You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

process measurement solutions<br />

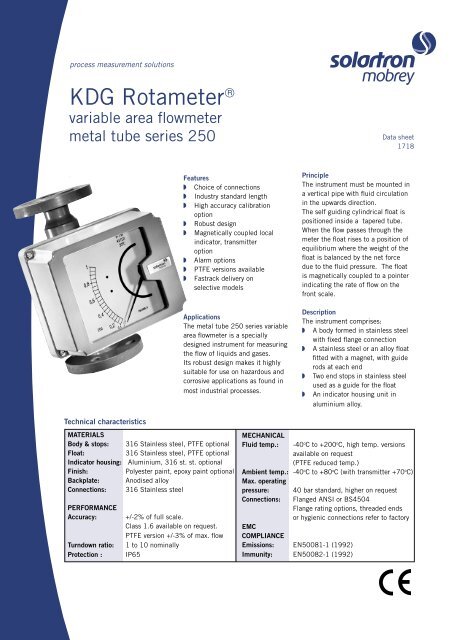

<strong>KDG</strong> Rotameter ®<br />

variable area flowmeter<br />

metal tube series 250<br />

Technical characteristics<br />

Features<br />

w Choice of connections<br />

w Industry standard length<br />

w High accuracy calibration<br />

option<br />

w Robust design<br />

w Magnetically coupled local<br />

indicator, transmitter<br />

option<br />

w Alarm options<br />

w PTFE versions available<br />

w Fastrack delivery on<br />

selective models<br />

Applications<br />

The metal tube 250 series variable<br />

area flowmeter is a specially<br />

designed instrument for measuring<br />

the flow of liquids and gases.<br />

Its robust design makes it highly<br />

suitable for use on hazardous and<br />

corrosive applications as found in<br />

most industrial processes.<br />

MATERIALS<br />

Body & stops: 316 Stainless steel, PTFE optional<br />

Float: 316 Stainless steel, PTFE optional<br />

Indicator housing: Aluminium, 316 st. st. optional<br />

Finish: Polyester paint, epoxy paint optional<br />

Backplate: Anodised alloy<br />

Connections: 316 Stainless steel<br />

PERFORMANCE<br />

Accuracy: +/-2% of full scale.<br />

Class 1.6 available on request.<br />

PTFE version +/-3% of max. flow<br />

Turndown ratio: 1 to 10 nominally<br />

Protection : IP65<br />

Data sheet<br />

1718<br />

Principle<br />

The instrument must be mounted in<br />

a vertical pipe with fluid circulation<br />

in the upwards direction.<br />

The self guiding cylindrical float is<br />

positioned inside a tapered tube.<br />

When the flow passes through the<br />

meter the float rises to a position of<br />

equilibrium where the weight of the<br />

float is balanced by the net force<br />

due to the fluid pressure. The float<br />

is magnetically coupled to a pointer<br />

indicating the rate of flow on the<br />

front scale.<br />

Description<br />

The instrument comprises:<br />

w A body formed in stainless steel<br />

with fixed flange connection<br />

w A stainless steel or an alloy float<br />

fitted with a magnet, with guide<br />

rods at each end<br />

w Two end stops in stainless steel<br />

used as a guide for the float<br />

w An indicator housing unit in<br />

aluminium alloy.<br />

MECHANICAL<br />

Fluid temp.: -40 o C to +200 o C, high temp. versions<br />

available on request<br />

(PTFE reduced temp.)<br />

Ambient temp.: -40 o C to +80 o C (with transmitter +70 o C)<br />

Max. operating<br />

pressure: 40 bar standard, higher on request<br />

Connections: Flanged ANSI or BS4504<br />

Flange rating options, threaded ends<br />

or hygienic connections refer to factory<br />

EMC<br />

COMPLIANCE<br />

Emissions: EN50081-1 (1992)<br />

Immunity: EN50082-1 (1992)

