Axial SWX Crawler reviewed in RRCi - CML Distribution

Axial SWX Crawler reviewed in RRCi - CML Distribution

Axial SWX Crawler reviewed in RRCi - CML Distribution

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

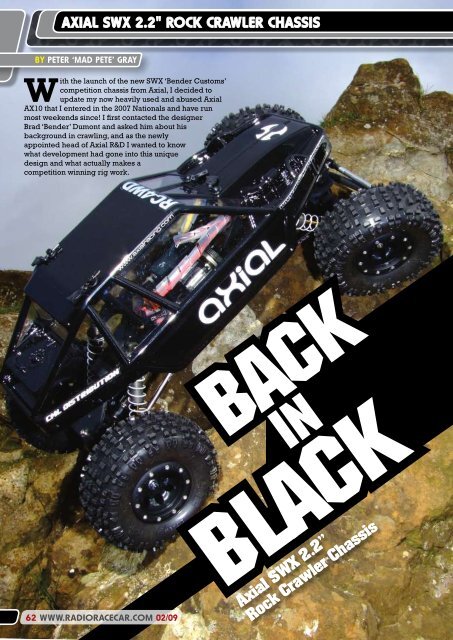

AxIAl sWx 2.2" ROCk CRAWlER ChAssIs<br />

By PEtER ‘MAD PEtE’ GRAy<br />

With the launch of the new <strong>SWX</strong> ‘Bender Customs’<br />

competition chassis from <strong>Axial</strong>, I decided to<br />

update my now heavily used and abused <strong>Axial</strong><br />

AX10 that I entered <strong>in</strong> the 2007 Nationals and have run<br />

most weekends s<strong>in</strong>ce! I first contacted the designer<br />

Brad ‘Bender’ Dumont and asked him about his<br />

background <strong>in</strong> crawl<strong>in</strong>g, and as the newly<br />

appo<strong>in</strong>ted head of <strong>Axial</strong> R&D I wanted to know<br />

what development had gone <strong>in</strong>to this unique<br />

design and what actually makes a<br />

competition w<strong>in</strong>n<strong>in</strong>g rig work.<br />

62 WWW.RADIORACECAR.COM 02/09<br />

back back<br />

<strong>in</strong><br />

black black<br />

<strong>Axial</strong> <strong>SWX</strong> 2.2”<br />

Rock <strong>Crawler</strong> Chassis

BItE My shINy DElRIN skIDPlAtE!<br />

Brad’s notoriety and the respect he’s garnered from<br />

enthusiasts worldwide all stems from his own product<br />

l<strong>in</strong>e that started with him compet<strong>in</strong>g <strong>in</strong> the 2.2" class <strong>in</strong><br />

Colorado and Moab. These competitions evolved <strong>in</strong>to<br />

him develop<strong>in</strong>g products such as the SW2, which Brad<br />

manufactured to sell to the general public under the<br />

name ‘Bender Customs’. The SW3 was the next chassis<br />

he designed which was essentially a no frills competition<br />

specification which went on to w<strong>in</strong> the 2007 RCCRawler.<br />

com ‘Peoples Choice Award’ for ‘Best Chassis’. After a<br />

short break from manufactur<strong>in</strong>g chassis, he designed the<br />

<strong>SWX</strong> chassis for <strong>Axial</strong> Rac<strong>in</strong>g’s AX10 kit. A culm<strong>in</strong>ation<br />

