diebautechnik | 2 - ThyssenKrupp Bautechnik

diebautechnik | 2 - ThyssenKrupp Bautechnik

diebautechnik | 2 - ThyssenKrupp Bautechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6<br />

That’s why it’s so beautiful along the Rhine!<br />

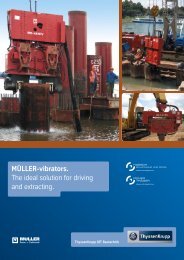

226 metre long new embankment consolidation in the port of Duisburg<br />

The port of Duisburg, Europe's second-largest<br />

inland port, is booming. In the last business year,<br />

the port's operator, the duisport Group, was able<br />

to increase sales by 14 percent to just under Euro<br />

42 million. The net profit before tax rose by 53<br />

percent to Euro 2.3 million. The volume of traffic<br />

increased to 39.4 million tonnes of goods (up six<br />

percent) in 2003. The board of management of<br />

Duisburger Hafen AG is particularly pleased at<br />

being able to report the increase in container handling,<br />

which rose by 37 percent to 4.2 million<br />

tonnes.<br />

New sheet pile<br />

However, wide-ranging refurbishing work is necessary<br />

in the harbour area for the port to continue to<br />

develop positively. The embankment consolidation<br />

on the North Rhine quay in Duisburg-Hochfeld is<br />

a left-over from the fifties of the last century and,<br />

over the course of time, had become in need of<br />

repair. Brückner Grundbau GmbH of Essen was<br />

contracted with the replacement of the embankment<br />

consolidation by Duisburger Hafen AG last year.<br />

<strong>ThyssenKrupp</strong> GfT <strong>Bautechnik</strong> supplied approx.<br />

700 tonnes of sheet piles for the construction<br />

project.<br />

The 226 metre long embankment consolidation on<br />

the North Rhine quay is used as a place of transhipment<br />

by the transport company Harpen. Suffering<br />

from heavy use, the edge of the embankment had<br />

become in need of refurbishment. “A new sheet pile<br />

wall with integrated landing piles had to be fitted<br />

in front of the already existing corrugated sheet<br />

pile,” says Frank Tapken of <strong>ThyssenKrupp</strong> GfT <strong>Bautechnik</strong>,<br />

describing the task. The new sheet pile<br />

wall was equipped with vertical ladders and pockettype<br />

bollards.<br />

To keep the restrictions on work to a minimum for<br />

the transportation company Harpen, the planners<br />

decided to carry out the refurbishment of the<br />

embankment consolidation in two constructional<br />

phases. The 700 tonnes of sheet piles were delivered<br />

by ship to Duisburg in November 2003.<br />

Since the sheet piles had to be positioned very<br />

deep, while the ground was very compact and the<br />

old coal bunkers no longer gave the impression<br />

of being very secure, the construction experts<br />

decided not to position the sheet piles using the<br />

vibration method. An elevated dredger was used<br />

to drive the sheet piles by a hydraulic hammer.<br />

Avoiding incidents<br />

While construction was under way, the planners<br />

took account of unfavourable circumstances such<br />

as dredging free the alignment of the pile drivers<br />

in front of the old corrugated sheet pile wall.<br />

Because of this, it was necessary over and over<br />

again to make provisional measurements as well<br />

as accompanying deformation measurements<br />

together with evaluations. So as to avoid unwanted<br />

incidents, comprehensive vibration measurements<br />

were made during the pile-driving work. HOESCH<br />

Spundwand und Profil GmbH developed a new<br />

sheet pile, the HOESCH 3600 n, for the embank-<br />

Water-tight: sheet piles on the Rhine quay<br />

in Duisburg. 700 tonnes of sheet piles were used to redevelop the Rh