7900 Instrument Stand - Haag-Streit USA

7900 Instrument Stand - Haag-Streit USA

7900 Instrument Stand - Haag-Streit USA

- TAGS

- haag-streit-usa.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

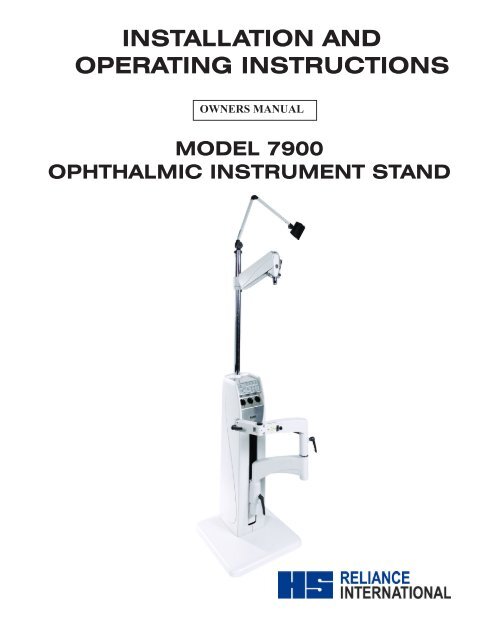

����INSTALLATION AND<br />

OPERATING INSTRUCTIONS<br />

OWNERS MANUAL<br />

MODEL <strong>7900</strong><br />

OPHTHALMIC INSTRUMENT STAND

MADE IN AMERICA<br />

serial number<br />

For your future reference, mark the serial number<br />

in the space provided.<br />

Quality management<br />

system<br />

registered to<br />

iso 9001:2000<br />

iso 13485:2003<br />

Reliance® Medical Products • 3535 Kings Mills Road • Mason, Ohio 45040-2303 • 1-800-735-0357 • www.reliance-medical.com

Table of Contents<br />

imPOrTanT inFOrmaTiOn................................................4<br />

1. inTrODuCTiOn...................................................5<br />

TeChniCal sPeCiFiCaTiOns................................6<br />

2. insTallaTiOn..................................................7<br />

unPaCking...............................................................7<br />

2.1 base unit..........................................................7<br />

2.2 instrument Console/base Cap.......................7<br />

replacement or repair...............................7<br />

2.3 support Column installation..........................8<br />

2.4 Configuring The switches For The b/P ...................8<br />

2.5 auxiliary (Third) arm .............................................9<br />

2.6 refractor suspension arm - Dual lock.........10<br />

2.7 refractor suspension arm - single lock......10<br />

2.8 Overhead lamp..............................................10<br />

2.9 slit lamp arm...............................................10<br />

2.10 Final assembly...........................................12<br />

Console/base Cap..........................................12<br />

2.11 Chair assembly............................................12<br />

2.12 miscellaneous.............................................12<br />

3. OPeraTing insTruCTiOns............................13<br />

3.1 slit lamp arm......................................13<br />

3.2 auxiliary (Third) arm....................................14<br />

3.3 refractor suspension arms........................14<br />

3.4 Overhead lamp............................................14<br />

3.5 instrument Console/base Cap....................14<br />

hand instrument Wells - rechargeable battery<br />

Ty p e ( C o n s o l e o n l y ) . . . . . . . . . . . . . . . . . . . . . . . . . 1 4<br />

3.6 Front Panel Controls.............................15<br />

standby switch (sTbY) ...............................15<br />

auxiliary switch (aux1)................................16<br />

lamp switch (lamp)...........................16<br />

lamp Down switch..................................16<br />

lamp up switch............................................16<br />

binding Post switch (b/P)............................16<br />

b/P Down switch...........................................16<br />

b/P up switch................................................16<br />

Chair base up switch...................................16<br />

Chair base Down switch..............................16<br />

auto switch.................................................16<br />

3.7 Fuses...........................................................17<br />

3.8. eclipse infrared room light Control<br />

system.......................................................................18<br />

Dual Zone vs. single Zone...........................18<br />

incandescent vs. Fluorescent......................19<br />

single Zone...................................................19<br />

Dual Zone......................................................19<br />

sWiTChPaCk #1 (sW1)......................................21<br />

sWiTChPaCk #2 (sW2).....................................22<br />

Programming single Zone room lights....23<br />

Programming Dual Zone room lights......24<br />

T r O u b l e s h O O T i n g g u i D e . . . . . . . . . . . . . . . . . . . . 2 9<br />

