Information Systems program currently reflects a FY10–15<br />

program objectives memorandum of $566 million. SEC-Lee<br />

views the PM LIS transition as an opportunity to build an<br />

enduring partnership with PEO EIS, characterized by shared<br />

goals, candid communications and support for the warfighters.<br />

www.MLF-kmi.com

Tanker Needs<br />

Rep. Jo Bonner (R-Ala.)<br />

First, I congratulate you, the<br />

men and women who maintain<br />

and support our military equipment<br />

and keep it in tremendous<br />

shape regardless of its age! As<br />

a group, you know better than<br />

anyone that the U.S. Air Force<br />

is in dire need of a replacement<br />

for the aging KC-135s. You know<br />

we can’t “get there from here” and effectively project power without<br />

a robust tanker fleet. Your maintenance and supply personnel know<br />

exactly how difficult and costly it is to sustain the current fleet and<br />

know it isn’t going to get any easier or cheaper—big bills are on the<br />

horizon to keep our 50-year-old tanker fleet flying.<br />

Meanwhile, the Pentagon has been trying to acquire a new tanker<br />

since 2001. You know the story: The first try, a deal to lease Boeing<br />

KC-767s, was riddled with corruption and unfortunately resulted<br />

in both Boeing and USAF officials going to jail. The second attempt<br />

introduced a competitor, the Northrop Grumman KC-45, based on the<br />

commercial Airbus A-330 airframe. After a competitive source selection<br />

between the KC-45 and the KC-767, the military decided in February<br />

2008 the KC-45 best met its needs and made a contract award. Boeing<br />

protested, the GAO found minor issues with the source selection<br />

process, and the Pentagon ultimately canceled the second acquisition.<br />

Now, here we go again—a new RFP is expected and a competition<br />

between the same competitors will begin anew.<br />

Frankly, there is more rhetoric and trash-talking about this competition<br />

than there is back home about the Alabama/Auburn football<br />

game. But in my view, the most relevant question—what it all comes<br />

down to—is which aircraft best meets our military’s needs? Simply<br />

put, the military deserves the aircraft that provides the best value.<br />

Everything else is secondary.<br />

Some, for example, say this competition should be about “Buy<br />

America.” In reality, with the globalization of the aerospace industry,<br />

both competing aircraft will contain foreign components, but both will<br />

have well over 50 percent U.S. content required by the Buy America<br />

Act.<br />

Some say this competition should be about preserving American<br />

jobs. In reality, both aircraft would be built in the U.S. by American<br />

workers. KC-767 production will reportedly employ 44,000 U.S. workers;<br />

Northrop Grumman’s analysis indicates KC-45 production will<br />

employ 48,000 U.S. workers.<br />

Some say this competition should be about preserving the U.S.<br />

industrial base. In fact, a Northrop Grumman win will mean two brandnew<br />

aircraft manufacturing factories in the U.S. Supplier factories are<br />

likely to follow. This would represent an expansion of the U.S. industrial<br />

base. Furthermore, EADS executives have made clear their desire to<br />

manufacture commercial A-330 freighter aircraft on the U.S. production<br />

line, adding even more jobs to the U.S. industrial base.<br />

Setting these secondary arguments aside let’s return to the most<br />

important question: which aircraft best meets our military’s needs?<br />

The KC-45 is a derivative of the A-330 commercial airliner. The<br />

A-330 is a 14-year newer design than the competing Boeing 767. The<br />

A-330 uses modern fly-by-wire control systems; today’s Boeing tanker<br />

aircraft does not. The A-330 continues to sell well in the commercial<br />

marketplace; the Boeing aircraft is near the end of its commercial sales<br />

life. The commercial, worldwide logistics chain for the A-330 should<br />

remain robust for decades.<br />

The KC-45 has the added advantage of offering an aircraft on the<br />

ramp sooner than its competitor. The KC-45 offered to the USAF is very<br />

similar to the tanker configuration being delivered to the air forces of<br />

Australia, the U.K., UAE and Saudi Arabia. That configuration, including<br />

a state-of-the-art boom, is nearing completion of flight test now. In<br />

contrast, the KC-767 configuration most recently offered to the USAF<br />

combines structural elements of the 767-200, 767-300 and 767-400.<br />

Neither this aircraft configuration nor Boeing’s next generation boom<br />

have been built, tested or flown.<br />

Of course, the ability to offload fuel downrange is the primary job of<br />

a tanker. The KC-45 can offload 153,000 pounds of fuel at 1,000 nautical<br />

miles (nm); the KC-767 variant offered is projected to offload 117,000<br />

pounds at 1,000 nm.<br />

The ability to maintain time on station downrange is also critical.<br />

The KC-45 can spend 14.2 hours on station at 1,000 nm, the KC-767<br />

11.8 hours.<br />

In addition, the KC-45, based on a more modern, efficient aircraft<br />

design, can deliver 1.96 pounds of fuel for every pound burned. The<br />

KC-767 delivers only 1.61 pounds for every pound burned.<br />

Beyond its primary mission, similar advantages accrue to the<br />

KC-45 with regard to a tanker’s secondary missions. The KC-45 can<br />

carry more pallets, more passengers and more aeromedical evacuation<br />

litters than its competitor.<br />

The military requirements for the new tanker are clear: “More is<br />

better”—more fuel downrange, more cargo, more passengers and more<br />

flexibility to accomplish the mix of missions that will confront our military<br />