Dimensions<br />

Size<br />

15<br />

1⁄2"<br />

25<br />

1"<br />

50<br />

2<br />

80<br />

3"<br />

100<br />

4"<br />

Standard model dimensions<br />

PN ∅ D ∅ K ∅ L N A<br />

16<br />

40<br />

150 lbs 88.9<br />

300 lbs 95.2<br />

16<br />

40<br />

150 lbs 107.9<br />

300 lbs 123.8<br />

16<br />

40<br />

150lbs<br />

300 lbs 165.1<br />

16<br />

150 lbs 190.5<br />

16<br />

95<br />

95<br />

115<br />

115<br />

165<br />

165<br />

152.4<br />

200<br />

220<br />

150 lbs 228.6<br />

65<br />

65<br />

60.3<br />

66.7<br />

85<br />

85<br />

79.4<br />

88.9<br />

125<br />

125<br />

120.6 19<br />

127<br />

160<br />

152.4 19<br />

180<br />

14<br />

14<br />

15.9<br />

15.9<br />

14<br />

14<br />

15.9<br />

19<br />

18<br />

18<br />

19<br />

18<br />

18<br />

190.5 19<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

8<br />

8<br />

4<br />

8<br />

8<br />

80<br />

80<br />

80<br />

80<br />

92<br />

92<br />

92<br />

92<br />

108<br />

108<br />

108<br />

108<br />

122.5<br />

122.5<br />

124<br />

124<br />

Flow range table Maximum capacities shown. Turndown ratio typically 10:1<br />

Normal<br />

size<br />

15<br />

(1⁄2")<br />

25<br />

(1")<br />

50<br />

(2")<br />

80<br />

(3")<br />

or<br />

100<br />

(4")<br />

M<br />

code<br />

M1<br />

M2<br />

M3<br />

M4<br />

M5<br />

M6<br />

M5<br />

M6<br />

M7<br />

M8<br />

M9<br />

M10<br />

M8<br />

M9<br />

M10<br />

M11<br />

M12<br />

M13<br />

M11<br />

M12<br />

M13<br />

M14<br />

M15<br />

M16<br />

M17<br />

LIQUID GAS PRESSURE DROP PTFE LINED<br />

Max liquid<br />

flow rates<br />

SG = 1<br />

100 l/h<br />

160 lh<br />

250 l/h<br />

400 l/h<br />

600 l/h<br />

1 m 3 /h<br />

600 l/h<br />

1 m 3 /h<br />

1.6 m 3/ h<br />

2.5 m 3 /h<br />

4 m 3 /h<br />

6 m 3 /h<br />

2.5 m 3 /h<br />

4 m 3 /h<br />

6 m 3 /h<br />

10 m 3 /h<br />

16 m 3 /h<br />

25 m 3 /h<br />

10 m 3 /h<br />

16 m 3 /h<br />

25 m 3 /h<br />

40 m 3 /h<br />

50 m 3 /h<br />

60 m 3 /h<br />

80 m 3 /h<br />

MG<br />

code<br />

MG2<br />

MG3<br />

MG4<br />

MG5<br />

MG6<br />

MG5<br />

MG6<br />

MG7<br />

MG8<br />

MG9<br />

MG10<br />

MG8<br />

MG9<br />

MG10<br />

MG11<br />

MG12<br />

MG13<br />

MG11<br />

MG12<br />

MG13<br />

MG14<br />

MG15<br />

MG16<br />

MG17<br />

Flow capacity<br />

Air - 20°C Atmospheric<br />

pressure<br />

5 m 3 /h<br />

7.5 m 3 /h<br />

12 m 3 /h<br />

18 m 3 /h<br />

30 m 3 /h<br />

18 m 3 /h<br />

30 m 3 /h<br />

48 m 3 /h<br />

75 m 3 /h<br />

120 m 3 /h<br />

180 m 3 /h<br />

75 m 3 /h<br />

120 m 3 /h<br />

180 m 3 /h<br />

300 m 3 /h<br />

480 m 3 /h<br />

750 m 3 /h<br />

300 m 3 /h<br />

480 m 3 /h<br />

750 m 3 /h<br />

1000m 3 /h<br />

1500m 3 /h<br />

1800m 3 /h<br />

2400m 3 /h<br />

mbar<br />

35<br />

60<br />

60<br />

60<br />

65<br />

70<br />

45<br />

80<br />

55<br />

80<br />

85<br />

125<br />

55<br />

80<br />

55<br />

80<br />

95<br />

130<br />

60<br />

90<br />

60<br />

125<br />

140<br />

165<br />

220<br />

Installation and maintenance<br />

Make sure the Rotameter is positioned as upright as possible and fluid flow is upwards.<br />