Cleaning anD mainTenanCe .......................31<br />

ParTs lisT.........................................................33<br />

model <strong>7900</strong> instrument stand assembly.....35<br />

base assembly.............................................36<br />

roller Frame assembly................................38<br />

Outlet Plate assembly..................................40<br />

back Cover assembly.................................42<br />

slit lamp arm assembly..............................44<br />

model 5250 Dual lock refractor<br />

assemblY...............................................................46<br />

model 5255 single lock refractor<br />

assemblY...............................................................48<br />

model 5380 auxiliary (3rd) arm assembly...50<br />

instrument Console W/O ir assembly........52<br />

instrument Console With ir assembly..........54<br />

instrument Console base Cap assembly W/O Wells<br />

.......................................................................56<br />

instrument Console base Cap assembly With<br />

Wells..................................................58<br />

Wire Diagram - Console<br />

(With and Without ir) ..............................................60<br />

Wire Diagram basecap.................................62<br />

limiTeD WarranTY..........................................67<br />

3

imPOrTanT inFOrmaTiOn<br />

saFeTY sYmblOls<br />

4<br />

!<br />

“Danger”, “Warning”, or “CauTiOn”<br />

The exclamation point within an equilateral<br />

triangle is intended to alert the user to<br />

the presence of important operating and<br />

maintenance (servicing) instructions in this<br />

Installation and Operating Instructions.<br />

“nOTe”<br />

Amplifies a procedure, practice, or condition.<br />

Type B, Applied Part<br />

<strong>Stand</strong>-By<br />

Dangerous Voltage / Shock Hazard<br />

Fuse Rating Specification<br />

Protective Earth Ground<br />

Alternating Current-AC<br />

Safe Working Load<br />

“Attention, Consult Accompanying<br />

Documents”<br />

TransPOrTaTiOn / sTOrage COnDiTiOns<br />

Temperature: Operating: 59 to 104º F<br />

15 to 40º C<br />

Storage: -22 to +140º F<br />

-30 to +60º C<br />

Relative Humidity: Operating: 5 to 95% without<br />

condensation<br />

Storage: 10 to 100%<br />

IN-<strong>7900</strong>

1. inTrODuCTiOn<br />

1.1. This Installation and Operating Instructions contains<br />

information applicable only to the Reliance® Model <strong>7900</strong><br />

ophthalmic instrument stand also known as floor unit.<br />

1.2. Whenever you see the symbols shown below, heed their<br />

instructions! Always follow safe operating and maintenance<br />

practices.<br />

“Danger”- The Danger sYmbOl<br />

iDenTiFies sPeCial insTruCTiOns Or<br />

PrOCeDures WhiCh, iF nOT COrreCTlY<br />

FOllOWeD, COulD resulT in lOss OF liFe<br />

Or PersOnal inJurY.<br />

‘’Danger” - le sYmbOle De Danger<br />

iDenTiFie les insTruCTiOns sPÉCiales<br />

O u l e s P r O C É D u r e s Q u i , s i n O n<br />

COrreCTemenT suiVi, POurraienT aVOir<br />

COmme COnsÉQuenCe la PerTe De Vie Ou<br />

De blessures.<br />

“Warning”- The Warning sYmbOl<br />

iDenTiFies sPeCial insTruCTiOns Or<br />

PrOCeDures WhiCh, iF nOT COrreCTlY<br />

FOllOWeD, COulD resulT in PersOnal<br />

inJurY.<br />

« aVerTissanT » - le sYmbOle<br />

D ’ aV e r T i s s e m e n T i D e n T i F i e l e s<br />

insTruCTiOns sPÉCiales Ou les<br />

PrOCÉDures Qui, sinOn COrreCTemenT<br />

suiVi, POurraienT aVOir COmme<br />

COnsÉQuenCe Des blessures.<br />

“CauTiOn”- This caution symbol identifies<br />

special instructions or procedures which, if<br />

not strictly observed, could result in damage<br />

to or destruction of equipment.<br />

« aTTenTiOn » - ce symbole d’attention<br />

identifie les instructions spéciales ou les<br />

procédures aux lesquelles, sinon strictement<br />

observés, pourrait avoir comme conséquence<br />

les dégâts ou la destruction du matériel.<br />

“nOTe”- Note indicates points of particular or<br />

additional information.<br />

« nOTe » - la note indique des remarques<br />

d’information particulière ou supplémentaire.<br />

1.3 Should your product not perform properly, or if you<br />

have any questions concerning the use and care of any<br />

Reliance® product, contact the Reliance® Distributor,<br />

where you purchased this product or contact the Technical<br />

Service Department, Reliance® Medical Products, Inc.,<br />

3535 Kings Mills Road, Mason, Ohio 45040-2303, or call<br />

(800) 735-0358.<br />

nOTe: Always have the model number and serial<br />

number available before contacting Reliance® or<br />

your authorized Reliance® Distributor.<br />

nOTe: Ayez toujours le numéro et le numéro<br />

de série de type disponibles avant Reliance®<br />

entrant en contact ou votre distributeur autorisé<br />

de Reliance®.<br />

“ClassiFieD bY CanaDian sTanDarDs<br />

assOCiaTiOn® Csa WiTh resPeCT TO<br />

eleCTriC shOCk, Fire anD meChaniCal<br />

haZarDs OnlY in aCCOrDanCe WiTh ieC<br />

60601-1.”<br />

According to Clause 5 in IEC 60601-1, sec 6.8.1, this unit<br />

is classified by the following:<br />

• The type of protection against electric shock: EQUIPMENT<br />

energized from an external electrical power source:<br />

CLASS I EQUIPMENT<br />

• The degree of protection against electric shock: TYPE<br />

B EQUIPMENT<br />

• The degree of protection against harmful ingress of<br />

water: ORDINARY DEGREE<br />

• The degree of safety of application in the presence of a<br />

FLAMMABLE ANAESTHETIC MIXTURE WITH AIR or WITH<br />

OXYGEN OR NITROUS OXIDE: EQUIPMENT not suitable<br />

for use in the presence of a FLAMMABLE ANAESTHETIC<br />

MIXTURE WITH AIR or WITH OXYGEN OR NITROUS<br />

OXIDE<br />

• The mode of operation: CONTINUOUS OPERATION<br />

IN-<strong>7900</strong> 5

6<br />

Warning: TO PreVenT Fire Or shOCk<br />

haZarD, DO nOT exPOse This aPPlianCe<br />

TO rain Or mOisTure.<br />

aTTenTiOn: POur PrÉVenir le risQue<br />

D’inCenDie Ou De ChOC, n’exPOseZ<br />

Pas CeT aPPareil À la Pluie Ou À<br />

l’humiDiTÉ.<br />

TeChniCal sPeCiFiCaTiOns<br />

rating for 120V instrument stand<br />

This equipment is rated Class I, Type B<br />

Equipment Model<br />

<strong>Instrument</strong> <strong>Stand</strong> <strong>7900</strong><br />

Volts Hertz Amps<br />

120V 50/60 12.0<br />

Class I Type B<br />

�<br />

��������<br />

���������<br />

����������<br />

rating for 230V instrument stand<br />

This equipment is rated Class I, Type B<br />

Equipment Model<br />

<strong>Instrument</strong> <strong>Stand</strong> <strong>7900</strong><br />

Volts Hertz Amps<br />

230V 50/60 6.0<br />

Class I Type B<br />

�<br />

��������<br />

���������<br />

����������<br />

U.S. Patent No.<br />

D503,233 D512,507 5,717,480<br />

D504,515 D514,701 5,907,387<br />

D506,257 D424,200 6,264,329<br />

imPOrTanT user Warnings<br />

Warning- exPlOsiOn: This sTanD musT<br />

nOT be useD in The PresenCe OF Flammable<br />

anesTheTiCs.<br />

“aVerTissanT” - DÉCOmPOsiTiOn : CeTTe<br />

gabariT ne DOiT Pas êTre uTilisÉe en<br />

PrÉsenCe Des anesThÉsiQues inFlammables<br />

POTenTial eleCTrOmagneTiC or OTher<br />

inTerFerenCe<br />

This equipment generates, uses and can radiate radio<br />

frequency energy and, if not installed and used in accordance<br />

with the instructions, may cause harmful interference to other<br />

devices in the vicinity. However, there is no guarantee that<br />

interference will not occur in a particular installation.<br />

If this equipment does cause harmful interference to other<br />

devices, which can be determined by turning the equipment<br />

off and on, the user is encouraged to try to correct the<br />

interference by one or more of the following measures:<br />

• Reorient or relocate the receiving device.<br />

• Increase the separation between the equipment.<br />

• Connect the equipment into an outlet on a circuit different<br />

from that to which the other device(s) are connected.<br />

• Consult the manufacturer or field service technician for<br />

help.<br />

This product contains lead. Check with local ordinance or<br />

laws for proper disposal.<br />

IN-<strong>7900</strong>

2. insTallaTiOn<br />

2.1. unpacking<br />

2.1.1. base unit<br />

2.1.1.1 Remove all external shipping tapes and wrappings.<br />

Remove the base unit from the skid and set it in the desired,<br />

final location.<br />

2.1.1.2 Loosen the two screws that hold the back cover<br />

(Figure 1) in place, located in bottom of cover. Cover lifts<br />

off the base unit.<br />

2.1.1.3. Squeeze, the slit lamp arm release lever (Figure<br />

1) and at the same time push down on slit lamp arm. Arm<br />

should move approximately 1/4 inch. Release the lever to<br />

set the slit lamp arm lock.<br />

2.1.1.4. Inside the rear of the unit, remove the wood brace<br />

beneath the counterbalance weights and the cords which<br />

hold incremental weights to the large weight. While pushing<br />

firmly down (50 pounds force) on the slit lamp arm, again<br />

squeeze the lock release lever. Allow the slit lamp arm to<br />

rise to its full height and again release the lever.<br />

Warning- WiTh WeighT braCe remOVeD,<br />

arm assemblY Will rise abruPTlY iF<br />

release leVer is DePresseD.<br />

aVerTissanT -lOrsQue le blOQueur<br />

De DÉPlaCemenT esT reTirÉ, le<br />

bras COnTrebalanCÉ remOnTera<br />

PrOmPTemenT si le leVier Du Frein esT<br />

enFOnCÉ.<br />

2.2. instrument Console/base Cap<br />

CauTiOn- The power supply cord should not<br />

be connected to the power supply during the<br />

installation process.<br />

aVerTisseZ -le cordon d’alimentation ne<br />

doit pas être connecté au secteur électrique<br />

