datasheet winder series 900 - SML

datasheet winder series 900 - SML

datasheet winder series 900 - SML

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

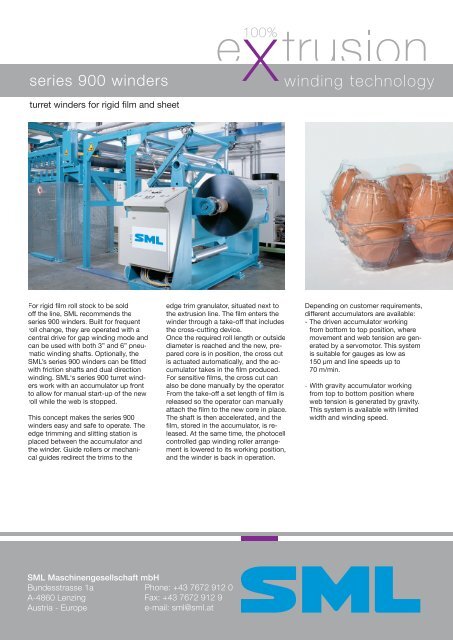

<strong>series</strong> <strong>900</strong> <strong>winder</strong>s<br />

turret <strong>winder</strong>s for rigid film and sheet<br />

For rigid film roll stock to be sold<br />

off the line, <strong>SML</strong> recommends the<br />

<strong>series</strong> <strong>900</strong> <strong>winder</strong>s. Built for frequent<br />

roll change, they are operated with a<br />

central drive for gap winding mode and<br />

can be used with both 3” and 6” pneumatic<br />

winding shafts. Optionally, the<br />

<strong>SML</strong>’s <strong>series</strong> <strong>900</strong> <strong>winder</strong>s can be fitted<br />

with friction shafts and dual direction<br />

winding. <strong>SML</strong>‘s <strong>series</strong> <strong>900</strong> turret <strong>winder</strong>s<br />

work with an accumulator up front<br />

to allow for manual start-up of the new<br />

roll while the web is stopped.<br />

This concept makes the <strong>series</strong> <strong>900</strong><br />

<strong>winder</strong>s easy and safe to operate. The<br />

edge trimming and slitting station is<br />

placed between the accumulator and<br />

the <strong>winder</strong>. Guide rollers or mechanical<br />

guides redirect the trims to the<br />

<strong>SML</strong> Maschinengesellschaft mbH<br />

Bundesstrasse 1a<br />

A-4860 Lenzing<br />

Austria - Europe<br />

edge trim granulator, situated next to<br />

the extrusion line. The film enters the<br />

<strong>winder</strong> through a take-off that includes<br />

the cross-cutting device.<br />

Once the required roll length or outside<br />

diameter is reached and the new, prepared<br />

core is in position, the cross cut<br />

is actuated automatically, and the accumulator<br />

takes in the film produced.<br />

For sensitive films, the cross cut can<br />

also be done manually by the operator.<br />

From the take-off a set length of film is<br />

released so the operator can manually<br />

attach the film to the new core in place.<br />

The shaft is then accelerated, and the<br />

film, stored in the accumulator, is released.<br />

At the same time, the photocell<br />

controlled gap winding roller arrangement<br />

is lowered to its working position,<br />

and the <strong>winder</strong> is back in operation.<br />

Phone: +43 7672 912 0<br />

Fax: +43 7672 912 9<br />

e-mail: sml@sml.at<br />

Depending on customer requirements,<br />

different accumulators are available:<br />

- The driven accumulator working<br />

from bottom to top position, where<br />

movement and web tension are generated<br />

by a servomotor. This system<br />

is suitable for gauges as low as<br />

150 µm and line speeds up to<br />

70 m/min.<br />

- With gravity accumulator working<br />

from top to bottom position where<br />

web tension is generated by gravity.<br />

This system is available with limited<br />

width and winding speed.

<strong>series</strong> <strong>900</strong> <strong>winder</strong>s<br />

turret <strong>winder</strong>s for rigid film and sheet<br />

www.sml.at<br />

printed 02/2009<br />

we reserve the right of technical alterations.<br />

<strong>series</strong> <strong>900</strong> <strong>winder</strong>s: single web<br />

with simple accumulator of 17 m storage capacity, cross cutting by hand<br />

<strong>series</strong> <strong>900</strong> <strong>winder</strong>s: single web<br />

with motorized accumulator of 26 m storage capacity, automatic cross-cutting<br />

number of webs 1 - 3<br />

winding mode gap winding<br />

nominal width of take-off unit 750, 1000, 1400, 1600, 1800 mm<br />

mechanical speed 40, 50, 70 m/min<br />

max. mechnical winding diameter 1000 mm<br />

length of film stored in simple accumulator<br />

(max. nominal width 1400 mm)<br />

12, 17 m<br />

length of film stored in motorized accumulator 17, 26, 36, 44 m<br />

thickness range 150 - 1200 µm<br />

51