of four years of R&D, it’s by far the most compact and<br />

capable chassis he’s designed to date.<br />

‘MAD’ PEtE INtERVIEWs BRAD<br />

Here’s my <strong>in</strong>terview with the<br />

man himself, his thoughts and<br />

ideas on what makes a good<br />

competition rig perform and<br />

his views on the ever-grow<strong>in</strong>g<br />

crawler scene:<br />

Mad Pete: Where does the Bender <strong>in</strong><br />

Bender Customs come from then? I’m<br />

th<strong>in</strong>k<strong>in</strong>g Futurama, am I on the right<br />

track?<br />

Brad: You are correct, the name ma<strong>in</strong>ly<br />

comes from Futurama. That show cracks<br />

me up, and Bender is the best character<br />

on it <strong>in</strong> my op<strong>in</strong>ion<br />

So how long have you been <strong>in</strong>to R/C<br />

rock crawl<strong>in</strong>g?<br />

I’ve been R/C rock crawl<strong>in</strong>g s<strong>in</strong>ce 2000,<br />

but became heavily <strong>in</strong>volved with<br />

it when I stumbled upon RC<strong>Crawler</strong>.<br />

com <strong>in</strong> 2004. I won the 2006 USRCCA<br />

nationals with a rig I designed and built.<br />

Been compet<strong>in</strong>g all over the US for<br />

the last couple years. My first chassis<br />

design for the public was the SW2,<br />

which was designed to be a chassis<br />

that could be built with any axles out<br />

there. The next chassis was my SW3,<br />

which was designed to be strictly a 2.2<br />

comp chassis. Then I designed the <strong>SWX</strong><br />

hIs MAIN POINts ON BuIlDING A GOOD COMP RIG ARE As fOllOWs:<br />

• For a 4-l<strong>in</strong>ked chassis, l<strong>in</strong>k set-up, ride height<br />

and shock angle play the biggest role <strong>in</strong> how<br />

a rig performs<br />

• Have the upper and lower l<strong>in</strong>ks double triangulated<br />

• Ride height has to be set so the rig has a decent<br />

‘break over’ angle (ground clearance), but<br />

still set low enough to climb steep vertical faces<br />

• Driv<strong>in</strong>g style, as well as terra<strong>in</strong>, can play a big role<br />