for the next 40 years. Some have argued that the value of additional<br />

capabilities over and above a minimum should not be considered. They<br />

argue the Pentagon should simply conduct a “low-cost shoot-out” and<br />

award to the lowest cost offer that meets the minimums. This simplistic<br />

approach may be okay for buying #2 pencils, but it has no place when<br />

it comes to buying complex weapon systems. It would incentivize competitors<br />

to offer “stripped-down” tankers that would likely require costly<br />

upgrades later. It would not allow the military to even consider the<br />

value of “more,” such as additional fuel offload downrange, even though<br />

that additional capability would have value to our military.<br />

The Pentagon must move forward with increased urgency and conduct<br />

a fair, best-value source selection. Then the Pentagon should pick<br />

the aircraft that offers the best value in meeting its needs. We must not<br />

make short-sighted decisions that will haunt us for decades to come. A<br />

best-value approach is the only acceptable path.<br />

Rep. Jo Bonner (R-Ala.) serves in the U.S. House ofRepresentatives<br />

for Alabama’s first district.<br />

www.MLF-kmi.com MLF 3.7 | 9

THE NEED FOR SPEEDY LOADING, UNLOADING ELEVATES FORKLIFTS TO<br />

‘KEY’ LOGISTICAL PIECE. BY J.J. SMITH<br />

MLF CORRESPONDENT<br />

smithj@kmimediagroup.com<br />

10 | MLF 3.7<br />

www.MLF-kmi.com

Because sustaining the warfighter is such an important part<br />

of a battle plan, moving supplies from location to location is<br />

vital to supporting a war effort. Yet such an effort can be slowed<br />

because of having to load and unload trucks by hand. Therefore,<br />

the need for speedy loading and unloading of trucks or aircraft,<br />

or anything that transports supplies, has made forklifts “a key<br />

logistical piece” of sustaining military operations, say representatives<br />

of companies that produce those machines.<br />

When moving an armed force the size of the U.S. military,<br />

war planners need to be able to<br />

move mountains of supplies, and<br />

that includes loading and unloading<br />

containers and vehicles, said<br />

Jake Verhoef, JLG Industries Inc.’s<br />

director of government sales. The<br />

ability to do just that makes the<br />

forklift “a key piece of the puzzle<br />

of a giant military,” he said. Without<br />

a forklift, trucks have to be<br />

loaded and unloaded by hand, and<br />

Jake Verhoef<br />

the average warfighter is limited<br />

to single-handedly lifting up to 60<br />

pounds, he added. Loading or unloading a truck by hand can take<br />

an exorbitant amount of time, whereas a telescopic forklift can<br />

pick up a palette or large items, and unload a truck in minutes,<br />

making “these machines invaluable when it comes to logistics<br />

support.”<br />

JLG oversees production of the TRAK International 6000M<br />

variable reach rough terrain forklift truck (VRRTFLT); the JLG<br />

all-terrain lifter-Army system (ATLAS and ATLAS II); and the<br />

OminQuip Millennia military vehicle (MMV).<br />

In 1990, TRAK International acquired the first contract for<br />

a 6,000-pound capacity, VRRTFLT, Verhoef said. Based on Army<br />

specifications, TRAK designers combined aspects of commercial<br />

sector forklifts with what they knew about tanks to develop a<br />

machine that can descend a steep grade, and operate in rough<br />

terrain and in temperatures ranging<br />

from -25 degrees Fahrenheit<br />

to 140 degrees Fahrenheit, he said.<br />

In addition, it had to meet requirements<br />

for a 24 volt system and run<br />

on JP8 fuel.<br />

In 1995, TRAK was awarded a<br />

contract for the ATLAS, which has<br />

the same appearance as the VRRT-<br />

FLT, but which increased lift capacity<br />

to 10,000 pounds, Verhoef said.<br />

Chris Saucedo In addition, the forks were narrowed<br />

and their profile lowered, enabling<br />

it to pick up 463L palettes, which are aluminum palettes that go<br />

on aircraft. ATLAS can unload the palettes from an aircraft in a<br />

non-airport setting, and move the palettes over rough terrain. It<br />

is more than traditional what vertical lift forklifts—operating on<br />

smooth, hard terrain—are designed to do, he said.<br />

Top Photo Page 10:<br />

The JCB high-mobility rough terrain forklift. [Photo courtesy of JCB]<br />

Bottom Photo Page 10:<br />

The JLG Industries all-terrain lifter-Army system (ATLAS). [Photo courtesy of JLG]<br />

