Rapid prototyping in tissue engineering: challenges and potential

Rapid prototyping in tissue engineering: challenges and potential

Rapid prototyping in tissue engineering: challenges and potential

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Review TRENDS <strong>in</strong> Biotechnology Vol.22 No.12 December 2004<br />

<strong>Rapid</strong> <strong>prototyp<strong>in</strong>g</strong> <strong>in</strong> <strong>tissue</strong><br />

eng<strong>in</strong>eer<strong>in</strong>g: <strong>challenges</strong> <strong>and</strong> <strong>potential</strong><br />

Wai-Yee Yeong 1 , Chee-Kai Chua 1 , Kah-Fai Leong 1 <strong>and</strong> Margam Ch<strong>and</strong>rasekaran 2<br />

1<br />

<strong>Rapid</strong> Prototyp<strong>in</strong>g Research Laboratory, Design Research Centre, School of Mechanical <strong>and</strong> Production Eng<strong>in</strong>eer<strong>in</strong>g,<br />

Nanyang Technological University, S<strong>in</strong>gapore 639798<br />

2<br />

Form<strong>in</strong>g Technology Group, S<strong>in</strong>gapore Institute of Manufactur<strong>in</strong>g Technology, S<strong>in</strong>gapore 638075<br />

Tissue eng<strong>in</strong>eer<strong>in</strong>g aims to produce patient-specific<br />

biological substitutes <strong>in</strong> an attempt to circumvent the<br />

limitations of exist<strong>in</strong>g cl<strong>in</strong>ical treatments for damaged<br />

<strong>tissue</strong> or organs. The ma<strong>in</strong> regenerative <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g<br />

approach <strong>in</strong>volves transplantation of cells onto<br />

scaffolds. The scaffold attempts to mimic the function of<br />

the natural extracellular matrix, provid<strong>in</strong>g a temporary<br />

template for the growth of target <strong>tissue</strong>s. Scaffolds<br />

should have suitable architecture <strong>and</strong> strength to serve<br />

their <strong>in</strong>tended function. This paper presents a comprehensive<br />

review of the fabrication methods, <strong>in</strong>clud<strong>in</strong>g<br />

conventional, ma<strong>in</strong>ly manual, techniques <strong>and</strong> advanced<br />

process<strong>in</strong>g methods such as rapid <strong>prototyp<strong>in</strong>g</strong> (RP)<br />

techniques. The <strong>potential</strong> <strong>and</strong> <strong>challenges</strong> of scaffoldbased<br />

technology are discussed from the perspective of<br />

RP technology.<br />

Tissue eng<strong>in</strong>eer<strong>in</strong>g has ga<strong>in</strong>ed more attention <strong>in</strong> the past<br />

decade, ow<strong>in</strong>g to its success <strong>in</strong> enabl<strong>in</strong>g <strong>tissue</strong> regeneration<br />

for therapeutic purposes. It is an <strong>in</strong>terdiscipl<strong>in</strong>ary<br />

field which applies the pr<strong>in</strong>ciples of eng<strong>in</strong>eer<strong>in</strong>g <strong>and</strong> life<br />

sciences to the development of biological substitutes that<br />

restore, ma<strong>in</strong>ta<strong>in</strong> or improve <strong>tissue</strong> function [1].<br />

Tissue eng<strong>in</strong>eer<strong>in</strong>g aims to produce patient-specific<br />

biological substitutes <strong>in</strong> an attempt to circumvent the<br />

limitations of exist<strong>in</strong>g cl<strong>in</strong>ical treatments for damaged<br />

<strong>tissue</strong> or organs. These limitations <strong>in</strong>clude shortage of<br />

donor organs, chronic rejection <strong>and</strong> cell morbidity. The<br />

ma<strong>in</strong> regenerative <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g approaches <strong>in</strong>clude<br />

<strong>in</strong>jection of cells alone, development of encapsulated<br />

systems <strong>and</strong> transplantation of cells onto scaffolds [2].<br />

The latter approach appears to be the dom<strong>in</strong>ant method<br />

used <strong>in</strong> research on <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g because it permits<br />

experimental manipulation at three levels to achieve<br />

optimal construct: the cells, the polymer scaffolds <strong>and</strong><br />

the construction method [3].<br />

The scaffold attempts to mimic the function of the natural<br />

extracellular matrix. The primary roles of scaffold are: (i) to<br />

serve as an adhesion substrate for the cell, facilitat<strong>in</strong>g the<br />

localization <strong>and</strong> delivery of cells when they are implanted;<br />

(ii) to provide temporary mechanical support to the newly<br />

grown <strong>tissue</strong> by def<strong>in</strong><strong>in</strong>g <strong>and</strong> ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g a 3D structure<br />

<strong>and</strong> (iii) to guide the development of new <strong>tissue</strong>s with the<br />

appropriate function [4].<br />

Correspond<strong>in</strong>g author: Chee-Kai Chua (mckchua@ntu.edu.sg).<br />

Available onl<strong>in</strong>e 2 November 2004<br />

www.sciencedirect.com 0167-7799/$ - see front matter Q 2004 Elsevier Ltd. All rights reserved. doi:10.1016/j.tibtech.2004.10.004<br />

A successful scaffold should possess the follow<strong>in</strong>g<br />

characteristics [5]: (i) a suitable macrostructure to<br />

promote cell proliferation <strong>and</strong> cell-specific matrix production;<br />

(ii) an open-pore geometry with a highly porous<br />

surface <strong>and</strong> microstructure that enables cell <strong>in</strong>growth;<br />

(iii) optimal pore size employed to encourage <strong>tissue</strong><br />

regeneration <strong>and</strong> to avoid pore occlusion; (iv) suitable<br />

surface morphology <strong>and</strong> physiochemical properties to<br />

encourage <strong>in</strong>tracellular signal<strong>in</strong>g <strong>and</strong> recruitment of<br />

cells <strong>and</strong> (v) be<strong>in</strong>g made from a material with a predictable<br />

rate of degradation, with a nontoxic degraded material.<br />

Scaffolds can be produced <strong>in</strong> a variety of ways, us<strong>in</strong>g<br />

conventional techniques or advanced process<strong>in</strong>g methods.<br />

Conventional scaffold fabrication methods<br />

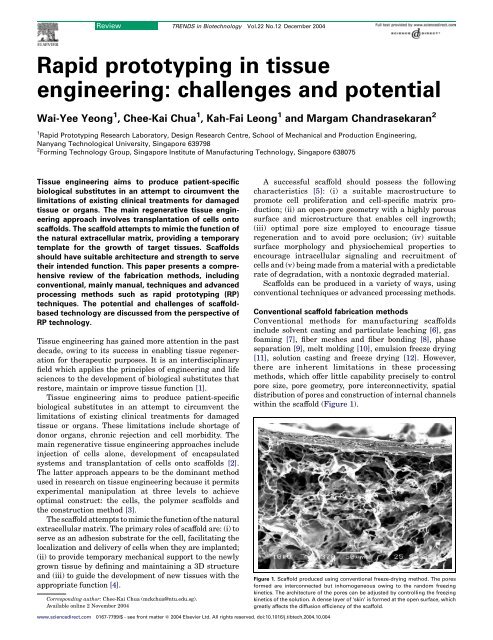

Conventional methods for manufactur<strong>in</strong>g scaffolds<br />

<strong>in</strong>clude solvent cast<strong>in</strong>g <strong>and</strong> particulate leach<strong>in</strong>g [6], gas<br />

foam<strong>in</strong>g [7], fiber meshes <strong>and</strong> fiber bond<strong>in</strong>g [8], phase<br />

separation [9], melt mold<strong>in</strong>g [10], emulsion freeze dry<strong>in</strong>g<br />

[11], solution cast<strong>in</strong>g <strong>and</strong> freeze dry<strong>in</strong>g [12]. However,<br />

there are <strong>in</strong>herent limitations <strong>in</strong> these process<strong>in</strong>g<br />

methods, which offer little capability precisely to control<br />

pore size, pore geometry, pore <strong>in</strong>terconnectivity, spatial<br />

distribution of pores <strong>and</strong> construction of <strong>in</strong>ternal channels<br />

with<strong>in</strong> the scaffold (Figure 1).<br />

Figure 1. Scaffold produced us<strong>in</strong>g conventional freeze-dry<strong>in</strong>g method. The pores<br />

formed are <strong>in</strong>terconnected but <strong>in</strong>homogeneous ow<strong>in</strong>g to the r<strong>and</strong>om freez<strong>in</strong>g<br />

k<strong>in</strong>etics. The architecture of the pores can be adjusted by controll<strong>in</strong>g the freez<strong>in</strong>g<br />

k<strong>in</strong>etics of the solution. A dense layer of ‘sk<strong>in</strong>’ is formed at the open surface, which<br />

greatly affects the diffusion efficiency of the scaffold.