pendant d’installation.<br />

Refractor<br />

Suspension<br />

Arm<br />

Auxiliary<br />

(Third) Arm<br />

<strong>Instrument</strong><br />

Console or<br />

Base Cap<br />

Handle<br />

Release Lever<br />

Slit Lamp Arm<br />

Handle<br />

Overhead<br />

Lamp<br />

Monitor<br />

Arm<br />

Figure 1<br />

Support<br />

Column<br />

31”<br />

(787.4 mm)<br />

16”<br />

(406.4 mm)<br />

7 1/2 ”<br />

(190.5 mm)<br />

nOTe: If you are installing room light controls<br />

on this instrument stand, also refer to the “Eclipse<br />

Room Light Control Operating Instructions<br />

Section.”<br />

nOTe : Si vous installez le système de contrôles<br />

d’éclairage sur le support ophtalmique, veuillez<br />

suivre les consignes d’installation en vous référant<br />

au manuel d’instruction du système de contrôle<br />

d’éclairage éclipse.<br />

2.2.1. replacement or repair<br />

Back<br />

Cover<br />

Wood Brace<br />

(Inside)<br />

IN-<strong>7900</strong> 7<br />

Base<br />

Unit<br />

In the event that the instrument console or cap must be<br />

mounted or removed for replacement or repair purposes, it<br />

will be necessary to remove the back cover and disconnect<br />

the eight connectors from the console. To continue removing<br />

the console, remove the three Phillips Head screws from the

8<br />

mounting tabs then lift the console out from the front of the<br />

unit.(See Figure2)<br />

To install a console, connect the four connectors on top of<br />

the base to the matching connectors hanging from the back<br />

of the console. The lamp jumper cable will drop throught the<br />

large opening and be connected to the matching connector<br />

that hangs from underneath the support column. Figure 2<br />

illustrates the connections that must be made. Align the three<br />

mounting tabs in the base unit with the matching holes in the<br />

console and attach with Phillps Head screws.<br />

2.3. support Column installation<br />

Remove Philips Head shipping screw. Unwrap the support<br />

column. Remove the column support pin and the collar from<br />

the instruction manual bag. Insert the column in the hole at<br />

Chair Control<br />

(Ref)<br />

Overhead<br />

Lamp<br />

Slit Lamp<br />

Arm from<br />

Roller Frame<br />

Mounting<br />

Tabs<br />

Ground from<br />

AC Input<br />

Figure 2<br />

Ground from 3rd Arm &<br />

Slit Lamp<br />

AC Input<br />

from Outlet<br />

Plate<br />

3rd Arm<br />

from Back<br />

Cover<br />

Aux from<br />

Back Cover<br />

the top of the base unit. Line up the hole in the column with<br />

the hole in the base unit and insert the pin. Note that the<br />

small screw at the top of the column faces the rear of the<br />

unit. Tighten the set screws under the support pin. Remove<br />

set screw from bag and install where shipping screw had<br />

been. Slide the collar down firmly against the console/base<br />

cap. Insert and tighten set screw.<br />

2.4. Configuring The switches For The b/P<br />

Switchpack SW2 on the console must be configured<br />

for proper operation of the stand. Individual switches 1,<br />

2 and 3 control the voltage and power to the Indirect<br />

Ophthalmoscope. See Table 1 on Page 8.<br />

Switchpack<br />

(SW2)<br />

Overhead<br />

Lamp<br />

Overhead<br />

Lamp<br />

Jumper<br />

B/P Jumper<br />

from Module<br />

Chair Control<br />

from Outlet<br />

Plate<br />

Switchpack<br />

(SW1)<br />

Optional<br />

Chair<br />

Control<br />

IN-<strong>7900</strong>

TABLE 1<br />

SWITCH SETTINGS FOR B/P VOLTAGES<br />

S W2-1 S W2-2 S W2-3 B /P V OLTAG E<br />

OF F OF F OF F 6V /18W INC ANDE S C ANT<br />

ON OF F OF F 7V INC ANDE S C ANT<br />

OF F ON OF F 12V INC ANDE S C ANT<br />

ON ON OF F NOT DE F INE D<br />

OF F OF F ON 6V /10W HALOG E N<br />

ON OF F ON 6V /18W HALOG E N<br />

OF F ON ON 12V /12W HALOG E N<br />

ON ON ON NOT DE F INE D<br />

PRESS HERE<br />

TO TURN OFF<br />

oFF<br />

SW2<br />

auXiliary<br />

"3rd" arm<br />

ProJeCtor<br />

1 2 3 4 5 6 7 8<br />

PRESS HERE<br />

TO TURN ON<br />

�<br />

��������<br />

���������<br />

����������<br />

���<br />

����<br />

Figure 3<br />

2.5 auxiliary (Third) arm<br />

2.5.1. If supplied, unpack the auxiliary (third) arm. Slide the<br />

clamp member carefully down over the support column until<br />

positioned as shown in Figure 1. Tighten the clamp screw<br />

using the hex key wrench provided.<br />

2.5.2. Position the clamp initially so that the clamp screw is<br />

toward the rear of the unit. If necessary, this position can be<br />

altered to center the rotation of the arm about the column<br />

(300°) within the desired range of movement.<br />

2.5.3. Springs are used to counterbalance the instrument<br />

mounted on the arm. Adjustment of the springs is by means<br />

of a screw which is accessible upon removal of plug button.<br />

Rotating the screw clockwise increases the tension. With<br />

the instrument in place, adjust the screw for the 20 to 50<br />

pounds.<br />

If used with a console, plug the third arm into the<br />

connector marked “3RD ARM.” Securely attach the green<br />

ground wire to the stud with the nut provided. If used with a<br />

base cap, plug the third arm into the connector on the back<br />

of the base cap housing. Once again, securely attach the<br />

green ground wire to the stud with the nut provided.<br />

Binding<br />

Posts<br />

IN-<strong>7900</strong> 9<br />

!

10<br />

2.6. refractor suspension - Dual lock<br />

2.6.1. Unpack the refractor suspension arm. Slide the<br />

clamp member carefully down over the support column until<br />

positioned as shown in Figure 1. Tighten the clamp screw<br />

securely, using the hex key wrench provided.<br />

2.6.2. Note that the chrome plug button in the front of<br />

the assembly covers the counterbalance spring adjusting<br />

screw. If necessary, after the instrument is attached to the<br />

suspension, remove this button and adjust the screw, turning<br />

it clockwise to increase tension. Optimum adjustment is<br />

reached when the suspension barely supports the weight<br />

at the upper limit of it’s travel. The suspension will support<br />

instruments weighing a maximum of 20 pounds.<br />

2.7. refractor suspension-single lock<br />

2.7.1. Unpack the refractor suspension. Slide the clamp<br />

member carefully down over the support column until<br />

positioned as shown in Figure 1. Tighten the clamp screw<br />

securely, using the hex key wrench provided.<br />

2.7.2. After the refractor is mounted on the suspension<br />

arm, the counter balance spring may require adjustment.<br />

The 1/2” adjustment screw may be found just below the<br />

cover by viewing the suspension from the support column.<br />

Turning the screw clockwise will increase tension. Optimum<br />

adjustment is reached when the suspension barely supports<br />

the weight at the upper limit of it’s travel. The suspension<br />

arm will support instruments weighing a maximum of 20<br />

pounds.<br />

2.8. Overhead lamp<br />

2.8.1. Unpack the lamp assembly. Remove the small screw<br />

near the top of the support column. Feed the plug and coiled<br />

extension cord into the tip of the support column until the<br />

lamp support member can be inserted into the column.<br />

Replace the screw previously removed.<br />

2.8.2 Remove the support tube pin (Item11, Fig. 20) to<br />

allow the lamp cord plug to drop free of the support column.<br />

Replace the support pin, being careful not to pinch the lamp<br />

cord.<br />

Insert the plug from the overhead lamp extension into the<br />

matching connector hanging down from the console in the<br />

rear of the unit.<br />

When all connections have been completed, replace the<br />

back cover.<br />

2.9 slit lamp arm<br />

2.9.1. After slit lamp arm is unpacked and set into place,<br />

the option of changing the instrument stand can be done at<br />

this time. For example if the unit is order as a right-handed<br />

and needed to be changed to left-handed unit; follow the<br />

listed instructions below.<br />

2.9.1.1 To convert the Slit Lamp Arm to a left-handed unit,<br />

remove the four (4) #8-32 Screws that hold the Cover<br />

Plates with the Outlet and Rocker Switch. Carefully pull<br />

the Plates off of the Upper Arm. Loosen the center Screw<br />

holding the two plates together but do not completely<br />

remove it. Pull the two Plates apart and rotate them so<br />

the Outlet and Rocker Switch are now on the opposite<br />

side of the Upper Arm. Place the Plates back into the<br />

recessed area of the Upper Arm. Be careful not to pinch<br />

any wires between the Plates and the Upper Arm when<br />

making this change.<br />

2.9.1.2 Loosen the three Set Screws that lock the Arm<br />

Extension in place at the end of the Slit Lamp Arm. Loosen<br />

the Black Knob on top of the Slit Lamp Arm.Rotate Arm<br />

Extension so it is approximately 60 degrees from the side<br />

of the Upper Arm of the Slit Lamp Arm and tighten the Set<br />

Screws. Tighten the Black Knob on top of the Slit Lamp<br />

Arm. Remove Adjustable Handle and Plug Button from the<br />

Arm Extension and place them on the opposite side they<br />

were on. (See Figure 4) and (See Figures 4a, 4b, 4c, 4d<br />

page 10 and Figure 27 page 42 for details.)<br />

Voltage laBel<br />

outlet<br />

oPPosite side<br />

uPPer arm CoVer Plate, Plain<br />

uPPer arm CoVer Plate<br />

#8-32 tHms<br />

PusH Button sWitCH W/ ir (sHoWn)<br />

Plug Button W/o ir<br />

Figure 4<br />

roCKer<br />

sWitCH<br />

#8-32 PHms<br />

IN-<strong>7900</strong>

Figure 4a Figure 4b<br />

Figure 4C Figure 4D<br />

reference to changing the instrument stand from a right-handed to a left-hand unit.<br />