Select DoD contract efforts for<br />

material handling equipment.<br />

Light Capability Rough Terrain Forklift<br />

The Tank-automotive and Armaments Command is in the process<br />

of soliciting for a single model light capability rough terrain<br />

forklift (LCRTF) with a 4,000/6,000 pound capacity. Dimensionally,<br />

the overall length, with the boom retracted, should be 235<br />

inches; width 80 inches; height, with the boom fully lowered,<br />

should be 84 inches. The extendible boom of the LCRTF is<br />

expected to have a minimum forward reach of 110 inches with a<br />

minimum boom lift angle of 60 degrees and minimum lift height<br />

of 140 inches. The minimum payload at 140 inches lift height<br />

has to be 500 pounds and the minimum pick load at 110 inches<br />

forward reach must be 1,750 pounds. In order for the LCRTF to<br />

provide complete operator protection in all directions against<br />

blast and fragmentation from munitions, a crew protection kit<br />

(CPK) must be available. The kit must be easily and quickly<br />

installed, and maximize commonality of attaching hardware with<br />

no special tools required for maintenance. The overall weight<br />

with the A kit cab, but without the addition of the B or C kit<br />

cannot exceed 14,322 pounds. This is driven by the helicopter<br />

transportability requirement. The LCRTF shall be able to load<br />

and remove standard 40-inch by 48-inch cargo pallets, stacked<br />

two high, from the 40-inch end, side by side inside an 8-foot tall,<br />

20- or 40-foot long ISO container, without manual adjustments to<br />

the fork tines. The LCRTF, without the CPK installed and using a<br />

trained operator, has to be able to move 16 pallets from a loaded<br />

20-foot ISO container, on the ground, into an empty 20-foot ISO<br />

container, on the ground, with an average cycle time of no more<br />

than five minutes per pallet. The maximum travel speed of the<br />

LCRTF (with A-kit) for self-deployment, is to be a minimum of 20<br />

mph, without load, on improved roads for a distance of 30 miles.<br />

With a rated load, it has to be able to travel for distances up to<br />

3 miles over unimproved surfaces, at a forward speed of at least<br />

10 miles per hour. The expectant contract from this solicitation<br />

is expected to be a 5-year, firm fixed price award with an estimated<br />

1,414 LCTRFs ordered.<br />

SEI Manufacturing Inc., Huntsville, Ala., awarded a $27,000<br />

contract for miscellaneous material handling equipment.<br />

The Army Contracting Agency, Fort Shafter has issued a<br />

solicitation for a Hyster H280HD forklift or equal. (Solicitation<br />

Number: W912CN09R0077)<br />

The Army Contracting Agency (ITEC4-West) has issued a solicitation<br />

for forklifts. (Solicitation Number: W9124A09T0246)<br />

The Naval Facilities Engineering Command has issued a<br />

solicitation for a 100-ton straddle/rubber tired gantry crane for<br />

the Defense Logistics Agency, Barstow, Calif. The estimated<br />

range of the procurement is between $1 million and $5 million.<br />

(Solicitation Number: N6247009R7004)<br />

The U.S. Amy Sustainment Command has issued a solicitation<br />

for a 400-pound capacity manipulator with attachments<br />

and an 800-pound capacity manipulator with attachments. This<br />

procurement is for the purchase of one 400-pound lifting capac-<br />

www.MLF-kmi.com MLF 3.7 | 11

ity manipulator with a custom attachment to handle 5-inch, 8-inch,<br />

105-mm and 155-mm munition projectiles; and one 800-pound<br />

lifting capacity manipulator with a custom munition attachment to<br />

handle 8-inch and 155-mm munition round and a custom munition<br />

attachment to handle MK-82 type bomb. Each manipulator is to<br />

include the option of added base weight (counterweight) for extra<br />

lifting capacity, to be integrated within design for the unit. Approximate<br />

weight of the counterweight could be as much as 3,000<br />

pounds. (Solicitation Number: W52P1J-09-T-3035)<br />

V&H Material Handling LLC has been awarded a $219,153<br />

contract for the proposed procurement of two storage devices for<br />

the tool crib area of Building 370, Letterkenny Army Depot, Chambersburg,<br />

Pa. These devices will operate with a programmable logic<br />