644<br />

Review TRENDS <strong>in</strong> Biotechnology Vol.22 No.12 December 2004<br />

Consequently, researchers try to modify the conventional<br />

techniques to overcome these <strong>in</strong>herent process<br />

limitations. Kim <strong>and</strong> Mooney [13] produced polyglycolic<br />

acid (PGA) fibers bonded with poly-L-lactide (PLLA) to<br />

enhance the mechanical strength <strong>and</strong> the degradation<br />

rate of the unbonded PGA fiber meshes. As a variant to the<br />

freeze-dry<strong>in</strong>g process, Ho et al. [14] prepared scaffolds<br />

us<strong>in</strong>g a freeze-extraction method, which was relatively<br />

more time- <strong>and</strong> energy efficient. Murphy et al. [15]<br />

enhanced pore <strong>in</strong>terconnectivity by fus<strong>in</strong>g the porogen<br />

together to form a template, <strong>in</strong>stead of us<strong>in</strong>g unbounded<br />

particles <strong>in</strong> so1vent cast<strong>in</strong>g/particulate leach<strong>in</strong>g process.<br />

The result showed that holes were formed <strong>in</strong> pore walls,<br />

guarantee<strong>in</strong>g pore <strong>in</strong>terconnectivity. Chen <strong>and</strong> Ma [16]<br />

created nanofibrous PLLA scaffolds which <strong>in</strong>corporated<br />

<strong>in</strong>terconnected spherical macropores. The macropores<br />

were voids left by paraff<strong>in</strong> spheres, which were thermally<br />

bonded before the cast<strong>in</strong>g of the polymer solution. In place<br />

of paraff<strong>in</strong> spheres, Gross <strong>and</strong> Rodríguez-Lorenzo [17]<br />

used a s<strong>in</strong>tered salt template to produce PLLA-re<strong>in</strong>forced<br />

apatite scaffolds.<br />

Notwithst<strong>and</strong><strong>in</strong>g the improvements that have been<br />

atta<strong>in</strong>ed, the control over scaffold architecture us<strong>in</strong>g these<br />

conventional techniques is highly process dependent<br />

rather than design dependent. As a result, RP is seen to<br />

be a viable alternative for achiev<strong>in</strong>g extensive <strong>and</strong><br />

detailed control over scaffold architecture [18,19].<br />

Advanced scaffold-fabrication methods<br />

RP is a common name for a group of techniques that can<br />

generate a physical model directly from computer-aided<br />

design data. It is an additive process <strong>in</strong> which each part is<br />

constructed <strong>in</strong> a layer-by-layer manner. Table 1 presents<br />

<strong>and</strong> compares the RP techniques that can be used to<br />

fabricate scaffolds directly or <strong>in</strong>directly.<br />

Direct RP fabrication method<br />

RP systems such as fused deposition model<strong>in</strong>g (FDM), 3D<br />

pr<strong>in</strong>t<strong>in</strong>ge (3-DP) <strong>and</strong> selective laser s<strong>in</strong>ter<strong>in</strong>g (SLS) have<br />

been shown to be feasible for produc<strong>in</strong>g porous structures<br />

for use <strong>in</strong> <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g. In this review, the <strong>tissue</strong><br />

scaffold fabrication techniques are categorized by virtue of<br />

their mode of assembly <strong>in</strong>to one of two processes: the melt–<br />

dissolution deposition technique <strong>and</strong> the particle bond<strong>in</strong>g<br />

technique.<br />

Melt–dissolution deposition technique<br />

In a typical melt–dissolution deposition system, each layer<br />

is created by extrusion of a str<strong>and</strong> of material through an<br />

orifice while it moves across the plane of the layer crosssection.<br />

The material cools, solidify<strong>in</strong>g itself <strong>and</strong> fix<strong>in</strong>g to<br />

the previous layer [20]. Successive layer formation, one<br />

atop another, forms a complex 3D solid object.<br />

Porosity <strong>in</strong> the horizontal XY plane is created by<br />

controll<strong>in</strong>g the spac<strong>in</strong>g between adjacent filaments<br />

(Figure 2). The vertical Z gap is formed by deposit<strong>in</strong>g the<br />

subsequent layer of filaments at an angle with respect to<br />

the previous layer. Repetitive pattern draw<strong>in</strong>g will<br />

produce a porous structure ready to be used as a scaffold.<br />

A representative system us<strong>in</strong>g melt–dissolution<br />

www.sciencedirect.com<br />

deposition is FDM. This method sp<strong>in</strong>s off several new<br />

systems that operate under similar pr<strong>in</strong>ciples.<br />

FDM: In this method, a filament of a suitable material<br />

is fed <strong>and</strong> melted <strong>in</strong>side a heated liquefier before be<strong>in</strong>g<br />

extruded through a nozzle. The system operates <strong>in</strong> a<br />

temperature-controlled environment to ma<strong>in</strong>ta<strong>in</strong> sufficient<br />

fusion energy between each layer.<br />

Researchers have demonstrated the feasibility of<br />

utiliz<strong>in</strong>g FDM to fabricate a functional scaffold directly.<br />

Ze<strong>in</strong> et al. [21] fabricated polycaprolactone (PCL) scaffolds<br />

with a honeycomb structure <strong>and</strong> a channel size of 160–<br />

770 mm. Samar et al. [22] have successfully produced a<br />

polymer-ceramic composite scaffold made of polypropylene-tricalcium<br />

phosphate (PP-TCP). The scaffolds were<br />

reported to have a pore size of 160 mm <strong>and</strong> a mechanical<br />

strength of 12.7 MPa, which is comparable to the tensile<br />

strength of natural cancellous bone, which has a value of<br />

7.4MPa [23]. In a recent study, human mesenchymal<br />

progenitor cells were seeded on PCL <strong>and</strong> PCL-hydroxyapatite<br />

(HA) scaffolds fabricated by FDM [24]. Proliferation<br />

of cells toward <strong>and</strong> onto the scaffold surfaces was detected.<br />

Drawbacks of the FDM technique <strong>in</strong>clude the need for<br />

<strong>in</strong>put material of a specific diametric size <strong>and</strong> material<br />

properties to feed through the rollers <strong>and</strong> nozzle. Any<br />

changes <strong>in</strong> the properties of the material require effort to<br />

recalibrate the sett<strong>in</strong>g of the feed<strong>in</strong>g parameters. As a<br />

result, FDM has a narrow process<strong>in</strong>g w<strong>in</strong>dow. The<br />

resolution of FDM is relatively low, at 250 mm. In FDM,<br />

a limited range of material s can be used, with almost<br />

complete exclusion of natural polymers, as the material<br />

used must be made <strong>in</strong>to filaments <strong>and</strong> melted <strong>in</strong>to a semiliquid<br />

phase before extrusion. The operat<strong>in</strong>g temperature<br />

of the system is too high to <strong>in</strong>corporate biomolecules <strong>in</strong>to<br />

the scaffold, hence limit<strong>in</strong>g the biomimetic aspects of the<br />

scaffold produced. Moreover, the material deposited<br />

solidifies <strong>in</strong>to dense filaments, block<strong>in</strong>g the formation of<br />

microporosity. Microporosity is an important factor <strong>in</strong><br />

encourag<strong>in</strong>g neovascularization <strong>and</strong> cell attachment [25].<br />

Modifications of FDM to circumvent these limitations<br />

have encouraged the emergence of several new techniques.<br />

These <strong>in</strong>clude techniques that elim<strong>in</strong>ate the<br />

requirement of precursor filaments or a system with<br />

reduced operat<strong>in</strong>g temperatures. Some variants of the<br />

FDM process <strong>in</strong>clude the 3D fiber-deposition technique<br />

[26], precision extrud<strong>in</strong>g deposition (PED) [27] <strong>and</strong> precise<br />

extrusion manufactur<strong>in</strong>g (PEM) [28].<br />

3D fiber-deposition technique: In this method, the<br />

feedstock material is <strong>in</strong> a pellet or granule form that can<br />

be poured <strong>in</strong>to the heated liquefier directly. Poly(ethylene<br />

glycol)-terephthalate-poly(butylenes terephthalate)<br />

(PEGT–PBT) block copolymer scaffolds have been<br />

fabricated for articulate <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g applications<br />

[26]. Material flow is regulated by apply<strong>in</strong>g<br />

pressure to the syr<strong>in</strong>ge.<br />

PED: The extruder <strong>in</strong> this system is equipped with a<br />

built-<strong>in</strong> heat<strong>in</strong>g unit to melt the feedstock material, hence<br />

elim<strong>in</strong>at<strong>in</strong>g the need to produce precursor filaments. PCL<br />

scaffolds with a pore size of 250 mm were fabricated [27].<br />

PEM: PLLA scaffolds with controllable porous<br />

architectures from 200 to 500 mm <strong>in</strong> size have been<br />

produced [28].