IN-<strong>7900</strong> 11

12<br />

2.10. Final assembly<br />

2.10.1. Console<br />

If an additional instrument is to be connected to the binding<br />

posts or if any auxiliary equipment is to be plugged into<br />

the”AUX” power connector, make these connections at<br />

this time.<br />

2.11. Chair assembly<br />

2.11.1 The chair control switches located on the floor unit<br />

may control any Reliance® low voltage chair. Refer to the<br />

chair instructions for unpacking and assembling the chair.<br />

2.11.2. A chair control cable is provided to control the<br />

vertical movement of the chair base from the floor unit.<br />

One end of the cable is to be inserted into the black circular<br />

receptacle on the Outlet Plate Assembly. See Figure 5. The<br />

other end of the cable is to be inserted into the mating<br />

receptacle marked “CHAIR CONTROL CABLE” in the rear of<br />

your Reliance® chair.<br />

2.12. miscellaneous<br />

Figure 5<br />

2.12.1. When attaching an instrument to the slit lamp arm,<br />

note the thrust bearing which should be in place between<br />

the instrument and the arm.<br />

2.12.2. Proper balance of an instrument on the slit lamp<br />

arm is achieved by adding or removing counter-balance<br />

weights as shown in Figure 6. See Page 12 for a table of<br />

weight settings.<br />

2.12.3 Finally, plug the power cord into a wall receptacle<br />

and check all electrical functions as described in the<br />

Installation and Operating Instructions. If all functions are<br />

normal, reattach the base unit rear cover.<br />

2.12.4 To disconnect power to <strong>Instrument</strong> <strong>Stand</strong> unplug<br />

power cord from wall receptacle.<br />

nOTe: Outlet wires are hot.<br />

nOTe : Les fils de sortie sont chauds<br />

CauTiOn-“accessory equipment connected<br />

to the analog and interfaces must be certified<br />

according to the respective ieC standards<br />

(i.e. ieC 950 for data processing equipment<br />

and ieC 601-1 for medical equipment).<br />

Furthermore all configurations shall comply<br />

with the system standard ieC 601-1-1.<br />

everybody who connects additional equipment<br />

to the signal input part or output part<br />

configures a medical system, and is therefore<br />

responsible that the system complies with<br />

the requirements of ieC 601-1-1. if in doubt,<br />

consult the technical services department or<br />

your local representative.”<br />

equipment with siP/sOP connectors should<br />

either indicate the connected equipment<br />

comply with ieC 601-1 and/or ieC 601-<br />

1-1 harmonized national standard or the<br />

combination should be evaluated.<br />

aTTenTiOn- “les équipements branché sur<br />

le support ophtalmique doivent répondre aux<br />

normes ieC (i.e. ieC 950 pour le matériel<br />

informatique et le ieC 601-1 pour le matériel<br />

médical). en outre toutes les configurations<br />

devront étre conformes á la norme ieC<br />

601-1-1.<br />

Tout personne qui branché un équipement<br />

supplémentaire au systéme doit s’assurer<br />

que cet équipement répond aux normes<br />

médicales ieC 601-1-1 et en est responsable.<br />

en cas de doute, consultez le service<br />

technique de votre distributeur ou votre<br />

préposé technique local.”<br />

le matériel avec des connecteurs de type<br />

siP/sOP devront être conformes à la norme<br />

ieC 601-1 et/ou être conformes à la norme<br />

nationale harmonisée ieC 601-1-1.<br />

IN-<strong>7900</strong>

3. OPeraTing insTruCTiOns<br />

3.1. slit lamp arm<br />

3.1.1. This arm is counterbalanced by means of weights<br />

and all its movements are controlled manually.<br />

3.1.2. The vertical lock for this arm is controlled by the<br />

release lever located under the upper arm. (See Figure 1),<br />

grip the upper arm and depress the release lever to unlock<br />

the arm. Releasing the release lever will lock vertical travel<br />

in both directions.<br />

SLIT LAMP<br />

TABLE<br />

Warning- arm Will rise abruPTlY iF<br />

release leVer is DePresseD anD arm<br />

is nOT COunTer-balanCeD.<br />

aVerTissanT- le bras COnTrebalanCÉ<br />

remOnTera PrOmPTemenT si le leVier<br />

Du Frein esT enFOnCÉ eT Que le bras<br />

n’esT Pas COnTrebalanCÉ.<br />

BEARINGS<br />

OUTER ARM<br />

SET SCREWS<br />

(6)<br />

Figure 6<br />

LEVELING<br />

SLEEVE<br />

OUTERMOST<br />

HANDLE<br />

3.1.3. Incremental weights are added or removed to<br />

achieve proper balance in accordance with the weight<br />

settings-slit lamp arm chart. (See Figure 7).<br />

3.1.4. The handle under the innermost pivot point of<br />

the slit lamp arm (Figure 1), is to restrain rotation of the<br />

complete arm assembly. The handle at the intermediate<br />

joint on the slit lamp arm locks rotation of the outer arm<br />

section. The handle and set screws directly under the slit<br />

lamp locks rotation of the outer arm section. The handle<br />

directly under the slit lamp locks rotation of the instrument<br />

about its pivot point.<br />

instrument gross<br />

weight-lbs.(kg)<br />

12-16 ( 5.44-7.25) None<br />

16-20 ( 7.25-9.0) Light<br />

20-23 ( 9.0-10.43) Medium<br />

23-25 ( 10.43-11.34) Heavy<br />

incremental weights<br />

25-28 ( 11.34-12.7) Light, Medium<br />

28-30 ( 12.7-13.6) Light, Heavy<br />

30-33 ( 13.6-14.97) Medium, Heavy<br />

33-35 ( 14.97-15.88) 2 Heavy<br />

35-38 ( 15.88-17.24) Light, Medium, Heavy<br />

38-40 ( 17.24-18.14) 1 Light, 2 Heavy<br />

40-43 ( 18.14-19.5) 1 Medium, 2 Heavy<br />

43-45 ( 19.5-20.41) 3 Heavy<br />

45-48 ( 20.41-21.77) 1 Light, 1 Medium, 2 Heavy<br />

48-50 ( 21.77-22.68) 1 Light, 3 Heavy<br />

50-53 ( 22.68-24.04) 1 Medium, 3 Heavy<br />

53-55 ( 24.04-24.95) 4 Heavy<br />

55-58 ( 24.95-26.31) 1 Light, 1 Medium, 3 Heavy<br />

58-60 ( 26.31-27.22) 1 Light, 4 Heavy<br />

Weight settings-slip lamp arm Chart<br />

3.1.5. The outer end of the slit lamp arm contains a sleeve<br />

and six set screws for field re-leveling of the instrument, if<br />

necessary. A hex key wrench (1/8) and a small, accurate<br />

level will be required. Remove the instrument from the table<br />

and refer to Figure 6.<br />

Warning- WiTh insTrumenT remOVeD,<br />

arm Will rise abruPTlY iF release<br />

leVer is DePresseD.<br />

aVerTissanT- lOrs Du reTraiT<br />

D’insTrumenT, le bras COnTrebalanCÉ<br />

remOnTera PrOmPTemenT si le lÈVera<br />

Du Frein esT enFOnCÉ.<br />

The outermost handle must be into the sleeve, but not<br />

tightened. Rotate the slit lamp arm to the examining position<br />

and tighten the other (2) handles. It may be necessary to<br />

loosen several set screws to reposition screws securely<br />

and check level.<br />

IN-<strong>7900</strong> 13

14<br />

Figure 7<br />

3.1.6. The handle on the outermost knob can be adjusted<br />

to any preferred, locked position. Simply pull out on handle,<br />

rotate as desired, and release.<br />

3.1.7. The outer arm contains an outlet for instrument<br />

power, and a rocker switch to control vertical movement<br />

of the chair. The Chair Control Cable (Item 17, Figure 22)<br />

must be installed. (refer to Section 2.10). Depress the “UP”<br />

arrow on the switch to raise the chair. Depress the “Down”<br />

arrow to lower the chair.<br />

nOTe: Switch action is momentary; but may<br />

be programmed to function as maintained<br />

depending on the chair model. See chair manual<br />

for programming instructions.<br />

n O T e : L’action de contact est<br />

momentanée ; mais peut être programmé<br />

pour fonctionner comme mis à jour selon<br />

le modèle de présidence. Voir le manuel<br />

de présidence pour des instructions de<br />

programmation.<br />

3.2. auxiliary (Third) arm<br />

3.2.1. Three handles control all motions of this arm<br />

assembly. The handle nearest the column controls rotation<br />

about the column. The handle at the pivot point of the outer<br />

arm controls both vertical movement and the rotation of the<br />

outer arm. The handle in the outer arm controls rotation of<br />

the instrument at the outermost pivot points.<br />

3.2.2. Adjustment of the spring counterbalance is as<br />

described in the Installation and Operating Instructions,<br />

Section 2.5.3. Plug the power cord into back cover.<br />

3.3. refractor suspension<br />

3.3.1. If the refractor suspension assembly is of the dual<br />

lock style, thehandle nearest the support column controls<br />

the clamp for locking rotation of the entire assembly about<br />

the column. The lever locks both vertical movement and<br />

rotation of the outer arm. If the refractor assembly is of the<br />

single lock style, the movements of the assembly around<br />

the column, the vertical position of the refractor and it’s<br />

rotation are all controlled by the single handle located<br />

below the arms.<br />

3.3.2. Refer to the Installation and Operating Instructions<br />

2.6 or 2.7 for the method of adjusting the counterbalancing<br />

spring.<br />

3.4. Overhead lamp<br />

3.4.1. Movements of the overhead lamp arms are<br />

controlled by friction and spring-compensated joints, each<br />

of which is adjustable. Tighten all three knobs with moderate<br />

hand pressure. This will allow you to move to move the lamp<br />

easily. The lamp should hold its position without repeated<br />

knob adjustments. The lamp has an ON/OFF switch located<br />

at the top of the head, which can be controlled separately<br />

from the instrument stand.<br />

3.5. instrument Console/base Cap<br />

3.5.1. The instrument console or Base Cap contains all<br />

electrical controls for the entire unit. Refer to Figure 8, 9<br />

& 10 for the location of controls.<br />

3.5.2. hand instrument Wells - rechargeable<br />

battery Type (Console only)<br />

3.5.2.1. The rechargeable battery type well is internally<br />

connected to the charging circuit at the factory and will<br />

charge instrument 3.5V NiCd batteries as long as the<br />

instrument handle is fully seated in the well.<br />

3.5.2.2. An indicator light (LED), located below each<br />

rechargeable well is supplied as a visual aid for determining<br />

that instrument is properly seated in the well and is<br />

recharging.<br />

IN-<strong>7900</strong>

CauTiOn- The lamp inside the instrument<br />

must be turned off before inserting the<br />

handle into the well. also, the wells will<br />

charge continuously as long as the power<br />

supply cord is attached to the floor unit.<br />

aVerTisseZ- l’ampoule de l’instrument<br />

doit être éteint avant de l’insérer dans le<br />

puits de charge et les puits chargeront<br />

continuellement la pile de l’instrument tout<br />

aussi longtemps que le support ophtalmique<br />

sera branché sur le secteur électrique.<br />

Figure 8<br />

WiThOuT inFrareD<br />

Figure 9<br />

WiTh inFrareD<br />

Figure 10<br />

baseCaP<br />

3.6. Front Panel Controls<br />

3.6.1. The controls for the stand are located on the panel<br />

above the instrument wells. Refer to Figure 6, 7 and 8 for<br />

identification of the various controls.<br />

3.6.1.1. standby switch (sTbY)<br />

• Turns secondary power ON and OFF to the system.<br />

• Turns the STBY, BASE, and AUTO LED’s ON.<br />