controller to include: software capable of displaying weight of tray<br />

and allowing various speeds for both vertical and horizontal movements<br />

and compress open spaces within the storage device.<br />

Intercontinental Truck Body, Conrad, Mont., has been issued<br />

a contract by the DLA for a ramp loading vehicle in the amount of<br />

$49,494. (Solicitation Number: SPM8ED09T1035)<br />

The Army Contracting Agency, Fort Hood, Texas, has issued a<br />

solicitation for a 6,000-pound capacity, gasoline-powered forklift.<br />

(Solicitation Number: W45NQ99140N207)<br />

Indian<br />

Ocean<br />

Pacific Region<br />

South China Sea<br />

Yellow<br />

Sea<br />

12 | MLF 3.7<br />

East China<br />

Sea<br />

Sea of Japan<br />

Sea of Okhotsk<br />

Coral Sea<br />

Bering Sea<br />

North Pacific Ocean<br />

Gulf of<br />

Alaska<br />

North America<br />

Gulf of Mexico<br />

Hudson Bay<br />

Caribbean Sea<br />

Labrador Sea<br />

North<br />

A t l a n t i c<br />

O c e a n<br />

Local and Deployment Zone Materiel and Support<br />

Global Distribution and Logistics<br />

Fleet Automotive Support<br />

Supply Chain Management<br />

Facilities Maintenance and Management<br />

Manufacturing Solutions<br />

Disaster and Emergency Preparedness<br />

1-800-860-7940 � www.supplycore.com<br />

The DLA’s Defense Supply Center Philadelphia-Construction &<br />

Equipment—BSM has awarded an $87,367 contract to Intercomp<br />

Co., Medina, Minn., for a material handling series MH300. (Solicitation<br />

Number: SPM8EF09T2226)<br />

The same office, Defense Supply Center Philadelphia-Construction<br />

& Equipment—BSM, has issued a solicitation for a rail<br />

cargo flatrack (NSN 3990014587323). (Solicitation Number:<br />

SPM8EF09T2384)<br />

The Army Sustainment Command has issued a $128,000 contract<br />

award to Rapid Rentals & Sales, West Chicago, Ill., for multidirectional<br />

forklifts (Combilift Model C22000 or equivalent).<br />

The National Guard Bureau of Nevada has issued solicitation for<br />

a compact wheel loader with a Caterpillar C3.4 diesel engine and<br />

906H MA3 comfort cab. (Solicitation Number: W9124X09T0006)<br />

TACOM-LCMC has issued a solicitation for a rough terrain<br />

5,500-pound capacity diesel-powered forklift to support the Iraqi<br />

and Afghanistan security forces. (Solicitation Number: W56HZ-<br />

V09RG090)<br />

MATERIEL PROCUREMENT � PERFORMANCE-BASED LOGISTICS � SUPPORT SERVICES<br />

S o u t h<br />

Norwegian Sea<br />

Europe<br />

A t l a n t i c<br />

DLA MRO Prime Vendor � Fleet Automotive Support Initiative � GSA Schedule Holder � DOD EMALL<br />

North Sea<br />

Mediterranean Sea<br />

Black Sea<br />

Get all your supplies where you<br />

need them, when you need them.<br />

Call SupplyCore today.<br />

Red<br />

Sea<br />

Middle East<br />

Arabian<br />

Sea<br />

Indian Ocean<br />

www.MLF-kmi.com

In 2001, OmniQuip modified an existing extended boom<br />

forklift to produce the MMV for the Marine Corps. The MMV is<br />

capable of operating over rough terrain and certified for rail, sea<br />

and air transport, and it too can move 463L palettes.<br />

Because forklifts have become so invaluable to the U.S.<br />

military, each branch of the service has its own specifications<br />

and requirements for those machines, said Chris Saucedo,<br />

JCB’s vice president of military products. Different missions<br />

determine how the different materiel handlers are designed, he<br />

said. The Marine Corps looks for multiple use equipment that is<br />

mobile, or “expeditionary”; the Army and the Air Force look for<br />

more containerized type applications that are long-term uses,<br />

he said.<br />

While use requirements might differ, there are aspects of<br />

forklift specifications that are militarywide, say forklift manufacturers’<br />

representatives. Those specifications are transportation,<br />

reliability and protection. Of those, reliability is the most<br />

important, said Saucedo, whose company produces a highmobility<br />

rough terrain forklift (HMRTF) and a high-mobility<br />

engineer excavator (HMEE), which doubles as an equipment<br />

loader.<br />

Sgt. Marcus McDowell, a native of Helena, Mont., a soldier of the 639th Combat Sustainment<br />

