appendix

appendix

appendix

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Application Manual -- Liquid Cooled Generator Sets<br />

Figure 6--30. Coolant Heater Installation (note heater isolation valve, hose type,<br />

and hose routing) ............................................ 6--44<br />

Figure 6--31. Water Boiling Temperature As A Function Of Altitude And<br />

System Pressure ............................................ 6--45<br />

Figure 6--32. ”Ambient” vs. ”Air--on--Core” Temperature ....................... 6--46<br />

Figure 6--33. Deaeration Type of Radiator Top Tank .......................... 6--48<br />

Figure 6--34. Factory-Mounted Radiator Cooling ............................. 6--49<br />

Figure 6--35. Remote Radiator Cooling (Deaeration Type System,<br />

See Figure 6--33) ............................................ 6--51<br />

Figure 6--36. Remote Radiator With Auxiliary Coolant Pump and<br />

Auxiliary Tank ............................................... 6--53<br />

Figure 6--37. Remote Radiator With Hot Well and Auxiliary Coolant Pump ....... 6--56<br />

Figure 6--38. A Horizontal Remote Radiator and Aftercooler Radiator ........... 6--58<br />

Figure 6--39. Factory-Mounted Heat Exchanger Cooling ...................... 6--59<br />

Figure 6--40. Dual Heat Exchanger System (With Secondary<br />

Liquid--to--Air Cooler) ......................................... 6--61<br />

Figure 6--41. Diagram of Representative Cooling Tower Application ............ 6--62<br />

Figure 6--42. Frictional Pressure Losses for Inch (mm) Diameter Pipes ......... 6--64<br />

Figure 6--43. Heat Emitted To The Room From A Generator Set (QGS) ......... 6--67<br />

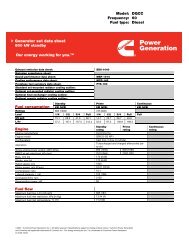

Figure 6--44. Example DFXX Generator Set Specification Sheet ............... 6--68<br />

Figure 6--45. Heat Emitted to the Room from the Muffler and Exhaust Piping .... 6--68<br />

Figure 6--46. Maximum Acceptable Room And Ambient Temperatures .......... 6--70<br />

Figure 6--47. Example DFXX Generator Set Specification Sheet ............... 6--71<br />

Figure 6--48. Example DFXX Generator Set Specification Sheet ............... 6--72<br />

Figure 6--49. Example Ventilation System For Factory--installed Radiator<br />

and Fan .................................................... 6--73<br />

Figure 6--50. Example Ventilation System For Remote--cooled,<br />

Non--factory--installed Radiator and Fan (NOTE: cooling system is not<br />

shown in this illustration) ...................................... 6--74<br />

Figure 6--51. ”Top” Views of Generator Set Room Layouts .................... 6--75<br />

Figure 6--52. ”Side” Views Of Generator Set Room Layouts ................... 6--76<br />

Figure 6--53. Example DFXX Generator Set Specification Sheet. ............... 6--77<br />

Figure 6--54. Room inlet and outlet airflow restriction. ......................... 6--78<br />

Figure 6--55. Example DXXX Cooling System Data Sheet ..................... 6--78<br />

Figure 6--56. Multiple Generator Set Installation .............................. 6--79<br />

Figure 6--57. Room Recirculation System ................................... 6--80<br />

Figure 6--58. Blocking Wall and Turning Vane ............................... 6--80<br />

Figure 6--59. Measuring Airflow Restriction .................................. 6--82<br />

Figure 6--60. MEasuring Airflow Restriction ................................. 6--82<br />

Figure 6--61. Factory-Mounted Radiator Cooling ............................. 6--83<br />

Figure 6--62. Typical Air Temperature Surrounding an Operating Genset ........ 6--85<br />

Figure 6--63. Recommended Instrumentation for Measuring Air Flow<br />

Restriction .................................................. 6--88<br />

Figure 6--64. Figure Cooling Capability in Elevated Ambients .................. 6--88<br />

Figure 6--65. Ventilation for a Heat Exchanger Cooling System ................ 6--89<br />

Figure 6--68. Typical Gaseous Fuel System ................................. 6--103<br />

Figure 6--69. Minimum LPG Tank Size (50% Full) Required to Maintain 5 PSIG at<br />

Specific Withdrawal Rate and Min. Expected Winter Temperature .. 6--105<br />

Figure 6--70. Typical Noise Levels ......................................... 6--111<br />

Figure 6--71. Graph Of Values For Adding Noise Levels ....................... 6--112<br />

Figure 6--72. Decrease In Loudness As Distance Increases (Free Field) ........ 6--113<br />

Figure A--1. GenSize--New Project Parameters Dialog Box) .................. A--5<br />

Figure A--2. GenSize Application Project Window ........................... A--14<br />

Figure A--5. Recommended Generator Report in View Mode ..................<br />

A--21<br />

H--4 APPENDIX H<br />

Rev. Jan 2011