The Army Maintenance Management System (TAMMS) Users Manual

The Army Maintenance Management System (TAMMS) Users Manual

The Army Maintenance Management System (TAMMS) Users Manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

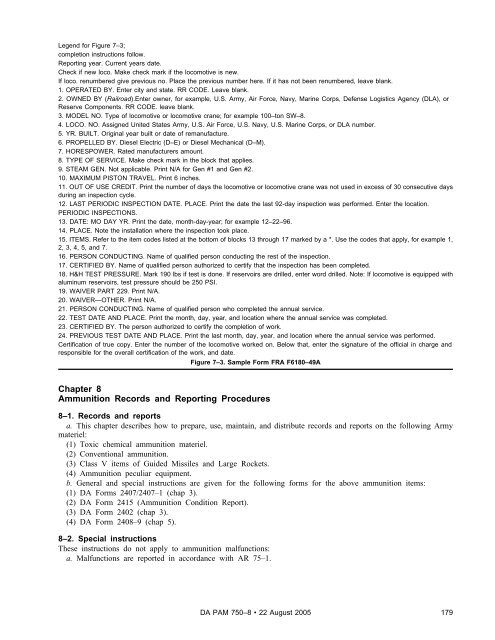

Legend for Figure 7–3;<br />

completion instructions follow.<br />

Reporting year. Current years date.<br />

Check if new loco. Make check mark if the locomotive is new.<br />

If loco. renumbered give previous no. Place the previous number here. If it has not been renumbered, leave blank.<br />

1. OPERATED BY. Enter city and state. RR CODE. Leave blank.<br />

2. OWNED BY (Railroad).Enter owner, for example, U.S. <strong>Army</strong>, Air Force, Navy, Marine Corps, Defense Logistics Agency (DLA), or<br />

Reserve Components. RR CODE. leave blank.<br />

3. MODEL NO. Type of locomotive or locomotive crane; for example 100–ton SW–8.<br />

4. LOCO. NO. Assigned United States <strong>Army</strong>, U.S. Air Force, U.S. Navy, U.S. Marine Corps, or DLA number.<br />

5. YR. BUILT. Original year built or date of remanufacture.<br />

6. PROPELLED BY. Diesel Electric (D–E) or Diesel Mechanical (D–M).<br />

7. HORESPOWER. Rated manufacturers amount.<br />

8. TYPE OF SERVICE. Make check mark in the block that applies.<br />

9. STEAM GEN. Not applicable. Print N/A for Gen #1 and Gen #2.<br />

10. MAXIMUM PISTON TRAVEL. Print 6 inches.<br />

11. OUT OF USE CREDIT. Print the number of days the locomotive or locomotive crane was not used in excess of 30 consecutive days<br />

during an inspection cycle.<br />

12. LAST PERIODIC INSPECTION DATE. PLACE. Print the date the last 92-day inspection was performed. Enter the location.<br />

PERIODIC INSPECTIONS.<br />

13. DATE: MO DAY YR. Print the date, month-day-year; for example 12–22–96.<br />

14. PLACE. Note the installation where the inspection took place.<br />

15. ITEMS. Refer to the item codes listed at the bottom of blocks 13 through 17 marked by a *. Use the codes that apply, for example 1,<br />

2, 3, 4, 5, and 7.<br />

16. PERSON CONDUCTING. Name of qualified person conducting the rest of the inspection.<br />

17. CERTIFIED BY. Name of qualified person authorized to certify that the inspection has been completed.<br />

18. H&H TEST PRESSURE. Mark 190 lbs if test is done. If reservoirs are drilled, enter word drilled. Note: If locomotive is equipped with<br />

aluminum reservoirs, test pressure should be 250 PSI.<br />

19. WAIVER PART 229. Print N/A.<br />

20. WAIVER—OTHER. Print N/A.<br />

21. PERSON CONDUCTING. Name of qualified person who completed the annual service.<br />

22. TEST DATE AND PLACE. Print the month, day, year, and location where the annual service was completed.<br />

23. CERTIFIED BY. <strong>The</strong> person authorized to certify the completion of work.<br />

24. PREVIOUS TEST DATE AND PLACE. Print the last month, day, year, and location where the annual service was performed.<br />

Certification of true copy. Enter the number of the locomotive worked on. Below that, enter the signature of the official in charge and<br />

responsible for the overall certification of the work, and date.<br />

Figure 7–3. Sample Form FRA F6180–49A<br />

Chapter 8<br />

Ammunition Records and Reporting Procedures<br />

8–1. Records and reports<br />

a. This chapter describes how to prepare, use, maintain, and distribute records and reports on the following <strong>Army</strong><br />

materiel:<br />

(1) Toxic chemical ammunition materiel.<br />

(2) Conventional ammunition.<br />

(3) Class V items of Guided Missiles and Large Rockets.<br />

(4) Ammunition peculiar equipment.<br />

b. General and special instructions are given for the following forms for the above ammunition items:<br />

(1) DA Forms 2407/2407–1 (chap 3).<br />

(2) DA Form 2415 (Ammunition Condition Report).<br />

(3) DA Form 2402 (chap 3).<br />

(4) DA Form 2408–9 (chap 5).<br />

8–2. Special instructions<br />

<strong>The</strong>se instructions do not apply to ammunition malfunctions:<br />

a. Malfunctions are reported in accordance with AR 75–1.<br />

DA PAM 750–8 22 August 2005<br />

179