Keep the inside of the instrument in a good clean state.<br />

Code<br />

MP<br />

MP2<br />

MP3<br />

MP4<br />

MP5<br />

MP6<br />

MP5<br />

MP6<br />

MP7<br />

MP8<br />

MP9<br />

MP8<br />

MP9<br />

MP10<br />

MP11<br />

MP10<br />

MP11<br />

MP12<br />

MP13<br />

Max liquid<br />

flow<br />

SG = 1<br />

160 l/h<br />

250 l/h<br />

400 l/h<br />

600 l/h<br />

1 m 3 /h<br />

600 l/h<br />

1 m 3 /h<br />

1.6 m 3 /h<br />

2.5 m 3 /h<br />

4 m 3 /h<br />

2.5 m 3 /h<br />

4 m 3 /h<br />

6 m 3 /h<br />

10 m 3 /h<br />

6 m 3 /h<br />

10 m 3 /h<br />

16 m 3 /h<br />

25 m 3 /h

Electronic transmitter option<br />

Standard version (Pointer and scale plate indicator) – T5 code<br />

Output signal 4 to 20mA proportional from 10 to 100% of flow range<br />

4mA corresponds to 0 of the scale (position marked 0)<br />

5,6 mA corresponds to 10% of tfull scale<br />

(first measuring value 10%).<br />

20mA corresponds to 100% of full scale<br />

(top measuring value 100%).<br />

Transmission 2 wires (connection : see alarm)<br />

Power supply UB = 8 to 24V dc<br />

Linearity 0,5% of max. current<br />

Temperature deviation < 0.05% /°C<br />

Ambient temperature T= –25 to + 65°C in operation<br />

Type i250 – Intrinsic safety version – "T6 code" (specify when ordering)<br />

ATEX II 2 G EExia IIC T6<br />

Certificate N° LCIE01ATEX6063X<br />

IS Characteristics C internal = 0 nF, L internal = 1.8 mH,<br />

li = 100mA, Pi = 0.75W<br />

Only connect to an<br />

approved source in EEx ia lIC T6 max.<br />

IS version permissible ambient temperature 65°C.<br />

IS power supply Voltage UB

Ordering information<br />

Code Connection code<br />

15 ISO PN Flange NFE 29203/ NE1092 - DN15<br />

25 ISO PN Flange NFE 29203/ NE1092 - DN25<br />

50 ISO PN Flange NFE 29203/ NE1092 - DN50<br />

80 ISO PN Flange NFE 29203/ NE1092 - DN80<br />

100 ISO PN Flange NFE 29203/ NE1092 - DN100<br />

1⁄2" Flange ANSI B15-5 DN 1⁄2"<br />

1" Flange ANSI B15-5 DN 1"<br />

2" Flange ANSI B15-5 DN 2"<br />

3" Flange ANSI B15-5 DN 3"<br />

4" Flange ANSI B15-5 DN 4"<br />

Code Construction code<br />

C1 Stainless steel 316, ISO PN16 Flange RF<br />

C2 Stainless steel 316, ISO PN40 Flange RF<br />

C3 Stainless steel 316, Flange ANSI 150# RF<br />

C4 Stainless steel 316, Flange ANSI 300# RF<br />

C5 PTFE Construction, ISO PN16 Flange (RF)<br />

C6 PTFE Construction, Flange ANSI 150# RF<br />

CX Special Construction (on request)<br />

Code Measuring element code<br />

M - See flow range table<br />

Code Transmitter<br />

T6 I.S. magnetic transmitter 4-20mA II2G ATEX EExiaIICT6 (standard housing IP65)<br />

T5 Standard magnetic transmitter 4-20mA (standard housing IP65)<br />

Ti Not yet available -<br />

T4 Magnetic transmitter 4-20mA (exposion -proof housing) II2G ATEX EExdIICT6<br />

Code Alarms<br />

S1 1 low alarm (without relay)<br />

S2 1 high alarm (with relay)<br />

S3 2 high and low alarms (without relay)<br />

S4 1 low alarm (with relay)<br />

S5 1 high alarm (with relay)<br />

S6 2 high and low alarms (with relay)<br />

S7 2 high and low alarms explosion-proof housing (II2G ATEX EExdIICT6)<br />

Code Options<br />

Z1 Damping system (essential for gas flow)<br />

Z2 High temperature shield<br />

Z3 Degreasing and specific packaging for oxygen<br />

Z4 Accuracy class 1.6 (liquids within viscosity limits)<br />

Z5 Intrinsic safety for codes T and/or S<br />

Z6 Special scale<br />

Z7 IS power supply + retransmission<br />

Z9 Epoxy painted indicator housing<br />

Z10 Stainless steel indicator housing<br />

t t t t t t<br />

250 - 25 - C1 - M8 - T4 - S3 - Z1-Z6<br />

Information required for quote or order:<br />

w Fluid type to be measured.<br />

w Maximum and minimum flow rate required.<br />

w Specific gravity and viscosity at operating conditions.<br />

w Normal working temperature of fluid to be measured.<br />

Solartron Mobrey Limited<br />

<strong>KDG</strong> Instruments Division<br />

Crompton Way Crawley<br />

West Sussex RH10 9QR<br />

Tel: 01293 525151<br />

Fax: 01293 530849<br />

e-mail: sales@solartron.com<br />

www.solartronmobrey.com<br />

w Maximum temperature of fluid to be measured.<br />

w Normal pressure of fluid to be measured.<br />

w Maximum pressure of fluid to be measured.<br />

w Scale flow units M 3 /hr or litres per min.<br />

Solartron Mobrey USA tel: 281 398 7890<br />

Solartron Mobrey GmbH Deutschland tel: 0211/99 808-0<br />

Solartron Mobrey Ltd China tel: 021 6353 5652<br />

Solartron Mobrey sp z o o Polska tel: 022 871 7865<br />

Solartron Mobrey AB Sverige tel: 08-725 01 00<br />

Solartron Mobrey SA France tel: 01.30.17.40.80<br />

Solartron Mobrey SA-NV Belgium tel: 02/465 3879<br />

abcdef<br />

The right is reserved to amend details given in this publication without notice<br />

1718<br />

Jan 05