Table 1. Comparison of different rapid <strong>prototyp<strong>in</strong>g</strong> (RP) technologies applied <strong>in</strong> <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g<br />

RP system Resolution (mm) Material Strength Weakness Refs<br />

Melt–dissolution deposition technique<br />

Fused deposition model<strong>in</strong>g 250 PCL a , PP-TCP,<br />

PCL-HA, PCL-<br />

TCP<br />

The melt process is generally undesirable from the<br />

perspective of scaffold bioactivity because of the elevated<br />

temperatures <strong>in</strong>volved. This limitation drives researchers<br />

to replace the melt<strong>in</strong>g process with that of dissolution of<br />

materials. Systems developed <strong>in</strong>clude low-temperature<br />

deposition manufactur<strong>in</strong>g (LDM) [29], mult<strong>in</strong>ozzle<br />

Good mechanical strength;<br />

versatile <strong>in</strong> lay-down pattern<br />

design<br />

High temperature; need to<br />

produce filament material;<br />

narrow process<strong>in</strong>g w<strong>in</strong>dow;<br />

rigid filament<br />

High temperature;<br />

rigid filament<br />

3D fiber-deposition technique 250 PEGT-PBT Input material <strong>in</strong> pellet form;<br />

preparation time is reduced<br />

[26]<br />

Precision extrud<strong>in</strong>g depo- 250 PCL Input material <strong>in</strong> pellet form High temperature;<br />

[27]<br />

sition<br />

rigid filament<br />

Precise extrusion<br />

200–500 PLLA-TCP Input material <strong>in</strong> pellet form High temperature;<br />

[28]<br />

manufactur<strong>in</strong>g<br />

rigid filament<br />

Low-temperature deposition 400 PLLA-TCP Can <strong>in</strong>corporate biomolecule Solvent is used;<br />

[29]<br />

manufactur<strong>in</strong>g<br />

requires freeze dry<strong>in</strong>g<br />

Multi-nozzle deposition 400 PLLA-TCP Enhanced range of materials Solvent is used;<br />

[30]<br />

manufactur<strong>in</strong>g<br />

can be used; can <strong>in</strong>corporate<br />

biomolecule<br />

requires freeze dry<strong>in</strong>g<br />

Pressure-assisted<br />

10–600 PCL, PLLA Enhanced range of materials Small nozzle <strong>in</strong>hibits<br />

[31]<br />

microsyr<strong>in</strong>ge<br />

can be used; can <strong>in</strong>corporate <strong>in</strong>corporation of particle;<br />

biomolecule; very f<strong>in</strong>e resol- narrow range of pr<strong>in</strong>table<br />

ution can be achieved<br />

viscosities; solvent is used<br />

Robocast<strong>in</strong>g 100–1000 Organic <strong>in</strong>k Enhanced range of materials Precise control of <strong>in</strong>k properties [34]<br />

can be used<br />

is crucial<br />

3D bioplotter 250 Hydrogel Enhanced range of materials Low mechanical strength; [35]<br />

can be used; can <strong>in</strong>corporate smooth surface; low accuracy;<br />

biomolecule<br />

slow process<strong>in</strong>g; precise control<br />

of properties of material<br />

<strong>and</strong> medium; calibration for<br />

new material<br />

<strong>Rapid</strong> <strong>prototyp<strong>in</strong>g</strong> robotic 400–1000 Chitosanchito- Enhanced range of materials Precise control properties of [36]<br />

dispens<strong>in</strong>g system<br />

san-HA<br />

can be used; can <strong>in</strong>corporate material <strong>and</strong> medium; requires<br />

Particle bond<strong>in</strong>g techniques<br />

biomolecule<br />

freeze dry<strong>in</strong>g<br />

3-dimensional pr<strong>in</strong>t<strong>in</strong>ge 200 PLGA, starch- Microposity <strong>in</strong>duced <strong>in</strong> the Material must be <strong>in</strong> powder [41]<br />

based polymer scaffold; enhanced range of form; limited mechanical<br />

materials can be used; water strength; Powdery surface<br />

used as b<strong>in</strong>der; no support f<strong>in</strong>ish; trapped powder issue;<br />

structure needed; fast<br />

process<strong>in</strong>g<br />

might require postprocess<strong>in</strong>g<br />

TheriForme 300 PLLA Microposity <strong>in</strong>duced <strong>in</strong> the Material must be <strong>in</strong> powder [45]<br />

scaffold; enhanced range of form; powdery surface f<strong>in</strong>ish;<br />

materials can be used; nonorganic<br />

b<strong>in</strong>der is possible; no<br />

support structure is needed;<br />

fast process<strong>in</strong>g<br />

trapped powder<br />

Selective laser s<strong>in</strong>ter<strong>in</strong>g 500 PEEK-HA, PCL Microposity <strong>in</strong>duced <strong>in</strong> the Material must be <strong>in</strong> powder [47]<br />

scaffold enhanced range of form; high temperature;<br />

materials can be used;<br />

powdery surface f<strong>in</strong>ish;<br />

Indirect RP fabrication method<br />

no support structure needed;<br />

fast process<strong>in</strong>g<br />

trapped powder<br />

Melt deposition 250 Thermoplastic Enhanced range of materials Multisteps <strong>in</strong>volved [48]<br />

polymer<br />

can be used; control of external<br />

<strong>and</strong> <strong>in</strong>ternal morphology<br />

Droplet deposition 180 Wax Enhanced range of materials<br />

can be used; control of external<br />

<strong>and</strong> <strong>in</strong>ternal morphology<br />

Multisteps <strong>in</strong>volved [49]<br />

Photo-polymerization 366 Res<strong>in</strong> Enhanced range of materials<br />

can be used; control of external<br />

<strong>and</strong> <strong>in</strong>ternal morphology<br />

Multisteps <strong>in</strong>volved [50]<br />

a<br />

Abbreviations: HA, hydroxyapatite; PCL, polycaprolactone; PEEK-HA, polyetheretherketone-hydroxyapatite; PEGT-PBT, poly(ethylene glycol)-terephthalate-poly(butylenes<br />

terephthalate; PLLA, poly-L-lactide; PP-TCP, polypropylene-tricalcium phosphate.<br />

www.sciencedirect.com<br />

Review TRENDS <strong>in</strong> Biotechnology Vol.22 No.12 December 2004 645<br />

[21]<br />

deposition manufactur<strong>in</strong>g (MDM) [30], pressure-assisted<br />

microsyr<strong>in</strong>ges (PAM) [31] <strong>and</strong> robocast<strong>in</strong>g [32].<br />

LDM: The scaffold-build<strong>in</strong>g cycle is performed <strong>in</strong> a lowtemperature<br />

environment under 08C [29]. A PLLA–TCP<br />

pipe scaffold has been produced.<br />

MDM: This is an improved version of LDM, with the

646<br />

Figure 2. structure produced us<strong>in</strong>g fused deposition model<strong>in</strong>g. Uniformly<br />

<strong>in</strong>terconnected square channels are obta<strong>in</strong>ed with a pattern sett<strong>in</strong>g of 08 or 908.<br />

The scaffold structure is highly regular <strong>and</strong> reproducible. The portion of the<br />

filament that spans across two support<strong>in</strong>g po<strong>in</strong>ts is subjected to gravity-<strong>in</strong>duced<br />

deformation dur<strong>in</strong>g the solidification phase. Therefore, the sett<strong>in</strong>g of the mach<strong>in</strong>e<br />

parameters, as well as the material properties, must be precisely controlled to<br />

ensure m<strong>in</strong>imum filament deflection. Filaments are aligned orthogonally, with<br />

grooves at the <strong>in</strong>tersection po<strong>in</strong>t between consecutive layers. Cells on the scaffold<br />

must span across these grooves to cellularize the entire structure.<br />

advantage of be<strong>in</strong>g able to use a greater range of<br />

materials. The enhancement is achieved by <strong>in</strong>corporat<strong>in</strong>g<br />

more jett<strong>in</strong>g nozzles <strong>in</strong>to the system [29]. Support<br />

structures can be built us<strong>in</strong>g water, which is nontoxic<br />

<strong>and</strong> easy to remove. In the work by Zhuo et al. [30],<br />

biomolecules <strong>in</strong> the form of bone morphogenic prote<strong>in</strong><br />

were embedded <strong>in</strong> the bulk material <strong>and</strong> then released<br />

slowly as the scaffold degraded.<br />

PAM: A microsyr<strong>in</strong>ge is used to expel the dissolved<br />

polymer under low <strong>and</strong> constant pressure to form the<br />

desired pattern. The resolution of this method is on a<br />

cellular scale, which is remarkably high compared with<br />

the techniques described previously. Vozzi et al. [31]<br />

developed PCL <strong>and</strong> PLLA scaffolds with l<strong>in</strong>e width of<br />

20 mm. It has been demonstrated that the performance of<br />

this method is comparable to that of soft lithography [33].<br />

However, capillaries with a very small diameter require<br />

careful h<strong>and</strong>l<strong>in</strong>g to avoid any tip breakage. Higher<br />

pressure is also needed to expel the material from a<br />

small orifice.<br />

Robocast<strong>in</strong>g: This patented system is able to lay down<br />

a highly concentrated, pseudoplastic-like colloidal suspension<br />

[32]. Therriault et al. [34] fabricated a 3D microvascular<br />

network by robocast<strong>in</strong>g fugitive organic <strong>in</strong>k,<br />

followed by scaffold <strong>in</strong>filtration with epoxy res<strong>in</strong> <strong>and</strong><br />

further postprocess<strong>in</strong>g.<br />

In general, the scaffolds fabricated us<strong>in</strong>g the melt or<br />

solution deposition techniques described are usually<br />

meant to serve as hard-<strong>tissue</strong> scaffolds. L<strong>and</strong>ers <strong>and</strong><br />