Support Company, 398th Combat Sustainment Support Battalion, 10th Sustainment Brigade, loads<br />

a pallet of cinderblocks. [Photo courtesy of DoD]<br />

The HMRTF uses telescopic handler technology to load<br />

and unload standard containers—it has a lift capacity of 5,000<br />

pounds up to 16.5 feet high—but what distinguishes the HMRTF<br />

is its ability to travel at a sustained speed of 52 miles per hour.<br />

In addition, the machine can be compacted so that it can<br />

be transported by attaching it to the underside of a Chinook<br />

helicopter or inside a C-130 aircraft.<br />

However, the HMRTF is surpassed in speed by the HMEE,<br />

which can travel up to 60 mph on both paved roads and cross<br />

country surfaces, making it the world’s fastest backhoe loader,<br />

according to JCB. The HMEE has full suspension and anti-lock<br />

braking technology, allowing for controlled stopping in difficult<br />

www.MLF-kmi.com MLF 3.7 | 13

conditions. In addition, it has run-flat<br />

tires, thereby reducing troop exposure<br />

and providing time for operators to reach<br />

safety. In addition, the speed of the HMEE<br />

provides battlefield commanders with<br />

logistics capabilities in front patrols.<br />

Most of JCB’s military customers look<br />

at the reliability factor as the most important<br />

buying decision, Saucedo said. The<br />

concept of life cycle management of the<br />

equipment is very important to military<br />

customers, he added. To illustrate how<br />

important, Saucedo said JCB’s commercial<br />

products have a three- to five-year life<br />

cycle depending on the product. While a<br />

commercial big-wheel loader might have<br />

a seven-year life cycle and skiff loaders a<br />

life of up to three years, military customers<br />

look for products that have a life cycle<br />

of 30 years, making life cycle management<br />

crucial, he said.<br />

The concern for a vehicle’s reliability<br />

and sustained performance has companies<br />

like JCB providing the government with<br />

cost projections for the use of those pieces<br />

of equipment, some as far as 15 years. In addition, some companies<br />

are forecasting when the product needs to be rebuilt,<br />

when equipment failures can be anticipated, as well as proactive<br />

maintenance schedules, Saucedo said. Monitoring those vehicles<br />

has JCB incorporating radio frequency identification (RFI)<br />

technology—which was initially used to track the movement of<br />

packages—so remote prognostic and diagnostic capabilities can<br />

be implemented, he said. The RFI diagnostic capabilities enable<br />

supervisors and mechanics to monitor maintenance needs of a<br />

vehicle—ranging from engine work to oil changes—on duty in<br />

Afghanistan from within the United States, half a world away,<br />

he said.<br />

While in many cases, the features and capabilities required<br />

for a military version of forklift, telescopic lift and forklift are<br />

unique to a combat environment, in other cases, the same piece<br />

of equipment durable enough for a construction site may do<br />

equally as well with the military. Several other companies manufacture<br />

material handling equipment suitable for military use<br />

including: Terex, <strong>Gen</strong>ie (a subsidiary of Terex), Manitou, Gehl (a<br />

wholly-owned subsidiary of Manitou), Xtreme Mfg., Caterpillar,<br />

Case Construction, and Pettibone Traverse Lift.<br />

14 | MLF 3.7<br />

PROTECTING THE LOGISTICIAN<br />

Operator protection is credited with saving the life of Army<br />

Staff Sergeant Adam Smith. On May 29, 2009, Smith—whose<br />

unit is the 9th Engineer Battalion, 172nd Infantry Brigade—<br />

was operating a JCB HMEE near South Balad Ruz, Iraq, when<br />

an anti-tank mine exploded near the machine. Smith walked<br />

away from the explosion that destroyed a large section of the<br />

HMEE, and the machine’s armor is credited with saving the staff<br />

sergeant’s life.<br />

In addition, JGL has armor kits available for the ATLAS,<br />

and the armor is credited with saving another, unnamed<br />

A military forklift loads a truck with empty ammunition boxes at Forward Operating Base Now Zad, Helmand Province, Afghanistan.<br />

Second platoon with Motor Transportation Company, Combat Logistics Battalion 3, successfully transported a piece of heavy<br />

equipment and more than 50,000 pounds of provisions to the FOB in support of Lima Company, 3rd Battalion, 8th Marine Regiment<br />

(Reinforced), the ground combat element of Special Purpose Marine Air Ground Task Force – Afghanistan. CLB-3 is the logistics<br />

combat element of Special Purpose Marine Air Ground Task Force-Afghanistan, whose mission is to conduct counterinsurgency<br />

operations, with a focus on training and mentoring the Afghan national police. [Photo courtesy of DoD]<br />