• Applies MAIN power to the S/L ARM and AUX power<br />

connectors if on.<br />

• Disables all system functions, except charging of the<br />

instrument wells when in the OFF position.<br />

IN-<strong>7900</strong> 15

16<br />

Warning- main POWer (120VaC Or<br />

240VaC) is alWaYs PresenT insiDe<br />

The sYsTem When The POWer COrD is<br />

PluggeD inTO The Wall.<br />

aVerTissanT- l’alimenTaTiOn ÉleC-<br />

TriQue De (120VaC Ou 240VaC) esT TOu-<br />

JOurs PrÉsenTe À l’inTÉrieur Du suP-<br />

POrT OPhTalmiQue QuanD Celui-Ci esT<br />

branChÉ sur le rÉseau ÉleCTriQue.<br />

3.6.1.2. auxiliary switch (aux)<br />

• Turns MAIN power ON and OFF to the AUX power<br />

connector.<br />

• Turns the AUX LED ON when MAIN power is applied to the<br />

AUX power connector.<br />

• The primary purpose of the switch is to turn the projector<br />

ON and OFF.<br />

3.6.1.3. lamp switch (lamp)<br />

• Turns the overhead lamp ON and OFF.<br />

• Turns the lamp ON at 50% intensity when the switch is<br />

pressed for the first time after the system’s power cord<br />

is plugged into the wall. Afterwards, the light will turn ON<br />

at its previous intensity level.<br />

• Turns the LAMP LED ON when power is applied to the<br />

overhead lamp.<br />

3.6.1.4. lamp Down switch<br />

• Decreases the intensity of the overhead lamp.<br />

3.6.1.5. lamp up switch<br />

• Increases the intensity of the overhead lamp.<br />

3.6.1.6 binding Post switch (b/P)<br />

• The B/P Switch is enabled when Switch 5 of SW2 is turned<br />

OFF. See Table 1.<br />

• When enabled, turns power to the binding posts (Indirect<br />

Ophthalmoscope) ON and OFF.<br />

• Turns the B/P LED ON when power is applied to the<br />

Ophthalmoscope.<br />

• When disabled, the B/P Switch has no function. Power to<br />

the Ophthalmoscope is controlled by the optional hanger<br />

assembly.<br />

3.6.1.7. b/P Down switch<br />

• Decreases the intensity of the Indirect Ophthalmoscope.<br />

3.6.1.8. b/P up switch<br />

• Increases the intensity of the Indirect Ophthalmoscope<br />

3.6.1.9. Chair base up switch<br />

• Causes the chair base to raise.<br />

3.6.1.10. Chair base Down switch<br />

• Causes the chair base to lower<br />

3.6.1.12. auto switch<br />

• On a low voltage 980, 7000, 710 or FX920 Chair, this<br />

switch causes the chair base to lower to its lowest position<br />

and the chair top to move to its full upright position.<br />

CauTiOn- The chair will move automatically.<br />

To sTOP chair movement, press the sTOP<br />

switch located on the side of the chair<br />

back.<br />

aVerTisseZ- la chaise ophtalmique se<br />

positionnera automatiquement. Pour<br />

arrêTer le mouvement de la chaise,<br />

appuyez sur le bouton “arrêT” situé du côté<br />

de la chaise.<br />

• On a low voltage 5200, 6200 or FXM920 Chair, this<br />

switch causes the chair base to lower to its lowest<br />

position. The chair top must be manually returned to it’s<br />

full upright position.<br />

CauTiOn- The chair will move automatically.<br />

To sTOP chair movement, press the sTOP<br />

switch located on the side of the chair<br />

back.<br />

aVerTisseZ- la chaise ophtalmique<br />

se positionnera automatiquement. Pour<br />

arrêTer le mouvement de la chaise,<br />

appuyez sur le bouton “arrêT” situé du côté<br />

de la chaise.<br />

• On an older high voltage chair, this switch causes the<br />

chair base to lower to its lowest position. The chair top<br />

does not move.<br />

CauTiOn- The chair will move automatically.<br />

To sTOP chair movement, press either the<br />

base uP or base DOWn switches located<br />

on the floor unit.<br />

aVerTisseZ- la chaise ophtalmique se<br />

positionnera automatiquement. Pour arrêTer<br />

le mouvement de la chaise, appuyez sur le<br />

bouton “hauT” ou “bas” situé sur le pédalier<br />

de la chaise.<br />

IN-<strong>7900</strong>

3.6.2<br />

• The round button under the “B/P” arrows is used to turn<br />

on and off the indirect hanger. The up and down arrows<br />

are used to control the output voltage (i.e. the intensity)<br />

of the indirect bulb.<br />

3.6.3<br />

• The round button under the “LAMP” arrows is used to turn<br />

on and off the overhead lamp. The up and down arrows<br />

are used to control the output voltage (i.e. the intensity)<br />

of the overhead lamp.<br />

3.7. Fuses<br />

�������<br />

Warning- DisCOnneCT FlOOr uniT FrOm<br />

main inPuT POWer beFOre PrOCeeDing<br />

WiTh eleCTriCal insPeCTiOns Or<br />

mainTenanCe.<br />

aVerTissemenT-DÉbranCheZ le<br />

suPPOrT OPhTalmiQue Du rÉseau<br />

ÉleCTriQue POur PrOCÉDer À une<br />

insPeCTiOns Ou mainTenanCe.<br />

CauTiOn- replace fuse(s) as marked. all<br />

fuses must be replaced with a fuse of the<br />

same size and rating. refer to the wiring<br />

diagrams on pages 56-59.<br />

l’aTTenTiOn- remplacement des fusible<br />

(s) tel qu’indiqué. Tous les fusibles doivent<br />

être remplacés avec un fusible de même<br />

taille et de même ampérage et/ou voltage.<br />

référez-vous aux diagrammes de câblage<br />

aux page 56-59.<br />

3.7.1. Floor units contain two fuses located inside the AC<br />

Input Module on the Outlet Plate Assembly.<br />

3.7.2. Consoles and Base Caps contain no additional<br />

fuses.<br />

3.7.3. Fuse replacement (aC input module)<br />

method for removing fuse drawer:<br />

1. The fuse drawer is located above the power cord.<br />

Remove the power cord.<br />

Place a small bladed screwdriver into appropriate slot<br />

(shown above) and push the flat spring towards the<br />

center of the power module until a click is heard. (Click<br />

may not be heard in all cases.) The drawer will come<br />

forward slightly.<br />

Once the flap has been pushed towards the center, the<br />

drawer will extend slightly beyond the power module.<br />

Remove the drawer by pulling it out by your fingers.<br />

CauTiOn- never install the drawer into the<br />

aC input module without fuses.<br />

aTTenTiOn- ne jamais introduire le<br />

module de support des fusibles sans avoir<br />

inséré les fusibles.<br />

IN-<strong>7900</strong> 17<br />

2.<br />

3.<br />

4.<br />

5.

18<br />

3.8. eCliPse rOOm lighT COnTrOl sYsTem<br />

The Eclipse Room Light Control System, available as an<br />

option on the Model <strong>7900</strong> instrument stands with console.<br />

The Eclipse System allows one to control examination room’s<br />

incandescent and/or fluorescent lights from the <strong>Instrument</strong><br />

<strong>Stand</strong>. This infrared (IR) system has a maximum of 16 different<br />

lighting combinations or scenes (dual zone). The Eclipse is<br />

available in either a single or dual zone system.<br />

The Eclipse console has an additional switch for room<br />

light controls (See Figure 11, switch marked “ROOM”) and<br />

a transmitter that attaches to the top of the support pole.<br />

The software in the unit is designed to operate a designated<br />

function on the stand. A signal is sent to a receiver that is<br />

installed in the in place of the room light switch. The signal is<br />

an infrared signal, the same technology as remote control.<br />

The signal tells the receiver what “scene” the lights being<br />

controlled need to go into. A scene is a lighting environment<br />

programmed into the receiver. Each function has its own<br />

scene which the user has the ability to manipulate. For<br />

example, removing the instrument from well #1 is scene 1.<br />

When the handle is removed the software tells the receiver<br />

to go to scene 1, and controls the light as scene 1 has<br />

been programmed.<br />

inFrareD signal<br />

Figure 11<br />

3.8.1. Dual Zone vs. single Zone<br />

3.8.1.1 A Zone refers to a bank of lights controlled by one<br />

room light switch. For example a room with a group of canned<br />

lights controlled by one switch and fluorescent controlled by<br />

another switch has two lighting zones. A dual zone system<br />

allows a scene to operate both zones and program them so<br />

the zones are programmed independently. When a handle is<br />

removed from well #1 the user can have one bank of lights<br />

dim and the other turn completely off. When the handle is<br />

replaced the lights go back to the original settings. A single<br />

zone system can only control one lighting zone.<br />

Dual Zone receiver/standard 2 Zone switch<br />

3.8.1.2. number of scenes<br />

Dual zone has 16 scenes or 8 functions on the instrument<br />

stand that can control room lights.<br />

• Room light switch.<br />

• B/P switch.<br />

• Auxiliary switch.<br />

• Lamp switch.<br />

• Switch on the slit lamp arm.<br />

Single zone is controlled by the room light switch.<br />

• Well #1.<br />

• Well #2.<br />

• B/P switch.<br />

• Switch on the slit lamp arm.<br />

The B/P switch and Slit lamp switch share the same<br />

scene.<br />

3.8.1.3 Program Features<br />

Dual zone system is programmed at the receiver mounted<br />

in the wall (see figure 17), while the single zones uses a<br />

hand held remote to program (see figure 16). The dual<br />

zone system allows one to set a fade rate of the lighting,<br />

while the single zone does not. The single zone requires<br />

the B/P switch and Slit lamp arm switch to share a scene,<br />

while dual zone does not.<br />

3.8.1.4 indirect hanger<br />

Both systems accept a indirect hanger which is mounted to<br />

the back of the pole. The hanger is designed so when the<br />

indirect is lifted off, the room lights go to the desired scene<br />

and the indirect comes on. Use of the hanger supersedes<br />

the B/P switch.<br />

IN-<strong>7900</strong>

3.8.2 incandescent vs. Fluorescent<br />

Both systems can accommodate fluorescent lighting.<br />

3.8.2.1 single Zone<br />

This system can only dim fluorescent. It requires a special<br />

receiver and dimming ballast installed to the lighting system.<br />

Incandescent only requires installing the receiver in lieu of<br />

the standard wall switch.<br />

installation Diagram: single Zone incandescent<br />

120 VaC or 277 VaC<br />

120V<br />

60 Hz<br />

Hot<br />

line<br />

side<br />

neutral<br />

BlaCK<br />

note: See Installation Instructions that comes<br />

with Receiver.<br />

note: Voir les instructions d’installation<br />

accompagnant le récepteur.<br />

BlaCK<br />

load<br />

side<br />

ConneCtion diagram<br />

BlaCK Wire must attaCH to<br />

line side only<br />

BlaCK Wire must attaCH to<br />

load side only<br />

Figure 12<br />

3.8.2.2 Dual Zone<br />

This system can either turn fluorescent on and off or dim.<br />

Turning the fluorescent on and off does require a relay<br />

assembly to be installed. Dimming fluorescent involves<br />

installing a dimming ballast and an interface, figure 20<br />

(note dimming ballast, figure 21 is purchased separate).<br />

Incandescent lighting is a direct install. The receiver replaces<br />

the dual light switches already in the wall.<br />

IN-<strong>7900</strong> 19<br />

load<br />

neutral

20<br />

installation Diagram: Dual Zone Flourescent On/OFF incandescent<br />

120 VaC or 277 VaC<br />

Resistor needs to be mounted. Recommended box to house relay and resistor- 6” x 6” x .04” thick and<br />

