NUMBER 02 - Haas Automation, Inc.

NUMBER 02 - Haas Automation, Inc.

NUMBER 02 - Haas Automation, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

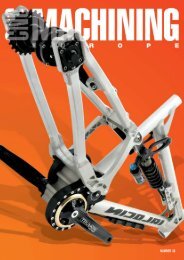

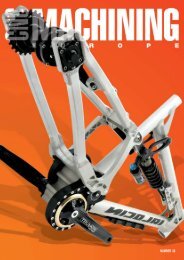

One of the main advantages of in-house machining is the<br />

speed with which new ideas can go from the drawing board<br />

– make that computer screen – to a finished prototype.<br />

Karlheinz says, “We design primarily in SolidWorks, and<br />

use both ESPRIT and VisualMill on the CAM side.” Design,<br />

programming and production are under one roof, and<br />

seamlessly integrate in an environment where designers,<br />

programmers and machine operators work closely together.<br />

The VF-2SS fit in perfectly.<br />

“With the <strong>Haas</strong> machine, we can have a prototype<br />

finished in the time it would take just to communicate with<br />

| www.<strong>Haas</strong>CNC.com<br />

vendors and get a price quote on making the part outside,”<br />

Karlheinz explains.<br />

Nicolai GmbH selects employees carefully, preferring to<br />

train motivated individuals with conventional machine shop<br />

experience onsite. And with only 15 full-time employees and<br />

a backlog of orders, it’s important that each person and every<br />

machine is productive from the start. The logical, user-friendly<br />

<strong>Haas</strong> control makes CNC machining easier to understand,<br />

reducing operator error and training time. Nicolai feels this<br />

has been a great advantage to his firm.