A Marine with Combat Logistics Battalion 8 guides an extended-boom forklift, also known as<br />

a Sky Track, through shin-high, powder-like dirt in front of Marine living quarters here during<br />

a sandstorm Aug. 6. This is the third day in a row the camp has experienced heavy sandstorm<br />

activity. The storms have lasted up to eight or more hours. [Photo courtesy of DoD]<br />

soldier’s life, according to Verhoef. In that situation, a mortar<br />

shell exploded near an ATLAS that was in use, and a soldier was<br />

wounded, “but only slightly,” he said. “The machine’s armor<br />

protected the individual,” he added.<br />

However, military customers are not only concerned about<br />

protecting the operator; they also want to protect the machines,<br />

Saucedo adds. During the last several years, there has been a<br />

huge focus on protection, but it is not completely focused on the<br />

operator, but rather on the overall functionality of the machines,<br />

he said. Therefore, the machines are being designed to resist a<br />

mine strike, or being hit by a projectile, but in such a way so the<br />

machines survive, as well as the operator, he said. ✯<br />

For more information, contact MLF Editor Jeff McKaughan at<br />

jeffm@kmimediagroup.com or search our online archives for related stories at<br />

www.MLF-kmi.com.<br />

www.MLF-kmi.com

Tactical Logistics Support<br />

A ROUNDTABLE ON THE STATUS OF THE GLOBAL COMBAT SUPPORT SYSTEM AND WHAT IT WILL DELIVER TO THE<br />

WARFIGHTER—AND WHEN!<br />

Supporting warfighters in operations<br />

around the globe is certainly not an easy<br />

task, and comprehensive solutions that<br />

allow transparency and visibility—and<br />

security—of the support tail from start<br />

to finish have been hard to come by. The<br />

Global Combat Support System has been<br />

developing for some time with the objective<br />

Q<br />

How will GCSS change the way<br />

the warfighter requests, tracks<br />

and receives supplies?<br />

COLONEL<br />

JEFFREY K. WILSON<br />

(ARMY)<br />

GCSS-Army is a Web-based tactical<br />

logistics system that automates processes<br />

and integrates functions. Retail supply<br />

functionality was first implemented in<br />

December 2007 and is successfully operating<br />

at the Army National Training Center,<br />

Fort Irwin, Calif. Users enter customer supply<br />

requirements only once, and they are<br />

immediately visible to all parties involved,<br />

providing an accurate view and status.<br />

The system saves time by automatically<br />

batching and transmitting requirements<br />

so these functions no longer need to be<br />

manually performed at specific time intervals.<br />

GCSS-Army eliminates the need for<br />

www.MLF-kmi.com<br />

of provided an integrated real-time picture<br />

across the combat service support spectrum.<br />

The goal is to be in an informed position<br />

to make decisions affecting operational<br />

support needs throughout the deployment<br />

environment.<br />

Systems are now in place that have<br />

taken GCSS from the theoretical to the<br />

time-consuming processes such as closeouts,<br />

backups, restores, and separate input<br />

and output logs.<br />

GCSS-Army simplifies the customer<br />

reconciliation process, which previously<br />

required hundreds of man-hours to execute.<br />

A re-engineered process for tracking<br />

and adjudicating overdue shipments provides<br />

a more precise and timely method for<br />

closing and reordering. GCSS-Army managers<br />

at all levels have a better view of the<br />

supply chain and more tools to accurately<br />

and efficiently handle the process.<br />

LIEUTENANT COLONEL<br />

JIM STONE<br />

(MARINE CORPS)<br />

Global Combat System Marine Corps<br />

[GCSS-MC] is scheduled to begin deployment<br />

in fiscal year 2010. It will forever<br />

change the way logistics support is delivered<br />

to the Marine Corps by providing standardized<br />

business processes and cutting-edge<br />

practical. Military Logistics Forum recently<br />

had the opportunity to pose three questions<br />

to Army, Air Force and Marine Corps GCSS<br />

offices to see where they are and what common<br />

ground they have.<br />

We spoke with Colonel Jeffrey K. Wilson<br />

(Army), Phillip Waugh (Air Force) and Lieutenant<br />

Colonel Jim Stone (Marine Corps).<br />

technology to Marines in both garrison<br />

and deployed environments. Unlike the<br />

Corps’ legacy logistics systems, GCSS-MC<br />

goes wherever warfighters go to provide<br />

Marine Air Ground Task Forces [MAGTFs]<br />

and the supporting establishment of an<br />

integrated, Web-based system designed to<br />

capture reliable, relevant and near realtime<br />

information. Requests for products<br />

and services are initiated at the lowest<br />

possible level, and the system provides a<br />

single point of data entry—a combination<br />

of functions that translates into improved<br />

speed and accuracy of logistics information<br />

and improved responsiveness of the<br />

logistics chain. In the past, when Marines<br />

have been deployed in austere environments,<br />

the lack of visible information<br />

has caused unfulfilled requests, redundant<br />

request and fulfillment, and dependency<br />