Mülhaupt [35] have developed an aqueous system, the 3D<br />

bioplotter, to meet the dem<strong>and</strong> for fabrication of hydrogel<br />

scaffolds useful <strong>in</strong> soft-<strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g. Hydrogels are<br />

becom<strong>in</strong>g <strong>in</strong>creas<strong>in</strong>gly popular as a material for <strong>tissue</strong><br />

eng<strong>in</strong>eer<strong>in</strong>g because of their high water content <strong>and</strong> the<br />

fact that they have similar mechanical properties to those<br />

of many soft <strong>tissue</strong>s <strong>in</strong> the human body. Ang et al. [36]<br />

www.sciencedirect.com<br />

Review TRENDS <strong>in</strong> Biotechnology Vol.22 No.12 December 2004<br />

adopted a similar concept to develop a robotic dispenser,<br />

the rapid <strong>prototyp<strong>in</strong>g</strong> robotic dispens<strong>in</strong>g system(RPBOD),<br />

for the fabrication of a chitosan scaffold.<br />

3D bioplotter: The key feature of this method is the<br />

3D dispens<strong>in</strong>g of liquids <strong>and</strong> pastes <strong>in</strong>to a liquid medium<br />

with matched density. The plott<strong>in</strong>g material leaves the<br />

nozzle <strong>and</strong> solidifies <strong>in</strong> the plott<strong>in</strong>g medium after bond<strong>in</strong>g<br />

to the previous layer. The liquid medium compensates for<br />

gravity <strong>and</strong> hence no support structure is needed.<br />

Hydrogel scaffolds with well-def<strong>in</strong>ed <strong>in</strong>ternal pore<br />

structure were prepared by L<strong>and</strong>ers et al. [37]. The<br />

hydrogel scaffolds had <strong>in</strong>terconnected pores, 200–400 mm<br />

<strong>in</strong> diameter. However, the hydrogel presented a smooth<br />

surface, which might be nonadherent to cells [38]. Therefore,<br />

further surface coat<strong>in</strong>g was required to render the<br />

surface favorable for cell-adhesion. Fibroblasts seeded on<br />

the scaffolds showed almost complete coverage of cells.<br />

However, the scaffolds had limited resolution <strong>and</strong> mechanical<br />

strength. Material rigidity was shown to <strong>in</strong>fluence<br />

cell spread<strong>in</strong>g <strong>and</strong> migration speed, as demonstrated by<br />

Wong et al. [39]. Cells displayed a preference for stiffer<br />

regions, <strong>and</strong> tended to migrate faster on surfaces with<br />

lower compliance.<br />

RPBOD: This system, developed by Ang et al. [36],<br />

consists of a computer-guided desktop robot <strong>and</strong> a onecomponent<br />

pneumatic dispenser. Material <strong>in</strong> liquid form<br />

was dispensed <strong>in</strong>to a dispens<strong>in</strong>g medium through a small<br />

Teflon-l<strong>in</strong>ed nozzle. Chitosan scaffolds with pore size of<br />

400–1000 mm were produced <strong>in</strong> the prelim<strong>in</strong>ary study.<br />

Particle-bond<strong>in</strong>g techniques<br />

In particle-bond<strong>in</strong>g techniques, particles are selectively<br />

bonded <strong>in</strong> a th<strong>in</strong> layer of powder material. The th<strong>in</strong> 2D<br />

layers are bonded one upon another to form a complex 3D<br />

solid object. Dur<strong>in</strong>g fabrication, the object is supported by<br />

<strong>and</strong> embedded <strong>in</strong> unprocessed powder. Therefore, this<br />

technique enables the fabrication of through channels <strong>and</strong><br />

overhang<strong>in</strong>g features. After completion of all layers, the<br />

object is removed from the bed of unbonded powder [20].<br />

The powder utilized can be a pure powder or surfacecoated<br />

powder, depend<strong>in</strong>g on the application of the scaffold.<br />

It is possible to use a s<strong>in</strong>gle one-component powder or a<br />

mixture of different powders, blended together.<br />

These techniques are capable of produc<strong>in</strong>g a porous<br />

structure with controllable macroporosity as well as<br />

microporosity. The microporosity arises from the space<br />

between the <strong>in</strong>dividual granules of powder. These techniques<br />

offer control over pore architecture by manipulat<strong>in</strong>g<br />

the region of bond<strong>in</strong>g. However, the pore size is limited<br />

by the powder size of the stock material. Larger pores can<br />

be generated by mix<strong>in</strong>g porogen <strong>in</strong>to the powder bed<br />

before the bond<strong>in</strong>g process.<br />

The powder-based materials provide a rough surface to<br />

the scaffold. It has been suggested that topographical cues<br />

might have a significant effect upon cellular behavior [40].<br />

As a cell attaches to the scaffold, stretch receptors are<br />

activated. Receptors on the scaffold surface might be<br />

subjected to vary<strong>in</strong>g degrees of deformation, lead<strong>in</strong>g to<br />

activation of cell signal transduction pathways. Therefore,<br />

scaffolds fabricated via a particle-bond<strong>in</strong>g technique

might be more advantageous <strong>in</strong> the context of cell<br />

attachment.<br />

Typical systems <strong>in</strong> this category <strong>in</strong>clude 3-DP [41],<br />

TheriForme [42] <strong>and</strong> SLS [43].<br />

3DP: In this process, a stream of adhesive droplets is<br />

expelled through an <strong>in</strong>kjet pr<strong>in</strong>thead, selectively bond<strong>in</strong>g<br />

a th<strong>in</strong> layer of powder particles to form a solid shape [20].<br />

The resolution achieved is w300 mm. Kim et al. [44]<br />

employed 3DP us<strong>in</strong>g a particulate leach<strong>in</strong>g technique to<br />

create porous scaffolds us<strong>in</strong>g polylactic-co-glycolic acid<br />

(PLGA) mix with salt particles <strong>and</strong> a suitable organic<br />

solvent. Pores formed were of the scale 45–150 mm with<br />

60% porosity. In vitro cell culture with hepatocytes showed<br />

<strong>in</strong>growth of these cells <strong>in</strong>to the pore space.<br />

In an effort to render the system more biocompatible,<br />

Lam et al. [43] have formulated a blend of starch-based<br />

polymer powders that can be bonded together us<strong>in</strong>g<br />

distilled water. The group also tried to enhance the<br />

mechanical property of the scaffold produced by <strong>in</strong>filtrat<strong>in</strong>g<br />

the structure with PLLA <strong>and</strong> PCL copolymer solution.<br />

TheriForm: This system is similar to 3DP, <strong>in</strong> that a<br />

pr<strong>in</strong>thead assembly deposits b<strong>in</strong>der droplets onto selected<br />

regions of the powder, swell<strong>in</strong>g <strong>and</strong> dissolv<strong>in</strong>g the polymer<br />

powder <strong>in</strong> the pr<strong>in</strong>ted regions. Zelt<strong>in</strong>ger et al. [45]<br />

performed a study on a TheriForm-built PLLA scaffold<br />

with different pore sizes us<strong>in</strong>g can<strong>in</strong>e dermal fibroblasts<br />

(DmFb), vascular smooth muscle cells (VSMC) <strong>and</strong><br />

microvascular epithelial cells (MVEC). They found that<br />

DmFb is <strong>in</strong>different to pore size, whereas MVEC <strong>and</strong><br />

VSMC favored a pore size of 90 mm <strong>and</strong> 107 mm, respectively,<br />

suggest<strong>in</strong>g the existence of an optimal pore size for<br />

different cell types.<br />

SLS: This technique uses a deflected laser beam<br />

selectively to scan over the powder surface follow<strong>in</strong>g the<br />

cross-sectional profiles carried by the slice data. The<br />

<strong>in</strong>teraction of the laser beam with the powder elevates the<br />

powder temperature to reach the glass-transition<br />

temperature, caus<strong>in</strong>g surfaces <strong>in</strong> contact to deform<br />

<strong>and</strong> fuse together [20]. Thisisthepreferredfabrication<br />

process for produc<strong>in</strong>g complex porous ceramic matrices<br />

suitable for implantation <strong>in</strong> a bone defect, as demonstrated<br />

by Vail et al. [46].<br />

The authors’ group has successfully s<strong>in</strong>tered polyetheretherketone-hydroxyapatite<br />

(PEEK-HA) powder blends<br />

on a commercial SLS mach<strong>in</strong>e [47]. In the research,<br />

different weight percentage compositions of physically<br />

mixed PEEK-HA powder blends were s<strong>in</strong>tered by vary<strong>in</strong>g<br />

the laser power <strong>and</strong> temperature sett<strong>in</strong>gs (Figure 3).<br />

Indirect RP fabrication methods<br />

RP systems can also be utilized to produce a sacrificial<br />

mould to fabricate <strong>tissue</strong>-eng<strong>in</strong>eer<strong>in</strong>g scaffolds. These<br />

multistep methods usually <strong>in</strong>volve cast<strong>in</strong>g of material <strong>in</strong><br />

a mould <strong>and</strong> then remov<strong>in</strong>g or sacrific<strong>in</strong>g the mould to<br />

obta<strong>in</strong> the f<strong>in</strong>al scaffold. Such techniques enable the user<br />

to control both the external <strong>and</strong> the <strong>in</strong>ternal morphology of<br />

the f<strong>in</strong>al construct. In addition, <strong>in</strong>direct methods also<br />

require less raw scaffold material while <strong>in</strong>creas<strong>in</strong>g the<br />

range of materials that can be used <strong>and</strong> mak<strong>in</strong>g it possible<br />

to use composite blends that might require conflict<strong>in</strong>g<br />

process<strong>in</strong>g parameters. The orig<strong>in</strong>al properties of the<br />

www.sciencedirect.com<br />

Review TRENDS <strong>in</strong> Biotechnology Vol.22 No.12 December 2004 647<br />

