- Page 1 and 2:

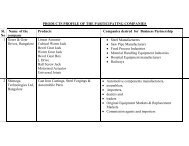

ENGINEERING PRODUCTS Sl. No. Export

- Page 3 and 4:

coated printed C17 Aluminium Foil-

- Page 5 and 6:

(Weight: 231 gms for item 1, 242 gm

- Page 7 and 8:

(Weight: 296 gms for item 1, 65 gms

- Page 9 and 10:

C9 Washer 3 Polypropylene 98 gms 4

- Page 11 and 12:

weight of the steel to be Nickel Pl

- Page 13 and 14:

C130 11 KV mass impregnated, paper

- Page 15 and 16:

for cable size 4 X 25 mm. sq. C144

- Page 17 and 18:

C155 Auto Transformers above 100000

- Page 19 and 20:

C165 Cast Resin Straight joints sui

- Page 21 and 22:

Insulated, GI/Single Wire Armoured,

- Page 23 and 24:

C183 Current Transformers above 72.

- Page 25 and 26:

C189 Electric Fan with Table Stand/

- Page 27 and 28:

C194 Electrical Ovens made of CRCA

- Page 29 and 30:

C204 Electromechanical Domestic app

- Page 31 and 32:

C213 Fluorescent Circular Lamp (23W

- Page 33 and 34:

C218 Fractional horse power single

- Page 35 and 36:

C225 H.P.S.V Lamps Arc Tube (Burner

- Page 37 and 38:

C240 J Halogen Lamps 300W,500W,110V

- Page 39 and 40:

* Note : The quantity of item nos 1

- Page 41 and 42:

m) i.e. 17.2x7.4 C259 PVC 3 Core Fl

- Page 43 and 44:

armoured for Voltage upto 1000 V of

- Page 45 and 46:

C280 Single phase shell constructio

- Page 47 and 48:

C282 Single phase shell constructio

- Page 49 and 50:

C288 Squirrel cage flame proof moto

- Page 51 and 52:

C295 Squirrel cage screen protected

- Page 53 and 54:

C311 Three Phase Electrical Energy

- Page 55 and 56:

C319 Totally enclosed fan cooled sq

- Page 57 and 58:

7 Pre-pressed boards/ moulded compo

- Page 59 and 60:

upto & including 10000 KVA, 3 Phase

- Page 61 and 62:

C342 Voltage (Potential) Transforme

- Page 63 and 64:

c) Selenium d) Lumps/Powder of Misc

- Page 65 and 66: C362 Casing Pipes conforming to API

- Page 67 and 68: a) Alloy Steel Scrap 1310 kgs. b) F

- Page 69 and 70: c) Monolithic/Gunning/Ramming/C ast

- Page 71 and 72: C390 Powrah/Hoe/Pickaxe/Kudali/Pick

- Page 73 and 74: Note: 1. The above norm is applicab

- Page 75 and 76: C407 Diamond Impregnated Segments -

- Page 77 and 78: Tungsten Carbide of diameter 0.05 M

- Page 79 and 80: C436 Contour Tape C79 pipeline & co

- Page 81 and 82: 31 Thermocouples Net to Net. 32 Ele

- Page 83 and 84: C83 export product. 95 Low Voltage

- Page 85 and 86: C450 Stainless Steel Pressure Vesse

- Page 87 and 88: allowed. 4. (i) 5.50 X(mean average

- Page 89 and 90: Induction Furnace using Non-alloy S

- Page 91 and 92: C463 Alumina Carbon Continuous Cast

- Page 93 and 94: C469 Cold Rolled Galvanised Colour

- Page 95 and 96: * For units having captive power pl

- Page 97 and 98: 10 Glycine 11 Vanadium Pentoxide 12

- Page 99 and 100: Note 1. In the case of export of Ra

- Page 101 and 102: C497 Iron Ore pellets (from Limonit

- Page 103 and 104: 2 Dry Drawing Lubricant/ Coating 8

- Page 105 and 106: c) Or (i) Ferro silicon (ii) Ferro

- Page 107 and 108: Vanadium/ Ferro Phosphorous/ Ferro

- Page 109 and 110: C109 sleeves/ slidegate plates stee

- Page 111 and 112: C111 p)Welding flux 8.0 kgs q)Weld

- Page 113 and 114: olling mill rolls and tungsten carb

- Page 115: e) Bar/Copper Rod(if copper is actu

- Page 119 and 120: 8 Other ferro alloy(s) (Including c

- Page 121 and 122: I) Any other Metal (not present in

- Page 123 and 124: Alloy Steel Scrap Quantity (kg) x %

- Page 125 and 126: C536 2" Galvanised/ Zinc Coated Bun

- Page 127 and 128: C549 Anchor Bolt with Nut 14 Alumin

- Page 129 and 130: 10 Inscription Ring 11 Pressing Pin

- Page 131 and 132: C589 Epoxy Polyester Powder coated

- Page 133 and 134: Teeth Plaque removing Brush: Rack P

- Page 135 and 136: C628 Divider Valves (Metering Devic

- Page 137 and 138: Alloy Steel (Galvanised) C644 Flang

- Page 139 and 140: Tillers (Spring loaded without spri

- Page 141 and 142: Truss Rods/ Drop Rods. C677 Deleted

- Page 143 and 144: C690 Cryogenic Tank for Liquified G

- Page 145 and 146: C698 Knitting Needles/ Pinsknobbed

- Page 147 and 148: C713 Marine freight containers of t

- Page 149 and 150: C730 Needle Roller Bearing Type BK/

- Page 151 and 152: EN/ AISI/ DIN/ JIS Series Steel exc

- Page 153 and 154: Blade) C773 Printed Lug Cap with In

- Page 155 and 156: C794 Seamless Stainless Steel Tubes

- Page 157 and 158: C815 Spot Grid C816 Stainless Steel

- Page 159 and 160: 2 Cellulose Film/BOPP Film (Wrapper

- Page 161 and 162: and Dial Rings) C846 Steel flexible

- Page 163 and 164: C868 Tower Crane Type F25/26C simil

- Page 165 and 166: C876 Deleted C877 Deleted C878 Dele

- Page 167 and 168:

C901 Zinc plated (Galvanised) condu

- Page 169 and 170:

(Cobalt Grade) C918 Cutting tools -

- Page 171 and 172:

tools C932 Industrial Diamond Prod.

- Page 173 and 174:

C954 Vetrified Grinding wheels : Mo

- Page 175 and 176:

56 Kick Shaft Assembly Net to net.

- Page 177 and 178:

C962 Deleted C963 Above 250 CC and

- Page 179 and 180:

C179 Granules 17 ABS Granules 2513.

- Page 181 and 182:

11 Butyl Rubber 485.000 gms 12 Synt

- Page 183 and 184:

e) M S Rods/ Bars 1.4777 kgs 2 Chem

- Page 185 and 186:

43 Auto Lamps Set (Bulbs only) (1 S

- Page 187 and 188:

C970 Alternator Assembly C971 Alumi

- Page 189 and 190:

C982 Asbestos Moulded Clutch Facing

- Page 191 and 192:

C1000 Cone Sleeve/Axle Stud sleeve

- Page 193 and 194:

C1020 Electric Starter C1021 End-Ca

- Page 195 and 196:

11 Isocyanate 1.05 kg/kg content in

- Page 197 and 198:

88 Cross Net to net. 89 Cylinder He

- Page 199 and 200:

C1037 Full Tension Sleeve made of S

- Page 201 and 202:

C1055 King Pin made out of Steel. C

- Page 203 and 204:

28 Magnetic Plut 1 NO. 29 Synchro R

- Page 205 and 206:

C1060 Lined Shoe Assembly for Autom

- Page 207 and 208:

61 Differential Bearings (1228-H- 5

- Page 209 and 210:

144 Seal Ring Valve 1 No. 145 Seal

- Page 211 and 212:

10 Clutch Release Brg. KOYO No.RCT

- Page 213 and 214:

C1076 Front/Rear Engine Auto Ricksh

- Page 215 and 216:

58 Wiper Assembly Net to net. 59 Co

- Page 217 and 218:

C217 Granules the export product. 1

- Page 219 and 220:

3 Nitrile Rubber 0.783 kg 4 Stainle

- Page 221 and 222:

C1092 Sleeve Shaft and Ball Joint S

- Page 223 and 224:

HP) (Minimum export product weight

- Page 225 and 226:

17G/A 17X/A 6/GA 6/A 300/G 73/SAE 7

- Page 227 and 228:

C1138 Tractor Brake Assembly C1139

- Page 229 and 230:

Aluminium Sow Ingots C1151 Deleted

- Page 231 and 232:

types C1172 Brass Wire 1 kg. 1 a) C

- Page 233 and 234:

C1189 Copper Wire C1190 Extruded Al

- Page 235 and 236:

C1213 Tin Metal of minimum 99.5% Pu

- Page 237 and 238:

25 Link Fork 1 No. 26 Locking Bolt

- Page 239 and 240:

C239 OR Cold Drawn Wire OR 574 kgs

- Page 241 and 242:

C1254 Tension for Plate 1 kg 1 CRCA

- Page 243 and 244:

6 Misc. items: Welding Flux, Up to

- Page 245 and 246:

C1303 L.V. Distribution Cabinet C13

- Page 247 and 248:

C1321 Instrument Cooling Fan Sleeve

- Page 249 and 250:

out in similar way. C1327 Auto Tran

- Page 251 and 252:

Ni-3.8%, Cr-0.5%, Mo- 1.0%, S-0.016

- Page 253 and 254:

Pressure Die Cast 2 Clad Concentrat

- Page 255 and 256:

9 b)Porcelain Bushings (LV) OR Porc

- Page 257 and 258:

Core Cable 0.5 Sq. mm 2 PVC Compoun

- Page 259 and 260:

(for automobile starter motor) spec

- Page 261 and 262:

C261 c) Filler (Calcium Carbonate/A

- Page 263 and 264:

C1398 Single Phase Shell constructi

- Page 265 and 266:

C1403 Aluminium cops C1404 Nut & Sh

- Page 267 and 268:

C1425 Insulated Adjacent Jumpers (2

- Page 269 and 270:

C1442 Aluminium Conductor 3 Core X

- Page 271 and 272:

DT Plus without Earth Plate and mod

- Page 273 and 274:

Reinforced (AACSR) C1480 Washing Ma

- Page 275 and 276:

C1484 ALPVCP VCSWP VC(1.1 kv) C1485

- Page 277 and 278:

C1495 Pneumatic Tool Heavy Duty Air

- Page 279 and 280:

C1499 Pneumatic Tool Scabbler with

- Page 281 and 282:

components made wholly or predomina

- Page 283 and 284:

Note: The above norm is applicable

- Page 285 and 286:

C1516 Pneumatic Tool Rammer C1517 P

- Page 287 and 288:

C1524 Pneumatic Tool-Clay Digger/Ut

- Page 289 and 290:

C1527 Pneumatic Tool-Non Reversible

- Page 291 and 292:

C1529 Pneumatic Tool- Reversible Dr

- Page 293 and 294:

C1531 Pneumatic Tools-Hand Drill wi

- Page 295 and 296:

C1534 Pneumatic Tool C1535 Pneumati

- Page 297 and 298:

C1537 Regulators with rotating outl

- Page 299 and 300:

C1548 Outdoor/Indoor Vaccum Circuit

- Page 301 and 302:

C1559 Shifted to Electronics Group

- Page 303 and 304:

C1587 CNC Hydraulic Press Brake C15

- Page 305 and 306:

C1596 Rolled Aluminium Colour coate

- Page 307 and 308:

C1614 Typewriter (Manual) with Meta

- Page 309 and 310:

C1626 Galvanised High Carbon Steel

- Page 311 and 312:

C1641 Shifted to Electronic Group C

- Page 313 and 314:

13 Structural materials, including

- Page 315 and 316:

C315 0.26Kgs. B) COMPONENTS 1 Coppe

- Page 317 and 318:

1 Universal Motor -750 W- 4249525 C

- Page 319 and 320:

C1655 Hair Dryer Model No. 4548 1 N

- Page 321 and 322:

6 Polyoxymethylene Master Batch 0.0

- Page 323 and 324:

C1663 PVC Insulated unarmoured cont

- Page 325 and 326:

C1677 (A) PVC Insulated Unarmoured

- Page 327 and 328:

C1684 Shifted to Electronic Group C

- Page 329 and 330:

C1692 Stainless Steel LPG Stove wit

- Page 331 and 332:

C1700 Shifted to Electronic Group C

- Page 333 and 334:

knocked down condition, with or wit

- Page 335 and 336:

and armouring ALXPE PVCs AWA PVC Ca

- Page 337 and 338:

meterial. C1734 Non Cast Hardware F

- Page 339 and 340:

C1744 Hydraulic Jacking Beam Model

- Page 341 and 342:

(5). Weight of component and the it

- Page 343 and 344:

C1759 Shifted to Chemical Group C17

- Page 345 and 346:

of copper, nickel and tin alloy (AS

- Page 347 and 348:

C1785 Ferro Boron Cored Wire C1786

- Page 349 and 350:

C1793 Aluminium Moulds for Plastic

- Page 351 and 352:

C1799 Filter Cartridge: Cylindrical

- Page 353 and 354:

C1808 Dish Ends (Ellipsoidal or Cir

- Page 355 and 356:

10 Calking 11 Sealant C355 11 may b

- Page 357 and 358:

C1833 Deleted C1834 Telephone Cable

- Page 359 and 360:

Runner System and Temperature Contr

- Page 361 and 362:

Lamps for Motor Vehicles (with or w

- Page 363 and 364:

C1875 Cast Article made of Zinc All

- Page 365 and 366:

C1886 Zinc Concentrates C365 in the

- Page 367 and 368:

24 Power Stearing Unit or component

- Page 369 and 370:

g) Calcium Carbide based Desulphuri

- Page 371 and 372:

C1910 Lightening Arrestor (Surge Ar

- Page 373 and 374:

C1912 Lightening Arrestor (Surge Ar

- Page 375 and 376:

C1914 Metal Oxide Varistor ## (MOV)

- Page 377 and 378:

C1917 Metal Oxide Varistor ## (MOV)

- Page 379 and 380:

C1920 Telephone Cables of different

- Page 381 and 382:

C1924 Transmission Line Tower Hardw

- Page 383 and 384:

3 furnace Oil (LSHS)/Light Diesel O

- Page 385 and 386:

on Kerosine & Petrol 4 Electrolytic

- Page 387 and 388:

C1961 Bismuth Alloy in the form of

- Page 389 and 390:

C1965 Tin alloy in the form of : Ro

- Page 391 and 392:

earing cages C1975 All Types of Con

- Page 393 and 394:

3 1"X¾" X5/8"L 3.75 4 1¼"X½"X¾"

- Page 395 and 396:

C1996 Air Cooled Fluid Cooler C1997

- Page 397 and 398:

a) LPG (for Supersonic Oxygen lance

- Page 399 and 400:

gms) (Bicycle part) C2018 Stainless

- Page 401 and 402:

C2028 Genset from 3 KVA upto & incl

- Page 403 and 404:

C403 Ingots Al-Si Alloy as per Engi