on forward-deployed materiel. In contrast,<br />

GCSS-MC will provide a clear picture of<br />

demand and inventory up and down the<br />

logistics chain so Marines will know the<br />

status of their requests, the availability<br />

of inventory and services, and the readiness<br />

of their equipment. They will have<br />

secure access to the critical information<br />

MLF 3.7 | 15

they need to enable faster, better-informed<br />

decisions and the flexibility and confidence<br />

that comes only with reliable, responsive<br />

logistics support.<br />

Prior to GCSS, supply systems were<br />

very compartmentalized. Information sharing<br />

was accomplished by batch updates at<br />

periodic intervals between legacy systems,<br />

and third-party applications were used to<br />

provide limited fleet or enterprise views of<br />

supply chain activity. Warfighters suffered<br />

from the lack of real-time business intelligence<br />

and limited ability to affect timely<br />

changes in response to a very dynamic<br />

operational environment.<br />

The introduction of GCSS enabled<br />

unprecedented access and integration<br />

across legacy systems in near real-time that<br />

dramatically changed the way warfighters<br />

make support decisions. With a single<br />

log-on, users can view asset balances and<br />

order status across 300 base-level supply<br />

accounts, Air Force depots, and even external<br />

suppliers, such as the Defense Logistics<br />

Agency. The resulting view of the supply<br />

chain in motion enables smarter decisions<br />

from an enterprise perspective. Local support<br />

priorities are no longer considered in<br />

isolation. Instead, critical spares are repositioned<br />

to meet the greatest need of the Air<br />

Force and the warfighter.<br />

The GCSS architecture also provides a<br />

mechanism for development of new functionality<br />

that identifies and acts on specific<br />

triggers between systems. For example,<br />

16 | MLF 3.7<br />

PHILLIP WAUGH<br />

(AIR FORCE)<br />

business rules that identify overdue shipments<br />

in one system and automatically<br />

checks for a receipt in another system or<br />

shipment status through the Global Transportation<br />

Network.<br />

Q<br />

How fully integrated and functional<br />

throughout the entire supply<br />

chain is GCSS?<br />

PHILLIP WAUGH<br />

(AIR FORCE)<br />

The supply chain is supported by a collection<br />

of nodes made up of numerous systems<br />

in various stages of maturity hosted on<br />

multiple platforms. GCSS is the net-centric<br />

lynchpin that enables a services-oriented<br />

solution that ties these systems together.<br />

GCSS-Air Force provides a standards-based,<br />

open architecture that handles the presentation,<br />

security, messaging, collaboration<br />

and hosting for many Air Force logistics<br />

applications. Some systems are fully integrated<br />

within GCSS, while others may only<br />

use certain services, or remain an external<br />

touch point. In addition, federation across<br />

GCSS instances further enables shared services<br />

and access to systems outside of the<br />

hosting services enclave.<br />

Net-centricity is a key performance<br />

parameter for new and legacy systems.<br />

GCSS provides the foundation from which<br />

to build the bridge between stovepiped<br />

applications and fully integrated systems.<br />

The entire Air Force supply chain is supported<br />

by GCSS to some extent, which<br />

should continue to be a core component of<br />

future logistics modernization efforts.<br />

GCSS-Army is taking an incremental<br />

approach to fielding that allows for testing<br />

and refinement as new functionality<br />

is introduced, resulting in a better final<br />

product for soldiers. At the same time, the<br />

Army Program Executive Office, Enterprise<br />

Information Systems [PEO EIS] Enterprise<br />

Resource Planning [ERP] Task Force is<br />

pursuing a coordinated system integration<br />

strategy that will allow GCSS-Army users<br />

to benefit from shared capabilities in other<br />

Army business areas such as finance and<br />

personnel. When fully deployed, GCSS-<br />

Army will share integrated data with organizations<br />

and personnel throughout the<br />

Army business enterprise, from the factory<br />

to the foxhole.<br />

GCSS-MC is not just replacing old<br />

systems with a new one. It is enabling an<br />

entirely new approach to Marine Corps<br />

logistics based on simplified and streamlined<br />

processes supported by modern technology.<br />

Regardless of location, the way<br />

logistics work is done and the tools used<br />

to accomplish it will be the same. Block 1,<br />

the first phase of the program, will integrate<br />

tactical-level supply, maintenance<br />

and service functionality in a shared data<br />

environment. The functional solution will<br />

provide the Marine Corps:<br />

•<br />

•<br />

LIEUTENANT COLONEL<br />

JIM STONE<br />

(MARINE CORPS)<br />

Requests for services, maintenance<br />

and supplies with automatic routing to<br />

the appropriate authority for approval<br />

and fulfillment<br />

Real-time validated information<br />

www.MLF-kmi.com

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Asset status and availability<br />