Figure 3. Micrographs of 90% polyetheretherketone by weight <strong>and</strong> 10% hydroxyapatite<br />

by weight s<strong>in</strong>tered us<strong>in</strong>g selective laser s<strong>in</strong>ter<strong>in</strong>g. The bond<strong>in</strong>g between<br />

granules of particles is clearly observed, <strong>in</strong>dicat<strong>in</strong>g the formation of microporosity<br />

with<strong>in</strong> the structure. The surface topography of the powder is irregular <strong>and</strong> rough.<br />

biomaterial are well conserved because no heat<strong>in</strong>g process<br />

is imposed on the scaffold material. Common RP techniques<br />

employed <strong>in</strong>clude melt deposition [48], droplet<br />

deposition [49] <strong>and</strong> photopolymerization [50].<br />

Melt deposition techniques<br />

The operat<strong>in</strong>g pr<strong>in</strong>ciple of these techniques, of which FDM<br />

is an example, is presented above.<br />

FDM: Bose et al. [48] produced alum<strong>in</strong>a <strong>and</strong> b-TCP<br />

ceramic scaffolds with pore sizes <strong>in</strong> the range of 300–500 mm<br />

<strong>and</strong> porosity of 25–45%. The moulds were made us<strong>in</strong>g a<br />

st<strong>and</strong>ard thermoplastic polymer. Their research aimed to<br />

<strong>in</strong>vestigate the effect of pore size <strong>and</strong> porosity on the<br />

mechanical <strong>and</strong> biological responses.<br />

Droplet deposition technique<br />

This technique is based on <strong>in</strong>kjet pr<strong>in</strong>t<strong>in</strong>g technology. A<br />

stream of molten thermoplastic droplets is deposited on a<br />

work<strong>in</strong>g surface. Thermal energy <strong>in</strong> the deposited droplet<br />

causes local melt<strong>in</strong>g on the previous layer <strong>and</strong> solidifies as<br />

one piece.<br />

Droplet deposition is a complex <strong>in</strong>teraction of droplet<br />

spread<strong>in</strong>g upon impact, settl<strong>in</strong>g as a result of viscous <strong>and</strong><br />

surface-tension forces, <strong>and</strong> a solidification process. A<br />

representative system is the ModelMakerIIe (MMII) [20].<br />

MMII: This mach<strong>in</strong>e uses a s<strong>in</strong>gle jet each for a plastic<br />

build<strong>in</strong>g material <strong>and</strong> a wax-like support material, which<br />

are held <strong>in</strong> a melted liquid state <strong>in</strong> reservoirs. The pr<strong>in</strong>ter<br />

head ejects droplets of the materials as they are moved <strong>in</strong><br />

X-Y fashion. After an entire layer of the object has<br />

hardened, a mill<strong>in</strong>g head is passed over the layer to<br />

ensure that a uniform thickness has been achieved.<br />

Taboas et al. [51] produced PLLA scaffolds with micro<strong>and</strong><br />

macroporosity for bone <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g, <strong>in</strong> this case<br />

specifically trabecular bone. The global pores (500 mm<br />

wide channels) were computationally designed, whereas<br />

the local pores (50–100 mm wide voids) were formed by the<br />

porogen. PLA–PGA discrete composites were made us<strong>in</strong>g<br />

melt process<strong>in</strong>g.

648<br />

MMII is selected by researchers to fabricate calcium<br />

phosphate scaffolds because the build<strong>in</strong>g material has a<br />

very low coefficient of thermal expansion. There will be<br />

m<strong>in</strong>imal risk of fracture due to coefficient of thermal<br />

expansion mismatch with the ceramic dur<strong>in</strong>g pyrolysis.<br />

Limpanuphap <strong>and</strong> Derby [52] fabricated TCP scaffolds<br />

with controlled <strong>in</strong>ternal porosity us<strong>in</strong>g a suspension of<br />

TCP <strong>in</strong> an acrylate b<strong>in</strong>der. A similar route was used to<br />

produce a polymer–TCP scaffold, which is believed to show<br />

more <strong>potential</strong> for cell adhesion. Wilson et al. [53]<br />

fabricated HA scaffolds with a def<strong>in</strong>ed macroarchitecture.<br />

Channels achieved are w350–400 mm wide. These authors<br />

suggested that the <strong>in</strong>herent surface texture obta<strong>in</strong>ed from<br />

an MMII-built mould <strong>in</strong>creased the surface area of the<br />

scaffold <strong>and</strong> led to a higher degree of calcium <strong>and</strong> phosphate<br />

release, which is advantageous to bone formation.<br />

Sachlos et al. [54] have successfully produced collagen<br />

scaffolds with predef<strong>in</strong>ed <strong>and</strong> reproducible <strong>in</strong>ternal channels.<br />

The smallest channel width achieved was reported to<br />

be as low as 135 mm. In a variation to Sachlos’ work, the<br />

authors have produced chitosan-collagen scaffolds. MMII<br />

moulds with <strong>in</strong>tricate channels were built to conta<strong>in</strong> a<br />

chitosan–collagen solution. The resultant gel-like scaffold<br />

was capable of atta<strong>in</strong><strong>in</strong>g the designed morphology<br />

(Figure 4). These channels can serve as flow channels<br />

when coupled with a customized bioreactor, achiev<strong>in</strong>g<br />

more efficient perfusion of the culture medium.<br />

Photopolymerization techniques<br />

For photopolymerization techniques, optical energy is<br />

applied to irradiate the th<strong>in</strong> layer at the surface of a<br />

liquid photopolymer res<strong>in</strong>. The irradiation areas of<br />

res<strong>in</strong> react chemically <strong>and</strong> transform <strong>in</strong>to a solid<br />

phase. A well-known photopolymerization technique is<br />

stereolithography (SLA) [20].<br />

SLA: A UV laser traces out the first layer of photocurable<br />

res<strong>in</strong>, solidify<strong>in</strong>g the model’s cross-section while<br />

leav<strong>in</strong>g the rema<strong>in</strong><strong>in</strong>g areas <strong>in</strong> liquid form. The elevator<br />

then drops by a sufficient amount to cover the solid<br />

polymer with another layer of liquid res<strong>in</strong>. A sweeper<br />

recoats the solidified layer with liquid res<strong>in</strong> <strong>and</strong> the laser<br />

traces the second layer atop the first.<br />

Chu et al. [50] have produced HA-based porous implants<br />

us<strong>in</strong>g SLA-built epoxy moulds. A thermal curable HA–<br />

acrylate suspension was cast <strong>in</strong>to the mould to obta<strong>in</strong> a<br />

scaffold with <strong>in</strong>terconnected channels. The resolution of<br />

channel width achieved was as low as 366 mm.<br />

In another study, <strong>in</strong>vestigators carried out an <strong>in</strong> vivo<br />

study us<strong>in</strong>g two different architecture designs, orthogonal<br />

Figure 4. Scaffold (right) produced us<strong>in</strong>g ModelMakerIIe-built mould (left). The<br />

scaffold is able to reproduce the predeterm<strong>in</strong>ed morphology of the mould. The<br />

channels ensure high diffusion efficiency across the scaffold.<br />

www.sciencedirect.com<br />

Review TRENDS <strong>in</strong> Biotechnology Vol.22 No.12 December 2004<br />

<strong>and</strong> radial channels [55]. The prelim<strong>in</strong>ary results showed<br />

that controll<strong>in</strong>g the overall geometry of the regenerated<br />

bone <strong>tissue</strong> was possible through the <strong>in</strong>ternal architectural<br />

design of the scaffolds.<br />

Challenges of RP <strong>in</strong> <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g<br />

In spite of the <strong>in</strong>creas<strong>in</strong>g <strong>in</strong>terest of <strong>tissue</strong> eng<strong>in</strong>eers <strong>in</strong> the<br />

use of RP, there are several <strong>challenges</strong> that need to be<br />

addressed, namely the limited range of materials, the<br />

optimal scaffold design, the bioactivity of the scaffold, as<br />

well as the issues of cell seed<strong>in</strong>g <strong>and</strong> vascularization. Each<br />

of the issues will be discussed <strong>in</strong> detail.<br />

Range of materials<br />

Material processability: RP techniques are very<br />

specialized technologies <strong>in</strong> terms of material processability.<br />

Each technique requires a specific form of <strong>in</strong>put<br />

material such as filament, powder, solid pellet or solution.<br />

Therefore, it must be ensured that the choice of materials<br />

for the scaffold is compatible with the selected RP process<br />

<strong>and</strong> that it can be efficiently produced <strong>in</strong> the form<br />

required. Other considerations dur<strong>in</strong>g the selection of<br />

materials <strong>in</strong>clude the degradation profile <strong>and</strong> the mechanical<br />

strength of the scaffold.<br />

Degradation rate: In an ideal case, the scaffold should<br />

be remodeled <strong>and</strong> resorbed by grow<strong>in</strong>g cells <strong>and</strong> gradually<br />

replaced by the newly formed extracellular matrix <strong>and</strong><br />

differentiated cells. A desirable feature would be synchronization<br />

of the polymer degradation rate with the rate of<br />

<strong>tissue</strong> <strong>in</strong>growth. Therefore, the degradation properties of a<br />

scaffold are of crucial importance for the success of the<br />

scaffold-based approach.<br />

The degradation–absorption mechanism is the result of<br />

many <strong>in</strong>terrelated factors, <strong>in</strong>clud<strong>in</strong>g the hydrophilicity of<br />

the polymer backbone, degree of crystall<strong>in</strong>ity, presence<br />

of catalysts, volume of porosity <strong>and</strong> the surface area.<br />

Balanc<strong>in</strong>g each of these factors will enable an implant to<br />

degrade slowly <strong>and</strong> transfer stress at an appropriate rate<br />

to the surround<strong>in</strong>g <strong>tissue</strong>s as they heal. This is one of the<br />

major <strong>challenges</strong> fac<strong>in</strong>g <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g research today.<br />