made of aluminum.<br />

note: See Grafik Eye for installation of GRX.<br />

Figure 13<br />

note : Voir l’oeil diagramme pour l’installation de GRX.<br />

IN-<strong>7900</strong>

Warning-The eCliPse inFrareD rOOm<br />

lighTs COnTrOl sYsTem musT maTCh<br />

The reQuiremenTs OF The user. iF The<br />

sYsTem is nOT PrOPerlY COnFigureD<br />

beFOre seCOnDarY POWer TO The uniT is<br />

TurneD On Via The sTbY sWiTCh, Damage<br />

TO The sYsTem Or insTrumenT bulbs<br />

maY OCCur.<br />

aVerTissanT-le sYsTÈme De COnTrôle<br />

inFrarOuge D’ÉClairage ÉCliPse DOiT<br />

COrresPOnDre aux COnDiTiOns De<br />

l’uTilisaTeur. si le sYsTÈme n’esT<br />

Pas COrreCTemenT COnFigurÉ aVanT<br />

D’allumer le suPPOrT OPhTalmiQue, Par<br />

le COnTrôle “sTbY”, Des DOmmages au<br />

suPPOrT Ou aux amPOules ÉleCTriQues<br />

PeuVenT se PrODuire.<br />

ECLIPSE ROOM LIGHT SYSTEM<br />

Press Here<br />

to turn oFF<br />

indireCt<br />

BulB ratings<br />

slit lamP<br />

BulB ratings<br />

sW2-1<br />

sW2-2<br />

sW2-3<br />

Hanger<br />

BeeP on<br />

oPen<br />

sW2-7<br />

sW2-8<br />

Press Here<br />

to turn on<br />

oFF<br />

sW2<br />

REAR VIEW OF CONSOLE ASSEMBLY<br />

eCliPse inFrareD rOOm lighT COnTrOls<br />

PrOgramming guiDe<br />

Configuring the system is accomplished by setting dip<br />

switches found on the circuit board. The dip switches<br />

are labeled SW1 and SW2. The following paragraphs<br />

provide the necessary information required to configure<br />

the system.<br />

sWiTChPaCk #1 (sW1)<br />

switch 1<br />

• Turn Switch 1 OFF if your system contains a single-zone<br />

infrared receiver.<br />

• Turn Switch 1 ON if your system contains a dual-zone<br />

infrared receiver (Factory default setting).<br />

1 2 3 4 5 6 7 8<br />

oFF<br />

sW1<br />

1 2 3 4 5 6 7 8<br />

enaBle-on<br />

dual Zone<br />

Well #1<br />

Well #2<br />

Well #3<br />

Binding Post<br />

s/l arm<br />

auXiliary<br />

lamP<br />

switch 2<br />

• Turn Switch 2 ON to enable Well #1 to affect room lights<br />

and fixation lights.<br />

• Turn Switch 2 OFF to disable Well #1 from affecting room<br />

lights and fixation lights.<br />

switch 3<br />

• Turn Switch 3 ON to enable Well #2 to affect room lights<br />

and fixation lights.<br />

• Turn Switch 3 OFF to disable Well #2 from affecting room<br />

lights and fixation lights.<br />

switch 4<br />

• Turn Switch 4 ON to enable Well #3 to affect room lights<br />

and fixation lights.<br />

• Turn Switch 4 OFF to disable Well #3 from affecting room<br />

lights and fixation lights.<br />

switch 5<br />

• If power to the Indirect Ophthalmoscope is controlled by<br />

the B/P Switch on the front panel, turn Switch 5 ON if<br />

you want the B/P Switch to affect room lights.<br />

• Turn Switch 5 OFF if you do not want the B/P Switch to<br />

affect room lights.<br />

switch 6<br />

• Turn Switch 6 ON to enable Slit Lamp Arm Switch to affect<br />

room lights.<br />

• Turn Switch 6 OFF to disable Slit Lamp Arm Switch from<br />

affecting room lights.<br />

switch 7<br />

• Turn Switch 7 ON to enable the AUX1 Switch to affect<br />

room lights.<br />

• Turn Switch 7 OFF to disable the AUX1 Switch from<br />

affecting room lights.<br />

switch 8<br />

• Turn Switch 8 ON to enable the LAMP Switch to affect<br />

room lights.<br />

• Turn Switch 8 OFF to disable the LAMP Switch from<br />

affecting room lights.<br />

IN-<strong>7900</strong> 21

22<br />

SWitchpAck #2 (SW2)<br />

switch 1 through 3<br />

These switches are used to determine the type and voltage of<br />

the Indirect Ophthalmoscope bulb. See the Chart below.<br />

B UL B VOL T AG E A ND T Y P E -IND. OP HT HA L MOS C OP E<br />

S witch 1 2 3<br />

6.5V /18W, Incandescent OF F OF F OF F<br />

R S V D Incandescent ON OF F OF F<br />

R S V D Incandescent OF F ON OF F<br />

R S V D Incandescent ON ON OF F<br />

6V /10W Halogen OF F OF F ON<br />

6V /20W Halogen ON OF F ON<br />

12V /12W Halogen OF F ON ON<br />

R S V D Halogen ON ON ON<br />

switch 4<br />

• Turn Switch 4 ON if your system contains a indirect<br />

hanger (Figure 13) for an Indirect Ophthalmoscope and<br />

you want that hanger to automatically supply power to<br />

the instrument.<br />

note: Turn Switch 5 on SW1 OFF if turning Switch<br />

4 ON.<br />

note: Positionnez le contact 5 á la position<br />

arrêt sur l’interrupteur SW1 et positionnez le<br />

contact 4 EN position MARCHE.<br />

• Turn Switch 4 OFF if your system does not contain a hanger<br />

for an Indirect Ophthalmoscope. In this case, power is<br />

turned ON and OFF to the instrument via the B/P Switch<br />

on the front panel (See Switch 5 on SW1).<br />

switch 5<br />

• If you want your system to beep whenever a switch is<br />

pressed , set Switch 5 ON.<br />

• If you do not want to hear a beep whenever a switch is<br />

pressed, set Switch OFF.<br />

switch 6<br />

• Reserved<br />

switches 7 and 8<br />

These switches are used to determine the type and voltage<br />

of the Slit Lamp bulb. See chart to the above right.(DOES<br />

NOT APPLY TO INSTRUMENT STANDS)<br />

B UL B VOL T AG E A ND T Y P E -S L IT L A MP B UL B<br />

S witch 7 8<br />

6V /4.5A, Incandescent OF F OF F<br />

R S V D ON OF F<br />

6V /20W Halogen OF F ON<br />

12V /30W Halogen ON ON<br />

standby switch (sTbY)<br />

• OFF- Unit is deactivated, except for charging wells.<br />

• ON- Activates all unit functions<br />

Figure 14<br />

(F actory default)<br />

auxiliary switch (aux1)<br />

• Affects the room lights and is programmable.<br />

• See section 3.8.3 for programming instructions if you<br />

have a single-zone infrared receiver.<br />

• See Switch 7 of Switchpack #1 in the Programming<br />

Instructions section of this manual for details.<br />

IN-<strong>7900</strong>

oom switch (rOOm)<br />

• Dual Zone turns the ROOM Lights OFF or ON to a<br />

pre-programmed intensity.<br />

• Single Zone turn ROOM Lights OFF or full ON.<br />

room Down switch<br />

• Decreases the intensity of the ALL room light(s).<br />

room up switch<br />

• Increases the intensity of the ALL room lights(s).<br />

lamp switch (lamP)<br />

• Affects the room lights and is programmable.<br />

• See section 3.8.3 for programming instructions if you<br />

have a single-zone infrared receiver.<br />

• See Switch 8 on Switchpack #1 in the Programming<br />

Instructions Section of this manual for details<br />

binding Post switch (b/P)<br />

• Affects the room lights and is programmable.<br />

• See section 3.8.3 for programming instructions if you<br />

have a single-zone infrared receiver.<br />

• See Switch 5 on Switchpack #1 in the Programming<br />

Instructions Section of this manual for details.<br />

hanger switch<br />

• Affects the room lights and is programmable.<br />

• See Switch 4 on Switchpack #2 in the Programming<br />

Instructions Section of this manual for details.<br />

Hanger<br />

Binding Posts<br />

toggle sWitCH<br />

rHeostat<br />

Figure 15<br />

