Compressors / compressed air - Aircraft

Compressors / compressed air - Aircraft

Compressors / compressed air - Aircraft

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

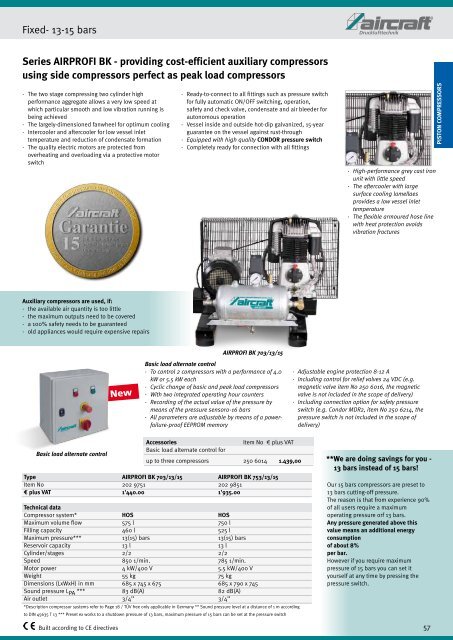

Fixed- 13-15 bars<br />

Series AIRPRoFI bK - providing cost-efficient auxiliary compressors<br />

using side compressors perfect as peak load compressors<br />

· The two stage compressing two cylinder high<br />

performance aggregate allows a very low speed at<br />

which particular smooth and low vibration running is<br />

being achieved<br />

· The largely-dimensioned fanwheel for optimum cooling<br />

· Intercooler and aftercooler for low vessel inlet<br />

temperature and reduction of condensate formation<br />

· The quality electric motors are protected from<br />

overheating and overloading via a protective motor<br />

switch<br />

Auxiliary compressors are used, if:<br />

· the available <strong>air</strong> quantity is too little<br />

· the maximum outputs need to be covered<br />

· a 100% safety needs to be guaranteed<br />

· old appliances would require expensive rep<strong>air</strong>s<br />

basic load alternate control<br />

New<br />

· Ready-to-connect to all fittings such as pressure switch<br />

for fully automatic ON/OFF switching, operation,<br />

safety and check valve, condensate and <strong>air</strong> bleeder for<br />

autonomous operation<br />

· Vessel inside and outside hot-dip galvanized, 15-year<br />

guarantee on the vessel against rust-through<br />

· Equipped with high quality ConDoR pressure switch<br />

· Completely ready for connection with all fittings<br />

AiRPROFi bK 703/13/15<br />

basic load alternate control<br />

· To control 2 compressors with a performance of 4.0<br />

kW or 5.5 kW each<br />

· Cyclic change of basic and peak load compressors<br />

· With two integrated operating hour counters<br />

· Recording of the actual value of the pressure by<br />

means of the pressure sensor0-16 bars<br />

· All parameters are adjustable by means of a powerfailure-proof<br />

EEPROM memory<br />

Accessories<br />

Basic load alternate control for<br />

Item No € plus VAT<br />

up to three compressors 250 6014 1.439,00<br />

Type AIRPRoFI bK 703/13/15 AIRPRoFI bK 753/13/15<br />

Item No 202 9751 202 9851<br />

€ plus VAT 1'440.00 1'935.00<br />

Technical data<br />

Compressor system* HoS HoS<br />

Maximum volume flow 575 l 750 l<br />

Filling capacity 460 l 525 l<br />

Maximum pressure*** 13(15) bars 13(15) bars<br />

Reservoir capacity 13 l 13 l<br />

Cylinder/stages 2/2 2/2<br />

Speed 850 1/min. 785 1/min.<br />

Motor power 4 kW/400 V 5.5 kW/400 V<br />

Weight 55 kg 75 kg<br />

Dimensions (LxWxH) in mm 685 x 745 x 675 685 x 790 x 745<br />

Sound pressure LPA ***<br />

Air outlet<br />

83 dB(A)<br />

3/4’’<br />

82 dB(A)<br />

3/4’’<br />

*Description compressor systems refer to Page 18 / TÜV free only applicable in Germany ** Sound pressure level at a distance of 1 m according<br />

to DIN 45635 T 13 *** Preset ex works to a shutdown pressure of 13 bars, maximum pressure of 15 bars can be set at the pressure switch<br />

· High-performance grey cast iron<br />

unit with little speed<br />

· The aftercooler with large<br />

surface cooling lamellaes<br />

provides a low vessel inlet<br />

temperature<br />

· The flexible armoured hose line<br />

with heat protection avoids<br />

vibration fractures<br />

· Adjustable engine protection 8-12 A<br />

· Including control for relief valves 24 VDC (e.g.<br />

magnetic valve item No 250 6016, the magnetic<br />

valve is not included in the scope of delivery)<br />

· Including connection option for safety pressure<br />

switch (e.g. Condor MDR2, item No 250 6214, the<br />

pressure switch is not included in the scope of<br />

delivery)<br />

**we are doing savings for you -<br />

13 bars instead of 15 bars!<br />

Our 15 bars compressors are preset to<br />

13 bars cutting-off pressure.<br />

The reason is that from experience 90%<br />

of all users require a maximum<br />

operating pressure orf 13 bars.<br />

Any pressure generated above this<br />

value means an additional energy<br />

consumption<br />

of about 8%<br />

per bar.<br />

However if you require maximum<br />

pressure of 15 bars you can set it<br />

yourself at any time by pressing the<br />

pressure switch.<br />

Built according to CE directives 57<br />

PISTon CoMPRESSoRS