too. Some people prefer wheel speed and some<br />

prefer a lot of torque, one set-up may not work<br />

for both situations. Experiment to see what’s<br />

good for you!<br />

around <strong>Axial</strong>’s AX10, which they decided<br />

to buy the rights too. I <strong>in</strong>terviewed with<br />

them shortly after that for a job as a<br />

product designer/R&D tester, which is<br />

now where I currently work <strong>in</strong> California.<br />

So where do you see rock crawl<strong>in</strong>g<br />

go<strong>in</strong>g <strong>in</strong> the future?<br />

For the future of R/C crawl<strong>in</strong>g I’d like<br />

to see the Super Class evolve more.<br />

I’m hop<strong>in</strong>g more companies will start<br />

to support this class. Right now there<br />

isn’t much support for it as far as<br />

aftermarket parts go. I th<strong>in</strong>k that’s the<br />

biggest reason that the attendance<br />

numbers for comps are down <strong>in</strong> that<br />

class. The 2.2 class seems to be gett<strong>in</strong>g<br />

all the attention lately, which is great to<br />

see but the Super Class is what really<br />

kicked this aspect of R/C off, and now it<br />

seems to have taken a back seat to the<br />

other classes. I also th<strong>in</strong>k that the scale<br />

trucks are go<strong>in</strong>g to receive a lot of<br />

attention over the next year. I can see<br />

more and more competitions popp<strong>in</strong>g<br />

up for them. Especially now that <strong>Axial</strong><br />

is releas<strong>in</strong>g the new SCX10 ‘scaler’. The<br />

toughest part about compet<strong>in</strong>g with<br />

the scale trucks is hav<strong>in</strong>g a set of rules/<br />

guidel<strong>in</strong>es that keeps the play<strong>in</strong>g field<br />

level, but still allows for all the creative<br />

ideas that people are com<strong>in</strong>g up with.<br />

The wheelbases vary greatly too, and<br />

<strong>RRCi</strong> fEAtuRE<br />

that is a big factor on how capable a rig<br />

is. The wheelbase rule for the 2.2 class<br />

is what keeps it very competitive.<br />

To dig or not to dig..?<br />

That is the question<br />

I don’t see dig go<strong>in</strong>g away <strong>in</strong> the US. It<br />

has really taken the capability of the 2.2<br />

class to a whole new level. There are so<br />

many situations where it is beneficial,<br />

and it allows us to run more technical/<br />

difficult courses then ever before. The<br />

USRCCA has also recently added a 1.9<br />

class to the rules. I believe this class<br />

will grow very fast, because they are<br />

not allow<strong>in</strong>g dig. This will let more new<br />

people that are on tight budgets to<br />

come <strong>in</strong> with relatively simple rigs and<br />

be competitive.<br />

So what are you work<strong>in</strong>g on at the<br />

moment? Is there an essential hop-up<br />

or must have <strong>Axial</strong> add-on?<br />

<strong>Axial</strong> is work<strong>in</strong>g on a bunch of new<br />

products for the 2009 season, but that’s<br />

about all I can say at this po<strong>in</strong>t without<br />

giv<strong>in</strong>g up any top-secret <strong>in</strong>fo. Right now<br />

I th<strong>in</strong>k the hottest hop-ups we have are<br />

the alum<strong>in</strong>ium knuckles, alum<strong>in</strong>ium axle<br />

C’s, the CVD’s. The <strong>SWX</strong> chassis also<br />

seems to be a pretty popular hop-up<br />

right now too, which is nice to see.<br />

• If you get a lot of torque twist <strong>in</strong> a shaft driven rig,<br />

add a stronger spr<strong>in</strong>g and oil to the offend<strong>in</strong>g rear<br />

shock, then try it aga<strong>in</strong>. If you still get twist move<br />

the upper l<strong>in</strong>k mount<strong>in</strong>g po<strong>in</strong>ts on the chassis<br />

down closer to the lower mount<strong>in</strong>g po<strong>in</strong>ts,<br />

and see if that helps<br />

• The best 4-l<strong>in</strong>k set-up is one that can flex<br />

with little change <strong>in</strong> the wheelbase<br />

02/09 WWW.RADIORACECAR.COM 63

AxIAl sWx 2.2" ROCk CRAWlER ChAssIs<br />

Left: Hardened diff<br />

lockers take anyth<strong>in</strong>g<br />

you throw at them<br />

Above: CDV’s give<br />

tighter turn<strong>in</strong>g circle<br />

without b<strong>in</strong>d<strong>in</strong>g at<br />

full lock<br />

Right: The <strong>SWX</strong><br />

chassis kit <strong>in</strong> all its<br />

dark glory has taken<br />

Brad 4 years to<br />

develop<br />

Left: RC4WD<br />

axle hous<strong>in</strong>gs <strong>in</strong><br />

super slippery<br />

Delr<strong>in</strong>, note<br />

rear requires no<br />

lockouts<br />

Right: Sub<br />

assemblies and<br />

‘Punisher’ drive<br />

shafts built to<br />

take abuse<br />

With all these po<strong>in</strong>ts <strong>in</strong> m<strong>in</strong>d, and a new <strong>SWX</strong> Bender chassis <strong>in</strong> my<br />

hands, I started to collect all the components required to make a<br />

serious competition rig for the 2009 nationals and local competitions.<br />

My first stop was <strong>CML</strong> <strong>Distribution</strong> who had also supplied me the<br />

chassis to review. I first upgraded the standard <strong>Axial</strong> diff lockers to the<br />

comp spec <strong>Axial</strong> hardened items. Next I swapped the standard front<br />

axle <strong>in</strong>ternals for <strong>Axial</strong> CVDs, allow<strong>in</strong>g a better steer<strong>in</strong>g angle without<br />

any b<strong>in</strong>d<strong>in</strong>g <strong>in</strong> the drivel<strong>in</strong>e, and I added hardened spool and p<strong>in</strong>ion<br />

gears to each diff. I wanted a black on black look for the rig to match<br />

the chassis so chose the new Pro-L<strong>in</strong>e Spider crawler shell and pla<strong>in</strong><br />

black Fastrax pa<strong>in</strong>t.<br />

Add<strong>in</strong>g to the stealth look, I chose black Pro-L<strong>in</strong>e Eight Shooter 2.2<br />

beadlock wheels, Pro-L<strong>in</strong>e memory foam <strong>in</strong>serts and the M3 soft<br />

compound Pro-L<strong>in</strong>e Badlands 2.2 crawler tyres. I kept the slipper<br />

clutch assembly but replaced the slipper pads and spur gear that has<br />

lasted a year of crawl<strong>in</strong>g, as I wanted to start fresh! I lastly added a<br />

