Technical Design Report Super Fragment Separator

Technical Design Report Super Fragment Separator

Technical Design Report Super Fragment Separator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DRAFT<br />

This leads to the design of a superferric magnet with warm iron (minimum cold mass, option →<br />

reduced cool down time) and potted (or vacuum-impregnated) low-current coils, wound with<br />

monolithic wire. Dipoles of this type are installed in the A1900 <strong>Fragment</strong>-<strong>Separator</strong> at MSU.<br />

The dipole magnets in the Main-<strong>Separator</strong> of the <strong>Super</strong>-FRS have a bending radius of 12.5 m and a<br />

maximum flux density of 1.6 T. Each dipole stage is build by 3 dipoles units having a deflection<br />

angle of 11° (Pre-<strong>Separator</strong>) and 9.75° (Main-<strong>Separator</strong>), respectively, which results in an effective<br />

path length of about 2.39 m (Pre-<strong>Separator</strong>) and 2.13 m (Main-<strong>Separator</strong>). We investigated several<br />

options for the iron design such as a C-shaped magnet, a D-shaped magnet, and a straight (rectangular)<br />

magnet. Advantages and disadvantages are summarized in Table 2.4.9. Considering the<br />

short length of one magnet unit the straight version is by far the simplest to fabricate.<br />

Table 2.4.9: Pros and cons of different magnet designs.<br />

C-shaped D-shaped Straight<br />

Pro 'minimum iron' solution<br />

Con<br />

difficult and expensive<br />

winding process due to<br />

negative curvature coil<br />

no negative curvature<br />

winding<br />

Variation of the lamination<br />

cross section along<br />

the magnet length<br />

no negative curvature<br />

winding<br />

pole widened by sagitta :<br />

'maximum iron' solution<br />

The prototyping of a superferric dipole magnet is under way in collaboration with the FAIR China<br />

Group of the Chinese Academie of Science.<br />

Magnetic design<br />

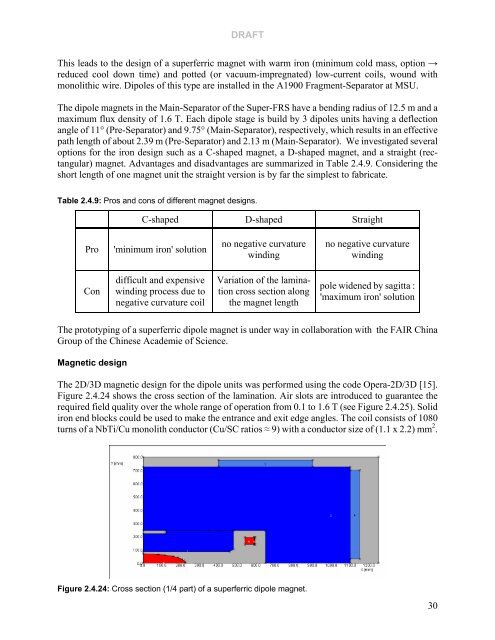

The 2D/3D magnetic design for the dipole units was performed using the code Opera-2D/3D [15].<br />

Figure 2.4.24 shows the cross section of the lamination. Air slots are introduced to guarantee the<br />

required field quality over the whole range of operation from 0.1 to 1.6 T (see Figure 2.4.25). Solid<br />

iron end blocks could be used to make the entrance and exit edge angles. The coil consists of 1080<br />

turns of a NbTi/Cu monolith conductor (Cu/SC ratios ≈ 9) with a conductor size of (1.1 x 2.2) mm 2 .<br />

Figure 2.4.24: Cross section (1/4 part) of a superferric dipole magnet.<br />

30