Degradation product: Even though degradation<br />

products of biodegradable polymers are known to be<br />

largely non-cytotoxic, little <strong>in</strong>formation is available<br />

regard<strong>in</strong>g the degradation rate-dependent acidic byproduct<br />

effect of the scaffold. Sunga et al. [56] found that fast<br />

degradation of the polymer negatively affects cell viability<br />

<strong>and</strong> migration <strong>in</strong>to the scaffold, both <strong>in</strong> vitro <strong>and</strong> <strong>in</strong> vivo.<br />

This can be expla<strong>in</strong>ed by the rapid local acidification due<br />

to polymer degradation. Therefore, a more systematic<br />

<strong>in</strong>vestigative approach is needed to classify the material<br />

degradation profile.<br />

Mechanical strength of scaffolds: Cells are able to<br />

detect with high sensitivity the mechanical properties of<br />

the adhesion substrate, <strong>and</strong> to regulate <strong>in</strong>tegr<strong>in</strong> b<strong>in</strong>d<strong>in</strong>g<br />

<strong>and</strong> the assembly of focal adhesion plaques <strong>and</strong> the<br />

cytoskeleton accord<strong>in</strong>gly [57]. If the adhesion substrate<br />

is too rigid <strong>and</strong> nondeformable, the cells are not able to<br />

reorganize <strong>and</strong> recruit the receptors <strong>in</strong>to focal adhesion<br />

plaques, which is a prerequisite for the delivery of signals,<br />

ensur<strong>in</strong>g the viability of anchorage-dependent cells.<br />

Similarly, if the material is too compliant, it does not

enable the anchorage of cells, ow<strong>in</strong>g to the <strong>in</strong>ability to<br />

resist the tractional forces generated by the assembl<strong>in</strong>g<br />

cytoskeleton.<br />

Scaffold architecture design<br />

Pore size: The diverse nature of <strong>tissue</strong>s requires<br />

different optimal pore size for different types of <strong>tissue</strong>.<br />

Despite numerous proof-of-concept studies exhibit<strong>in</strong>g the<br />

existence of an optimal range of pore size for different cell<br />

types [58–60], little is known about specific optimal pore<br />

sizes for particular types of cell. Therefore, the pore size<br />

selected is governed by general empirical guidel<strong>in</strong>es.<br />

Scaffold morphology: RP-fabricated scaffolds generally<br />

present many edges <strong>and</strong> grooves. The effect of these<br />

discont<strong>in</strong>uities <strong>in</strong> topography might affect the adhesion<br />

<strong>and</strong> migration of cells, as shown by Y<strong>in</strong>’s work. Y<strong>in</strong> et al.<br />

[61] grew cardiac cells on microgrooved elastic scaffolds to<br />

<strong>in</strong>vestigate the topography-driven changes <strong>in</strong> cardiac<br />

electromechanics. The grooves are 50 mm <strong>in</strong> depth <strong>and</strong><br />

120 mm <strong>in</strong> width. These authors demonstrated a direct<br />

<strong>in</strong>fluence of the microstructure on cardiac function <strong>and</strong><br />

susceptibility to arrhythmias via calcium-dependent<br />

mechanisms.<br />

Surface topography: The surface roughness of the<br />

scaffold is important <strong>in</strong> cell–matrix <strong>in</strong>teractions. The<br />

rough powder surface produced from powder-based RP<br />

techniques might enhance cell adhesion. However, if the<br />

surface is too rough, the cells adher<strong>in</strong>g to these materials<br />

might not be able to develop dist<strong>in</strong>ct focal adhesion<br />

plaques or bridge the irregularities. Moreover, the sharpness<br />

of the surface could damage the cell physically. In<br />

certa<strong>in</strong> RP systems, such as FDM <strong>and</strong> bioplotter, the<br />

smooth surface of solidified materials cannot ensure firm<br />

cell adhesion <strong>and</strong> therefore require further surface<br />

modification or coat<strong>in</strong>g.<br />

Bioactivity of RP-fabricated scaffolds<br />

The <strong>in</strong>teraction of cells with the scaffold is governed by<br />

both structural <strong>and</strong> chemical signal<strong>in</strong>g molecules that<br />

have a decisive role for cell adhesion <strong>and</strong> the further<br />

behavior of cells after <strong>in</strong>itial contact [62].<br />

The extent of <strong>in</strong>itial cell adhesion decides the number,<br />

size, shape <strong>and</strong> distribution of focal adhesion plaques<br />

formed on the cell membrane, which subsequently<br />

describes the size <strong>and</strong> shape of the cell-spread<strong>in</strong>g area.<br />

The extent of spread<strong>in</strong>g is crucial for further migratory,<br />

proliferation <strong>and</strong> differentiation behavior of anchoragedependent<br />

cells.<br />

Current strategies to control the proliferation <strong>and</strong> other<br />

behaviors of cells on advanced biospecific materials<br />

<strong>in</strong>volve pattern<strong>in</strong>g the material surfaces with adhesive<br />

molecules or by <strong>in</strong>corporat<strong>in</strong>g a controlled release of<br />

biomolecules, such as natural growth factors, hormones,<br />

enzymes or synthetic cell cycle regulators.<br />

Some RP systems that have excluded high-temperature<br />

operation, such as MDM <strong>and</strong> bioplotter, offer the opportunity<br />

of <strong>in</strong>corporat<strong>in</strong>g the biomolecule dur<strong>in</strong>g the build<strong>in</strong>g<br />

cycle. However, further <strong>in</strong>formation, such as the type<br />

of biomolecule, the optimal concentration <strong>and</strong> spatial<br />

control of these biomolecules, is needed to produce the<br />

most favorable scaffold.<br />

www.sciencedirect.com<br />

Review TRENDS <strong>in</strong> Biotechnology Vol.22 No.12 December 2004 649<br />

Cell seed<strong>in</strong>g <strong>and</strong> vascularization<br />

One significant challenge <strong>in</strong> the scaffold-based approach<br />

<strong>in</strong> <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g is to distribute a high density of cells<br />

efficiently <strong>and</strong> uniformly throughout the scaffold volume.<br />

The only Food <strong>and</strong> Drug Adm<strong>in</strong>istration-approved cell<br />

seed<strong>in</strong>g process <strong>in</strong>volves the use of a Petri dish. However,<br />

this method has been shown to fail to deliver cells deep<br />

<strong>in</strong>side the scaffold with uniform distribution [63–65].<br />

Therefore, the cellularization of a 3D scaffold is closely<br />

related to the advances of bioreactor technologies.<br />

Bioreactors are generally def<strong>in</strong>ed as devices <strong>in</strong> which<br />

biological <strong>and</strong>/or biochemical processes develop under<br />

closely monitored <strong>and</strong> tightly controlled operat<strong>in</strong>g conditions<br />

[66]. Types of bioreactor <strong>in</strong>clude the sp<strong>in</strong>ner flask,<br />

perfusion cartridge <strong>and</strong> rotary cell culture system [67].<br />

Each of the systems utilizes different physical pr<strong>in</strong>ciples<br />

<strong>and</strong> might necessitate specific design considerations <strong>in</strong><br />

terms of scaffold shape <strong>and</strong> strength.<br />

RP systems present great flexibility <strong>in</strong> scaffold design<br />

<strong>and</strong> development. RP-fabricated scaffolds can be designed<br />

to have <strong>in</strong>terconnected flow channels to fit <strong>in</strong>to the<br />

operation of the bioreactor, as displayed by the work of<br />

Sakai et al. [68].<br />

Sufficient vascularization of the scaffold, to ma<strong>in</strong>ta<strong>in</strong><br />

adequate perfusion, is a primary consideration <strong>in</strong> the<br />

eng<strong>in</strong>eer<strong>in</strong>g of large <strong>tissue</strong> constructs. <strong>Rapid</strong> <strong>and</strong> high<br />

levels of vascularization of the cell-seeded scaffold are<br />

essential to meet the challenge. One possible approach to<br />

achieve vascularization is by <strong>in</strong>corporat<strong>in</strong>g a growth<br />

factor <strong>in</strong>to the scaffold. Several angiogenic factors, such<br />

as vascular endothelial growth factor, fibroblast growth<br />

factor, epidermal growth factor, platelet-derived growth<br />

factors <strong>and</strong> transform<strong>in</strong>g growth factors, have been<br />

identified, <strong>and</strong> these promote the formation of new<br />

vascular beds from endothelial cells present with<strong>in</strong> <strong>tissue</strong>s<br />

[69]. Sheridan et al. [70] considered that the localization<br />

<strong>and</strong> controlled release of these factors from a matrix might<br />

br<strong>in</strong>g about enhanced vascularization of eng<strong>in</strong>eered<br />