Novak Rooster <strong>Crawler</strong> Edition ESC and the new Venom 50T <strong>Crawler</strong><br />

Spec motor, giv<strong>in</strong>g me slightly more wheel speed than a 55 or 60<br />

turn motor and the amaz<strong>in</strong>g drag brakes that have made this ESC my<br />

favourite choice for any crawler build.<br />

I then travelled north to visit K<strong>in</strong>g Cobra to see their new range of<br />

RC4WD <strong>Axial</strong> hop ups. I wanted to make this rig as bullet proof as<br />

possible across the whole drive-l<strong>in</strong>e so I chose a new alum<strong>in</strong>ium<br />

transmission case and hardened steel <strong>in</strong>ternal gears, clock-able<br />

alum<strong>in</strong>ium ‘C’ hubs and steer<strong>in</strong>g knuckles. I also used the RC4WD<br />

‘Punisher’ steel driveshafts especially made to fit the <strong>Axial</strong>. I also<br />

added the new Delr<strong>in</strong> axle hous<strong>in</strong>gs for a smooth and slippery surface<br />

to help avoid hang<strong>in</strong>g up on rocks.<br />

My f<strong>in</strong>al addition was a set of the Losi 2.2 100 mm crawler spec<br />

shocks. These have fast become the shock of choice <strong>in</strong> serious<br />

competition and are ideal for the <strong>SWX</strong>. With a threaded cartridge<br />

design, they are easy to assemble, fill and bleed. With Titanium Nitride<br />

64 WWW.RADIORACECAR.COM 02/09<br />

coated shafts, they are perfect for crawl<strong>in</strong>g and smooth <strong>in</strong> operation<br />

us<strong>in</strong>g the supplied soft white spr<strong>in</strong>gs. These have been used by Brad<br />

himself <strong>in</strong> his own <strong>SWX</strong> builds, though he designed the chassis to also<br />

use the standard 120 mm <strong>Axial</strong> shocks mounted <strong>in</strong> different holes or<br />

<strong>in</strong>deed your own shocks of choice. That’s the great th<strong>in</strong>g about a comp<br />

build, you choose everyth<strong>in</strong>g that you want to bolt on and build to<br />

whatever spec, you want.<br />

ClEANED, luBED, AND READy tO AssEMBlE<br />

The donor parts from the orig<strong>in</strong>al rig were the bear<strong>in</strong>gs, the diff spools<br />

and rear drive shafts. I thoroughly cleaned and lubed the bear<strong>in</strong>gs by<br />

leav<strong>in</strong>g them soak<strong>in</strong>g overnight <strong>in</strong> oil. I also replaced all bolts, washers<br />

and nylock nuts on everyth<strong>in</strong>g except the transmission case, as a year<br />

of wear and tear had taken its toll on the orig<strong>in</strong>al rig’s hardware with<br />

some bolt heads almost worn half away!<br />

When rebuild<strong>in</strong>g the diffs with hardened gears and lockers, I made<br />

sure the cases were packed with quality LM grease. This also goes for<br />

the new transmission cases and hardened gears; I want longevity from<br />

this build with the usual <strong>RRCi</strong> philosophy of ‘Fit and Forget’. Once built<br />

correctly these sub assemblies should last a season or two and still be<br />

ready for more. My orig<strong>in</strong>al <strong>Axial</strong> items have performed perfectly, and<br />

show m<strong>in</strong>imal wear <strong>in</strong>ternally, but the lower plastic diff cas<strong>in</strong>gs have<br />

taken a real beat<strong>in</strong>g so I thought it was time to give the Delr<strong>in</strong> RC4WD<br />

items ‘a day <strong>in</strong> court’.<br />

When both axles were f<strong>in</strong>ished I connected each built sub assembly<br />

to a cordless drill us<strong>in</strong>g a flexible extension and turned them slowly to<br />

check everyth<strong>in</strong>g ran smoothly and bed the r<strong>in</strong>g gear to the p<strong>in</strong>ion. The<br />

