YVAA Style A Air-Cooled Screw Liquid Chillers ... - Johnson Controls

YVAA Style A Air-Cooled Screw Liquid Chillers ... - Johnson Controls

YVAA Style A Air-Cooled Screw Liquid Chillers ... - Johnson Controls

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FORM 201.28-NM1.1<br />

SECTION 5 - TECHNICAL DATA<br />

ISSUE DATE: 8/29/2012<br />

CTION 5 - TECHNICAL DATA FORM_201.28-NM1.1.EN (1106)<br />

weight 78<br />

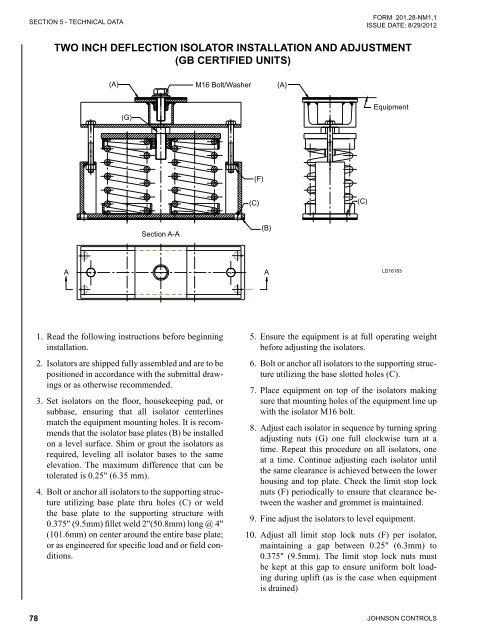

TWO INCH DEFLECTION ISOLATOR INSTALLATION AND ADJUSTMENT<br />

(GB CERTIFIED UNITS)<br />

TWO INCH DEFLECTION ISOLATOR INSTALLATION AND ADJUSTMENT<br />

(A)<br />

(G)<br />

Section A-A<br />

M16<br />

M16 Bolt/Washer<br />

Bolt/Washer<br />

A AA<br />

1. Read the following instructions before beginning<br />

installation.<br />

1. Read the following instructions before beginning<br />

installation.<br />

2. Isolators 2. Isolators are shipped are shipped fully fully assembled assembled and and are are to to be be<br />

positioned positioned in accordance in accordance with with the the submittal draw- draw-<br />

ings or as ings otherwise or as otherwise recommended.<br />

3. Set isolators on the floor, housekeeping pad, or<br />

subbase, ensuring that all isolator centerlines<br />

match the equipment mounting holes. It is recommends<br />

that the isolator base plates (B) be installed<br />

on a level surface. Shim or grout the isolators as<br />

required, leveling all isolator bases to the same<br />

elevation. The maximum difference that can be<br />

tolerated is 0.25" (6.35 mm).<br />

3. Set isolators on floor, housekeeping pad, or subbase,<br />

ensuring that all isolator centerlines match<br />

the equipment mounting holes. It is recommends<br />

that the isolator base plates (B) be installed on a<br />

level surface. Shim or grout as required, leveling<br />

all isolator base plates to the same elevation<br />

(0.25"(6.35mm) maximum difference can be<br />

tolerated).<br />

4. Bolt or anchor all isolators to the supporting structure<br />

utilizing base plate thru holes (C) or weld<br />

the base plate to the supporting structure with<br />

0.375" (9.5mm) fillet weld 2"(50.8mm) long @ 4"<br />

(101.6mm) on center around the entire base plate;<br />

or as engineered for specific load and or field conditions.<br />

4. Bolt or anchor all isolators to supporting structure<br />

utilizing base plate thru holes (C) or weld base<br />

plate to supporting structure with 0.375"(9.5mm)<br />

fillet weld 2"(50.8mm) long @ 4"(101.6mm) on<br />

centre around entire base plate or as engineered<br />

for specific load and or field conditions.<br />

5. The adjustment process can only begin after the<br />

equipment or machine is at its full operating<br />

6. Bolt or anchor all isolators to supporting structure<br />

(F)<br />

(C)<br />

(B)<br />

(A)<br />

(C)<br />

Equipment<br />

LD16183<br />

.<br />

7. Place equipment on top of isolators making sure<br />

that mounting holes of the equipment line up with<br />

5. Ensure the equipment is at full operating weight<br />

before adjusting the isolators.<br />

6. Bolt isolator or anchor M16 all bolt. isolators to the supporting structure<br />

utilizing the base slotted holes (C).<br />

8. Adjust each isolator in sequence by turning spring<br />

adjusting nuts (G) one full clockwise turn at a<br />

time. Repeat this procedure on all isolators, one<br />

at a time. Continue adjusting each isolator until<br />

same clearance is achieved between the lower<br />

housing and top plate. Check the limit stop lock<br />

nuts (F) periodically to ensure that clearance<br />

between the washer and grommet is maintained.<br />

7. Place equipment on top of the isolators making<br />

sure that mounting holes of the equipment line up<br />

with the isolator M16 bolt.<br />

8. Adjust each isolator in sequence by turning spring<br />

adjusting nuts (G) one full clockwise turn at a<br />

time. Repeat this procedure on all isolators, one<br />

at a time. Continue adjusting each isolator until<br />

the same clearance is achieved between the lower<br />

housing and top plate. Check the limit stop lock<br />

8. Fine adjust isolators to level equipment.<br />

nuts (F) periodically to ensure that clearance between<br />

the washer and grommet is maintained.<br />

9. Adjust all limit stop lock nuts (F) per isolator,<br />

maintaining 0.25"(6.3mm) to 0.375"(9.5mm) gap.<br />

The limit stop nuts must be kept at this gap to<br />

ensure uniform bolt loading during uplift (as the<br />

9. Fine adjust the isolators to level equipment.<br />

10. Adjust all limit stop lock nuts (F) per isolator,<br />

maintaining a gap between 0.25" (6.3mm) to<br />

0.375" case when (9.5mm). equipment The limit is stop drained) lock nuts must<br />

be kept at this gap to ensure uniform bolt loading<br />

during uplift (as is the case when equipment<br />

is drained)<br />

JOHNSON CONTROLS