<strong>tissue</strong>s.<br />

An alternative approach to enhance the rate of<br />

vascularization is to transplant endothelial cells onto the<br />

scaffold [71]. Experimental studies with rats have confirmed<br />

that the vascularization of matrices is accelerated<br />

with endothelial cell transplantation. The bioactivity of<br />

the scaffold has a crucial role <strong>in</strong> this approach.<br />

The RP fabrication method offers the flexibility <strong>and</strong><br />

capability to couple the design <strong>and</strong> development of a<br />

bioactive scaffold with the advances of cell-seed<strong>in</strong>g<br />

technologies, to enhance the success of scaffold-based<br />

<strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g.<br />

New development: automation <strong>and</strong> direct organ<br />

fabrication<br />

Automated design, development <strong>and</strong> characterization:<br />

RP has the <strong>potential</strong> of automat<strong>in</strong>g the design <strong>and</strong><br />

fabrication of patient-specific scaffolds. In the work of<br />

Cheah et al. [72], computer-aided design (CAD) data<br />

manipulation techniques were utilized to develop a<br />

program algorithm that can be used to design scaffold<br />

<strong>in</strong>ternal architectures from a selection of open-celled<br />

polyhedral shapes. The automated scaffold assembly

650<br />

algorithm can be <strong>in</strong>terfaced with various RP technologies,<br />

to achieve automated production of scaffolds.<br />

Because RP processes offer complete user control <strong>in</strong><br />

terms of the structural features of the scaffold, it is<br />

therefore possible to characterize the scaffold us<strong>in</strong>g an<br />

automated algorithm. A computer-aided characterization<br />

approach can be applied to predict the effective mechanical<br />

properties of scaffolds <strong>and</strong> also to <strong>in</strong>vestigate the effect<br />

of design <strong>and</strong> process parameters on the structural<br />

properties of the scaffolds. Fang et al. [73] characterized<br />

the effective mechanical properties of porous PCL scaffolds<br />

manufactured by PED us<strong>in</strong>g a computational algorithm<br />

for f<strong>in</strong>ite element implementation <strong>and</strong> numerical solution<br />

of asymptotic homogenization theory.<br />

The ease of scaffold fabrication us<strong>in</strong>g RP provides a<br />

straightforward way to study the cell–matrix <strong>in</strong>teraction.<br />

The effects of material rigidity, surface topography <strong>and</strong><br />

roughness, pore size <strong>and</strong> architecture can be <strong>in</strong>vestigated<br />

<strong>in</strong>dependently to ga<strong>in</strong> more <strong>in</strong>sight <strong>in</strong>to cell behavior.<br />

Recent studies have displayed a new school of thought,<br />

us<strong>in</strong>g the concept of layered manufactur<strong>in</strong>g techniques to<br />

produce an organ directly. These new technologies <strong>in</strong>clude<br />

organ pr<strong>in</strong>t<strong>in</strong>g [74–76], laser pr<strong>in</strong>t<strong>in</strong>g of cells [77],<br />

photopattern<strong>in</strong>g of hydrogel [78] <strong>and</strong> microfluidics technology<br />

[79].<br />

Organ pr<strong>in</strong>t<strong>in</strong>g: Bol<strong>and</strong> et al. [76] developed a cell<br />

pr<strong>in</strong>ter to implement the technology. The device is capable<br />

of pr<strong>in</strong>t<strong>in</strong>g s<strong>in</strong>gle cells, cell aggregates <strong>and</strong> the supportive<br />

thermoreversible gel that serves as ‘pr<strong>in</strong>t<strong>in</strong>g paper’. These<br />

authors demonstrated the feasibility of this technique by<br />

pr<strong>in</strong>t<strong>in</strong>g a tubular collagen gel with bov<strong>in</strong>e aortal<br />

endothelial cells.<br />

Laser pr<strong>in</strong>t<strong>in</strong>g of cells: A laser-based pr<strong>in</strong>ter, termed<br />

matrix-assisted pulsed laser evaporation direct write<br />

(MAPLE DW), was used to deposit micron-scale patterns<br />

of pluripotent embryonic carc<strong>in</strong>oma cells onto th<strong>in</strong> layers<br />

of hydrogel [77]. A cell viability of 95% was reported.<br />

Photopattern<strong>in</strong>g of hydrogels: Valerie <strong>and</strong> Sangeeta<br />

[78] adapted photolithographic techniques from the silicon<br />

chip <strong>in</strong>dustry. The process starts with fill<strong>in</strong>g a Teflon base<br />

with a th<strong>in</strong> layer of polymer solution loaded with cells. UV<br />

light is shone through a patterned template atop the th<strong>in</strong><br />

film, cur<strong>in</strong>g the exposed polymer that sets with cells<br />

<strong>in</strong>side. Complex 3D structures, conta<strong>in</strong><strong>in</strong>g regions of<br />

different cells, can be built by us<strong>in</strong>g different templates<br />

<strong>and</strong> add<strong>in</strong>g layers atop each other.<br />

Microfluidics technology: Tan <strong>and</strong> Desai [79]<br />

reported a layer-by-layer microfluidic method to build a<br />

3D heterogeneous multiplayer <strong>tissue</strong>-like structure <strong>in</strong>side<br />

microchannels. This approach extends the 2D cell pattern<strong>in</strong>g<br />

technique <strong>in</strong>to the vertical axis, <strong>in</strong>volv<strong>in</strong>g immobilization<br />

of a cell–matrix assembly, cell–matrix<br />

contraction <strong>and</strong> pressure-driven microfluidic delivery<br />

processes.<br />

Conclusion<br />

The emergence of various different approaches <strong>in</strong> <strong>tissue</strong><br />

eng<strong>in</strong>eer<strong>in</strong>g, rang<strong>in</strong>g from a scaffold-based approach to<br />

scaffold-free layer-by-layer manufactur<strong>in</strong>g technique, has<br />

highlighted the fact that the field of <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g is<br />

still grow<strong>in</strong>g. Look<strong>in</strong>g towards the future, RP technologies<br />

www.sciencedirect.com<br />

Review TRENDS <strong>in</strong> Biotechnology Vol.22 No.12 December 2004<br />

hold great <strong>potential</strong> <strong>in</strong> the context of scaffold fabrication.<br />

This technology enables the <strong>tissue</strong> eng<strong>in</strong>eer to have full<br />

control over the design, fabrication <strong>and</strong> model<strong>in</strong>g of the<br />

scaffold be<strong>in</strong>g constructed, provid<strong>in</strong>g a systematic learn<strong>in</strong>g<br />

channel for <strong>in</strong>vestigat<strong>in</strong>g cell–matrix <strong>in</strong>teractions.<br />

Additionally, <strong>in</strong>direct RP methods, coupled with conventional<br />

pore-form<strong>in</strong>g techniques, further exp<strong>and</strong> the range<br />

of materials that can be used <strong>in</strong> <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g.<br />

Inspired by the additive nature of layered manufactur<strong>in</strong>g,<br />

the layer-by-layer fabrication method underl<strong>in</strong>es the<br />

future development of <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g. Further development<br />

<strong>and</strong> advances <strong>in</strong> RP <strong>in</strong> <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g require<br />

the design of new materials, optimal scaffold design <strong>and</strong><br />

the <strong>in</strong>put of enhanced knowledge of cell physiology,<br />

<strong>in</strong>clud<strong>in</strong>g optimal cell seed<strong>in</strong>g <strong>and</strong> vascularization, so as<br />

to enable the <strong>tissue</strong> eng<strong>in</strong>eer to lay down more specific<br />

design requirements. Nevertheless, RP is a promis<strong>in</strong>g<br />

c<strong>and</strong>idate, serv<strong>in</strong>g as a methodical <strong>in</strong>terface between<br />

<strong>tissue</strong> <strong>and</strong> eng<strong>in</strong>eer<strong>in</strong>g.<br />

References<br />

1 Langer, R. <strong>and</strong> Vacanti, J. (1993) Tissue eng<strong>in</strong>eer<strong>in</strong>g. Science 260,<br />

920–926<br />

2 Sonal, L. et al. (2001) Tissue eng<strong>in</strong>eer<strong>in</strong>g <strong>and</strong> its <strong>potential</strong> impact on<br />

surgery. World J. Surg. 25, 1458–1466<br />

3 Jennifer, J.M. et al. (1998) Transplantation of cells <strong>in</strong> matrices for<br />

<strong>tissue</strong> regeneration. Adv. Drug Deliv. Rev. 33, 165–182<br />

4 Kim, B.S. et al. (2001) Development of biocompatible synthetic<br />

extracellular matrices for <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g. Trends Biotechnol. 16,<br />

224–230<br />

5 Leong, K.F. et al. (2003) Solid freeform fabrication of three-dimensional<br />

scaffolds for eng<strong>in</strong>eer<strong>in</strong>g replacement <strong>tissue</strong>s <strong>and</strong> organs.<br />

Biomaterials 24, 2363–2378<br />

6 Mikos, A.G. et al. (1994) Preparation <strong>and</strong> characterization of poly<br />

(L-lactic acid) foam. Polymer 35, 1068–1077<br />

7 Mooney, D.J. et al. (1996) Novel approach to fabricate porous sponge of<br />

poly(D,L-lactic-co-glycolic acid) without the use of organic solvents.<br />

Biomaterials 17, 1417–1422<br />

8 Freed, L.E. et al. (1994) Biodegradable polymer scaffolds for <strong>tissue</strong><br />

eng<strong>in</strong>eer<strong>in</strong>g. Biotechnology (N. Y.) 12, 689–693<br />

9 Lo, H. et al. (1995) Fabrication of controlled release biodegradable<br />

foams by phase separation. Tissue Eng. 1, 15–28<br />

10 Thomson, J.I. et al. (1995) Fabrication of biodegradable polymer<br />

scaffolds to eng<strong>in</strong>eer<strong>in</strong>g trabecular bone. J. Biomater. Sci. Polym. Ed.<br />