RC4WD Delr<strong>in</strong> cases do not need ‘lock outs’ on the rear assembly, as<br />

they are a straight mould<strong>in</strong>g that captures the bear<strong>in</strong>gs for the output<br />

shafts <strong>in</strong>ternally. This will not allow you to fit 4WS as you can with the<br />

orig<strong>in</strong>al <strong>Axial</strong> items, but as current 2.2 comp rules do not allow 4WS, it<br />

didn’t bother me.

The front assembly was completed, by add<strong>in</strong>g two M3 bolts to hold<br />

each ‘C’ hub <strong>in</strong> place. I realised when fitt<strong>in</strong>g these that the mould<strong>in</strong>gs<br />

on the axle cas<strong>in</strong>gs are smooth all the way around with noth<strong>in</strong>g to key<br />

the ‘C’ hubs other than the two M3 bolts. This would allow you to ‘clock’<br />

these hubs to any angle required just by re-drill<strong>in</strong>g the two holes <strong>in</strong><br />

a different position. If you make geometry changes <strong>in</strong> the future by<br />

alter<strong>in</strong>g l<strong>in</strong>k lengths the diff angle will change. Shorter bottom l<strong>in</strong>ks or<br />

longer top l<strong>in</strong>ks rotate the diff <strong>in</strong>put shaft upwards giv<strong>in</strong>g a better angle<br />

for the drive shafts and extra clearance <strong>in</strong> certa<strong>in</strong> situations when<br />

crawl<strong>in</strong>g. Just bear <strong>in</strong> m<strong>in</strong>d that as you rotate the front diff hous<strong>in</strong>g, you<br />

need to clock the ‘C’ hubs to counteract the castor change <strong>in</strong>duced,<br />

so the steer<strong>in</strong>g k<strong>in</strong>gp<strong>in</strong> stays as vertical as possible (zero castor) thus<br />

giv<strong>in</strong>g you a better turn<strong>in</strong>g circle and more precise steer<strong>in</strong>g.<br />

A DARk BuIlD<br />

The last job was to bolt all sub assemblies onto the chassis ensur<strong>in</strong>g<br />

you orientate the gearbox mount<strong>in</strong>g holes <strong>in</strong> the skid plate opposite<br />

the cut-out vertical chassis plate for the motor (and yes I put it the<br />

wrong way round the first time!)<br />

Top Tip<br />

Tap all the M3 holes on the skidplate first, as Delr<strong>in</strong> is a very hard<br />

material for screws to self-thread <strong>in</strong>to.<br />

The skid plate has a channel cut <strong>in</strong> the bottom face that helps stop<br />

you slipp<strong>in</strong>g laterally if you ground it over rocks or obstacles when<br />

runn<strong>in</strong>g the rig. All bolts on the sides of the chassis are countersunk<br />

to avoid catch<strong>in</strong>g on rocks and the chassis itself is very narrow <strong>in</strong><br />

comparison to the standard <strong>Axial</strong> item allow<strong>in</strong>g you to squeeze through<br />

gaps not possible with a stock rig as long as your bodyshell will allow.<br />

As the motor and transmission are wider once assembled than the<br />

chassis itself, Brad has made the motor side of the chassis open<br />

without a top bar, and even though this looks weird at first, <strong>in</strong> use it’s<br />

not an issue and caused no hang ups or damage to the motor or its<br />

mount<strong>in</strong>g plate.<br />

Below: Pro-L<strong>in</strong>e Eight Shooter beadlocks<br />

with memory foam <strong>in</strong>serts ready to<br />

assemble after add<strong>in</strong>g weights to rims<br />

Above: An assembled<br />

weight of 14 oz for each<br />

front, and 8 oz for each<br />

rear, ready to crawl<br />

Below: Completed roll<strong>in</strong>g chassis ready<br />

for electrics, check all l<strong>in</strong>ks move freely<br />

without b<strong>in</strong>d<strong>in</strong>g for smooth shock<br />

movement and better traction<br />

<strong>RRCi</strong> fEAtuRE<br />

The geometry of the chassis allows you to fit shocks between 100<br />

mm and 120 mm <strong>in</strong> length and still give good ground clearance while<br />

ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g a low centre of gravity. The more you lay the shocks down,<br />

the softer the set-up becomes. Endless variations are possible with<br />

enough mount<strong>in</strong>g holes to achieve whatever angle works for you. I<br />

opted to use the end mount holes as my shorter 100 mm Losi shocks<br />

fitted perfectly <strong>in</strong> that position and still allowed a good level of ground<br />

clearance.<br />

The supplied <strong>SWX</strong> l<strong>in</strong>ks were a breeze to assemble, I used new<br />

plastic rod ends and made sure that when fix<strong>in</strong>g them to the l<strong>in</strong>ks that<br />

the balls were able to move freely and the rod ends were not over<br />

tightened. I then custom made a set of comb<strong>in</strong>ation ‘4-l<strong>in</strong>k’ and servo<br />

mount plates from sheet Delr<strong>in</strong> to put the ends of the top l<strong>in</strong>ks under<br />

these plates and remove the <strong>Axial</strong> Y-pieces from the assembly. Built as<br />

standard the <strong>Axial</strong> items work f<strong>in</strong>e, but I have found a true ‘4-l<strong>in</strong>k’ more<br />

stable <strong>in</strong> use as it stops over articulation and once the shocks are setup<br />

correctly reduces torque twist significantly.<br />

I then turned to my wheels and tyres. I added lead ballast to the front<br />

Pro-L<strong>in</strong>e Eight Shooter rims to make the total weight with Badland<br />

tyres and memory foam <strong>in</strong>serts 14 oz per assembly. The rears were<br />

left without weight at just 8 oz once built. This difference really helps<br />

a rig’s ability to climb ledges and descend very steep angles, by<br />

putt<strong>in</strong>g the balance po<strong>in</strong>t further forward. Different builders alter this<br />

weight bias, some even run without weight<strong>in</strong>g their front wheels and<br />

concentrate weight forward by plac<strong>in</strong>g split battery packs on the front<br />

axles. In test<strong>in</strong>g I’ve found that weight<strong>in</strong>g the wheels gives me a more<br />

predictable set-up and once you learn what your rig can and can’t do,<br />

it’s your driv<strong>in</strong>g style and ability to choose the right l<strong>in</strong>es that makes all<br />

the difference <strong>in</strong> a comp.<br />

Above: RC4WD alloy transmission case and hardened gears for<br />

hours of ma<strong>in</strong>tenance free crawl<strong>in</strong>g<br />

Above: RC4WD alloy ‘C’ Hubs and steer<strong>in</strong>g knuckles allow<br />

‘clock<strong>in</strong>g’ to ma<strong>in</strong>ta<strong>in</strong> castor and full steer<strong>in</strong>g lock<br />

02/09 WWW.RADIORACECAR.COM 65

AxIAl sWx 2.2" ROCk CRAWlER ChAssIs<br />

sWx’y tOuChEs<br />

Mount<strong>in</strong>g plates were fabricated out of Lexan sheet to mount<br />

the ESC and LiPo pack fit to the top l<strong>in</strong>ks. I was sure to check<br />

the cable ties were not over tight so the movement of the l<strong>in</strong>ks<br />

would not be affected. Lastly I fitted a SR3100 DSM2 Spektrum<br />

receiver on another Lexan plate just above the transmission. To<br />

keep the wir<strong>in</strong>g tidy and away from mov<strong>in</strong>g parts, I spiral bound<br />