Warranty tracking and management<br />

Ownership and transfer of assets<br />

Escalation of requests<br />

Approvals and funds checking<br />

Proactive and reactive maintenance<br />

Maintenance history<br />

Effective management of resources<br />

Replenishment of supplies through<br />

automatic triggers<br />

Mobile field service enhanced, the ability<br />

work in connected or disconnected<br />

modes<br />

Subsequent GCSS-MC blocks will build<br />

on previous ones, adding new capabilities<br />

over time. When the program is mature<br />

and all requirements are fully implemented,<br />

it will consolidate more than 200 legacy<br />

logistics information systems into an integrated<br />

infrastructure that provides seamless<br />

end-to-end logistics chain management,<br />

advanced enterprisewide planning and joint<br />

interoperability.<br />

Q<br />

Q: What are the priorities for the<br />

next phase of the program and<br />

future enhancements?<br />

GCSS-MC capabilities will be delivered<br />

incrementally. To realize the benefits of integrated,<br />

state-of-the-art systems and common<br />

business processes as soon as possible, Block<br />

1, the first phase, has been divided into<br />

two releases. The initial release, Capability<br />

Release 1.1, focuses on providing capability<br />

www.MLF-kmi.com<br />

LIEUTENANT COLONEL<br />

JIM STONE<br />

(MARINE CORPS)<br />

to the MAGTF and the enterprise in three<br />

major functional areas: supply, maintenance<br />

and request management. This release is<br />

scheduled to begin field user evaluation<br />

at III Marine Expeditionary Force early in<br />

2010. The second release, Capability Release<br />

1.2, consists of the sophisticated technical<br />

solution that will enhance the MAGTF’s ability<br />

to access logistics data in any location or<br />

environment. Capability Release 1.2 allows<br />

for the secure transfer of data between the<br />

Nonsecure Internet Protocol Router Network<br />

[NIPRNET] and the Secure Internet<br />

Protocol Router Network [SIPRNET] and<br />

the ability to synchronize data between a<br />

continental United States GCSS-MC server<br />

[Enterprise Instance] and the scalable, tailored,<br />

deployed MAGTF instances that are<br />

cloned from the enterprise.<br />

While future blocks of capabilities are<br />

still in the planning stage, it is anticipated<br />

that they will focus on such areas as transportation/distribution,<br />

engineering, health<br />

services, life cycle management, advanced<br />

planning and base/garrison functions.<br />

PHILLIP WAUGH<br />

(AIR FORCE)<br />

From a logistics or supply chain perspective,<br />

the next big event for the Air Force is<br />

the integration of the Enterprise Resource<br />

Planning Solution—the Expeditionary<br />

Combat Support System [ECSS]. ECSS will<br />

replace most of the legacy logistics systems<br />

in use today, which is a huge undertaking.<br />

This phase of modernization will take<br />

several years with incremental deliveries of<br />

capability.<br />

As you might imagine, it’s important<br />

to maintain a stable baseline for the legacy<br />

systems being subsumed over the course<br />

of ECSS development. However, real-world<br />

events, such as securing the nuclear enterprise,<br />

will almost certainly drive some legacy<br />

system modifications. In addition, there<br />

are a small number of systems that will<br />

not be subsumed by ECSS. These systems,<br />

and the aforementioned modifications, will<br />

continue to target enterprise hosting and<br />

the shared services offered by GCSS.<br />

COLONEL<br />

JEFFREY K. WILSON<br />

(ARMY)<br />

The GCSS-Army project office is capturing<br />

lessons learned in the 2007 release<br />

at the National Training Center and is<br />

applying them to future implementations.<br />

The next release, scheduled for 2010, will<br />

include unit-level supply, property book,<br />

ground maintenance, and tactical finance<br />

support capabilities at the National Training<br />

Center. A future release planned for<br />

2011 will address aviation maintenance,<br />

ammunition, environmental health and<br />

safety, and cost management functions. It<br />

is estimated that more than 170,000 soldiers<br />

will use GCSS-Army when it is fully<br />

deployed. ✯<br />

Marine Corps Lieutenant Colonel Jim<br />

Stone is the senior Marine/director for<br />

global implementation. Phillip Waugh is<br />

with Air Force Headquarters 754th ELSG/<br />

ILSS. Army Colonel Jeffrey K. Wilson is the<br />

project manager Global Combat Support<br />

System-Army (GCSS-Army).<br />

MLF 3.7 | 17

18 | MLF 3.7<br />

Foam Protection<br />

A new drawer liner kit<br />

for Pelican’s 0450 case<br />

allows the end user to<br />

create professional-looking<br />

foam-lined tool drawers at<br />

a fraction of the cost of a<br />

fabricated solution. Each kit<br />

includes six shallow drawer<br />