7, 23–28<br />

11 Whang, K. et al. (1995) A novel method to fabricate bioabsorbable<br />

scaffolds. Polym. 36, 837<br />

12 Hsu, Y.Y. et al. (1997) Effect of polymer foam morphology <strong>and</strong> density<br />

on k<strong>in</strong>etics of <strong>in</strong> vitro controlled release of ionized from compressed<br />

foam matrices. J. Biomed Mater Sci 35, 107–116<br />

13 Kim, B.S. <strong>and</strong> Mooney, D.J. (1998) Eng<strong>in</strong>eer<strong>in</strong>g smooth muscle <strong>tissue</strong><br />

with a predef<strong>in</strong>ed structure. J. Biomed. Mater. Res. 41, 322–332<br />

14 Ho, M.H. et al. (2004) Preparation of porous scaffolds by us<strong>in</strong>g freezeextraction<br />

<strong>and</strong> freeze-gelation methods. Biomaterials 25, 129–138<br />

15 Murphy, W.L. et al. (2002) Salt fusion: an approach to improve pore<br />

<strong>in</strong>terconnectivity with<strong>in</strong> <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g scaffold. Tissue Eng. 8,<br />

43–52<br />

16 Chen, V.J. <strong>and</strong> Ma, P.X. (2004) Nano-fibrous poly(L-lactic acid)<br />

scaffolds with <strong>in</strong>terconnected spherical macropores. Biomaterials 25,<br />

2065–2073<br />

17 Gross, K.A. <strong>and</strong> Rodríguez-Lorenzo, L.M. (2004) Biodegradable<br />

composite scaffolds with an <strong>in</strong>terconnected spherical network for<br />

bone <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g. Biomaterials 25, 4955–4962<br />

18 Yang, S. et al. (2001) The design of scaffolds for use <strong>in</strong> <strong>tissue</strong><br />

eng<strong>in</strong>eer<strong>in</strong>g. Part I. Traditional factors. Tissue Eng. 7, 679–689<br />

19 Yang, S. et al. (2002) The design of scaffolds for use <strong>in</strong> <strong>tissue</strong><br />

eng<strong>in</strong>eer<strong>in</strong>g. Part II. <strong>Rapid</strong> <strong>prototyp<strong>in</strong>g</strong> techniques. Tissue Eng. 8,<br />

1–11

20 Chua, C.K. et al. (2003) <strong>Rapid</strong> Prototyp<strong>in</strong>g Pr<strong>in</strong>ciples <strong>and</strong> Applications,<br />

World Scientific<br />

21 Ze<strong>in</strong>, I. et al. (2002) Fused deposition model<strong>in</strong>g of novel scaffold<br />

architectures for <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g applications. Biomaterials 23,<br />

1169–1185<br />

22 Samar, J.K. et al. (2003) Development of controlled porosity polymerceramic<br />

composite scaffolds via fused deposition model<strong>in</strong>g. Mater Sci<br />

Eng C23, 611–620<br />

23 Ramakrishma, S. et al. (2001) Biomedical applications of polymercomposite<br />

materials: a review. Compos. Sci. Technol. 61, 1189–1224<br />

24 Endres, M. et al. (2003) Osteogenic <strong>in</strong>duction of human bone marrowderived<br />

mesenchymal progenitor cells <strong>in</strong> novel synthetic polymerhydrogel<br />

matrices. Tissue Eng. 9, 689–702<br />

25 Tienen, T.G.V. et al. (2002) Tissue <strong>in</strong>growth <strong>and</strong> degradation of two<br />

biodegradable porous polymers with different porosities <strong>and</strong> pore size.<br />

Biomaterials 23, 1731–1738<br />

26 Woodfield, T.B.G. et al. (2004) Design of porous scaffolds for cartilage<br />

<strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g us<strong>in</strong>g a three-dimensional fiber-deposition technique.<br />

Biomaterials 25, 4149–4161<br />

27 Wang, F. et al. (2004) Precision extrud<strong>in</strong>g deposition <strong>and</strong> characterization<br />

of cellular poly-3-Caprolactone <strong>tissue</strong> scaffolds. <strong>Rapid</strong> Prototyp<strong>in</strong>g<br />

J 10, 42–49<br />

28 Zhuo, X. et al. (2001) Fabrication of porous poly(L-lactic acid) scaffolds<br />

for born <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g via precise extrusion. Scripta Mater. 45,<br />

773–779<br />

29 Zhuo, X. et al. (2002) Fabrication of porous scaffolds for bone <strong>tissue</strong><br />

eng<strong>in</strong>eer<strong>in</strong>g via low-temperature deposition. Scripta Mater. 46,<br />

771–776<br />

30 Zhuo, X. et al. (2003) Layered manufactur<strong>in</strong>g of <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g<br />

scaffolds via multi-nozzle deposition. Mater. Lett. 57, 2623–2628<br />

31 Vozzi, G. et al. (2002) Microsyr<strong>in</strong>ge-based deposition of two-dimensional<br />

<strong>and</strong> three-dimensional polymer scaffolds with a well-def<strong>in</strong>ed<br />

geometry for application to <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g. Tissue Eng. 8,<br />

1089–1098<br />

32 Cesarano, J. <strong>and</strong> Calvert, P. (2000) Freeform<strong>in</strong>g objects with lowb<strong>in</strong>der<br />

slurry. US Patent 6,027,326<br />

33 Vozzi, G. et al. (2003) Fabrication of PLGA scaffolds us<strong>in</strong>g soft<br />

lithography <strong>and</strong> microsyr<strong>in</strong>ge deposition. Biomaterials 24, 2533–2540<br />

34 Therriault, D. et al. (2003) Chaotic mix<strong>in</strong>g <strong>in</strong> three-dimensional<br />

microvascular networks fabricated by direct-write assembly. Nat.<br />

Mater. 2, 265–271<br />

35 L<strong>and</strong>ers, R. <strong>and</strong> Mülhaupt, R. (2000) Desktop manufactur<strong>in</strong>g of<br />

complex objects, prototypes <strong>and</strong> biomedical scaffolds by means of<br />

computer-assisted design comb<strong>in</strong>ed with computer-guided 3D plott<strong>in</strong>g<br />

of polymers <strong>and</strong> reactive oligomers. Macromol. Mater. Eng. 282, 17–21<br />

36 Ang, T.H. et al. (2002) Fabrication of 3D chitosan-hydroxyapatite<br />

scaffolds us<strong>in</strong>g a robotic dispens<strong>in</strong>g system. Mater. Sci. Eng. C 20,<br />

35–42<br />

37 L<strong>and</strong>ers, R. et al. (2002) Fabrication of soft <strong>tissue</strong> eng<strong>in</strong>eer<strong>in</strong>g<br />

scaffolds by means of rapid <strong>prototyp<strong>in</strong>g</strong> techniques. J. Mater. Sci. 37,<br />

3107–3116<br />

38 L<strong>and</strong>ers, R. et al. (2002) <strong>Rapid</strong> <strong>prototyp<strong>in</strong>g</strong> of scaffolds derived from<br />

thermoreversible hydrogels <strong>and</strong> tailored for applications <strong>in</strong> <strong>tissue</strong><br />

eng<strong>in</strong>eer<strong>in</strong>g. Biomaterials 23, 4437–4447<br />

39 Wong, J.Y. et al. (2003) Directed movement of vascular smooth muscle<br />

cells on gradient-compliant hydrogels. Langmuir 19, 1908–1913<br />

40 Flemm<strong>in</strong>g, R.G. et al. (1999) Effects of synthetic micro- <strong>and</strong> nanostructured<br />

surfaces on cell behavior. Biomaterials 20, 573–588<br />

41 Lam, C.X.F. et al. (2002) Scaffold development us<strong>in</strong>g 3D pr<strong>in</strong>t<strong>in</strong>g with<br />

a starch-based polymer. Mater. Sci. Eng. C 20, 49–56<br />

42 Griffith, L.G. <strong>and</strong> Naughton, G. (2002) Tissue eng<strong>in</strong>eer<strong>in</strong>g – current<br />

<strong>challenges</strong> <strong>and</strong> exp<strong>and</strong><strong>in</strong>g opportunities. Science 298, 1009–1014<br />

43 Calvert, J.W. <strong>and</strong> Weiss, L. (2001) Assembled scaffolds for threedimensional<br />

cell cultur<strong>in</strong>g <strong>and</strong> <strong>tissue</strong> regeneration. US Patent<br />

6,143,293<br />

44 Kim, S.S. et al. (1998) Survival <strong>and</strong> function of hepatocytes on a novel<br />

three-dimensional synthetic biodegradable polymeric scaffold with an<br />

<strong>in</strong>tr<strong>in</strong>sic network of channels. Ann. Surg. 228, 8–13<br />

45 Zelt<strong>in</strong>ger, J. et al. (2001) Effect of pore size <strong>and</strong> void fraction on cellular<br />

adhesion, proliferation <strong>and</strong> matrix deposition. Tissue Eng. 7, 557–572<br />

46 Vail, N.K. et al. (1999) Materials for biomedical applications. Mater.<br />

Des. 20, 123–132<br />

www.sciencedirect.com<br />

Review TRENDS <strong>in</strong> Biotechnology Vol.22 No.12 December 2004 651<br />