everyth<strong>in</strong>g to add a f<strong>in</strong>al touch to the electrical <strong>in</strong>stallation. I did<br />

the usual C of G test by stand<strong>in</strong>g the rig sideways on its wheels<br />

and it sat there f<strong>in</strong>e with no sign of fall<strong>in</strong>g over. This is the<br />

simplest and best method of test<strong>in</strong>g how a rig will perform on<br />

a steep <strong>in</strong>cl<strong>in</strong>e. If it falls over the C of G is too high, with weight<br />

distributed <strong>in</strong> the right places you will be amazed how much<br />

better a rig will perform.<br />

F<strong>in</strong>ally I added the newly pa<strong>in</strong>ted Pro-L<strong>in</strong>e Spider shell, and<br />

<strong>in</strong>stead of mount<strong>in</strong>g it through the sides, I opted to use longer<br />

body mounts and attach it through the top of the shell, so there<br />

was noth<strong>in</strong>g on the shell that could hang up on rocks and I th<strong>in</strong>k<br />

it actually looks better aesthetically, keep<strong>in</strong>g the l<strong>in</strong>es of the<br />

shell uncluttered. I stood back and admired the completed rig,<br />

dark and moody…time to go test!<br />

ROCk sOlID PERfORMANCE<br />

On a usual British w<strong>in</strong>ter’s day, we took an <strong>RRCi</strong> crawl<strong>in</strong>g squad<br />

to Burton Dassett for a day’s test<strong>in</strong>g <strong>in</strong> a good old session of<br />

‘flow the leader’. I test here regularly and the terra<strong>in</strong> goes from<br />

easy climbs and sidehill<strong>in</strong>g sections, to extreme near vertical<br />

ledges, higher than the wheelbase of most rigs. There is also a<br />

section of almost impossible descents with tight channels ready<br />

to trap and b<strong>in</strong>d up a rig’s wheels and axles if the wrong l<strong>in</strong>e is<br />

taken.<br />

The <strong>SWX</strong> was a delight to run, as the low C of G really helps its<br />

stability. The rig climbed everyth<strong>in</strong>g thrown at it, only ground<strong>in</strong>g<br />

the straight lower l<strong>in</strong>ks over certa<strong>in</strong> ledges, and I’m sure the<br />

Above: 4-l<strong>in</strong>k plates with top l<strong>in</strong>ks<br />

mounted underneath help reduce<br />

torque twist and aid stability<br />

66 WWW.RADIORACECAR.COM 02/09<br />

extra clearance that bent lower l<strong>in</strong>ks would afford would make<br />

a world of difference. I must say that one th<strong>in</strong>g I sometimes had<br />

a problem with on my old rig, were high drop offs, but the <strong>SWX</strong><br />

just lapped them up. Hold<strong>in</strong>g the rig on drag brakes then lett<strong>in</strong>g<br />

it just drop slowly over the edge before giv<strong>in</strong>g it full throttle as it<br />

lands delivered a perfect result every time. Its ability to side-hill<br />

also amazed me, as it didn’t show any signs of want<strong>in</strong>g to roll<br />

over, it just sat there ready to go wherever you put it.<br />

The Pro-L<strong>in</strong>e Badlands <strong>in</strong> the soft M3 compound and memory<br />

foam really performed well, with great levels of grip on most<br />

surfaces and only struggl<strong>in</strong>g if the tread filled with mud. Once<br />

cleaned and wiped dry they felt sticky aga<strong>in</strong> and ready for<br />

action. The whole package when comb<strong>in</strong>ed with the bullet proof<br />

drive-tra<strong>in</strong> enhancements, CVD’s giv<strong>in</strong>g better turn<strong>in</strong>g circle<br />

and metal ‘C’ hubs and steer<strong>in</strong>g knuckles worked well together.<br />

I’m really look<strong>in</strong>g forward to putt<strong>in</strong>g the <strong>SWX</strong> through its paces<br />

at the GB Models Urban <strong>Crawler</strong> Course and Black Rocks <strong>in</strong><br />