inDireCT hanger sWiTCh<br />

• See section 3.8.3 for programming instructions if<br />

you have a single-zone infrared receiver.<br />

slit lamp switch<br />

• Affects the room lights and is programmable.<br />

• See section 3.8.3 for programming instructions if you<br />

have a single-zone infrared receiver.<br />

• See Switch 6 on Switchpack #1 in the Programming<br />

Instructions Section of this manual for details.<br />

• Push button at the beginning of Slit Lamp examination,<br />

then push button again after examination is complete.<br />

Well #1<br />

• Controls room light(s) when the rechargeable instrument<br />

is removed from well.<br />

• When the instrument is returned to the well, the room lights<br />

return to Scene #1. See section 3.8.3 for Programming<br />

Instructions.<br />

• See Switch 2 on Switchpack #1.<br />

Well #2<br />

• Controls room light(s) when the rechargeable instrument<br />

is removed from the well.<br />

• When the instrument is returned to the well, the room lights<br />

return to Scene #1. See section 3.8.3 for Programming<br />

Instructions.<br />

• See Switch 3 on Switchpack #1.<br />

Well #3<br />

• Controls room light(s) when the rechargeable instrument<br />

is removed from the well.<br />

• When the instrument is returned to the well, the room lights<br />

return to Scene #1. See section 3.8.3 for Programming<br />

Instructions.<br />

• See Switch 4 on Switchpack #1.<br />

3.8.3 Programming single Zone room lights<br />

3.8.3.1. Point the remote control (See Figure 14) at the<br />

single zone receiver. (See Figure 16)<br />

3.8.3.2. Toggle the Room Lights Settings switch up or<br />

down to set the room lights at the desired intensity.<br />

3.8.3.3. Press the switch designated for a section of the<br />

instrument stand.<br />

3.8.3.4. Maintain pressure on the switch until the small<br />

LED located next to the receiver begins to blink.<br />

Example:<br />

If one sets the room light for use while using Well #1.<br />

Follow steps 1 and 2. Press the second switch from the<br />

top of the remote (Figure 14) until the LED next to it blinks.<br />

Now when Well #1 is removed, the room lights will dim<br />

down to the designated level.<br />

IN-<strong>7900</strong> 23

22<br />

room ligHts on<br />

Well #1<br />

Well #2<br />

slit lamP arm & Binding Post<br />

room ligHts oFF<br />

room ligHt settings<br />

Figure 16<br />

Wireless remOTe COnTrOl<br />

3.8.4 Programming Dual Zone room lights<br />

3.8.4.1. Confirm that the STBY switch is lit and<br />

activated.<br />

3.8.4.2. Operate one of the functions at the instrument<br />

stand (eg. Remove a handle from a well, depress the<br />

B/P switch etc.).<br />

3.8.4.3. Raise the tinted, hinged cover located above<br />

the white panel on the receiver. (See Figure 15)<br />

3.8.4.4. Using the intensity switches lowers or raises<br />

the intensity of lighting in the room.<br />

3.8.4.5. Return the stand to its original condition (return<br />

handle to well, depress the B/P switch etc.) That function<br />

is now programmed.<br />

3.8.4.6. The fade rate for each lighting function may<br />

be controlled by the arrow buttons located below the<br />

fade window.<br />

3.8.4.7. Each function on the stand can be programmed<br />

as above.<br />

Zone<br />

numBer<br />

intensity<br />

raise/loWer<br />

Fade<br />

time<br />

Zone<br />

oVerride<br />

Figure 17<br />

Dual ZOne reCeiVer<br />

Hinged CoVer<br />

master<br />

raise/<br />

loWer<br />

Zone<br />

intensity system<br />

oFF<br />

sCene<br />

seleCts<br />

IN-<strong>7900</strong>

P/N 17185<br />

0.22<br />

Figure 18<br />

single ZOne reCeiVer<br />

2.60<br />

1.44<br />

4.12<br />

1.28<br />

BlaCK Wire<br />

BlaCK Wire<br />

gnd Wire<br />

IN-<strong>7900</strong> 25<br />

2.58<br />

note: See Installation Instructions that comes with Receiver.<br />

1.71<br />

note: Voir les instructions d’installation accompagnagt le récepteur.<br />

ir reCeiVer lens<br />

2.16

26<br />

Fade<br />

time<br />

Zone<br />

oVerride<br />

intensity Zone<br />

raise/loWer numBer<br />

Zone<br />

intensity<br />

5.31<br />

P/N 17186<br />

Hinged CoVer<br />

6.55<br />

2.13<br />

.36<br />

sCene<br />

seleCts<br />

system<br />

oFF<br />

master<br />

raise/<br />

loWer<br />

notes:<br />

desCriPtion: reCeiVer, i.r., tWo-Zone<br />

manuFaCturer: lutron eleCtroniCs Co., inC.<br />

7200 suter road<br />

CooPersBurg, Pa. 18036<br />

model no.: grX-3102-t-WH<br />

i.r. Codes: tHis Part numBer is<br />

ProPrietary to lutron<br />

no. oF Zones: 2<br />

unit CaPaCity: 1200 Watts/Va total<br />

mounts in u.s.<br />

WallBoX: 2-gang, 3.5" deeP, (2.75" dP min)<br />

enVironmental: 32-104°F (0-40°C)<br />

PoWer: inPut PoWer: 120VaC<br />

Zone CaPaCity: standard: 25-800 Watts/Va Per<br />

Zone (oPtional: uP to 30,000 W/Va<br />

Per Zone Via ngrX-PB PoWer<br />

Booster or Hi-PoWer 2-4-6<br />

dimming modules.)<br />

Figure 19<br />

Dual ZOne reCeiVer<br />

note: See Installation Instructions that comes with Receiver.<br />

note: Voir les instructions d’installation accompagnant le récepteur.<br />

.18<br />

2.06<br />

4.48<br />

Closed<br />

CoVer<br />

2.61<br />

.88<br />

3.28<br />

.33<br />

.97<br />

.94<br />

Ø.188 X .312<br />

4 PlaCes,<br />

mounting Holes<br />

ssa<br />

Zone 2<br />

Hot<br />

sW Hot<br />

neutral<br />

Zone 1<br />

1.50<br />

3.34<br />

5.17<br />

4<br />

3<br />

2<br />

1<br />

Class 2<br />

Cu Wire<br />

only<br />

load tyPes: inCandesCent<br />

FluoresCent (dim or non-dim)<br />

reQuires grX-FdBi FluoresCent<br />

interFaCe, relianCe P/n 17187<br />

or Hi-PoWer 2-4-6 dimming<br />

module, relianCe P/n 17188<br />

ligHting<br />

Control: sCenes: 16 standard<br />

Fade time: 0-59 seC ir 1-60 min.<br />

aCCessory: oPerating Voltage: Class 2, 12VdC<br />

Via 4 loW Voltage terminals tHat<br />

aCCePt (2) #18 aWg (1.0 mm)<br />

For maXimum PerFormanCe tHe FaCe oF tHe<br />

reCeiVer sHould Be mounted PerPendiCular to<br />

tHe transmitter.<br />

see installation diagram B-17475 WHen using<br />

non-dimming FluoresCent ligHts.<br />

see installation diagram B-17476 WHen using<br />

dimming FluoresCent ligHts.<br />

IN-<strong>7900</strong>

P/N 17187<br />

Figure 20<br />

FluOresCenT inTerFaCe<br />

IN-<strong>7900</strong> 27

28<br />

Figure 21<br />

insTallaTiOn Diagram-TWO ZOne WiTh FluOresCenT Dimming<br />

IN-<strong>7900</strong>

TrOubleshOOTing guiDe<br />

insTrumenT sTanD<br />

problem problem cause solution<br />

1) UNIT NOT GETTING POWER A) UNIT NOT PLUGGED INTO OUTLET A) PLUG POWER CORD INTO WALL<br />

2) CHAIR CONTROLS NOT<br />

FUNCTIONING<br />

B) BLOWN FUSE(S) B) REPLACE FUSE (S)<br />

C) BASE CAP OR CONSOLE NOT<br />

PLUGGED IN<br />

A) CHAIR CONTROL CABLE NOT<br />

CONNECTED TO STAND<br />

B) BASE CAP OR CONSOLE NOT<br />

CONNECTED TO CONTROL CABLE<br />

Should your <strong>Instrument</strong> <strong>Stand</strong> not perform properly, contact the Reliance®<br />

