Technical Design Report Super Fragment Separator

Technical Design Report Super Fragment Separator

Technical Design Report Super Fragment Separator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

dE/dV [kJ/cm 3 ]<br />

3<br />

2<br />

1<br />

DRAFT<br />

including fragmentation<br />

incl. frag. and inclination<br />

0<br />

0 1 2 3 4 5 6<br />

z [cm] graphite<br />

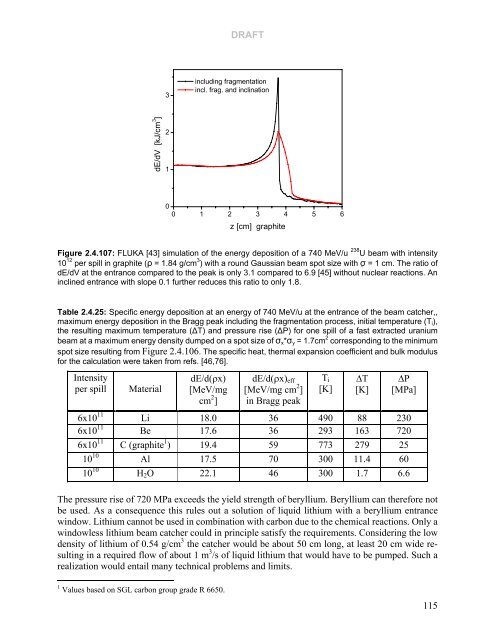

Figure 2.4.107: FLUKA [43] simulation of the energy deposition of a 740 MeV/u 238 U beam with intensity<br />

10 12 per spill in graphite (ρ = 1.84 g/cm 3 ) with a round Gaussian beam spot size with σ� = 1 cm. The ratio of<br />

dE/dV at the entrance compared to the peak is only 3.1 compared to 6.9 [45] without nuclear reactions. An<br />

inclined entrance with slope 0.1 further reduces this ratio to only 1.8.<br />

Table 2.4.25: Specific energy deposition at an energy of 740 MeV/u at the entrance of the beam catcher,,<br />

maximum energy deposition in the Bragg peak including the fragmentation process, initial temperature (Ti),<br />

the resulting maximum temperature (∆T) and pressure rise (∆P) for one spill of a fast extracted uranium<br />

beam at a maximum energy density dumped on a spot size of σx*σy = 1.7cm 2 corresponding to the minimum<br />

spot size resulting from Figure 2.4.106. The specific heat, thermal expansion coefficient and bulk modulus<br />

for the calculation were taken from refs. [46,76].<br />

Intensity<br />

per spill<br />

Material<br />

dE/d(ρx)<br />

[MeV/mg<br />

cm 2 ]<br />

dE/d(ρx)eff<br />

[MeV/mg cm 2 ]<br />

in Bragg peak<br />

Ti<br />

[K]<br />

∆T<br />

[K]<br />

∆P<br />

[MPa]<br />

6x10 11 Li 18.0 36 490 88 230<br />

6x10 11 Be 17.6 36 293 163 720<br />

6x10 11 C (graphite 1 ) 19.4 59 773 279 25<br />

10 10 Al 17.5 70 300 11.4 60<br />

10 10 H2O 22.1 46 300 1.7 6.6<br />

The pressure rise of 720 MPa exceeds the yield strength of beryllium. Beryllium can therefore not<br />

be used. As a consequence this rules out a solution of liquid lithium with a beryllium entrance<br />

window. Lithium cannot be used in combination with carbon due to the chemical reactions. Only a<br />

windowless lithium beam catcher could in principle satisfy the requirements. Considering the low<br />

density of lithium of 0.54 g/cm 3 the catcher would be about 50 cm long, at least 20 cm wide resulting<br />

in a required flow of about 1 m 3 /s of liquid lithium that would have to be pumped. Such a<br />

realization would entail many technical problems and limits.<br />

1 Values based on SGL carbon group grade R 6650.<br />

115