2009, so watch for the videos on my madpete98 ‘You Tube’<br />

channel!<br />

Brad has done a great job with the development and design of<br />

the <strong>SWX</strong> and I hope that he takes the <strong>Axial</strong> brand and crawl<strong>in</strong>g<br />

to even greater heights of <strong>in</strong>novation <strong>in</strong> 2009 and beyond. If<br />

you are look<strong>in</strong>g to upgrade your current <strong>Axial</strong> to someth<strong>in</strong>g<br />

more competitive or are scratch build<strong>in</strong>g a rig, then you can’t go<br />

far wrong with the <strong>SWX</strong> chassis kit as a start<strong>in</strong>g po<strong>in</strong>t. I would<br />

like to thank Brad for his thoughts and contribution to this<br />

article, and I hope to go to the West Coast of the US at some<br />

po<strong>in</strong>t <strong>in</strong> 2009 to crawl <strong>in</strong> the birthplace of the scene and to see<br />

what <strong>in</strong>spired him <strong>in</strong> the first place. <strong>RRCi</strong><br />

Below: Tidy electrics, with all weight kept<br />

as low as possible to help reduce the C of G<br />

Below: <strong>Crawler</strong><br />

spec shocks by<br />

Losi matched<br />

with white<br />

spr<strong>in</strong>gs seem<br />

to be the choice<br />

for serious<br />

competition

The Pro-L<strong>in</strong>e Spider shell<br />

gives the feel of a full size<br />

tube chassis, almost too<br />

good to scratch<br />

The <strong>SWX</strong> took on anyth<strong>in</strong>g we threw at it<br />

and came crawl<strong>in</strong>g back for more!<br />

<strong>RRCi</strong> fEAtuRE<br />

QUICK SPEC<br />

Class: 2.2” Competition Rock <strong>Crawler</strong><br />

Type: Self-assembly Chassis Kit<br />

Manufacturer: <strong>Axial</strong><br />

Price: <strong>Axial</strong> <strong>SWX</strong> Chassis £69.99<br />

EQuIPMENt usED<br />

AxIAl – CMl<br />

CVD drive shafts<br />

Hardened diff gears<br />

Hardened diff lockers<br />

Novak Rooster <strong>Crawler</strong><br />

Venom 50T motor<br />

Venom 800 mAh 2s LiPo<br />

PRO-lINE – CMl<br />

Spider shell<br />

Badlands M3<br />

Memory foams<br />

8 shooter beadlocks<br />

RC4WD – kING COBRA<br />

Delr<strong>in</strong> diff cases<br />

‘Punisher’ shafts<br />

Alloy ‘C’ hubs<br />

Steer<strong>in</strong>g knuckles<br />

Alloy ma<strong>in</strong> gear case<br />

Hardened reduction gears<br />

hORIZON hOBBy<br />

Losi 4" <strong>Crawler</strong> shocks<br />

Spektrum DX3R<br />

SR3100 DSM2<br />

DIslIkEs<br />

Skid plate holes very tight<br />

Straight bottom l<strong>in</strong>ks<br />

lIkEs<br />

National w<strong>in</strong>n<strong>in</strong>g design<br />

Four years real world R&D<br />

Narrow chassis design<br />

Virtually no torque twist<br />

Limit<strong>in</strong>g articulation works<br />

Delr<strong>in</strong> axle hous<strong>in</strong>gs<br />

Alloy hop-ups bulletproof<br />

Punisher’s drive shafts<br />

50T Venom Torque and Speed<br />

CONtACt<br />

<strong>CML</strong> <strong>Distribution</strong><br />

Tel 01527 575349<br />

or visit www.cmldistribution.co.uk<br />

K<strong>in</strong>g Cobra <strong>Distribution</strong> Ltd<br />

Tel 01706 260502<br />

or visit www.k<strong>in</strong>gcobra.co.uk<br />

Horizon Hobby UK<br />

Tel 01279 641097<br />

or visit www.horizonhobby.co.uk<br />

02/09 WWW.RADIORACECAR.COM 67