Distributor, where you purchased this product or contact the Technical<br />

Service Department, Reliance® Medical Products, Inc., 3535 Kings Mills<br />

Road, Mason, Ohio 45040-2303, or call (800) 735-0358.<br />

C) PLUG BASE CAP OR CONSOLE<br />

INTO BASE<br />

A) CONNECT CHAIR CONTROL<br />

CABLE TO STAND<br />

B) CONNECT BASE CAP OR<br />

CONSOLE TO CONTROL CABLE<br />

ON TOP OF THE STAND<br />

3) WELLS NOT RECHARGING A) UNIT NOT PLUGGED INTO OUTLET A) PLUG POWER CORD INTO WALL<br />

4) OVERHEAD LAMP NOT<br />

FUNCTIONING<br />

5) AUXILIARY ARM NOT<br />

RECEIVING POWER<br />

B) POOR CABLE CONNECTION B) CONNECT CABLE TO WELL PCB<br />

A) OVERHEAD LAMP NOT PLUGGED<br />

INTO "LAMP" OUTLET<br />

A) AUXILIARY ARM NOT PLUGGED<br />

INTO BASE CAP OR CONSOLE<br />

A) PLUG OVERHEAD LAMP INTO<br />

"LAMP" OUTLET<br />

A) PLUG AUXILIARY ARM INTO<br />

BASE CAP OR CONSOLE<br />

IN-<strong>7900</strong> 29

30<br />

1) ROOM LIGHTS NOT<br />

RESPONSIVE<br />

eClisPe rOOm lighT COnTrOl sYsTem<br />

problem problem cause solution<br />

2) SLIT LAMP ARM SWITCH<br />

DOES NOT EFFECT ROOM<br />

LIGHTS<br />

3) ROOM LIGHTS DO NOT<br />

RESPOND AS DESIRED<br />

4) WALL UNIT DOES NOT<br />

AFFECT LIGHTS<br />

A) LED IN TRANSMITTER DOES<br />

NOT EMIT RED LIGHT<br />

B) LED IN TRANSMITTER DOES<br />

EMIT RED LIGHT<br />

A) CHECK DIP SWITCHES FOR CORRECT<br />

SETTINGS<br />

A) INSURE THAT TRANSMITTER IS<br />

PROPERLY CONNECTED<br />

B) CHECK PROGRAMMING OFRECEIVER<br />

B) CHECK TO INSURE NO OBJECT IS<br />

POSITIONED IN FRONT OF TRANSMITTER<br />

OR RECEIVER<br />

B) INSURE THAT TRANSMITTER IS<br />

POINTED IN DIRECTION OF RECEIVER<br />

B) IF RECEIVER IS 5' OR LESS AWAY<br />

FROM STAND ADJUST POSITION OF<br />

TRANSMITTER SO IT IS DIRECTLY IN LINE<br />

WITH THE RECEIVER<br />

B) IF RECEIVER IS MORE THAN 5' AWAY<br />

FROM STAND PLACE THE TRANSMITTER<br />

AT TOP OF POLE<br />

A) UNIT NOT IN PROPER SCENCE A) ACTIVATE SWITCHES ON SLIT LAMP<br />

ARM AGAIN<br />

A) RECEIVER NOT PROGRAMMED<br />

CORRECTLY<br />

A) CHECK WIRING<br />

B) CHECK RECEIVER<br />

A) REPROGRAM RECEIVER<br />

A) CONTACT INSTALLER OF RECEIVER<br />

B) EXCHANGE RECEIVER<br />

IN-<strong>7900</strong>

Cleaning Painted surfaces<br />

The painted metal surfaces are covered in durable, powdercoated<br />

paint which is resistant to scratching and scuffing.<br />

It may be cleaned with a clean cloth dampened with mild,<br />

soapy water or equivalent household product that uses<br />

spray application.<br />

recommended infection Control Products<br />

The disinfectant/cleaner products that we have tested<br />

and recommend for our painted items and plastic covers<br />

are as follows.<br />

• Cavicide® Hospital Disinfectant<br />

• Precise® Hospital Foam Cleaner Disinfectant<br />

Cleaning stainless steel Face Plate<br />

• Non-Abrasive Pad<br />

Cleaning anD mainTenanCe<br />

CauTiOn- Follow manufacturer’s directions<br />

for concentration and application of<br />

disinfecting, material. avoid prolonged<br />

application of any disinfectant/ cleaner<br />

products, because they may cause staining<br />

or discoloration of material.<br />

aTTenTiOn- suivez les instructions du<br />

manufacturier pour la concentration et<br />

l’application des produits désinfection. Évitez<br />

l’application prolongée de tous les produits<br />

désinfectants nettoyants, parce qu’elles<br />

peuvent causer une détérioration ou une<br />

décoloration du produit.<br />

IN-<strong>7900</strong> 31

32<br />

note: When ordering parts, please:<br />

ParTs lisT<br />

relianCe® mODel <strong>7900</strong><br />

OPhThalmiC insTrumenT sTanD<br />

1. Advise dealer or factory of model and serial number of unit. These numbers are on the label<br />

that is located at rear, on back cover, of base unit.<br />

2. Specify color of painted parts. Painted parts have an asterisk(*) behind the part description.<br />

note : Lors d’une commande de pièces, s’il vous plaît :<br />

1. Avisez le distributeur ou le manufactunrier du modèle et du numéro de série de l’ensemble<br />

ophtalminque. Ces numéros apparaissent sur la plaque qui est située à l’arrière, près de la<br />

base, de l’unité centrale.<br />

2. Indiquez la couleur des pièces peintes. Les pièces peintes ont un astérisque (*) dans la<br />

description de la pièce.<br />

Should your <strong>Instrument</strong> <strong>Stand</strong> not perform properly, or if replacement<br />

parts are need, contact the Reliance® Distributor, where you purchased<br />

this product or contact the Technical Service Department, Reliance®<br />

Medical Products, Inc., 3535 Kings Mills Road, Mason, Ohio 45040-2303,<br />

or call (800) 735-0358.<br />

IN-<strong>7900</strong>

(nOTes)<br />

IN-<strong>7900</strong> 33

34<br />

(nOTes)<br />

IN-<strong>7900</strong>

19<br />

14<br />

21<br />

Figure 22<br />

mODel <strong>7900</strong> insTrumenT sTanD assemblY<br />

2<br />

6<br />

5<br />

10<br />

16<br />

3<br />

19<br />

23<br />

7<br />

13<br />

8<br />

9<br />

4<br />

15<br />

1<br />

22<br />

18<br />

11<br />

model and serial<br />

numBer Plate<br />

17<br />

20<br />

item part no. description item part no. description<br />

1 Base Assembly* (See Figure 23 ) 12 0514780 Collar-Chrome<br />

2 Slit Lamp Arm Assembly* (See Figure 27) 13 0722699 Sckt. H.S.S. 1/4 x 1/4<br />

3 Console* (See <strong>Instrument</strong> Console Section) 14 1677399 Lens<br />

4<br />

2034392 Dual B/P Assembly 15 0715799 Round H.M.S #10 x 1/4<br />

2034499 Twist Lock Hubbell Receptacle 16 1971599 Lock Cover<br />

2034503 Cover Plate - P.CT* 17 1550599 Chair Control Cable<br />

2040103 Indirect Receptacle Assembly<br />

1979592 <strong>Instrument</strong> Hanger Assembly<br />

18<br />

5 Refractor Arm Assembly* (See Figure 28,29) 2054092 Indirect Hanger Kit (I.R. Only)<br />

6 Auxiliary (Third) Arm* (See Figure 30) 19 2035199 Locking Handle<br />

7 525106 Lamp Assembly* 20 1659299 Power Cord Assembly<br />

8 0541680 Snap Plug 21 1677499 Retaining Ring<br />

9<br />

1974599 Support Tube (Shown) 22 1682199 Caution Label<br />

0537399 Column Stub 23 1969499 Lexan Shelf<br />

10 1569799 Bulb-12vdc, 20w, Type G4<br />

11 0503599 Support Pin<br />

24<br />

1568699 Chair Control Assembly (Not Shown)<br />

(used only to connect new stands to old<br />

chairs)<br />

IN-<strong>7900</strong> 35

36<br />

Figure 23<br />

base assemblY<br />

IN-<strong>7900</strong>

item part no. description item part no. description<br />

1 1598603 Base* 20 1974099 Bumper Pad<br />

2 1966892 <strong>7900</strong> Top Frame Assembly 21 0709399 Hex H.C.S. 1/2-13 x 3/4<br />

3 1971192 LH Side Panel 22 0708299 Hex H.C.S. 3/8-16 x 3/4<br />

4 1971092 RH Side Panel 23 0707199 Hex H.C.S. 5/16-18 x 1<br />

5 Outlet Plate Assembly*(See Figure 25) 24 0728399 Washer - Lock 5/16 Split<br />

6 0495599 Guide Rod 25 1734799 PHMS #10-32 x 3/8 W/Lock Washer<br />

7 0825584 Lift Bar Assembly 26 0729299 Washer - 1/2<br />

8 1971603 Side Panel Mounting Bracket - LH* 27 0728499 Washer - Lock 3/8 Split<br />

9 1971703 SIde Panel Mounting Bracket - RH* 28 1971292 <strong>7900</strong> Top Housing<br />

10 Roller Frame Assembly*(See Figure 24) 29 Back Cover Assembly* (See Figure 26)<br />

11 1225499 Lock Shaft ( in Item 10 ) 30 0591999 Cable Clamp<br />

12 1598799 Support Column 31 2034999 PHMS #8-32 x 3/8 W/Lockwasher<br />

13 2036099 1/2-20 Jam Nut 32 0705399 #8-32 Hex Nut<br />

14 0825392 Weight & Cable Assembly-45 lbs 33 1975099 Side Panel Clamp<br />

15 0548099 Counter Balance Weight - 10 lbs 34 0705599 #10-32 Keps Nut<br />

16 0548199 Counter Balance Weight - 7.5 lbs 35 1976399 Face Plate - Mount Bar<br />

17 0548299 Counter Balance Weight - 5 lbs 36 0821699 FHMS #8-32 x 3/8<br />

18 0513199 Cable Clamp 37 2035099 THMS #10-32 x 3/8<br />

19 0508599 3/8-16 Lock Nut 38 1282699 .625 Nylon Hole Plug<br />

To order complete Base Assembly use P/N’s.<br />

1967692 <strong>7900</strong> Base Assembly-120V*<br />

1967792 <strong>7900</strong> Base Assembly- 230V*<br />

*Please specify paint color when ordering.<br />

IN-<strong>7900</strong> 37

38<br />

10<br />

To order complete Roller Frame Assembly use P/N.<br />

1966192 <strong>7900</strong> Roller Frame Assembly*<br />

*Please specify paint color when ordering.<br />

7<br />

9<br />

Figure 24<br />

rOller Frame assemblY<br />

8<br />

6<br />

15<br />

5<br />

1<br />

4<br />

16<br />

2<br />

IN-<strong>7900</strong><br />

3

item part no. description<br />

1 1627295 Roller Frame*<br />

2 1663299 Ball Bearing<br />

3 1663699 Button H.C.S. 3/8 x 1<br />

4 0513099 Clamp Bracket<br />

5 0834992 Eccentric Bearing Assembly<br />

6 0789399 SCKT H.C.S. 5/16 x 1-1/4<br />

7 0728499 Lockwasher - 3/8 Split<br />

8 0729599 Washer - 3/8<br />

9 0730199 Washer - 5/16<br />

10 0728399 Lockwasher - 5/16 Split<br />

11 1225599 Lockshoe - Upper<br />

12 1225699 Lockshoe - Lower<br />

13 1730699 Wiring Clip<br />

14 1222399 Spring<br />

15 1970192 Coiled Cord Assembly-H.V. 3 Cond<br />